Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Guaranteed electromagnetic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

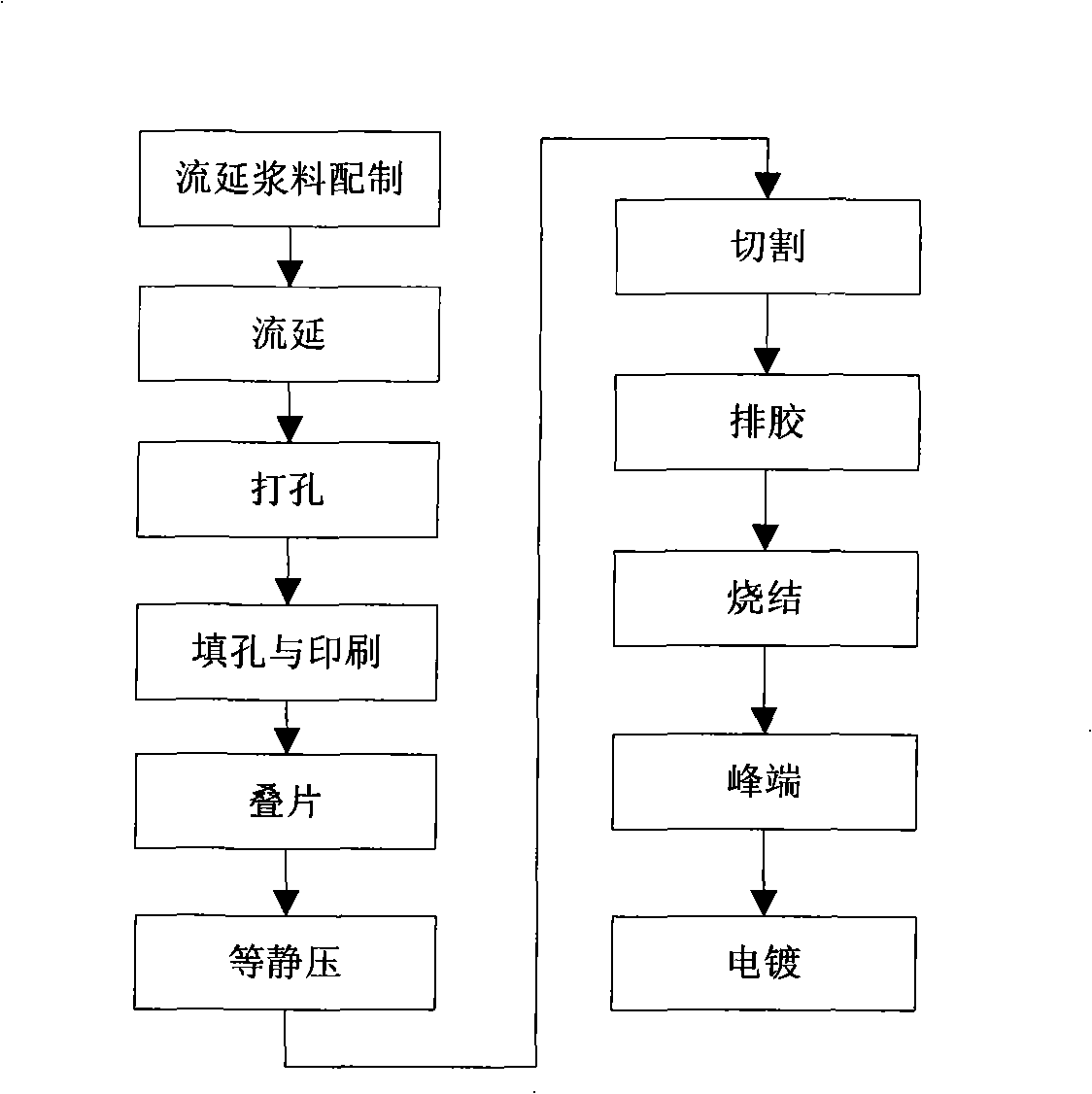

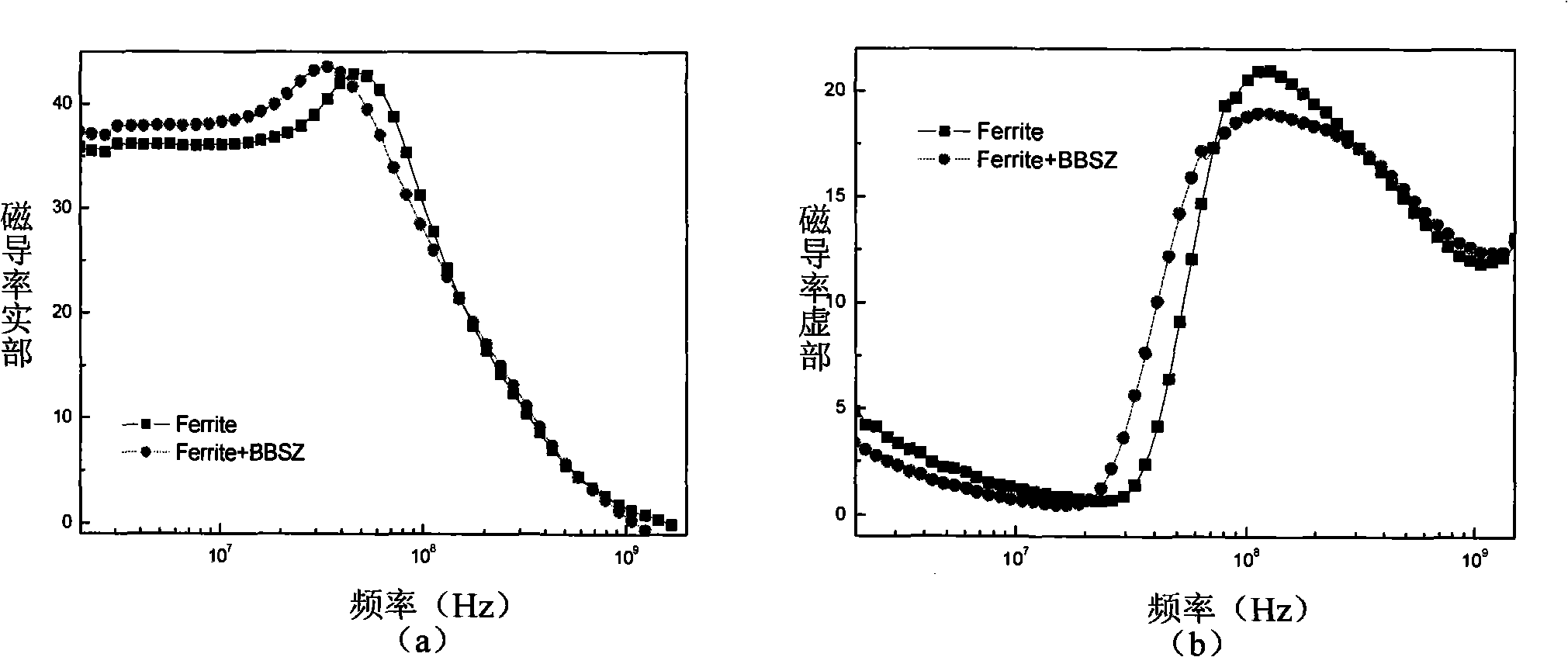

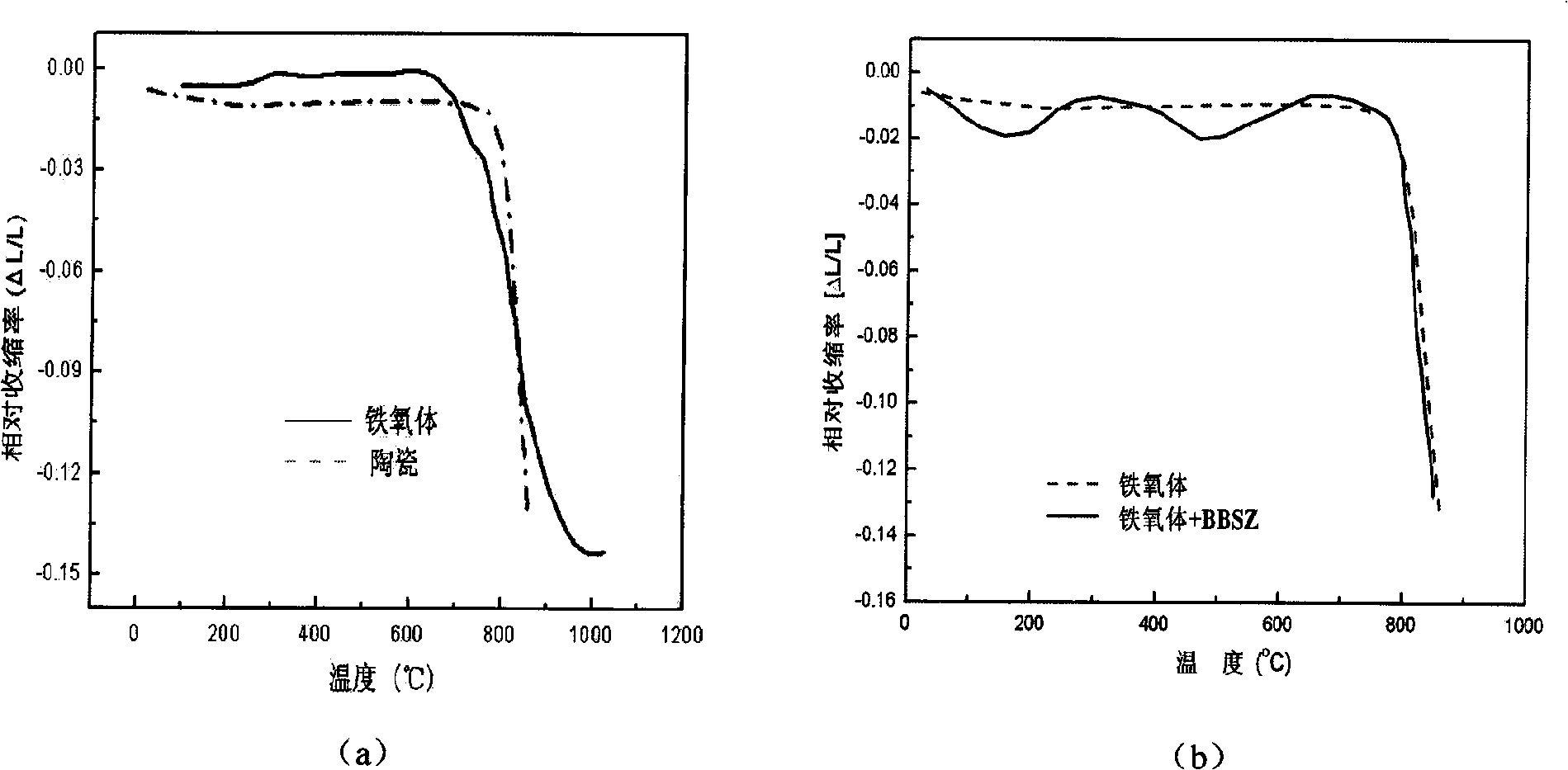

Low-temperature matching co-firing method of ferrite and ceramic material

InactiveCN101514102AAchieve matching cofiringImproving the characteristic parameters of low temperature sintering densificationFerrite powderSlurry

A low-temperature matching co-firing method of ferrite and ceramic material belongs to the technical field of electronic components and relates to the low-temperature co-firing method (LTCC technology) of ceramics and the ferrite, in particular to the method for eliminating stress in the LTCC technology and realizing the matching co-firing of heterogeneous materials. The method controls the consistency of sintering densification characteristic parameters between the heterogeneous materials by adding BBSZ glass which is equal to 5 percent by weight of ferrite powder material in a tape-casting slurry formula of the ferrite as a matching co-firing assist agent, thereby realizing the matching sintering during the co-firing process. The method can effectively improve the low-temperature sintering densification characteristic parameters of the materials and realize the matching co-firing of the heterogeneous materials; meanwhile, the method has little effect on the electromagnetic property of the ceramics or the ferrite powder material. The method is characterized by simplicity, good operability, cheap prices, obvious effect and the like, thereby being capable of being widely used in the LTCC technology for producing various electronic components.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

