Non-oriented silicon steel for sheet billet production and manufacturing method thereof

A technology of oriented silicon steel and a manufacturing method, applied in the production field of non-oriented silicon steel, can solve the problems of poor reduction effect of iron loss, etc., and achieve the effect of reducing iron loss value, meeting the requirements of punching processing, and good hot-rolled structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

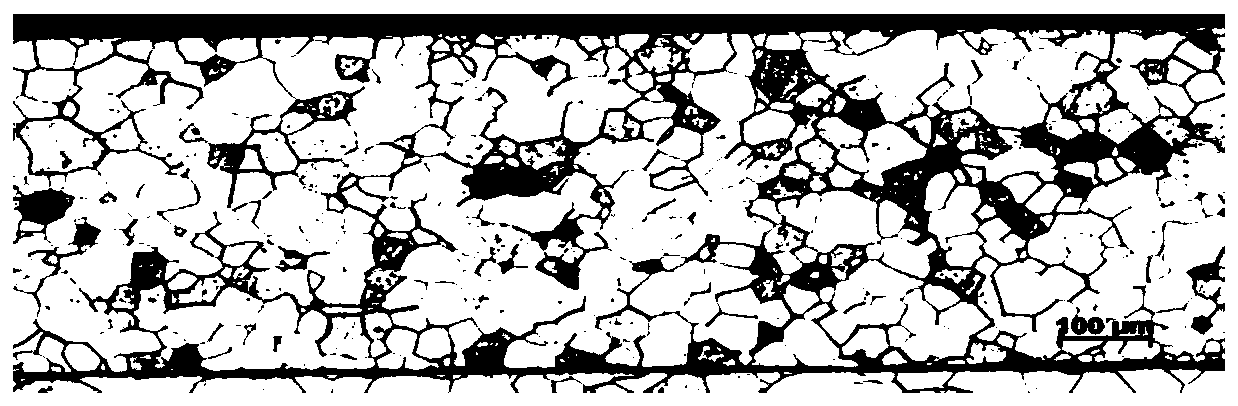

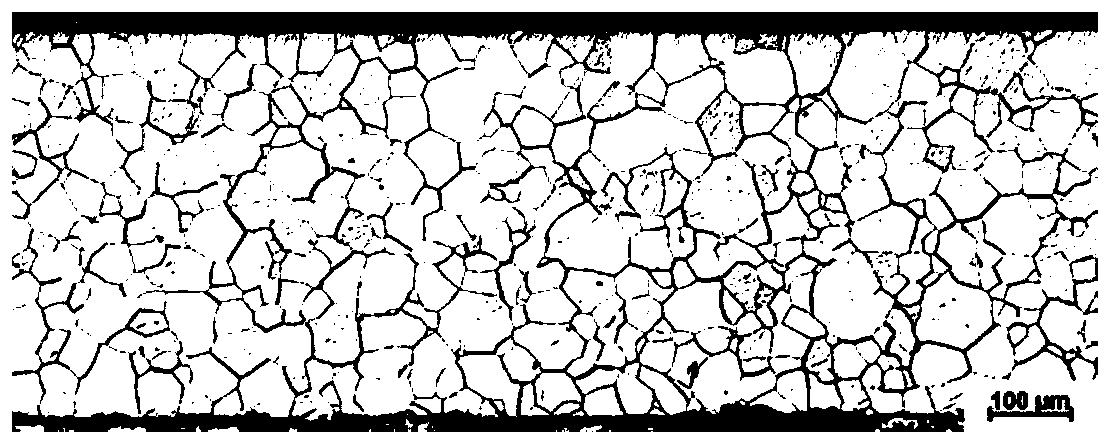

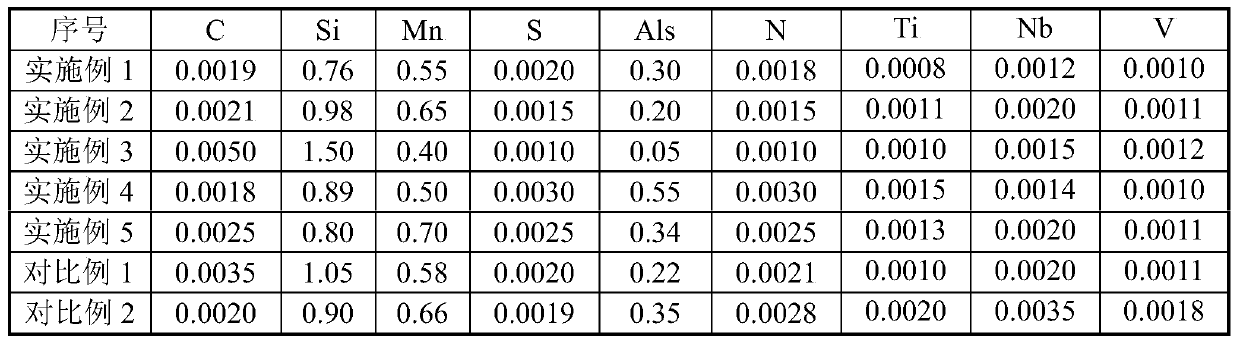

[0055] The chemical composition weight percent of present embodiment test steel is as image 3 As shown, the test steel was continuously cast into a 75mm slab after molten iron pretreatment, converter smelting, and vacuum treatment. The impurity elements C+S+N+Ti totaled 65ppm. After 0.5h, continuous hot rolling is carried out. The reduction rate of the first pass of hot rolling is controlled at 56%, the reduction rate of the second pass is controlled at 58%, and the final rolling temperature is kept at 800°C. The coil is rolled and coiled, and the coiling temperature is 760°C. The hot-rolled sheet after coiling is pickled and then cold-rolled to a thickness of 0.50mm, then annealed at 760°C for 45s, protected by nitrogen-hydrogen mixture, and the strip is treated according to the elongation rate of 5% before coating the insulating layer. The steel is leveled, coated with insulating coating, dried and cured at 450°C×15s, protected with nitrogen, and then stress-relieved annea...

Embodiment 2

