Core assembly pouring device for cylinder block casting in automobile engine

A technology for automobile engines and cylinder blocks, which is applied in the direction of casting moulds, mold cores, and mold components. Production cost, the effect of saving the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

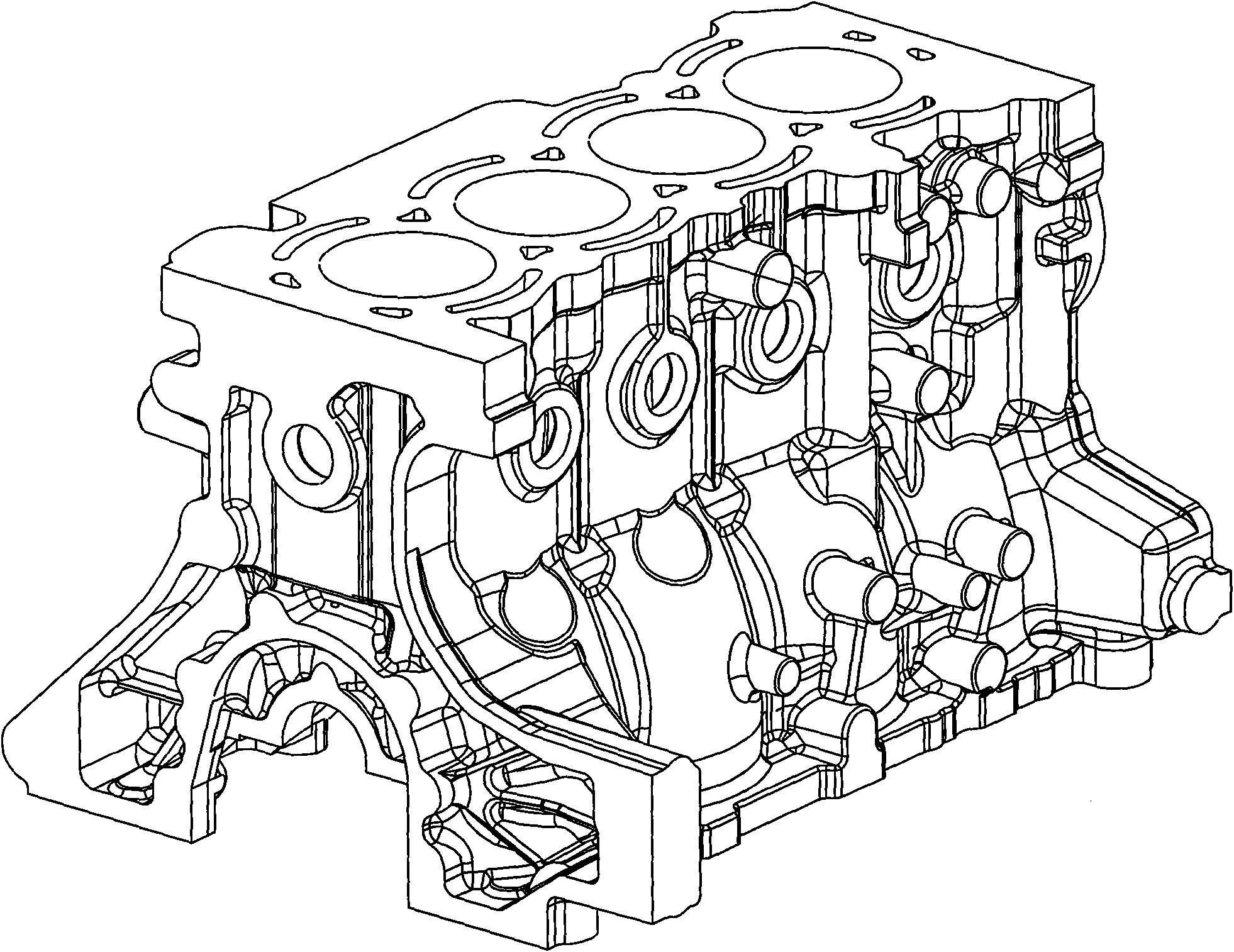

[0026] Depend on figure 1 As can be seen from the schematic diagram of parts of the cylinder block casting in the automobile engine of the present invention, its structure is more complicated, its casting difficulty is very large, and the probability of producing waste products is very high.