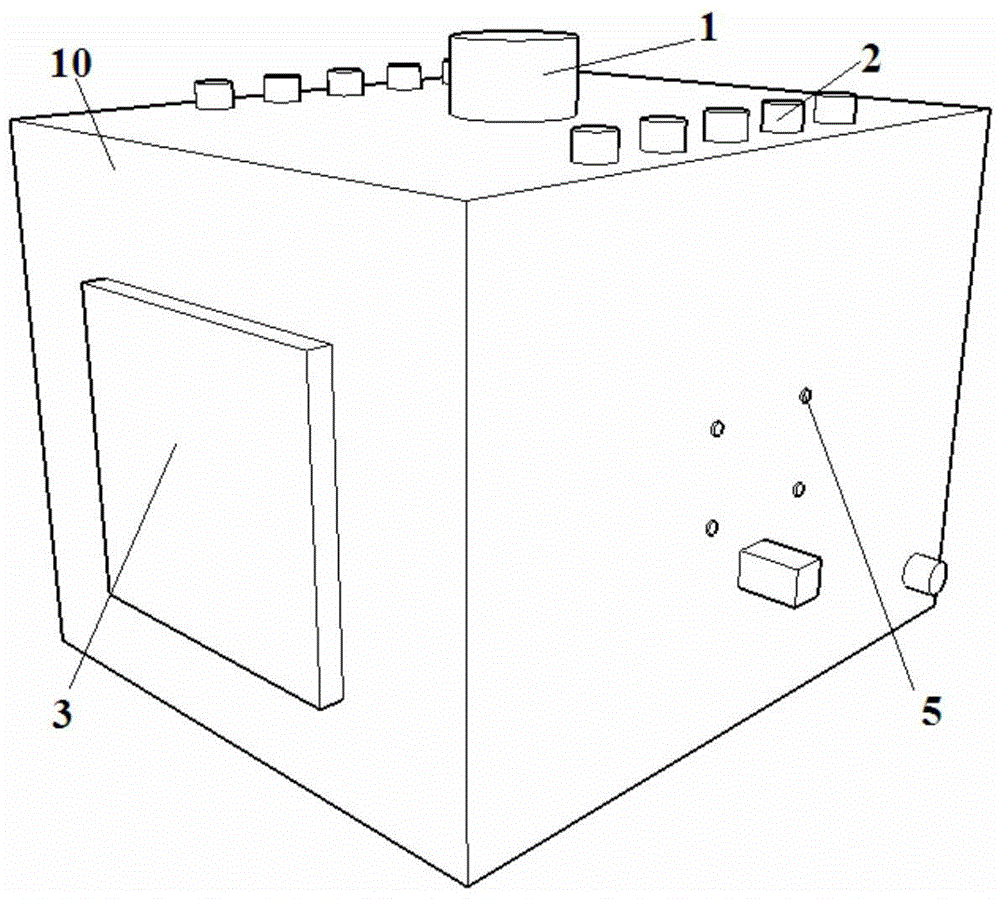

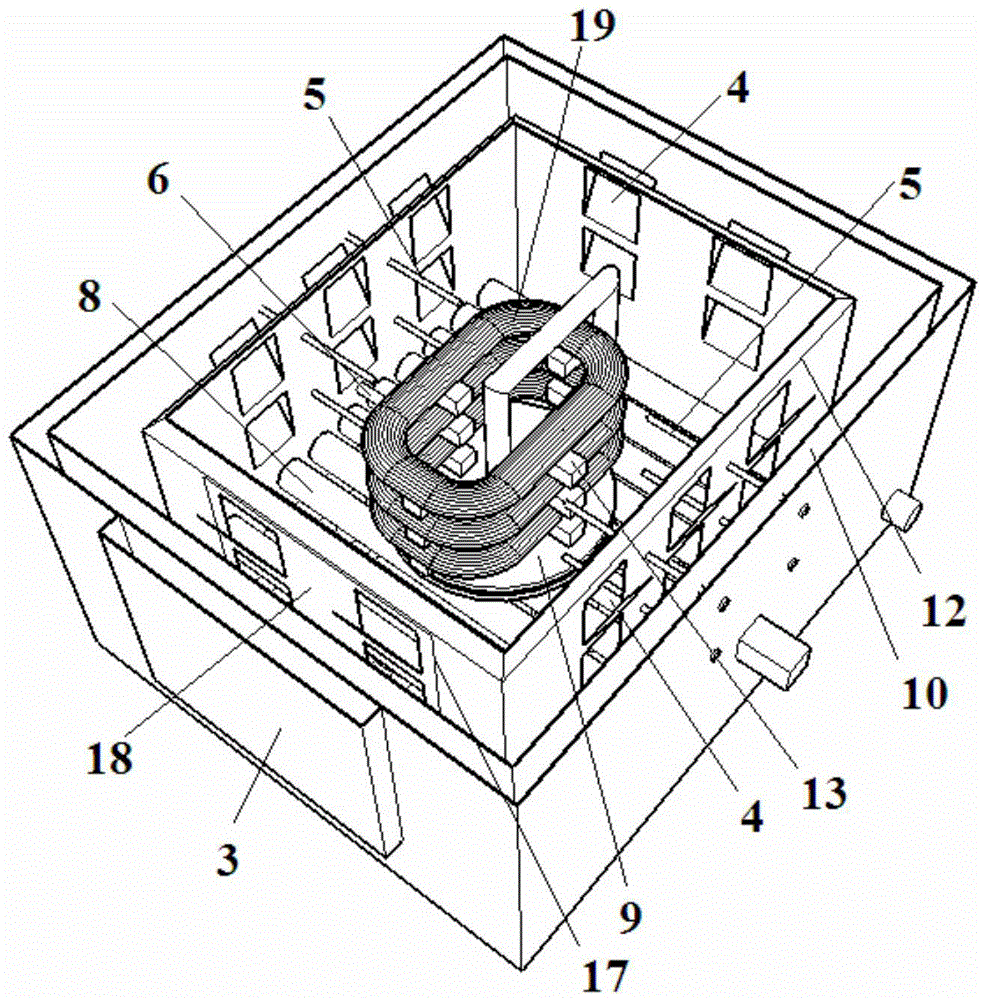

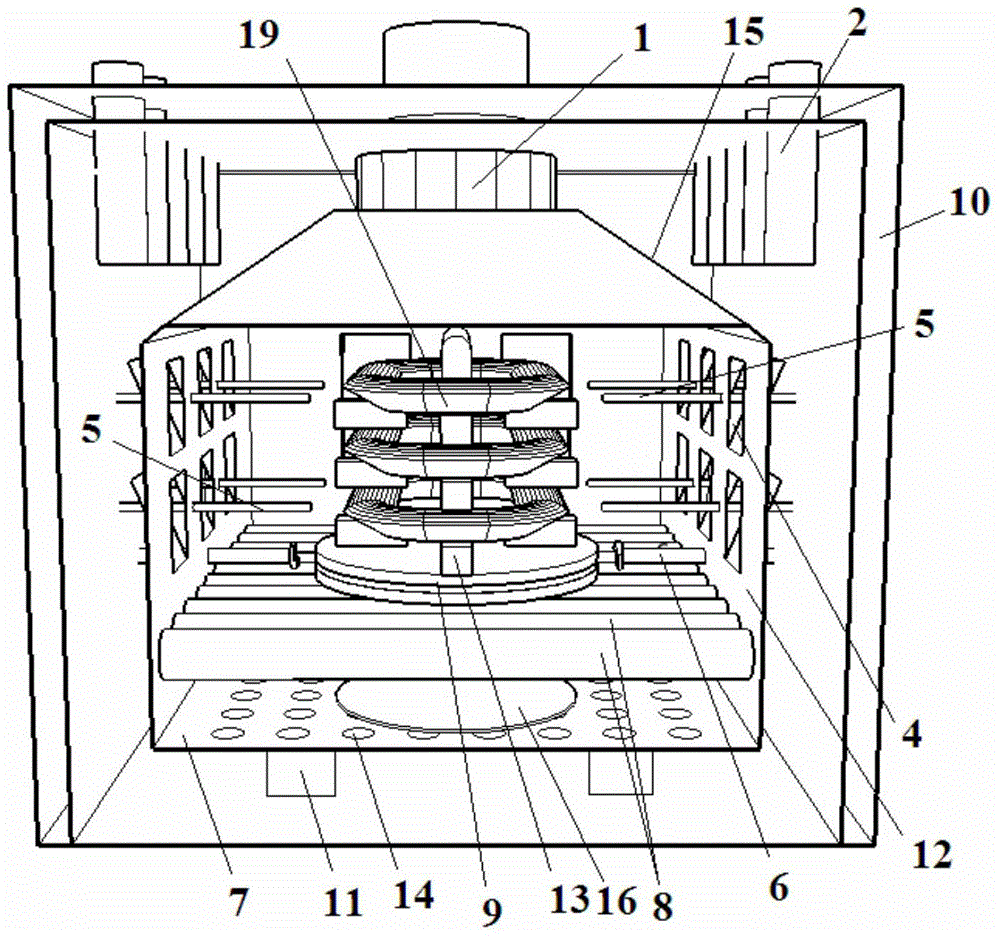

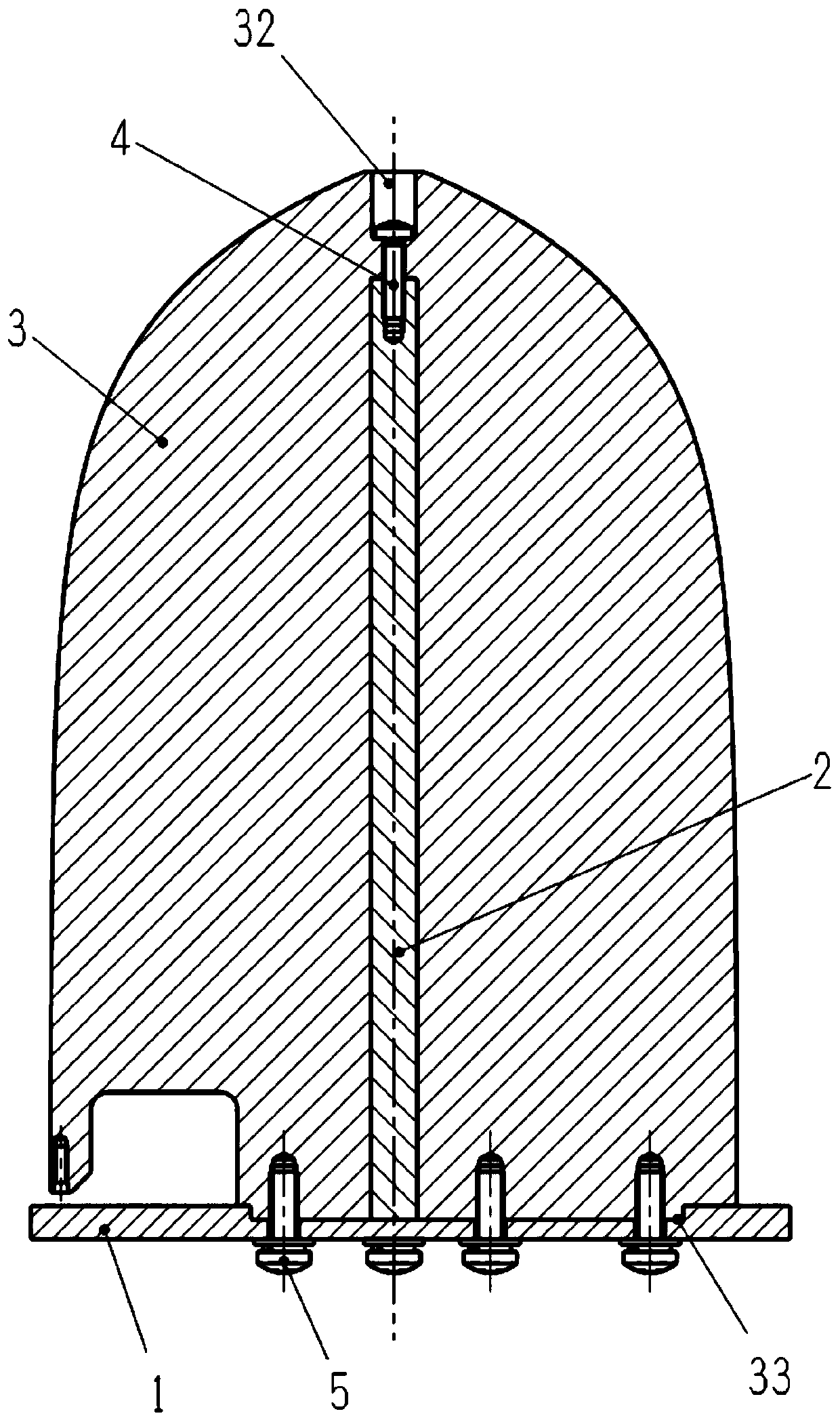

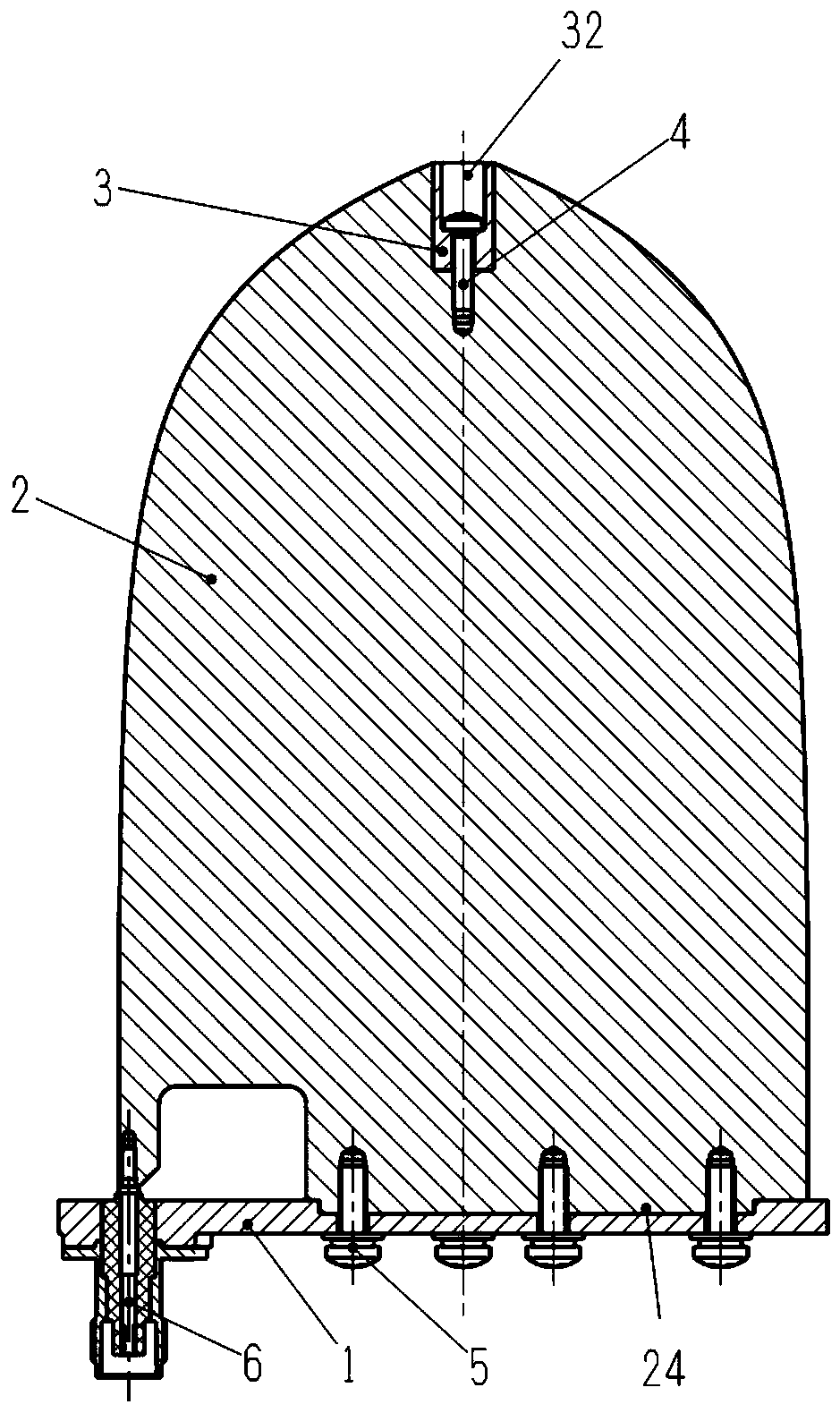

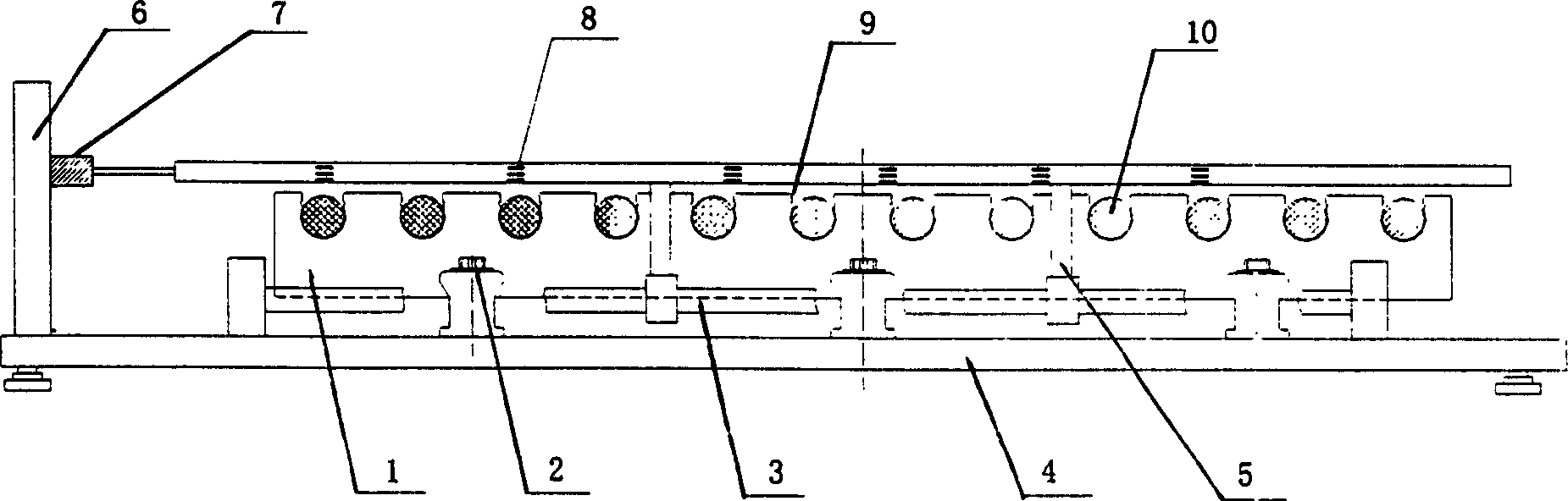

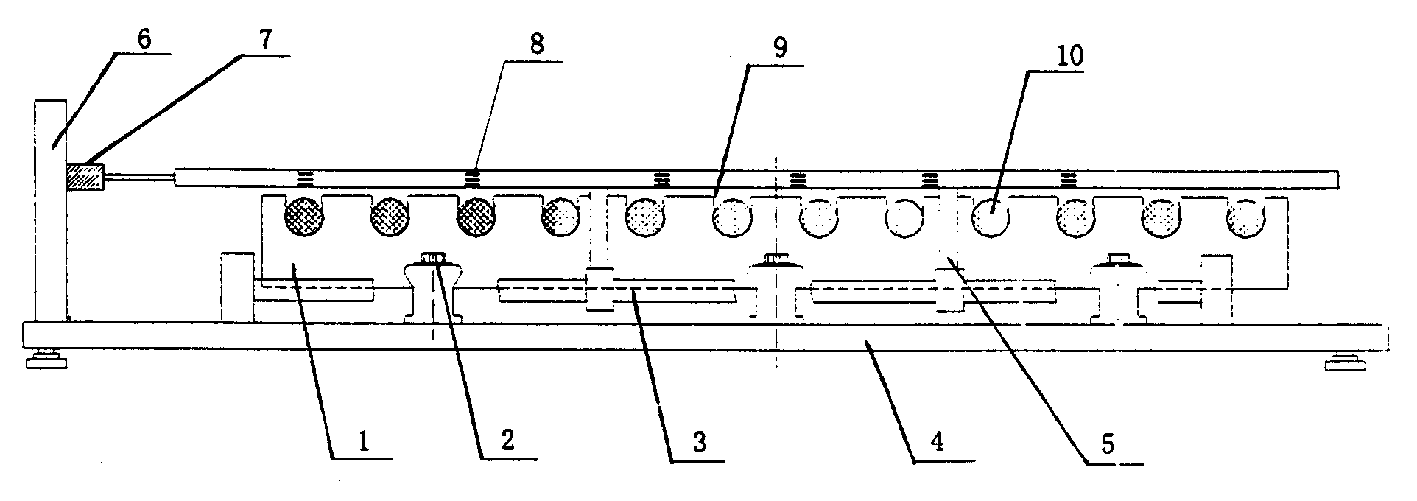

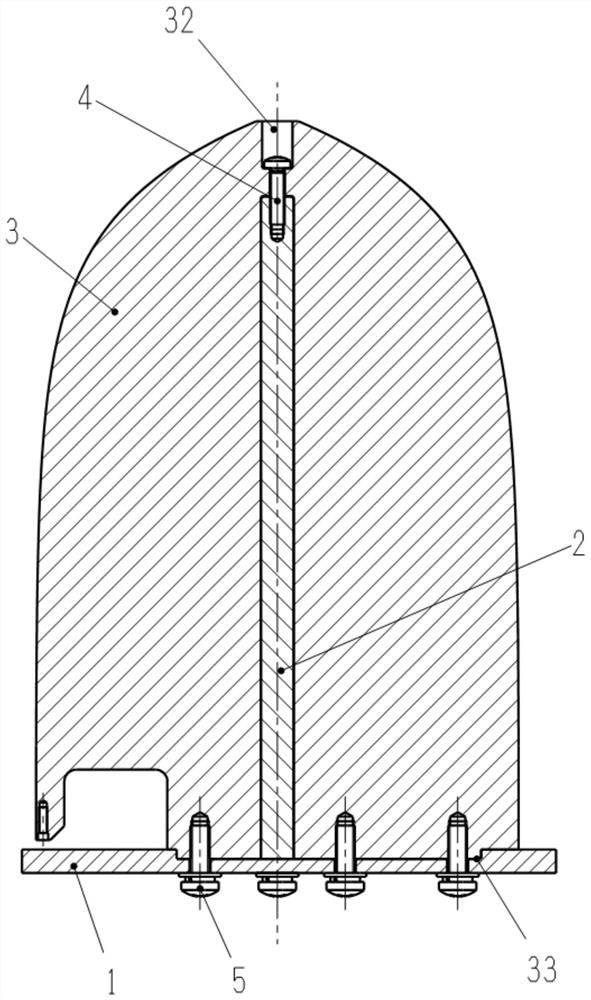

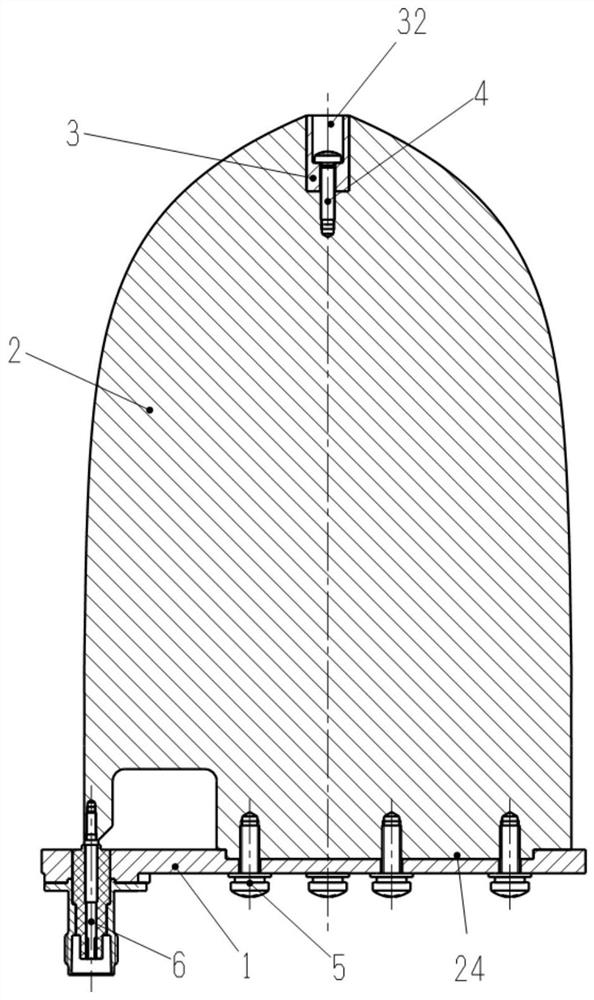

Amorphous alloy three-dimensional roll-core annealing furnace and annealing method

InactiveCN104694712AUniform temperatureAvoid direct contactFurnace typesHeat treatment furnacesMetallurgyAlloy

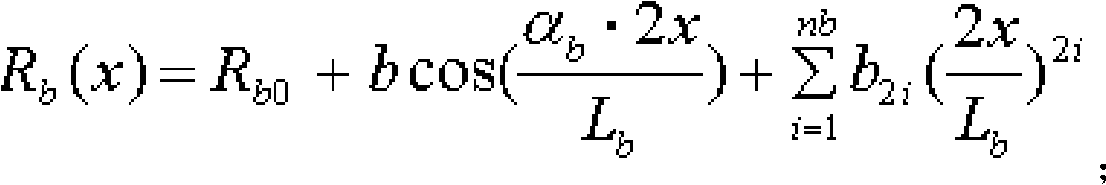

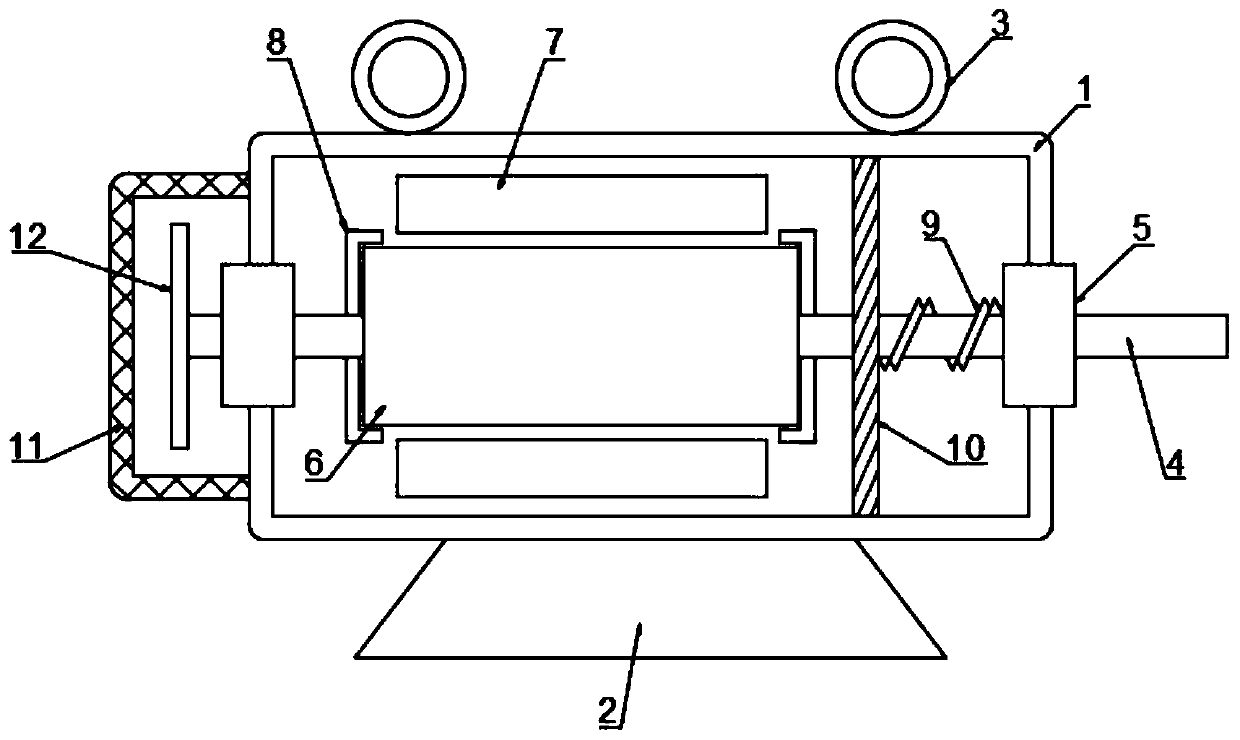

The invention discloses an amorphous alloy three-dimensional roll-core annealing furnace which comprises a cooling shell, a circulating fan, a heater, a heating chamber fixed in the cooling shell, a horizontal roller group, a tray arranged on the horizontal roller group, and a three-dimensional roll-core bracket arranged on the top surface of the tray, wherein an electrode facing the heating station of the tray is arranged on the side wall of the cooling shell; a heating chamber inlet is formed in the front side wall of the heating chamber; a heating chamber inlet baffle is arranged at the heating chamber inlet; a furnace opening which corresponds to the heating chamber inlet is formed in the side wall of the cooling shell; a furnace door is arranged on the furnace opening; multiple ventilating windows which can be independently opened and closed are formed in four side walls of the heating chamber; and multiple air holes are uniformly formed in the bottom plate of the heating chamber. According to the annealing furnace disclosed by the invention, the annealing process requirements of the amorphous alloy three-dimensional roll-core can be well met.

