Special precoated sand for cast of high alloy material

A technology of coated sand and alloy, which is applied in the direction of casting moulds, casting molding equipment, metal processing equipment, etc., can solve the problems that cannot meet the requirements of high-alloy castings, and achieve the effects of small expansion rate, fine structure and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

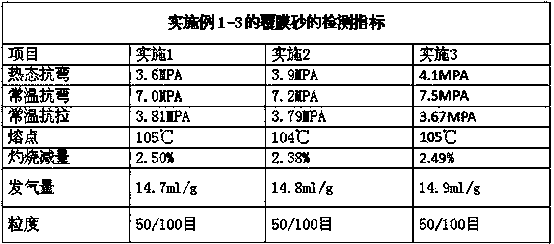

Embodiment 1

[0029] The composition ratio of the special coated sand of the high alloy material casting of the present invention is as follows:

[0030] Special coated sand, including raw sand, lubricants, binders, curing agents and coupling agents, of which recycled sand accounts for 50% of the total mass of original sand; Baozhu sand accounts for 35% of the total mass of original sand; magnetite sand accounts for 15% of the total mass of the sand, the binder accounts for 1.8% of the total mass of the original sand; the curing agent is 10% of the binder mass; the lubricant is 6% of the binder mass; the coupling agent is 6% of the binder mass 1.5%.

Embodiment 2

[0032] The composition ratio of the special coated sand of the high alloy material casting of the present invention is as follows:

[0033] Special coated sand, including raw sand, lubricants, binders, curing agents and coupling agents, of which recycled sand accounts for 50% of the total mass of original sand; Baozhu sand accounts for 35% of the total mass of original sand; magnetite sand accounts for 15% of the total mass of the sand, the binder accounts for 1.9% of the total mass of the original sand; the curing agent is 9% of the binder mass; the lubricant is 8% of the binder mass; the coupling agent is 8% of the binder mass 2%.

Embodiment 3

[0035] The composition ratio of the special coated sand of the high alloy material casting of the present invention is as follows:

[0036] Special coated sand, including raw sand, lubricants, binders, curing agents and coupling agents, of which recycled sand accounts for 50% of the total mass of original sand; Baozhu sand accounts for 35% of the total mass of original sand; magnetite sand accounts for 15% of the total mass of the sand, the binder accounts for 1.7% of the total mass of the original sand; the curing agent is 11% of the binder mass; the lubricant is 7% of the binder mass; the coupling agent is 7% of the binder mass 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gas output | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com