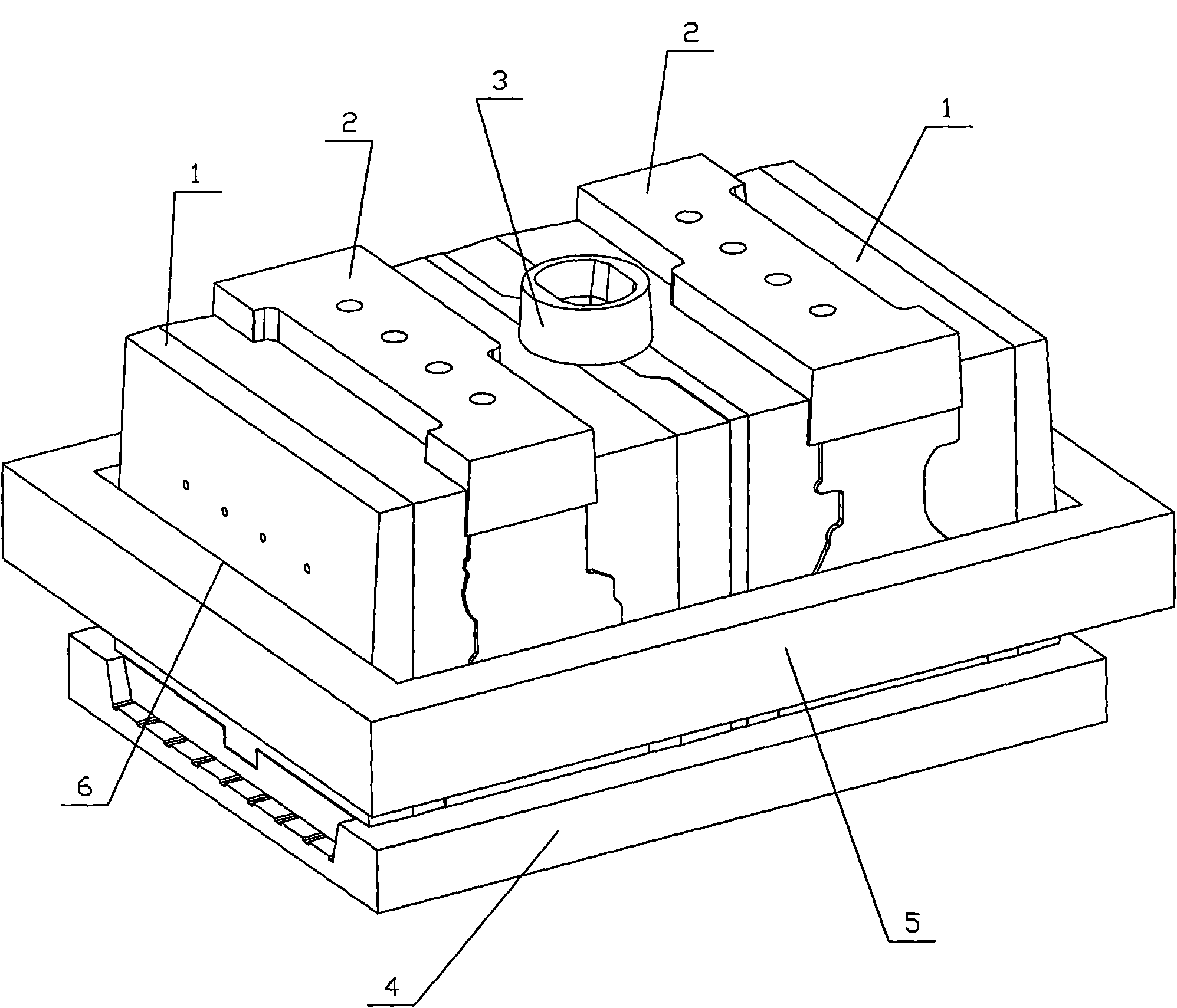

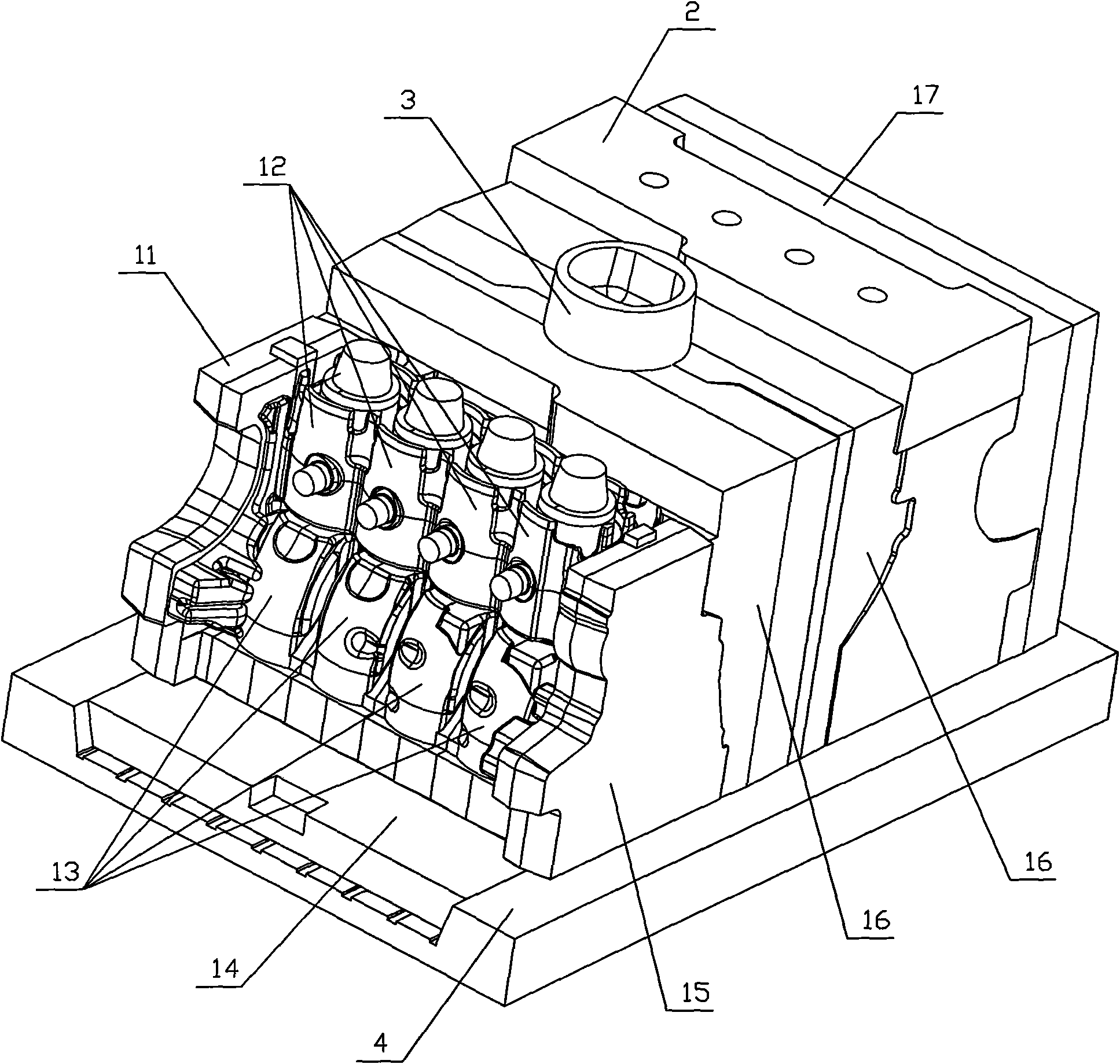

[0027] Depend on figure 2 As can be seen from the structural schematic diagram of the core pouring device of the cylinder casting in the automobile engine shown in the present invention, it includes a base plate 4, a riser core 2, a gate core 3, a sand core group 1 and a locking device 5, and the sand The core group 1 is connected to the bottom plate 4 and locked by the locking device 5 , the riser core 2 and the sprue core 3 are located on the sand core group 1 . The sand core groups 1 are two adjacent groups, both of which are clamped on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com