Owner:STATE GRID CORP OF CHINA +1

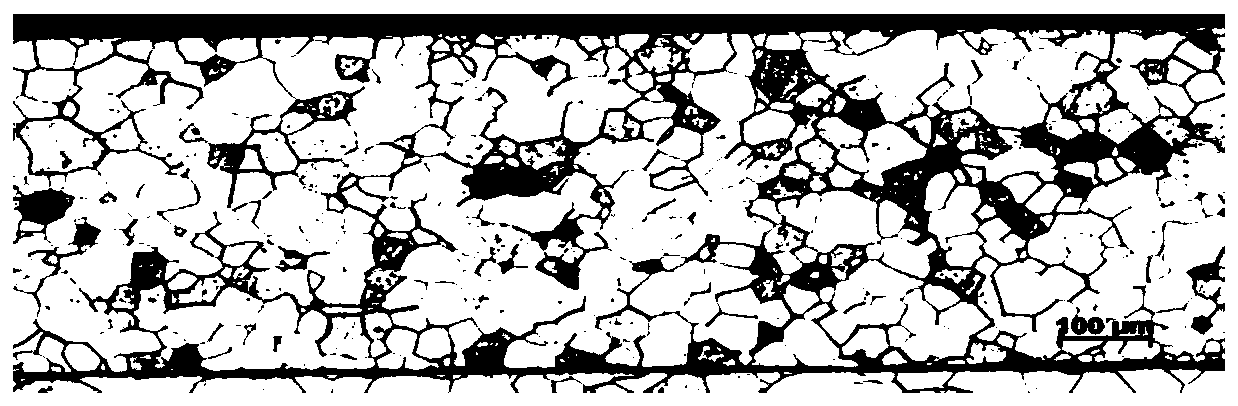

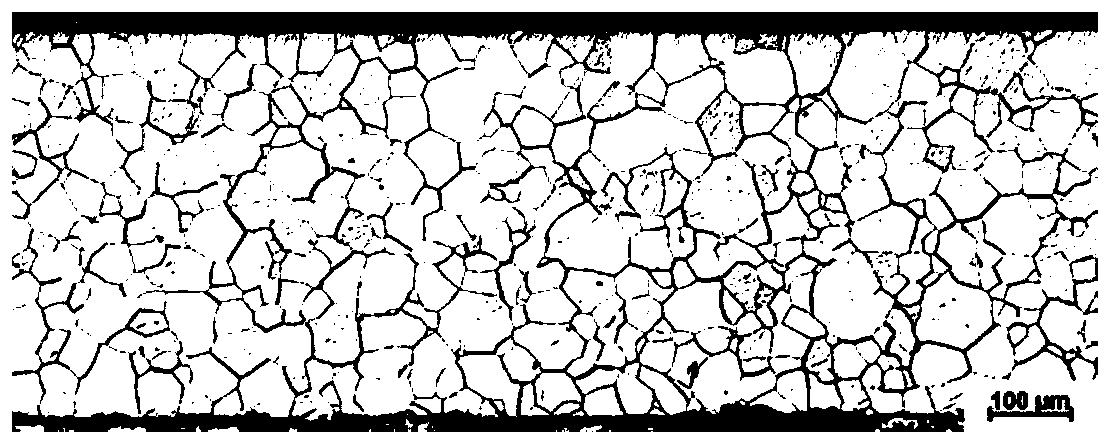

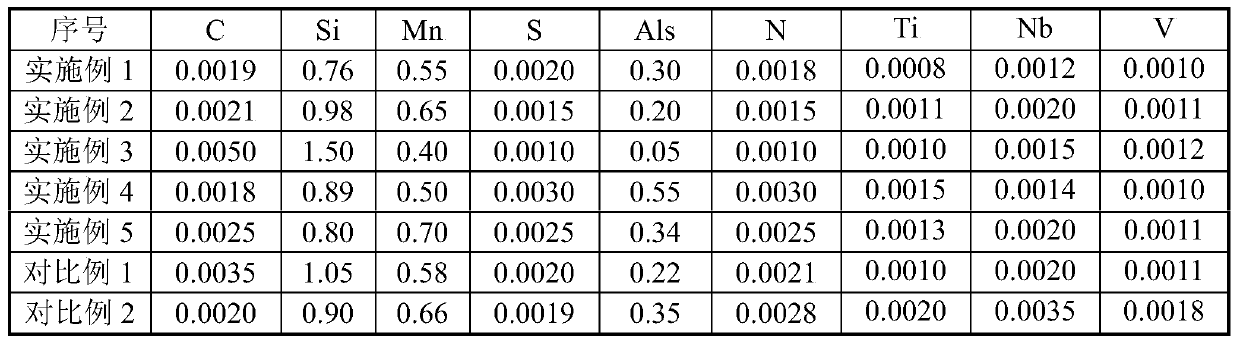

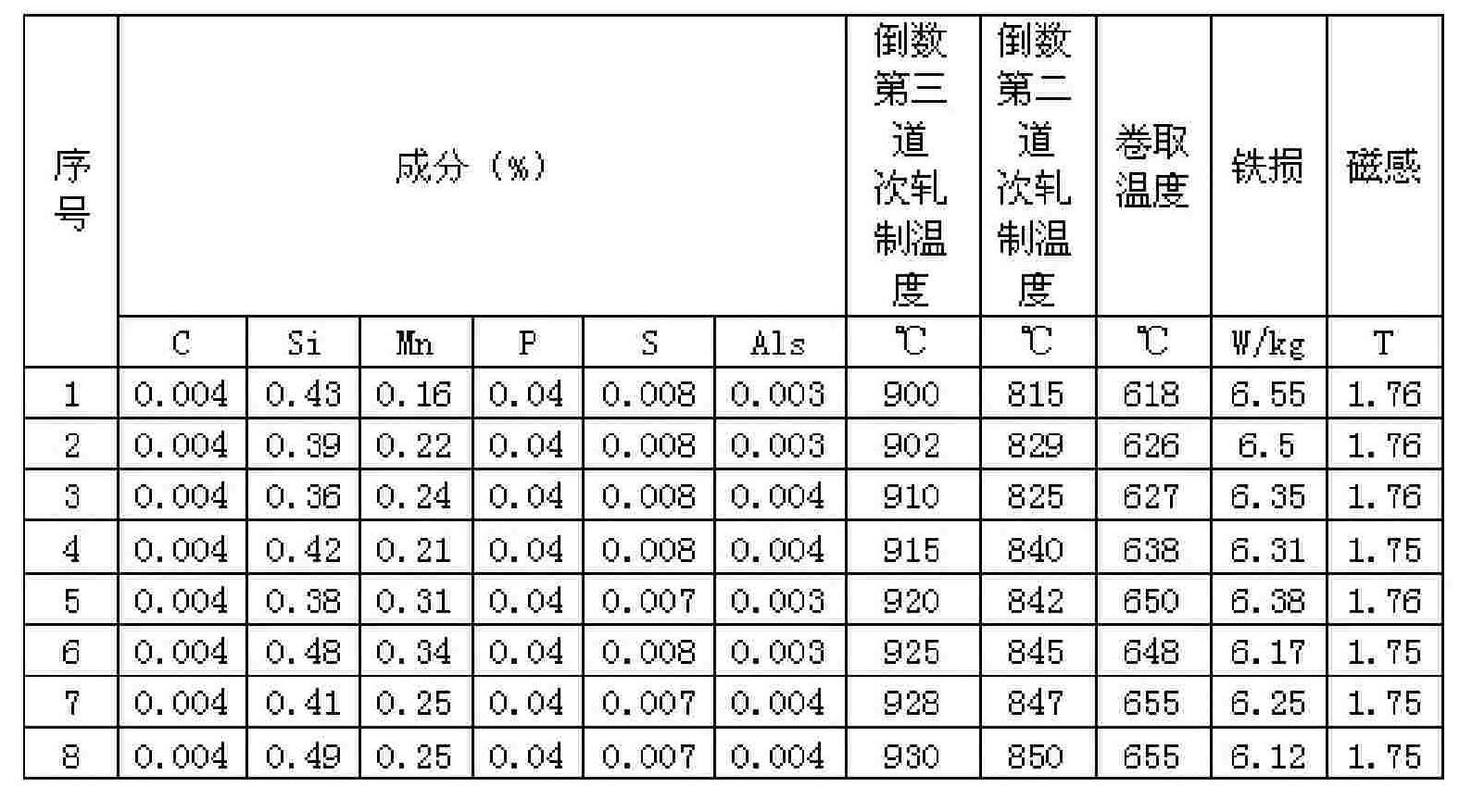

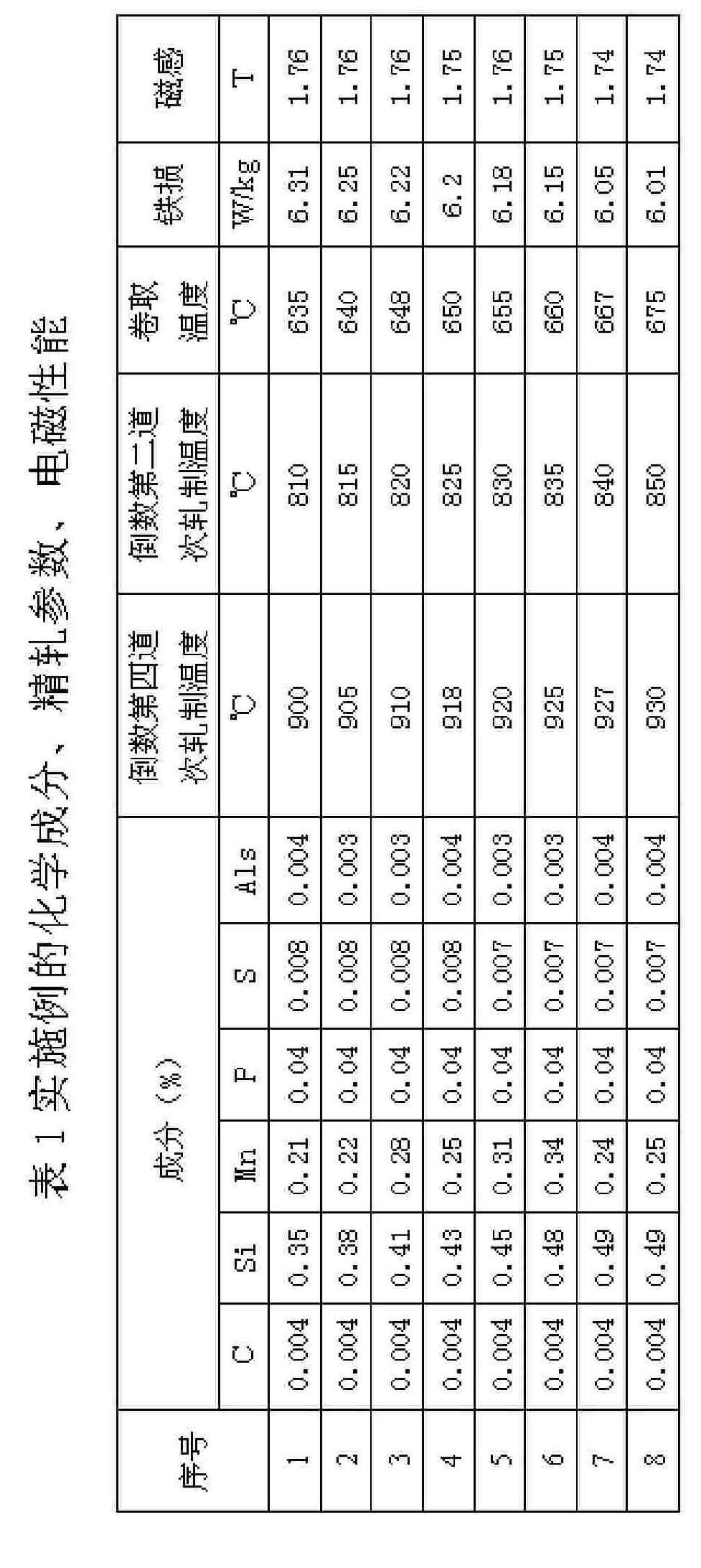

Non-oriented silicon steel for sheet billet production and manufacturing method thereof

The invention discloses non-oriented silicon steel for sheet billet production and a manufacturing method thereof and belongs to the technical field of production of non-oriented silicon steel. The non-oriented silicon steel comprises the chemical components in percent by weight: less than or equal to 0.005% of C, less than or equal to 1.50% of Si, greater than or equal to 0.40% but less than or equal to 0.70% of Mn, greater than or equal to 0.050% but less than or equal to 0.55% of Als, greater than or equal to 0.0010% but less than or equal to 0.0030% of S, greater than or equal to 0.0010% but less than or equal to 0.0030% of N, less than or equal to 0.0015% of Ti and the balance Fe and inevitable impurities. By carrying out process treatment such as smelting, continuous casting, heating, hot continuous rolling, rolling, pickling, cold rolling, product annealing, straightening and withdrawing, insulating layer coating and stress-relief annealing on the raw materials of the componentsby adopting a sheet billet production flow, the non-oriented silicon steel which is low in iron loss and high in magnetic polarization with the Si content of being less than 1.5% and the Al content of being within 0.05-0.5% is obtained under a condition of not adding noble metals. After stress-relief annealing, the decreasing proportion of the iron loss is relatively high, so that the electromagnetic property of the non-oriented silicon steel can be further improved.

Owner:MAANSHAN IRON & STEEL CO LTD

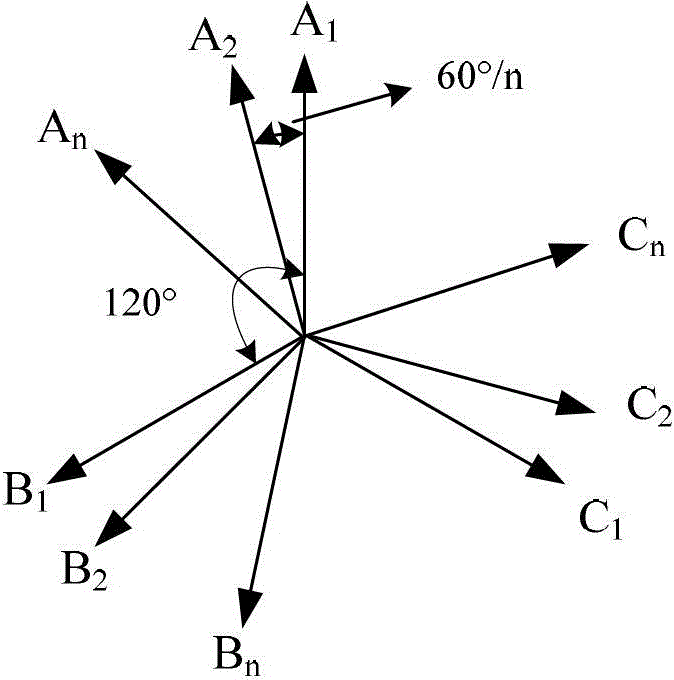

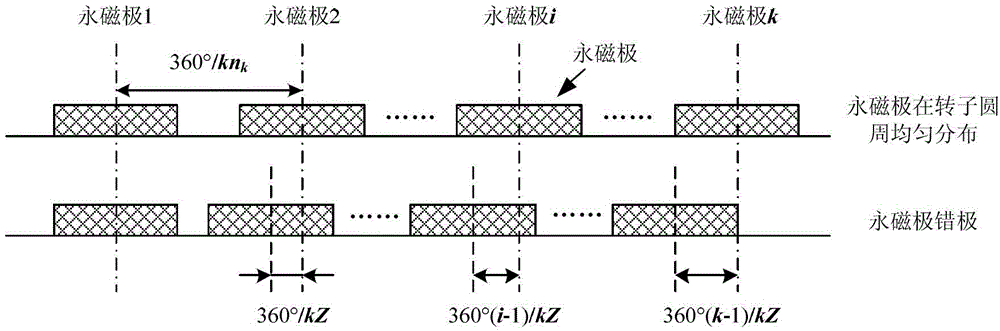

High-capacity low-speed permanent-magnet wind-driven generator

ActiveCN102868246ARealize material savingLow costMagnetic circuit rotating partsWindings conductor shape/form/constructionWind drivenWind force

The invention relates to a high-capacity low-speed permanent-magnet wind-driven generator. According to the generator, multiple three-phase windings are used and integer slots are centralized to improve the coefficient of the windings and the utilization ratio of an iron core; the number of in-series turns per phase of the armature winding is increased to reduce the axial length of the iron core of a motor; and a permanent-magnet pole is dislocated or skewed to reduce tooth harmonic and pulsating torque. On the premise of ensuring that the electromagnetic performance of the generator and the complexity of the motor manufacturing process meet the requirements, the invention realizes material saving of the permanent magnet in the high-capacity low-speed permanent-magnet wind-driven generator, effectively reduces the cost of the motor, and provides directions for the popularization and application of the high-capacity low-speed permanent-magnet wind-driven generator.