[0057] The chemical composition weight percent of present embodiment test steel is as image 3 As shown, the test steel was continuously cast into a 75mm slab after molten iron pretreatment, converter smelting, and vacuum treatment. The impurity elements C+S+N+Ti totaled 62ppm. After 0.5h, hot rolling is carried out. The reduction rate of the first pass of hot rolling is controlled at 58%, the reduction rate of the second pass is controlled at 58%, and the final rolling temperature is kept at 800°C. rolling. The coiling process was performed, and the coiling temperature was 800°C. The hot-rolled sheet after coiling is pickled and then cold-rolled to a thickness of 0.50mm, then annealed at 780°C for 45s, protected with nitrogen-hydrogen mixture, and treated with an elongation of 4% before coating the insulating layer. The steel is leveled, coated with insulating coating, dried and cured at 450°C×15s, protected with nitrogen, and then stress-relieved annealed at 750°C×2h to ob...

Embodiment 3

[0059] The chemical composition weight percent of present embodiment test steel is as image 3 As shown, the test steel was continuously cast into a 70mm slab after molten iron pretreatment, converter smelting, and vacuum treatment. The impurity elements C+S+N+Ti totaled 80ppm. After 1 hour, hot rolling is carried out, the reduction rate of the first pass of hot rolling is controlled at 55%, the reduction rate of the second pass is controlled at 60%, the final rolling temperature is kept at 750°C, and hot rolled into 2.0mm thick hot rolled roll. The coiling process was performed, and the coiling temperature was 700°C. The hot-rolled sheet after coiling is pickled, then cold-rolled to a thickness of 0.50mm, and then annealed at 750℃×40s. Due to the high content of C, in order to ensure that the performance of the finished product does not cause magnetic aging, humidification is added during the annealing process to achieve For the purpose of decarburization, nitrogen-hydrogen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com