Owner:WUHAN NEW ENERGY INST OF ACCESS EQUIP & TECH

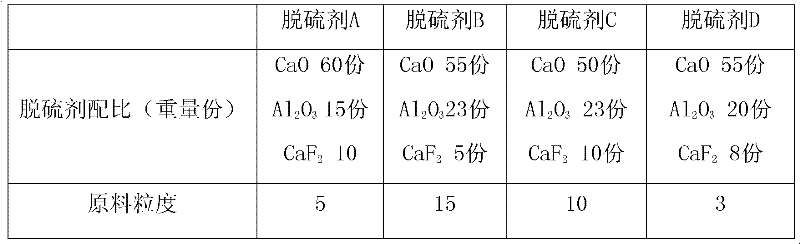

RH vacuum treatment desulfurizing agent used for non-oriented electrical steel, preparation method thereof, and desulfurizing method using same

InactiveCN102199687AGuaranteed electromagnetic performanceReduce iron lossElectrical steelRefractory

The invention relates to an RH vacuum treatment desulfurizing agent used for non-oriented electrical steel, a preparation method thereof, and a desulfurizing method using the same, belonging to the field of secondary refining of molten steel, so as to solve the problems that the RH vacuum treatment desulfurizing processes used for electrical steel in the prior art have serious erosion on refractory materials, high cost, slow melting speed and carburization risk to molten steel. The RH vacuum treatment desulfurizing agent used for non-oriented electrical steel is mainly composed of the following components: 50-60 weight parts of CaO, 10-25 weight parts of Al2O3 and 5-10 weight parts of CaF2. The invention also provides the preparation method of the RH vacuum treatment desulfurizing agent used for the non-oriented electrical steel, and the desulfurizing method using the RH vacuum treatment desulfurizing agent used for the non-oriented electrical steel. The RH vacuum treatment desulfurizing agent provided by the invention is mainly used for the RH vacuum treatment desulfurizing treatment of the non-oriented electrical steel.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +2

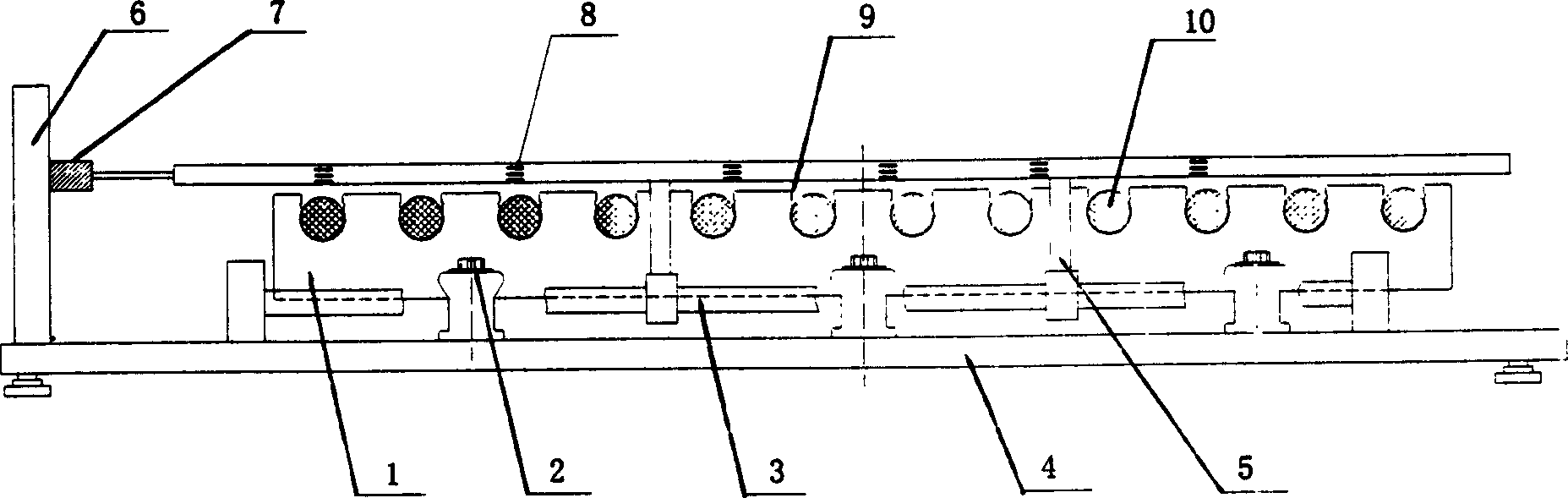

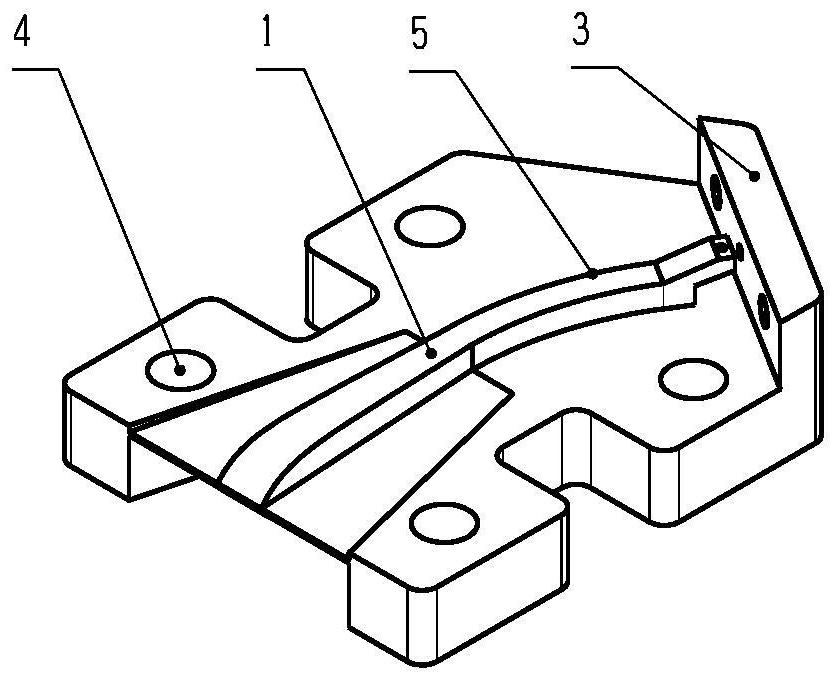

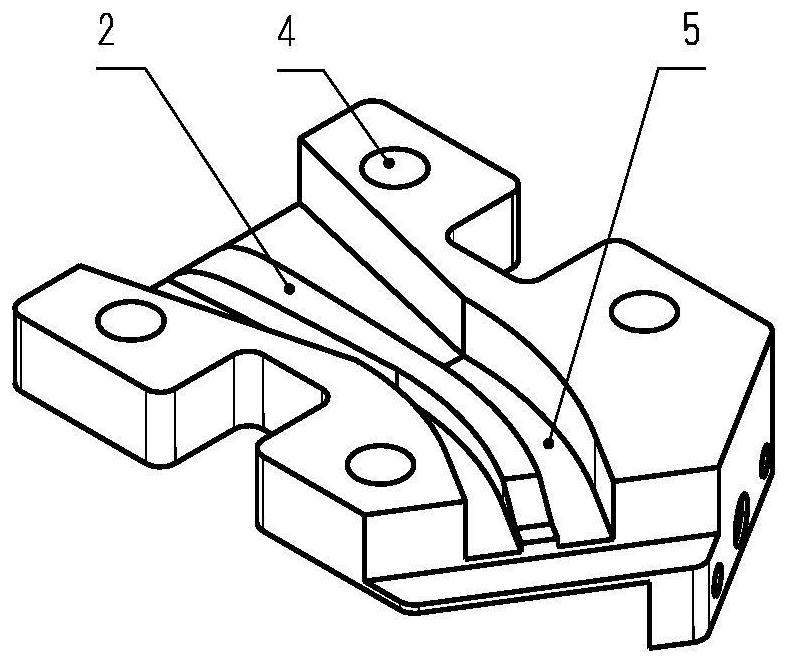

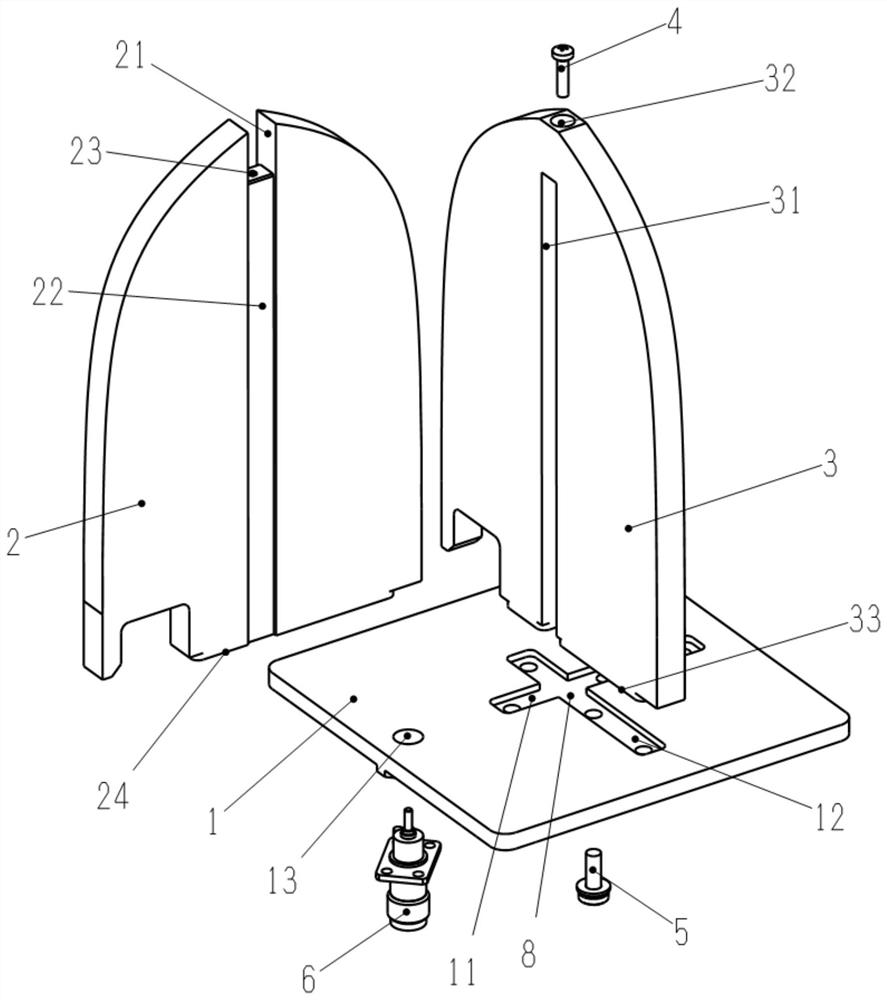

Long-stator linear machine electromagnetic performance off-line testing device

InactiveCN1460865AGuaranteed electromagnetic performanceFulfil requirementsForce measurementMagnetic property measurementsPull forceTransformer

The off-line testing equipment of electromagnetic performance of long-stator linear motor includes a testing platform, on its surface a guideway is set, one end of said testing platform is equipped with a fixed supporting frame on which one end of a pulling sensor with high accuracy is connected, said testing platform also is equipped with several fastening bolts. Said off-line testing equipment also includes a rotor steel plate connected with the above-mentioned guideway by means of supporting frame, said rotor steel plate has several holes, every hole interior is equipped with a group of electrodynamic induction coils, every group container three electrodynamic induction coils, and every induction coil is series-connected with A.C. electric meter. The long-stator to be tested is fixed on the testing platform.

Owner:TONGJI UNIV +2

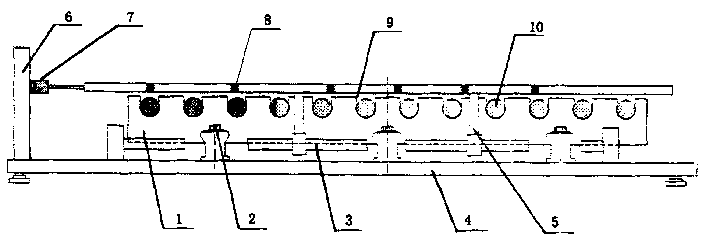

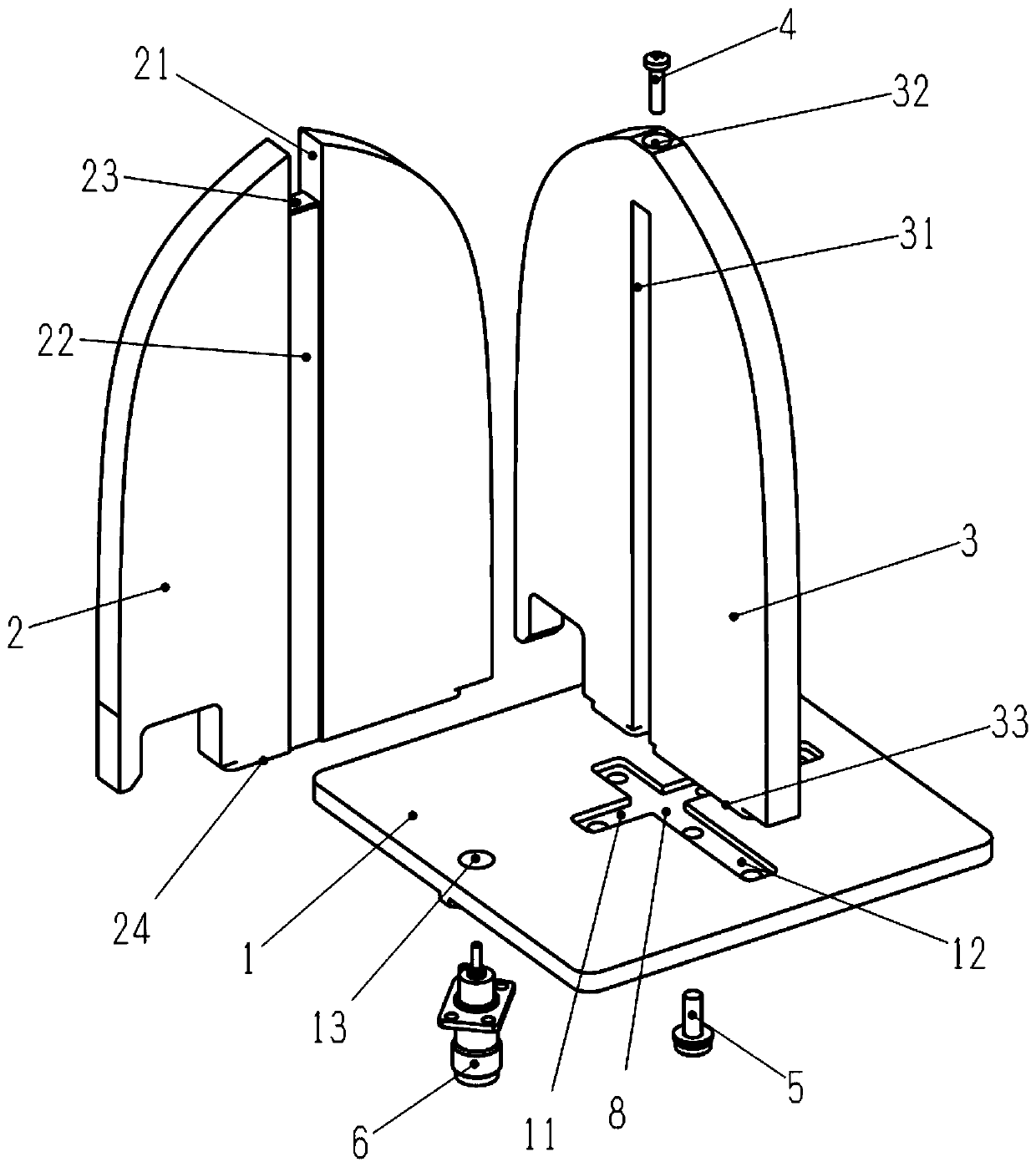

Orthogonal dual-polarized metal slot antenna array structure and antenna array containing the structure

ActiveCN109904587AGuaranteed accuracyGuaranteed electromagnetic performanceAntenna supports/mountingsRadiating elements structural formsUltimate tensile strengthRadiating element

The invention discloses an orthogonal dual-polarized metal slot antenna array structure and an antenna array containing the structure, and solves the problem in the prior art that high-temperature welding formation is adopted to cause poor antenna precision, resulting in reducing the yield, limiting by the welded aluminum alloy material and reducing the mechanical strength of the antenna, or the assembly formation of spare parts is adopted, resulting in increasing the weight of the antenna, reducing the mechanical strength of the antenna and increasing the number of structural parts that are independent of electromagnetic properties, so as to narrow the scope of application. The antenna array structure comprises an antenna bottom plate, and a sub-structure unit mounted on the antenna bottom plate and interposed by horizontal radiating unit pieces and vertical radiating element pieces. The antenna array includes an antenna array structure. The antenna array structure and the antenna array have the advantages of simple structure, scientific and reasonable design and convenient use, and can effectively ensure the accuracy of the antenna to improve the production yield, effectively improve the mechanical structure strength, reduce the weight of the antenna, and ensure the electromagnetic performance of the antenna array to expand the applicable range.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

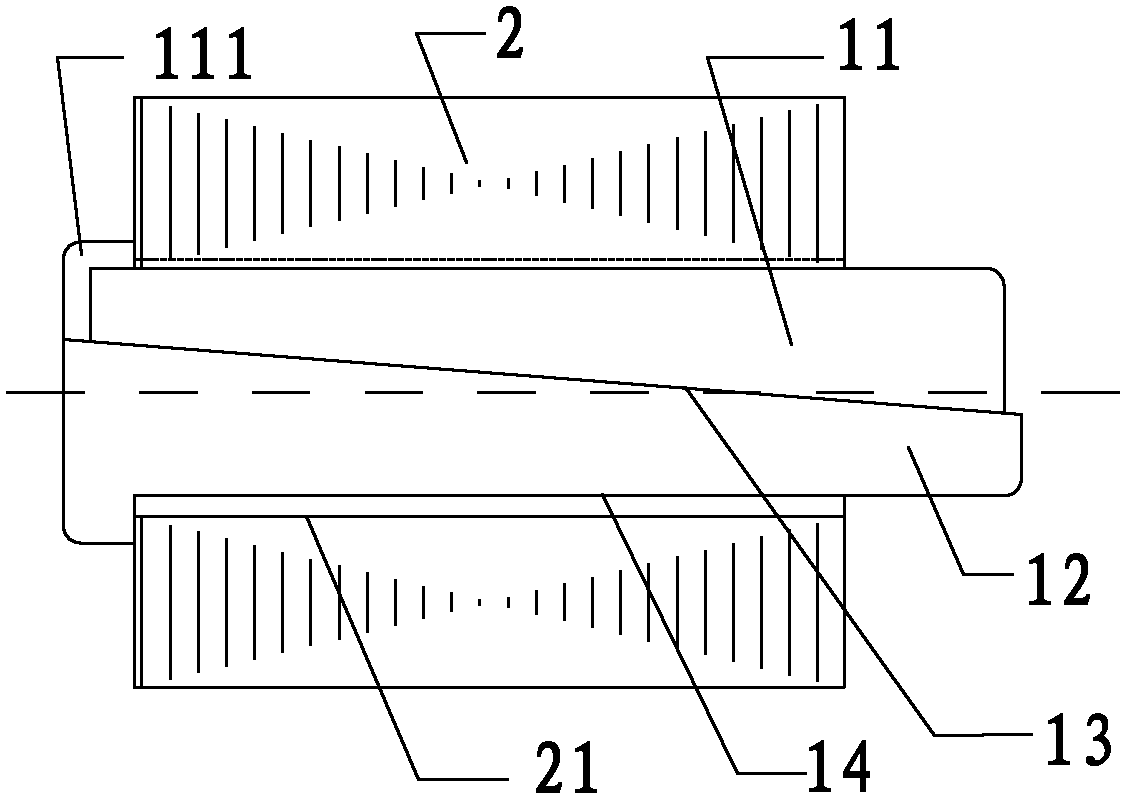

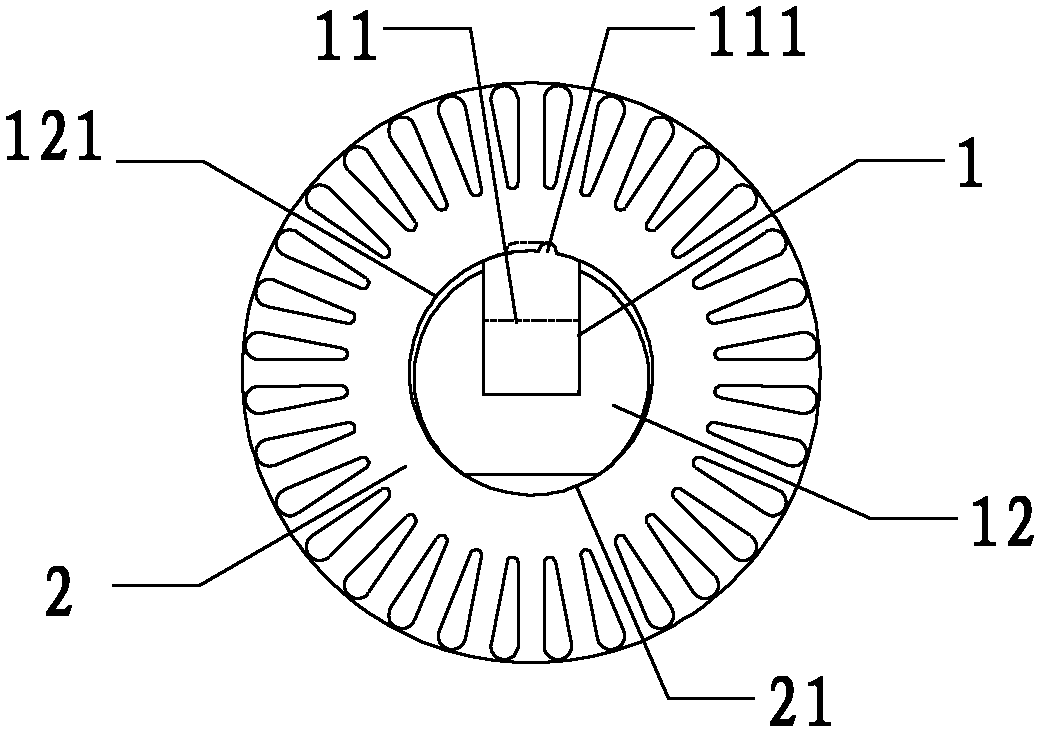

Technological mandrel and method for manufacturing squirrel-cage rotor by using same

InactiveCN102163884AElimination of reprocessing workGuaranteed flatnessMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringLinearity

The invention discloses a technological mandrel in an aluminum casting process of a squirrel-cage rotor of an asynchronous motor, and a method for manufacturing the squirrel-cage rotor by using the technological mandrel. The technological mandrel is called as a primary and secondary mandrel; the technological mandrel consists of a secondary mandrel part with convex keys and a primary mandrel which takes a smooth cylindrical surface as a main body structure; the secondary mandrel part and the primary mandrel part are matched with each other through a groove with a wedged oblique surface; and the direction of the wedged oblique surface is parallel to the axial direction of the rotor. According to the technical scheme of the invention, the flatness and linearity of the cylindrical surface in the inner hole of the aluminum cast rotor are guaranteed; and the squirrel-cage rotor manufactured in thermal jacket or cold pressing way can be prevented from reprocessing of the inner hole, and the labor cost and expenditure consumed by a cutter are reduced. For the occasion for producing the squirrel-cage rotor by virtue of common casting devices, by utilizing the method in invention, the products suitable for precision demands can be produced.

Owner:SHANGHAI REGAL BELOIT & JINLING

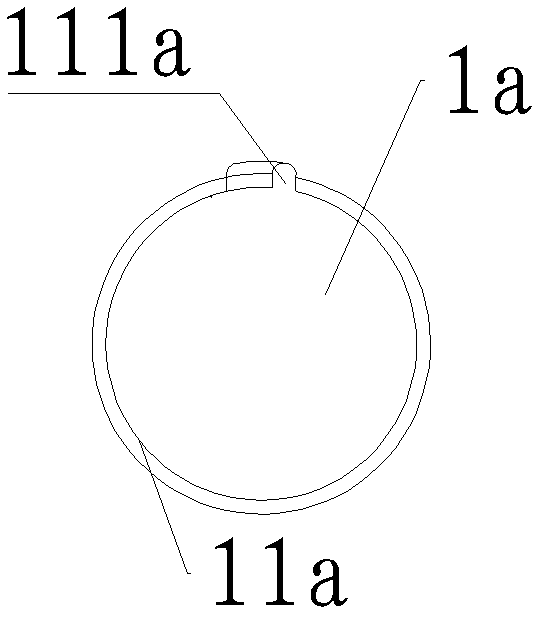

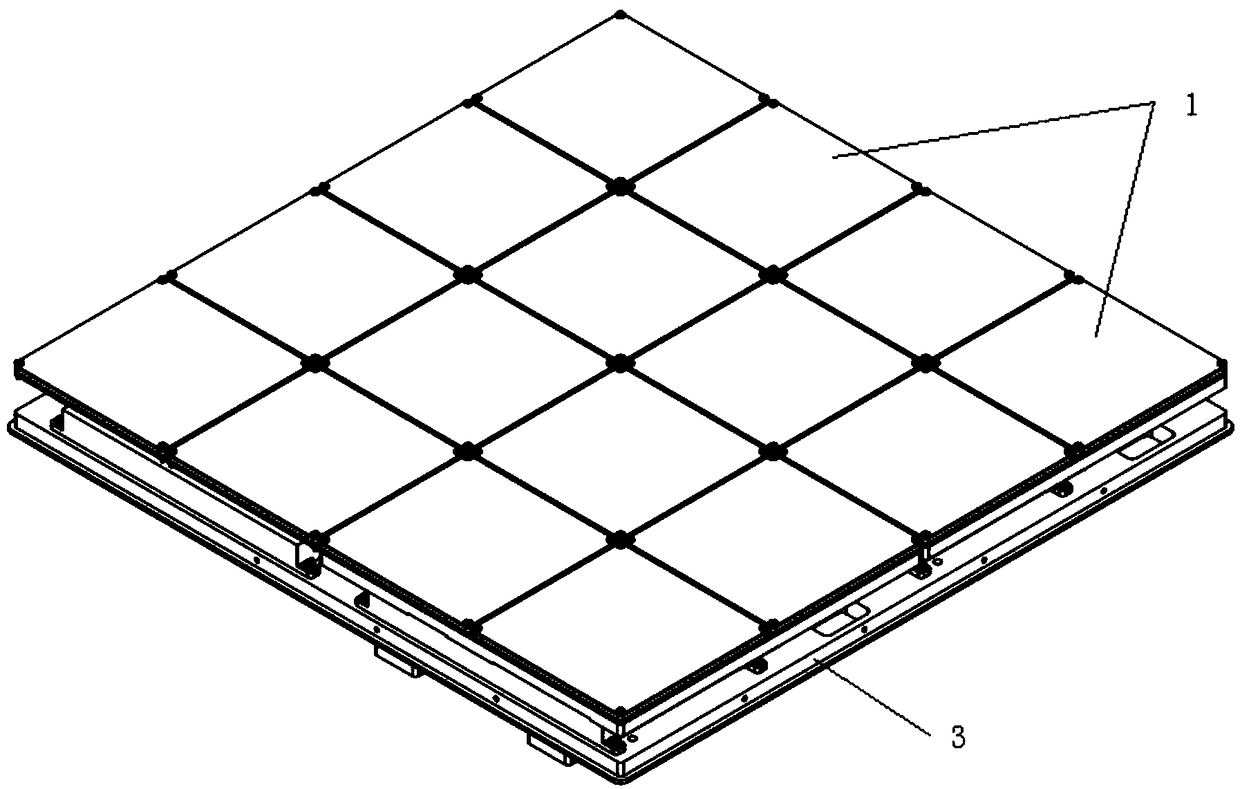

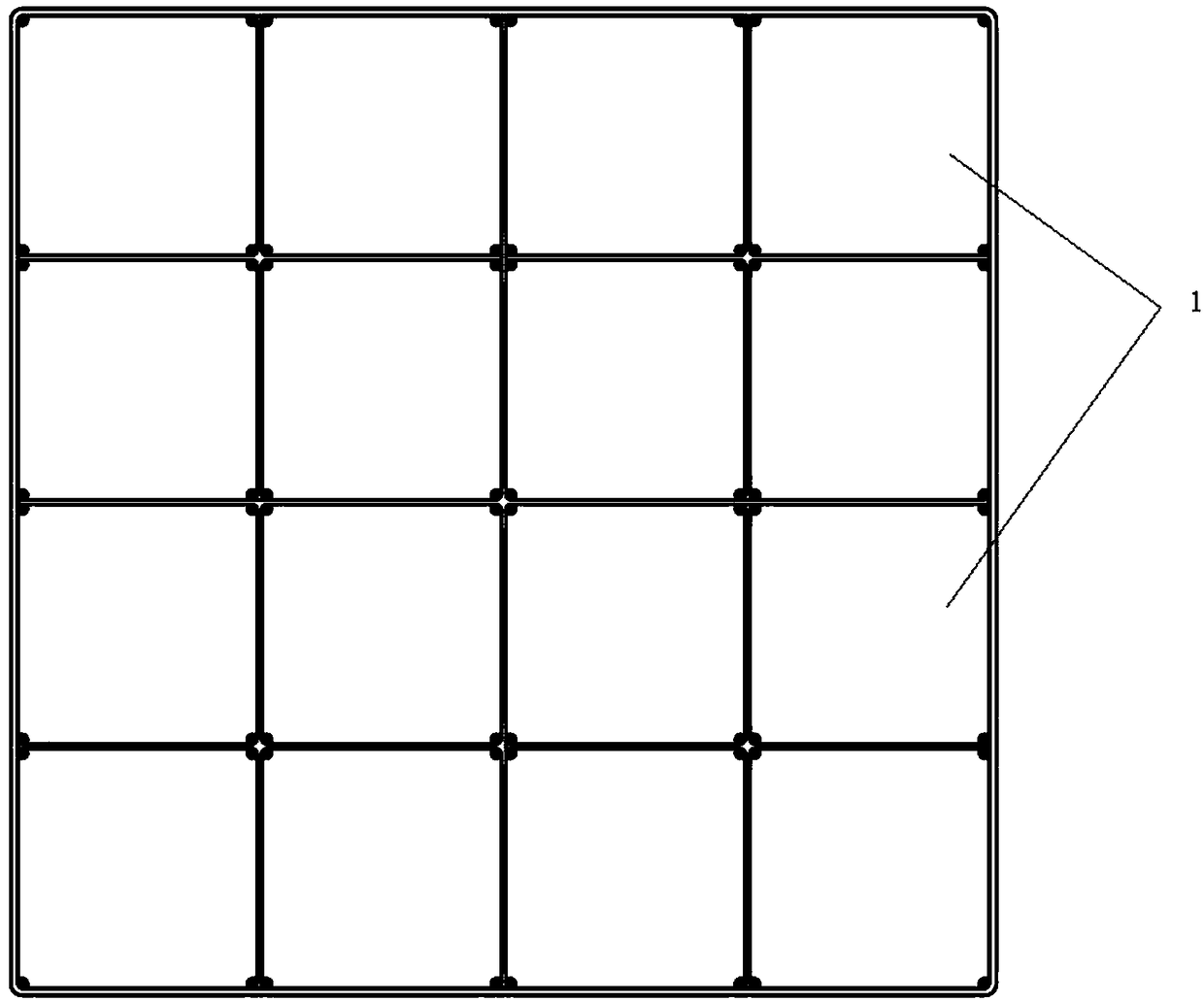

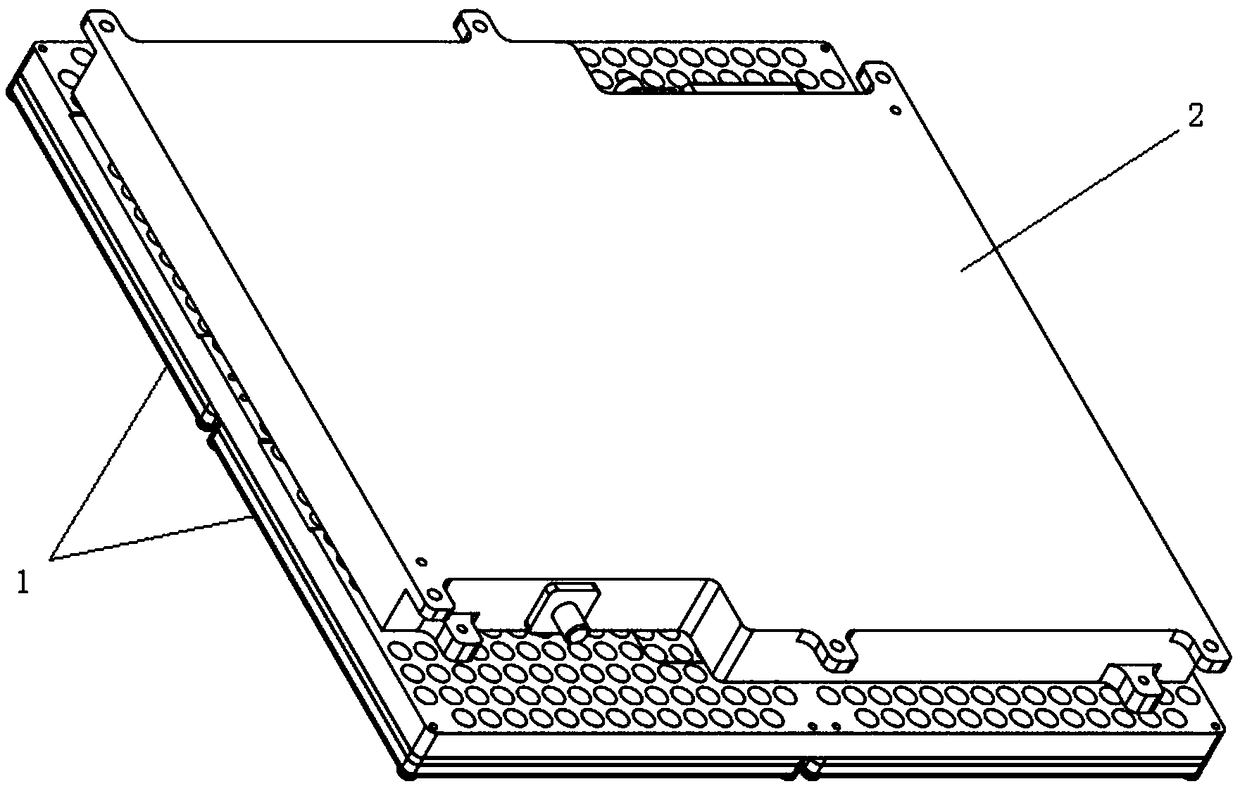

X-band active array sub-array structure

PendingCN108767415AComply with the collection folding requirementsCompact structureAntenna arraysRadiating elements structural formsArray data structureEngineering

The invention discloses an X-band active array sub-array structure, and relates to the technical field of electronic countermeasure. The X-band active array sub-array structure comprises an antenna layer, a module layer, a cold plate and an auxiliary layer, wherein the antenna layer comprises sixteen optimized aperture antenna units which are arranged a mode of four by four rectangular arrays, themodule layer comprises four unit assemblies in a mode of two by two rectangular arrays, a cold liquid passage is arranged in the cold plate, via holes are further formed in the cold plate, the auxiliary layer comprises an auxiliary module fixedly arranged on a bottom surface of the cold plate, and the unit assemblies are connected with a circularly-circulated device and a power control module bya feeder penetrating through the via holes. The X-band active array sub-array structure has the characteristics of structure independence and function independence, flexible block-type building can beachieved, modular splicing is facilitated, and the X-band active array sub-array structure is suitably used for large-size equipment with overlarge power and low cost.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Levelling method of non-oriented electrical steel

InactiveCN101358274AGuaranteed electromagnetic performanceQuality assuranceRoll force/gap control deviceCounter-pressure devicesProduction lineElectrical steel

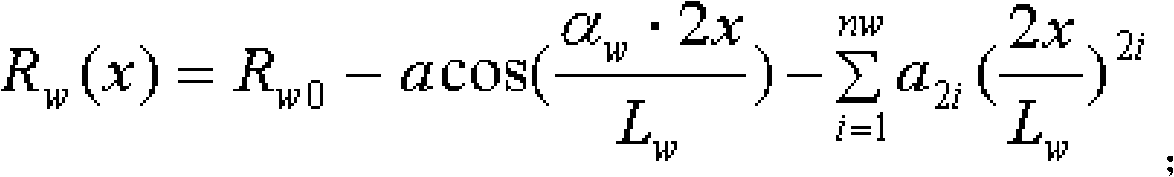

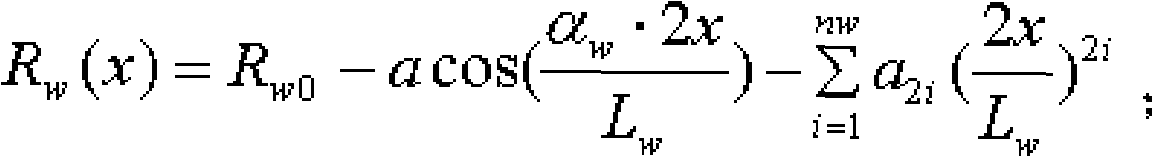

The invention discloses a non-oriented electrical steel leveling method capable of guaranteeing the magnetic property of products in the field of steel rolling. In order to guarantee the magnetic property of non-oriented electrical steel, the leveling elongation percentage is less than 0.1 percent, the unit width rolling force is from 80kN / m to 200kN / m, and the leveling tensile stress is from 10MPa to 30MPa. According to the characteristics of the non-oriented electrical steel that the transverse thickness difference is equal to 10 microns and the leveling elongation percentage is less than 0.1 percent, and in order to guarantee the uniform transverse distribution of rolling forces and improve produt surface quality, the non-oriented electrical steel is rolled by a working roller and a supporting roll which are in a shape of special function curve which is composed of a cosine function and an evenorder power function in a leveling machine. The invention does not increase the equipment improvemng investment and the production cost, is simple and easy to implement, and is especially suitable for the production of the non-oriented electrical steel on the common horizontal continuous anneal production lines.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Winding type asynchronous motor and manufacturing method

InactiveCN110365142AWon't breakWill not cause breakageMagnetic circuit rotating partsManufacturing stator/rotor bodiesInduction motorControl engineering

The invention belongs to the technical field of motors and particularly relates to a winding type asynchronous motor and a manufacturing method. The problems of expansion stress difference between aniron core and a rotating shaft, magnetic short circuit and autorotation of a rotor after a power failure in an existing asynchronous motor are solved. The provided motor comprises a housing; a base isintegrally formed on the lower side wall of the housing; two hanging rings are welded to the upper side wall of the housing; a rotating shaft is arranged in the housing in a penetrating mode; a rotoris fixed to the outer wall of the rotating shaft; a stator arranged on the outer wall of the rotor in a winding mode is fixed in the housing; a mounting opening is formed in the connecting position of the housing and the rotating shaft; and a bearing is fixed in the mounting opening. By arranging the annular iron core, the motor is prevented from contacting the rotating shaft and expansion stressis reduced; by arranging mounting grooves and partition blocks, magnetic contact is avoided, and the electromagnetic performance is guaranteed; and by setting a magnetic plate and a reset spring, therotor is fixed during the power failure, and the safety performance is greatly improved.

Owner:徐州亚泰电机有限公司

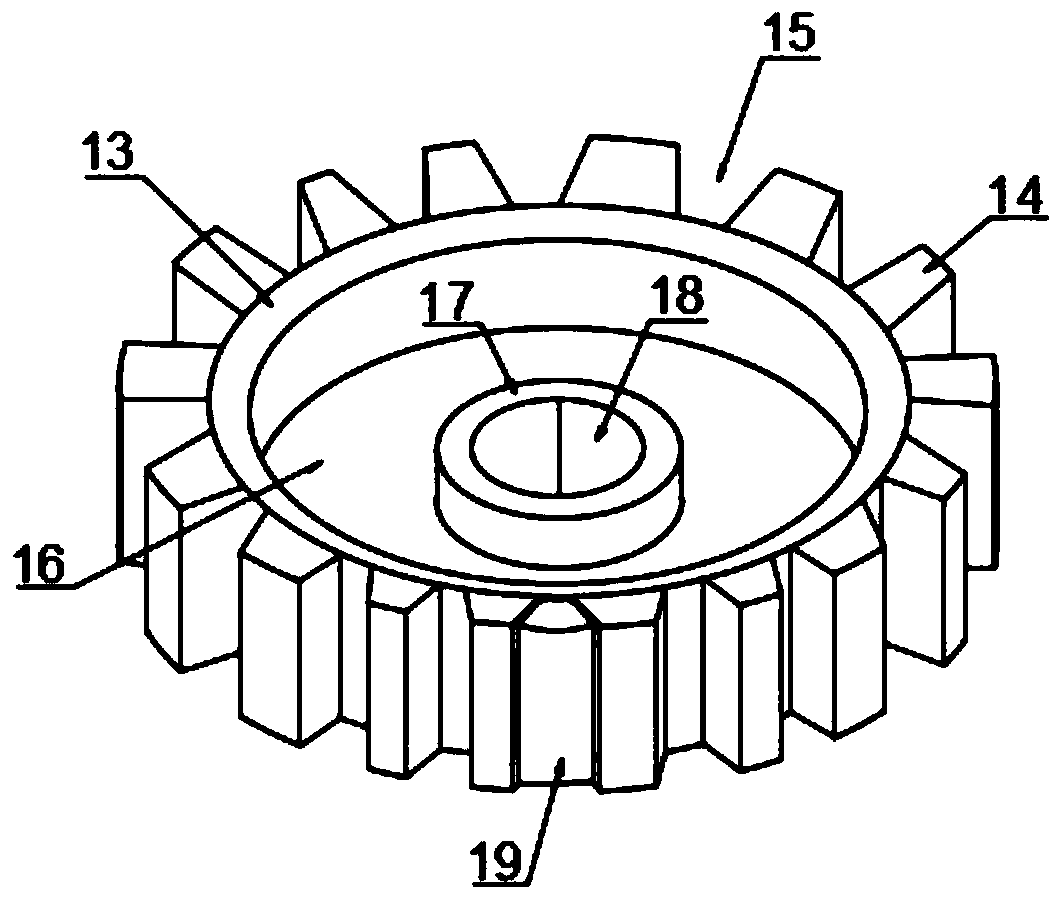

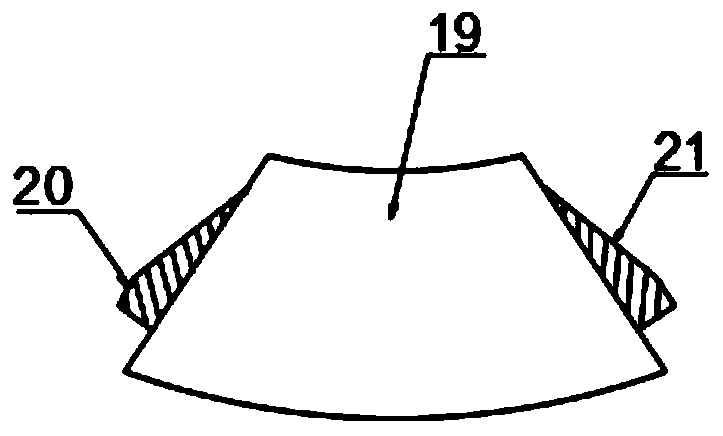

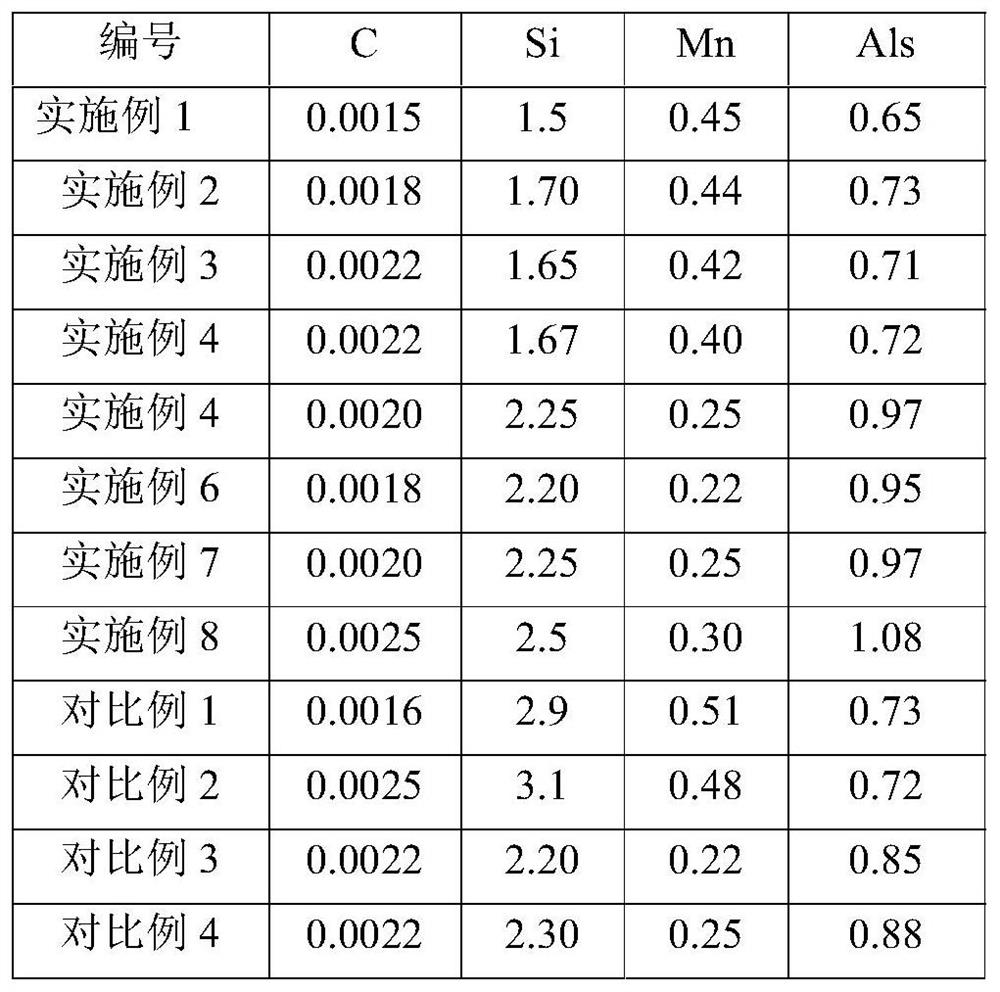

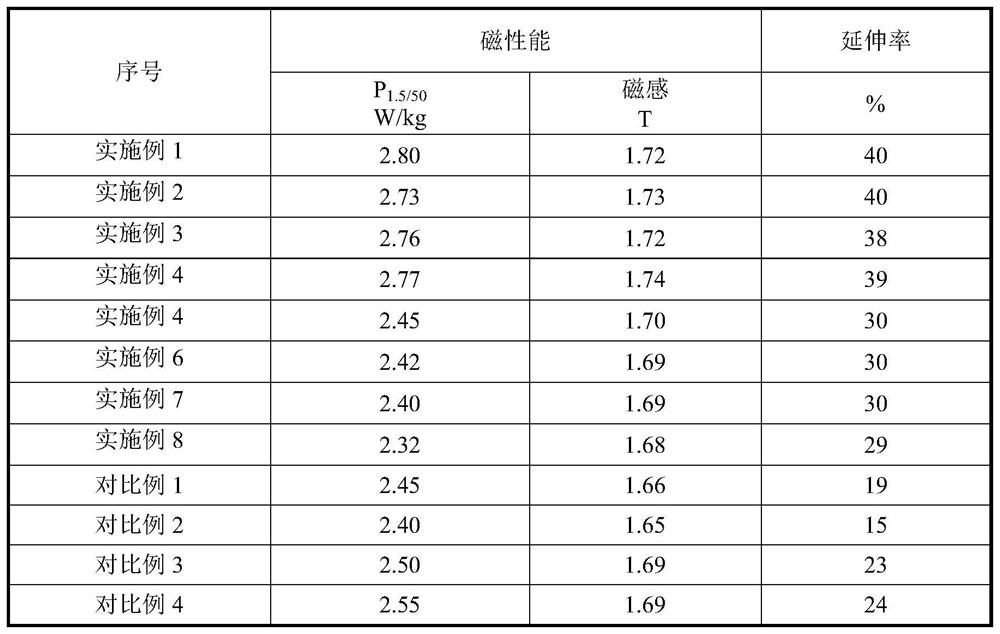

Low-iron-loss non-oriented silicon steel suitable for winding type machining and production method of low-iron-loss non-oriented silicon steel

The invention discloses low-iron-loss non-oriented silicon steel suitable for winding type machining and a production method of the low-iron-loss non-oriented silicon steel, and belongs to the technical field of silicon steel production. The non-oriented silicon steel comprises the following elements in percentage by mass: 1.5 to 2.5 percent of Si, 0.15 to 1.0 percent of Mn, 0.5 to 1.5 percent of Als and the balance of Fe and inevitable impurities. The production process comprises the steps of molten iron pretreatment, converter smelting, vacuum treatment and continuous casting. Heating and hot rolling; normalizing treatment; cold rolling and annealing; preserving heat and cooling; and coating with an insulating layer. The non-oriented silicon steel with excellent electromagnetic performance and elongation can be produced by optimizing the components and proportion of the non-oriented silicon steel in combination with process operation, so that the winding type processing and use requirements of the electrical steel can be effectively met, and the manufacturing process is short in flow and relatively low in cost.

Owner:MAANSHAN IRON & STEEL CO LTD

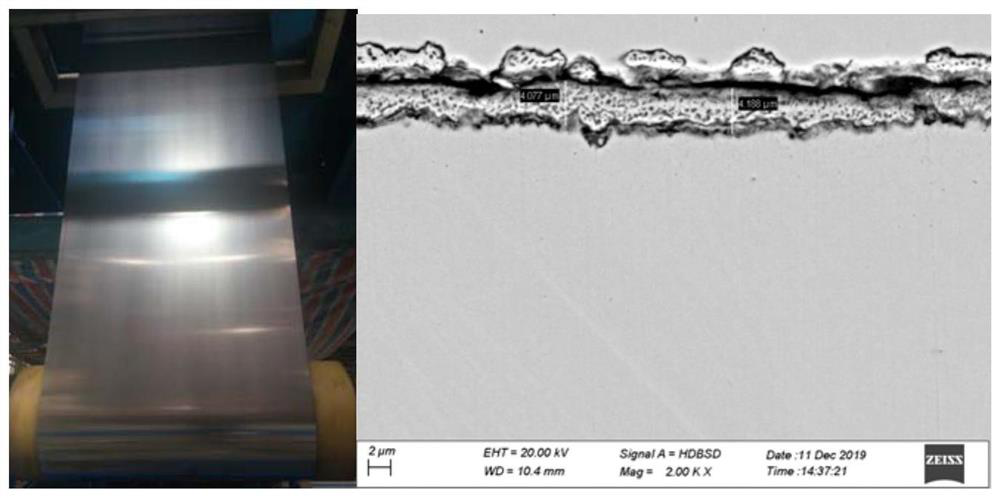

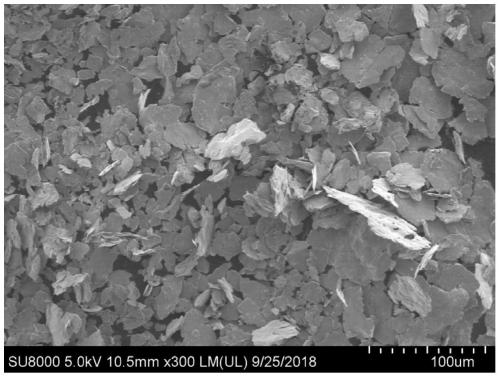

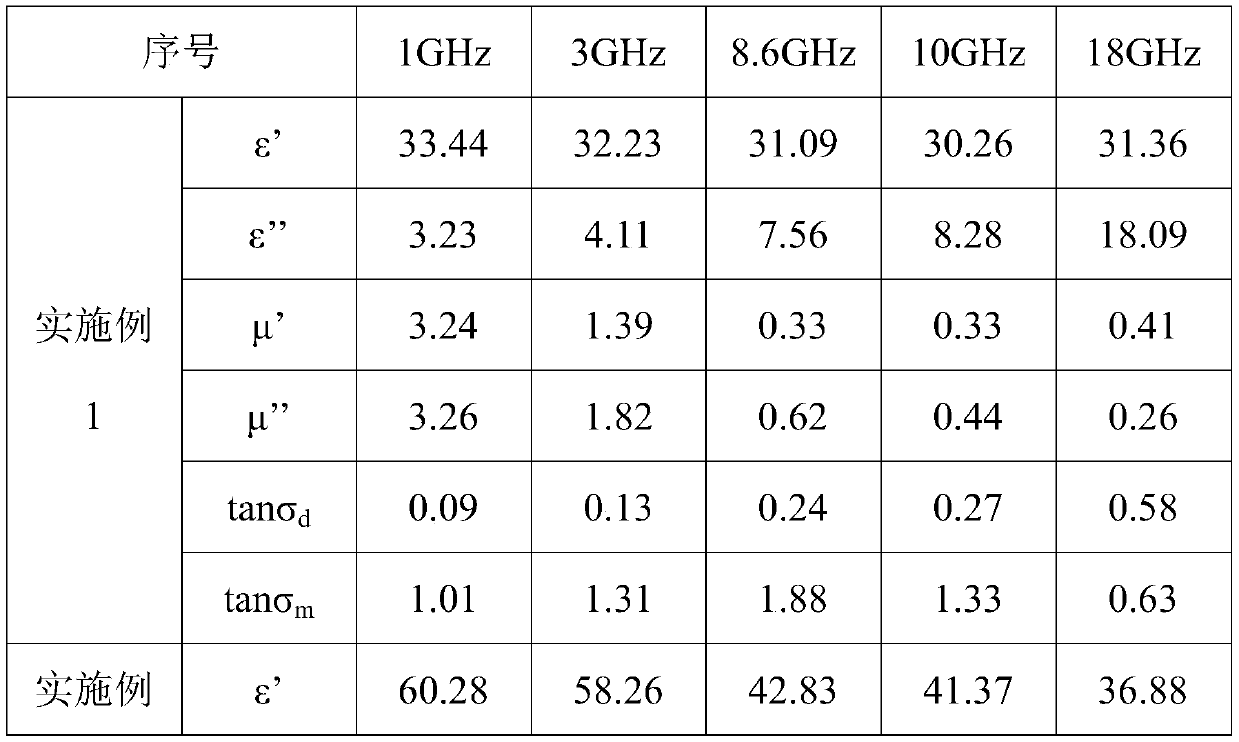

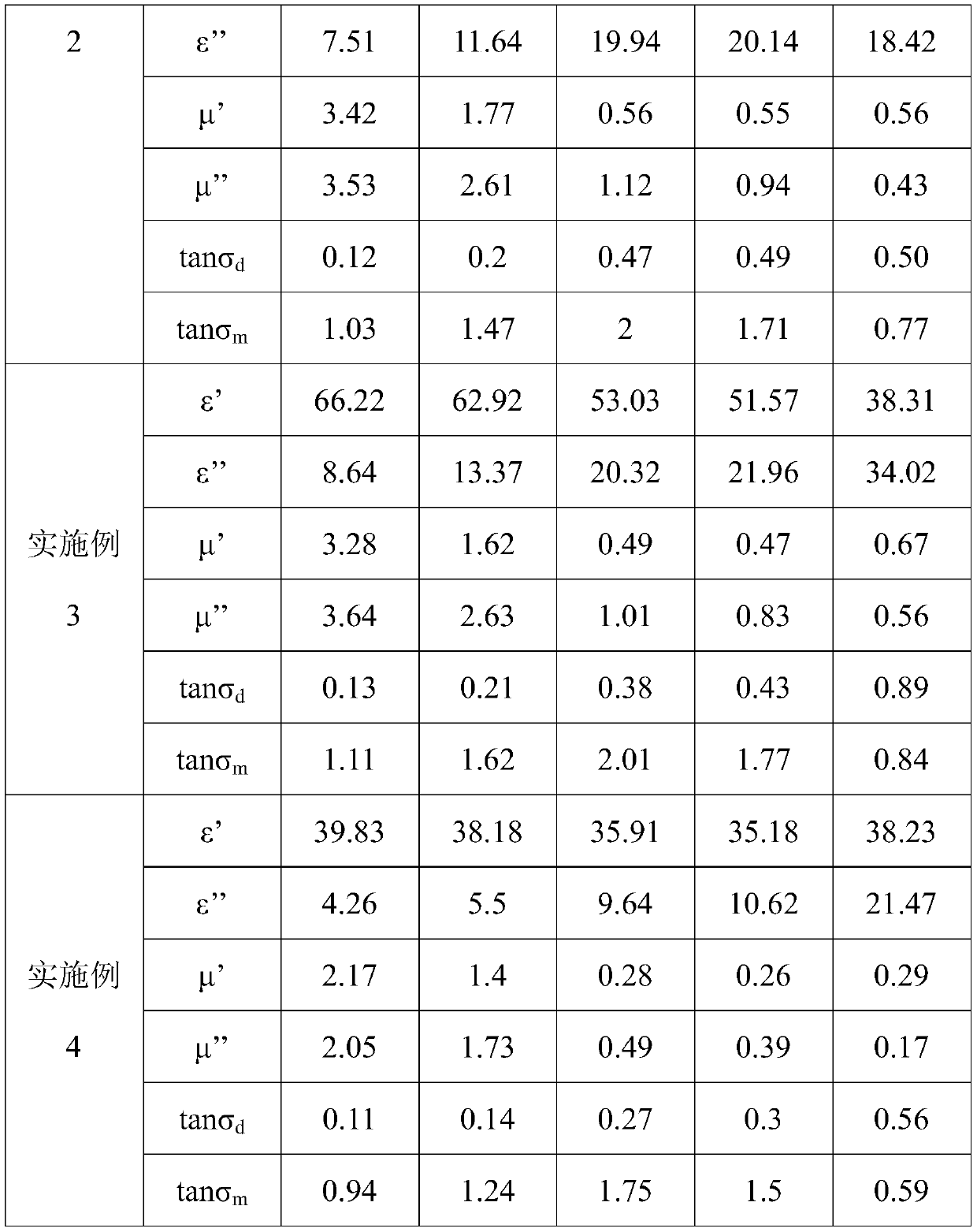

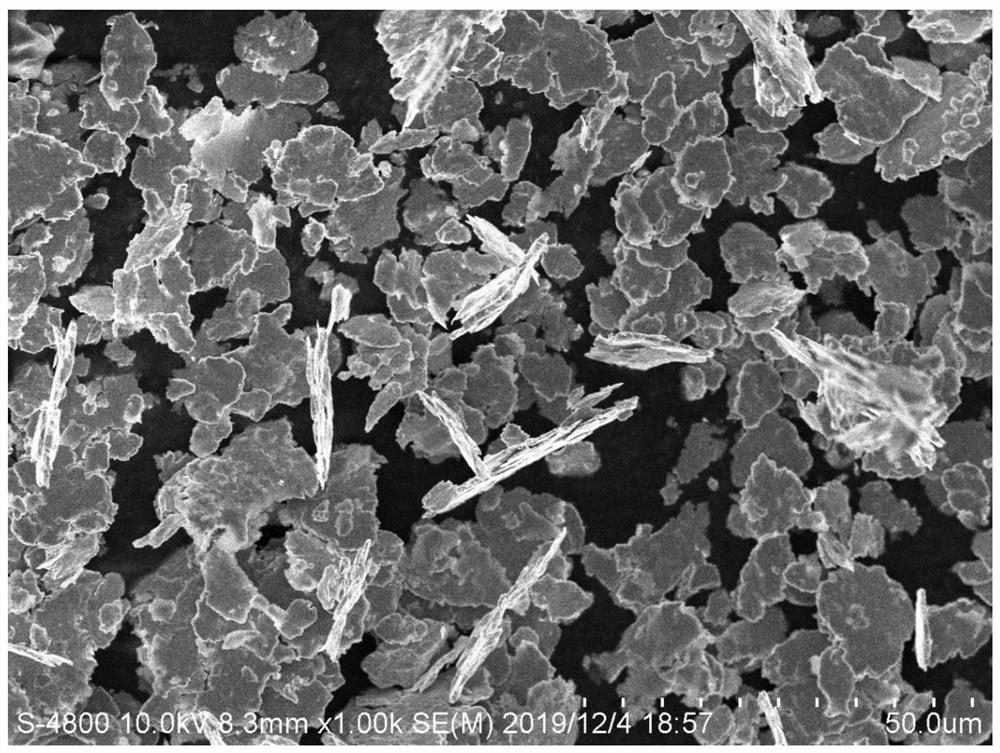

Sheet ferrite electromagnetic composite material and preparation method thereof

ActiveCN110283429AGuaranteed uniformityHigh electromagnetic parametersPigment physical treatmentSatelliteFerrite powder

The invention relates to a sheet ferrite electromagnetic composite material and a preparation method thereof. According to the preparation method, the composite material is prepared by using a sheet ferrite, a coupling modifier, resin, a curing agent and a diluent as raw materials and ball milling, mixing and molding the raw material components; the process conditions for preparing the sheet ferrite by ball milling are as follows: ferrite powder, steel balls, a ball milling assistant and a volatile solvent are subjected to ball milling for 7 to 8 h at the rotation of 400 to 500 r / min; the steel balls include 8 mm diameter steel balls and a 6 mm diameter steel balls. A ball milling method is adopted to prepare the sheet ferrite powder; by coupling modification and compounding with epoxy resin, and applying an autoclave process or ultrasonic curing, an electromagnetic load composite material is formed, which exhibits high electromagnetic parameters at 1 to 18 GHz and can be widely used in various fields such as radar, navigation, satellite communication, electronic countermeasures, broadcast television, mobile communication and the like.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

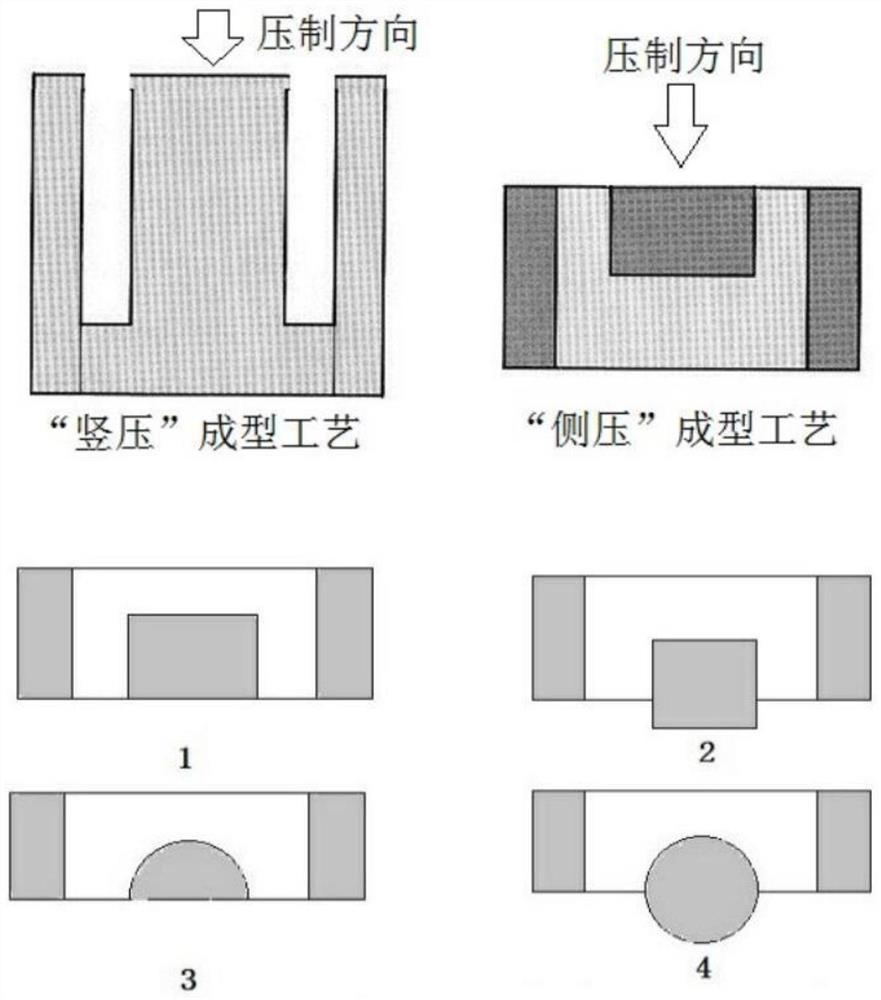

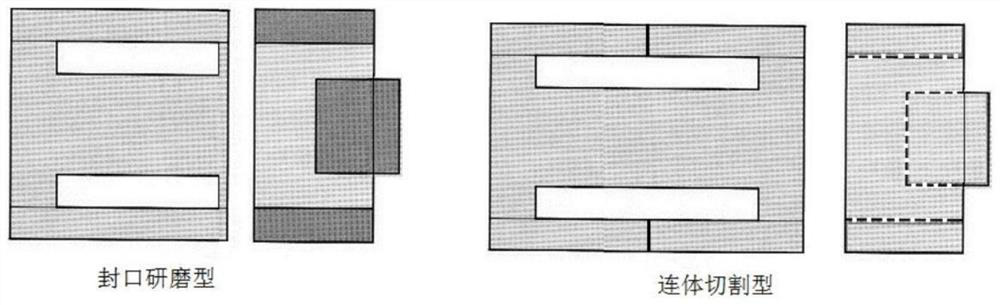

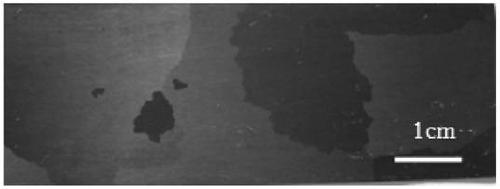

Manufacturing process of special-shaped ferrite magnetic core

PendingCN114005669AHigh dimensional accuracyOvercome the phenomenon that easily leads to product deformationMagnetic core manufactureManufacturing technologyPunching

The invention belongs to the technical field of ferrite, and particularly relates to a manufacturing process of a special-shaped ferrite core. The manufacturing process comprises the steps of (1) conducting punch forming, specifically, selecting soft magnetic ferrite particle powder, and preparing a sealed blank or a connected blank designed by the process on a vertical forming machine or a high-speed rotary forming machine by adopting a mold in a bidirectional punching manner; (2) sintering; (3) cutting and grinding; (4) carrying out ultrasonic cleaning; and (5) inspecting. According to the process, the phenomenon that a conventional preparation method for preparing the special-shaped magnetic core element is prone to causing product deformation can be overcome, the thinking frame that the special-shaped magnetic core element can only be formed in a vertical pressing mode but cannot be formed in a side pressing mode is broken through, and the process is achieved through a density compensation method. The manufacturing process is easy to operate, convenient to process and easy to industrialize, the special-shaped magnetic core element with high dimensional precision can be manufactured, the percent of pass is greatly increased, the cost is saved, and the manufacturing process has high industrial utilization value and is worthy of popularization and application.

Owner:江西尚朋电子科技有限公司

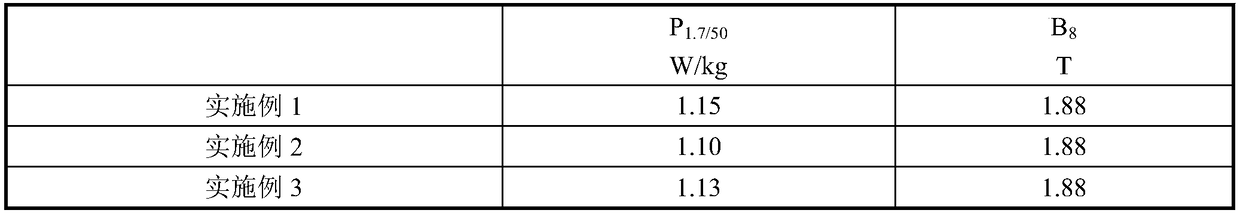

A kind of grain-oriented silicon steel and its preparation method

Owner:MAANSHAN IRON & STEEL CO LTD

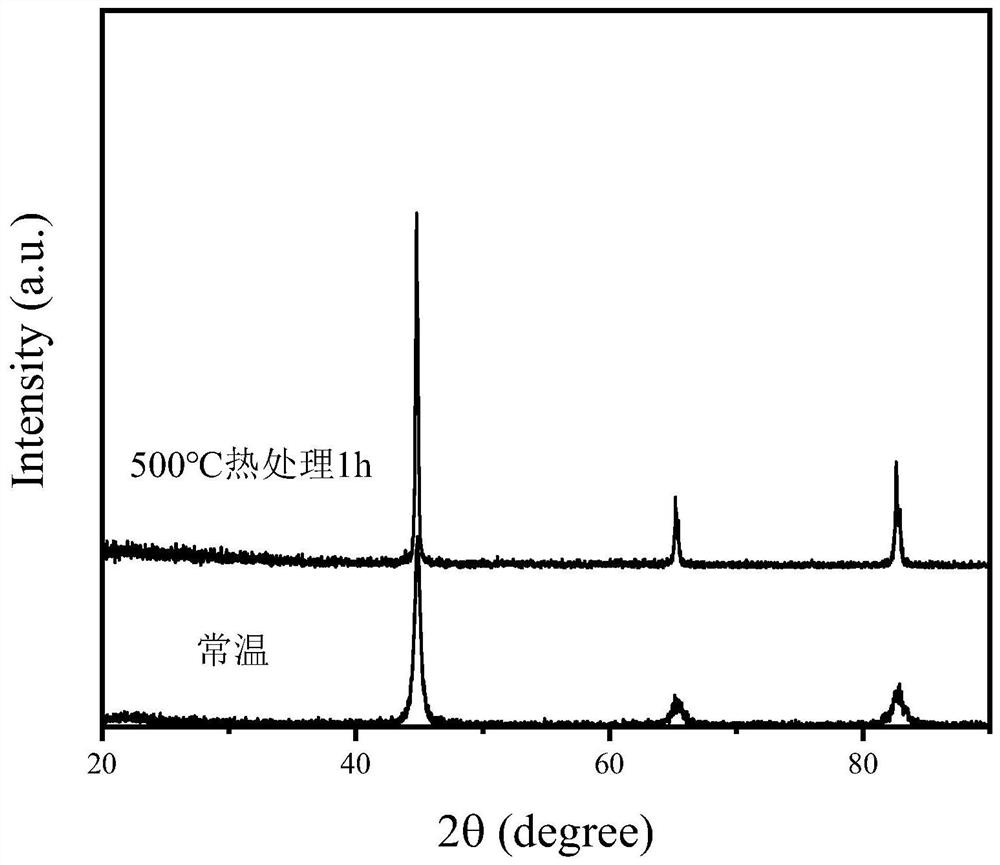

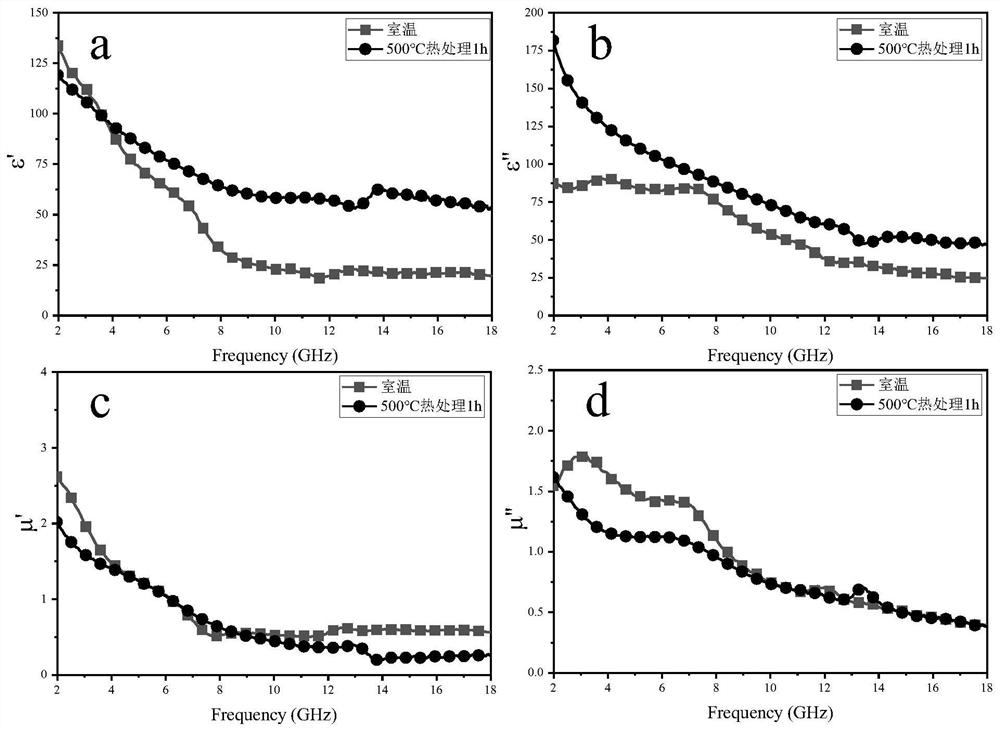

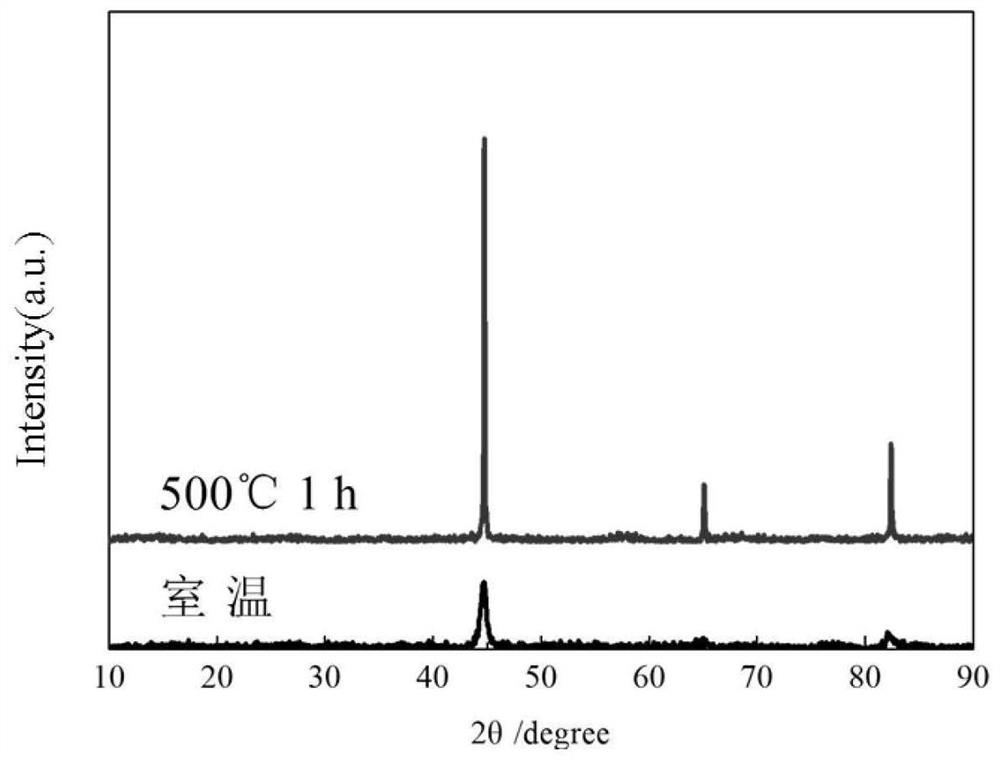

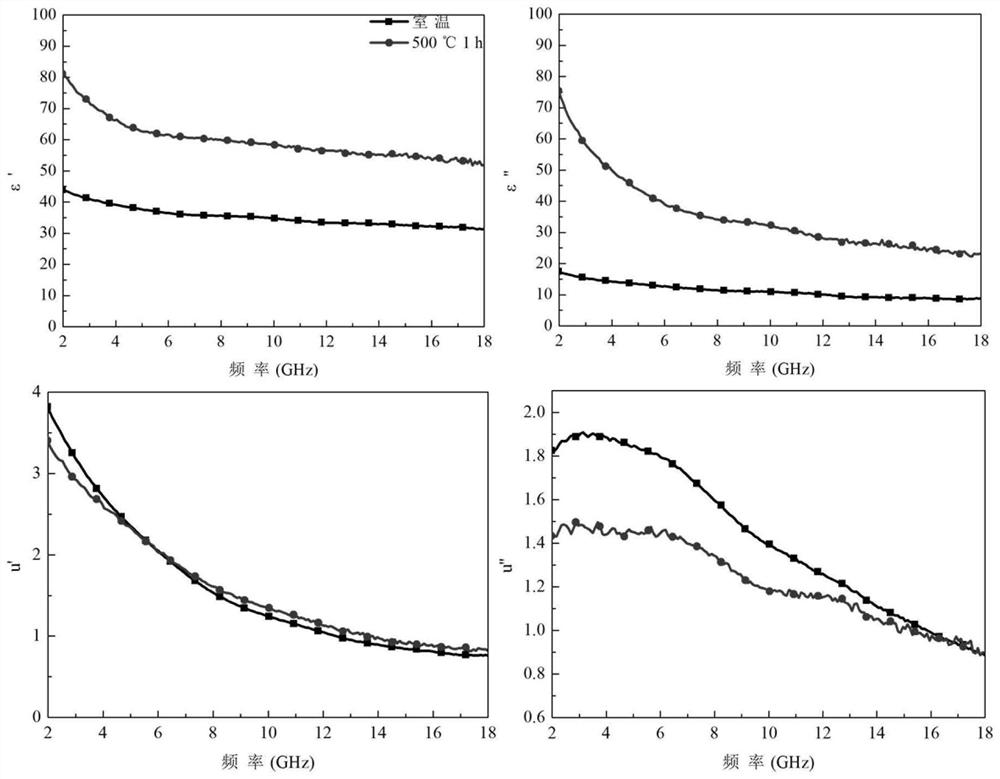

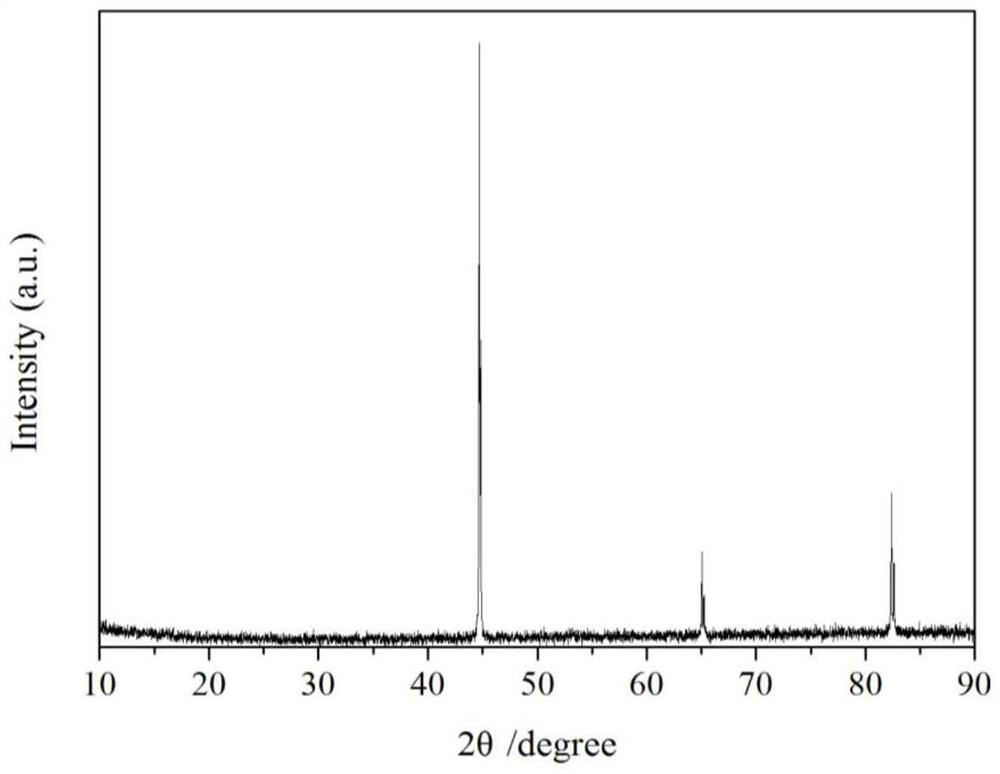

Iron-cobalt/silicon-barium composite alloy particle temperature-resistant magnetic wave-absorbing agent and preparation method thereof

The invention relates to an iron-cobalt / silicon-barium composite alloy particle temperature-resistant magnetic wave-absorbing agent and a preparation method thereof. The temperature-resistant magnetic wave-absorbing agent comprises FeCo nanocrystals, Si and Ba, wherein the Si and the Ba are distributed at crystal lattices and crystal boundaries of the FeCo nanocrystals. The preparation method comprises the following steps: 1) mixing SiBa alloy particles and FeCo alloy particles, carrying out ball milling under an anaerobic condition, and then separating powder; and 2) stirring and grinding the powder obtained in the step 1), separating the powder, and drying to obtain the iron-cobalt / silicon-barium composite alloy particle temperature-resistant magnetic wave-absorbing agent. According to the wave-absorbing agent, after heat treatment at the temperature of 500 DEG C, the grain size increase is small, meanwhile, the imaginary part peak value of the complex permeability at the frequency of 2-18 GHz is greatly increased, and the wave-absorbing agent has sound grain size and complex permeability high-temperature stability and is low in raw material price, simple in preparation method and easy to popularize.

Owner:WUHAN UNIV OF TECH

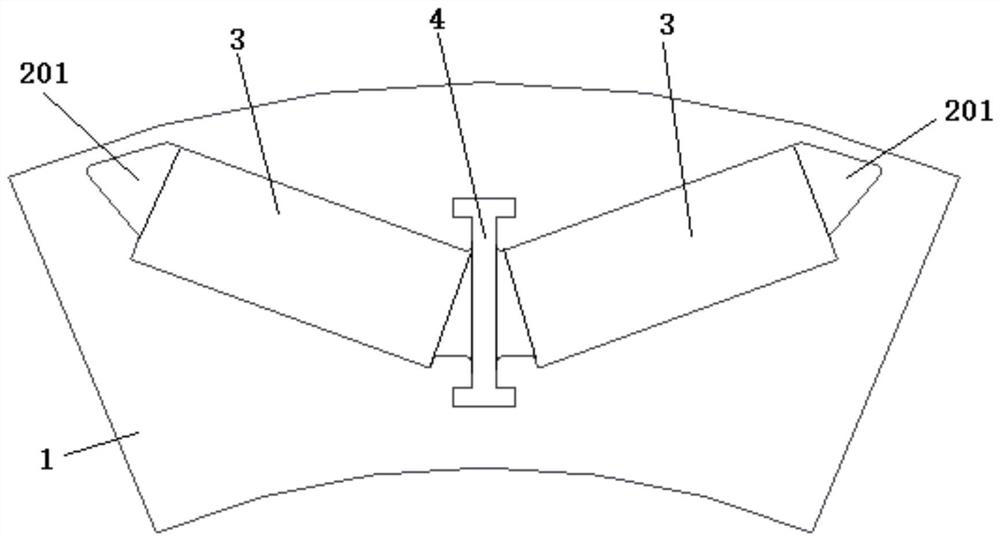

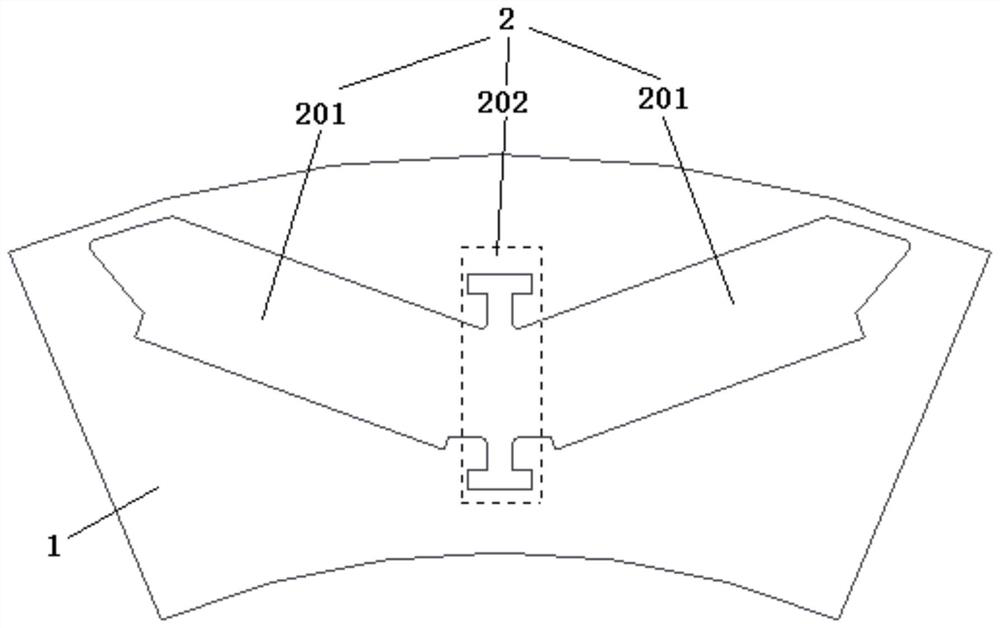

Motor rotor and built-in rotor permanent magnet motor

InactiveCN112713681AImprove structural strengthGuaranteed electromagnetic performanceMagnetic circuit rotating partsElectric machineryStructural engineering

The invention provides a motor rotor and a built-in rotor permanent magnet motor. The motor rotor comprises a rotor body; the rotor body is provided with a plurality of mounting groove units, and the plurality of mounting groove units are uniformly distributed along the circumferential direction of the rotor body; the mounting groove unit comprises a permanent magnet mounting groove in which a permanent magnet is mounted and a magnetic isolation bridge mounting groove in which a magnetic isolation bridge single body is mounted; the number of the permanent magnet mounting grooves is at least two, and one magnetic isolation bridge mounting groove is formed between any two adjacent permanent magnet mounting grooves. The design of integrally forming and manufacturing the magnetic isolation bridge in the prior art is improved, the magnetic isolation bridge single bodies are mounted through the magnetic isolation bridge mounting grooves in the rotor body to form a magnetic isolation bridge structure, and meanwhile, by reasonably selecting the materials of the magnetic isolation bridge single bodies, the structural strength of the magnetic isolation bridge can be improved, and meanwhile, the electromagnetic performance is effectively ensured.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

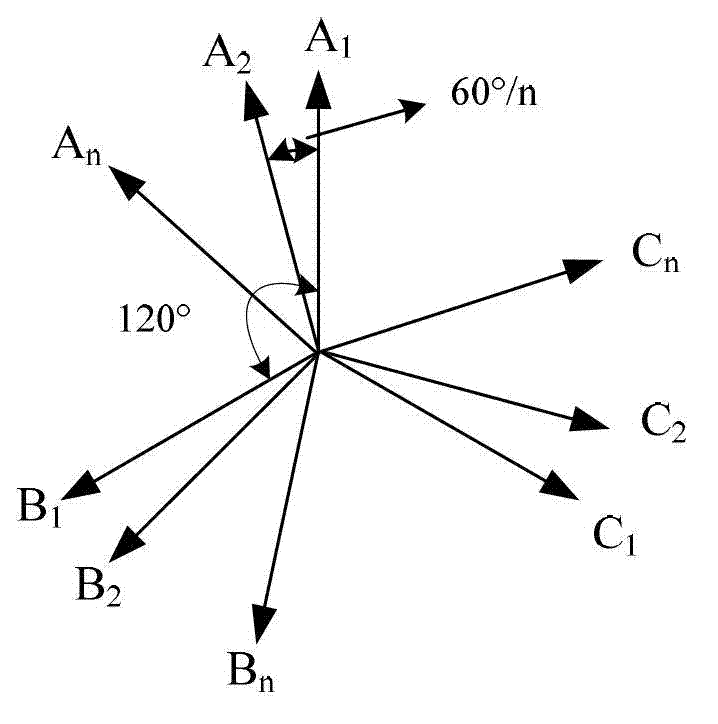

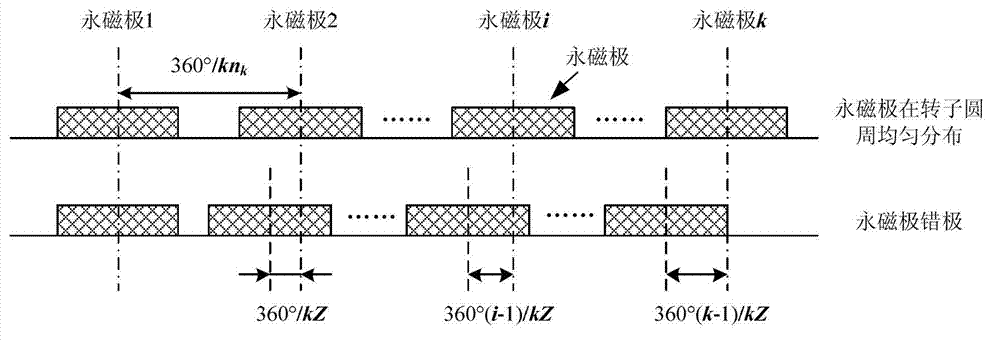

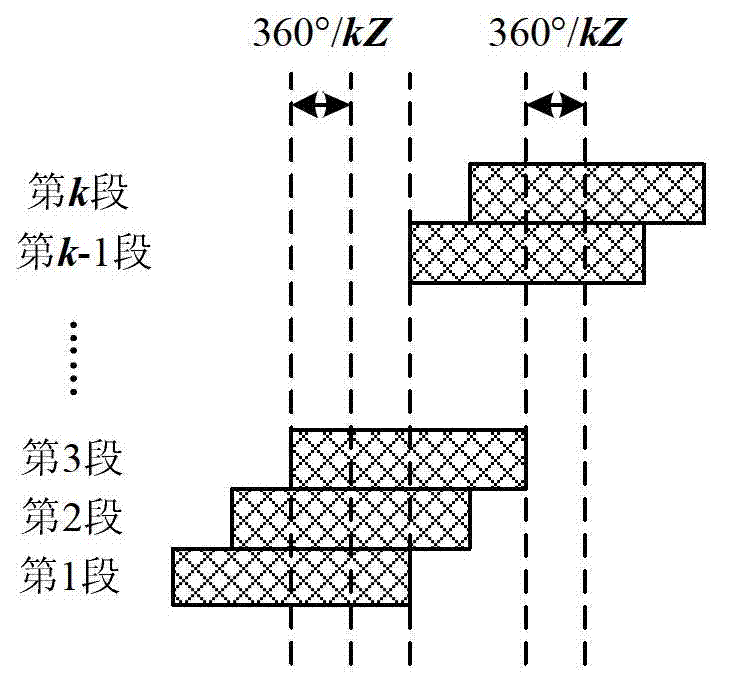

High-capacity low-speed permanent-magnet wind-driven generator

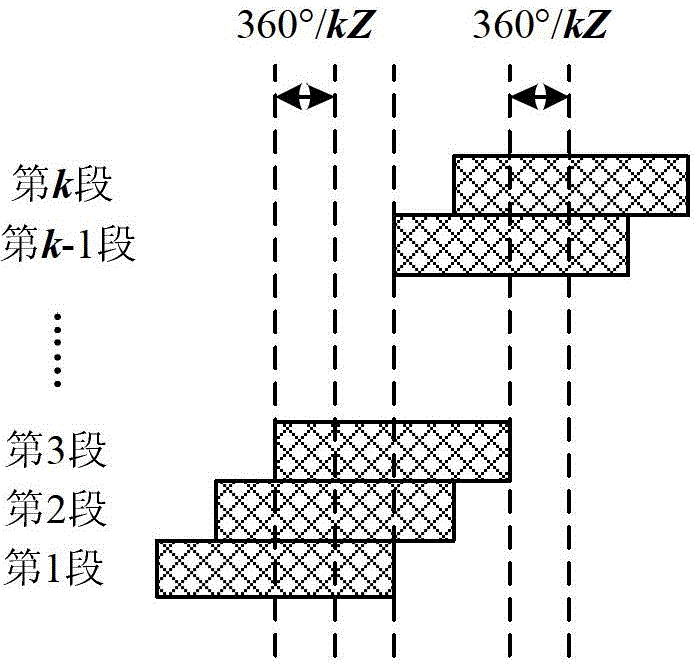

ActiveCN102868246BGuaranteed electromagnetic performanceGuarantee the complexity of the manufacturing processMagnetic circuit rotating partsWindings conductor shape/form/constructionWind drivenLow speed

The invention relates to a high-capacity low-speed permanent-magnet wind-driven generator. According to the generator, multiple three-phase windings are used and integer slots are centralized to improve the coefficient of the windings and the utilization ratio of an iron core; the number of in-series turns per phase of the armature winding is increased to reduce the axial length of the iron core of a motor; and a permanent-magnet pole is dislocated or skewed to reduce tooth harmonic and pulsating torque. On the premise of ensuring that the electromagnetic performance of the generator and the complexity of the motor manufacturing process meet the requirements, the invention realizes material saving of the permanent magnet in the high-capacity low-speed permanent-magnet wind-driven generator, effectively reduces the cost of the motor, and provides directions for the popularization and application of the high-capacity low-speed permanent-magnet wind-driven generator.

Owner:WUHAN NEW ENERGY INST OF ACCESS EQUIP & TECH

Rust-resistant carbonyl iron powder wave-absorbing material and preparation method thereof

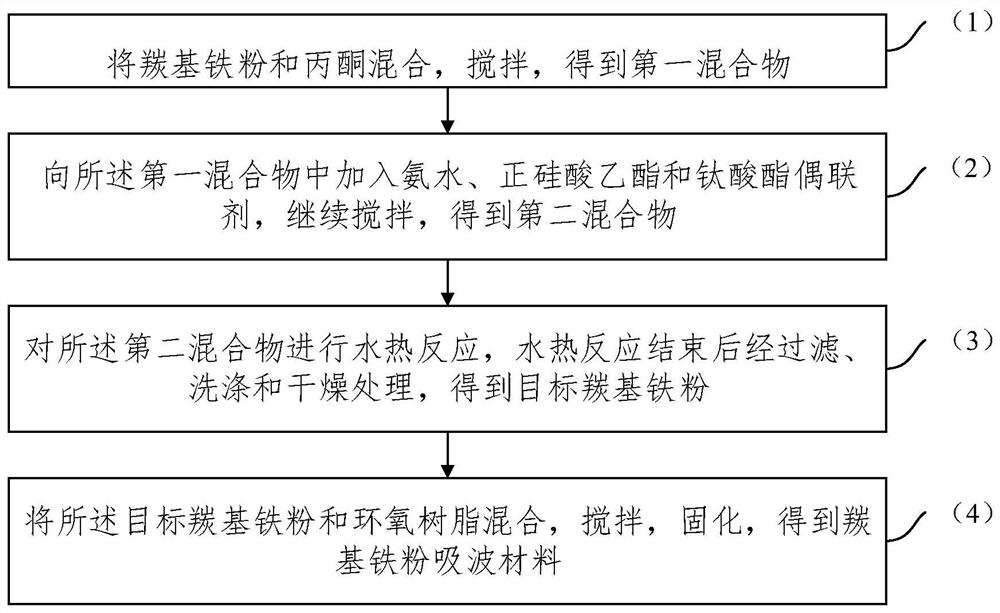

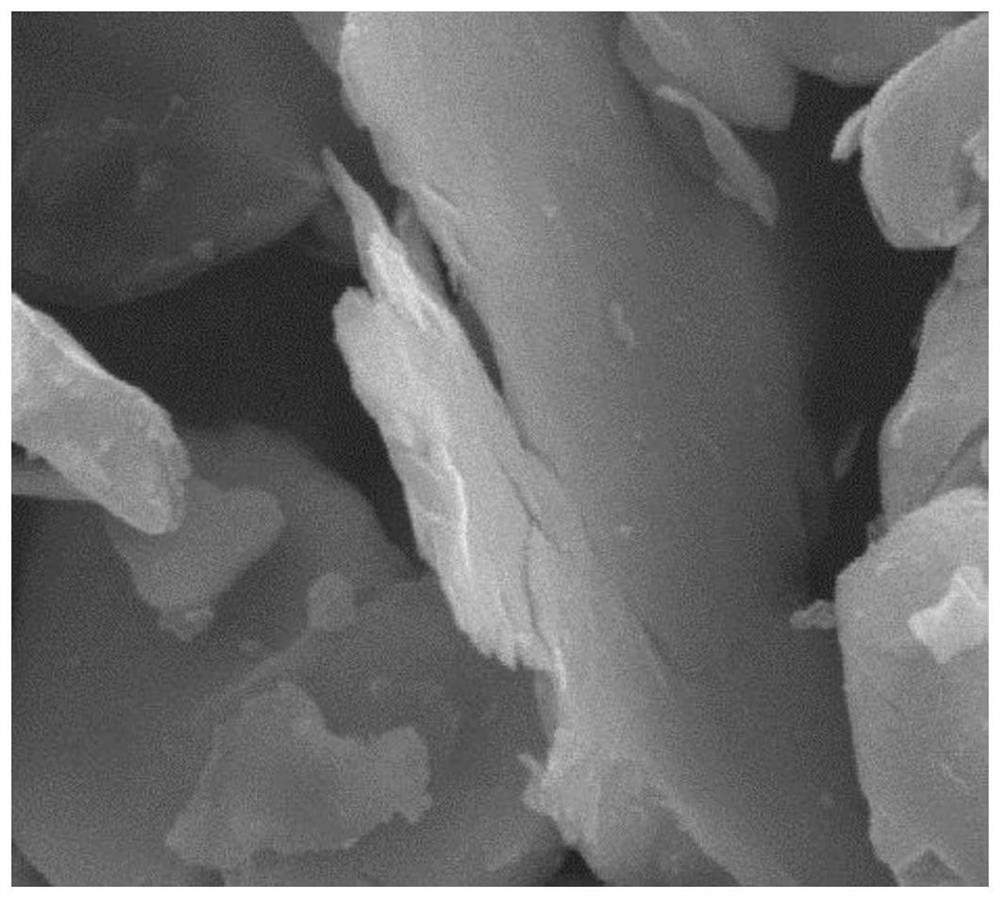

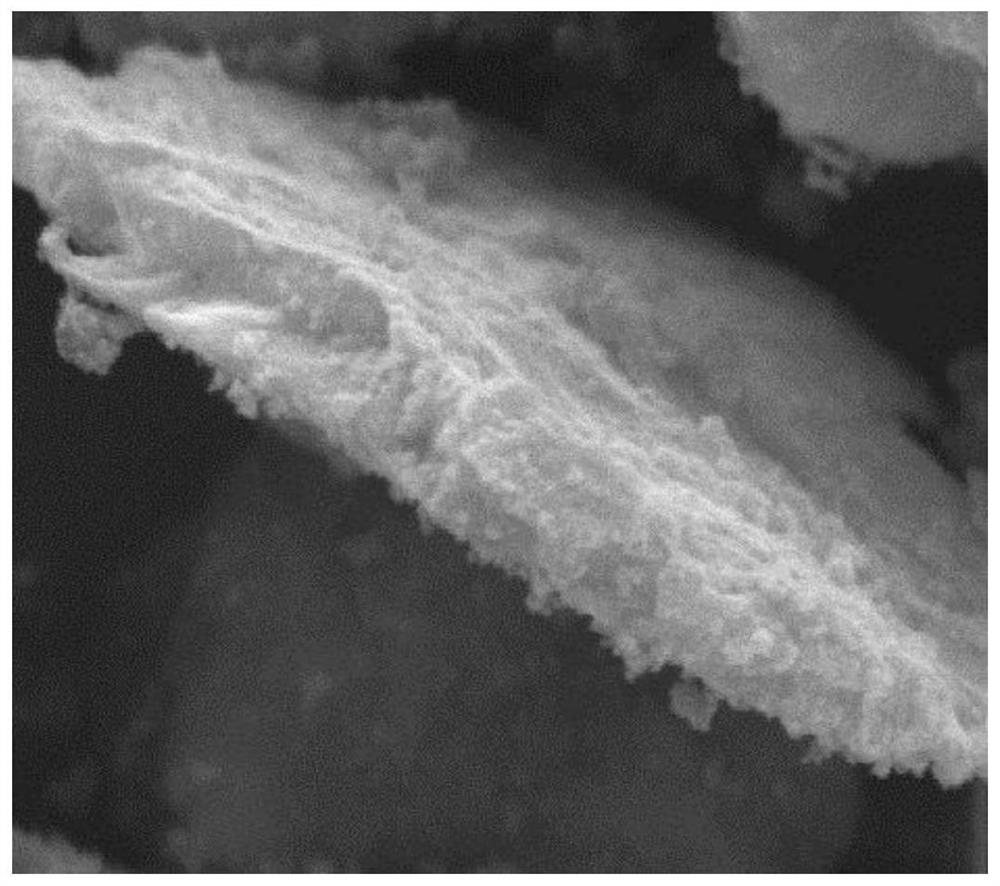

InactiveCN113388231AIsolated contactImprove corrosion resistanceMagnetic/electric field screeningAntennasEpoxySilicic acid

The invention provides a rust-resistant carbonyl iron powder wave-absorbing material and a preparation method thereof, and the method comprises the following steps: mixing carbonyl iron powder and acetone, and stirring to obtain a first mixture; adding ammonia water, tetraethoxysilane and a titanate coupling agent into the first mixture, and continuously stirring to obtain a second mixture; performing a hydrothermal reaction on the second mixture, and after the hydrothermal reaction is finished, performing filtering, washing and drying treatment to obtain target carbonyl iron powder; and mixing the target carbonyl iron powder with epoxy resin, stirring, and curing to obtain the carbonyl iron powder wave-absorbing material. According to the scheme, the rust-resistant carbonyl iron powder wave-absorbing material can be provided, the problem that a wave-absorbing material prepared from carbonyl iron powder is prone to rusting under complex working conditions such as military and civil fields is solved, and the rust resistance of the carbonyl iron powder wave-absorbing material is improved on the premise that the electromagnetic performance is guaranteed.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

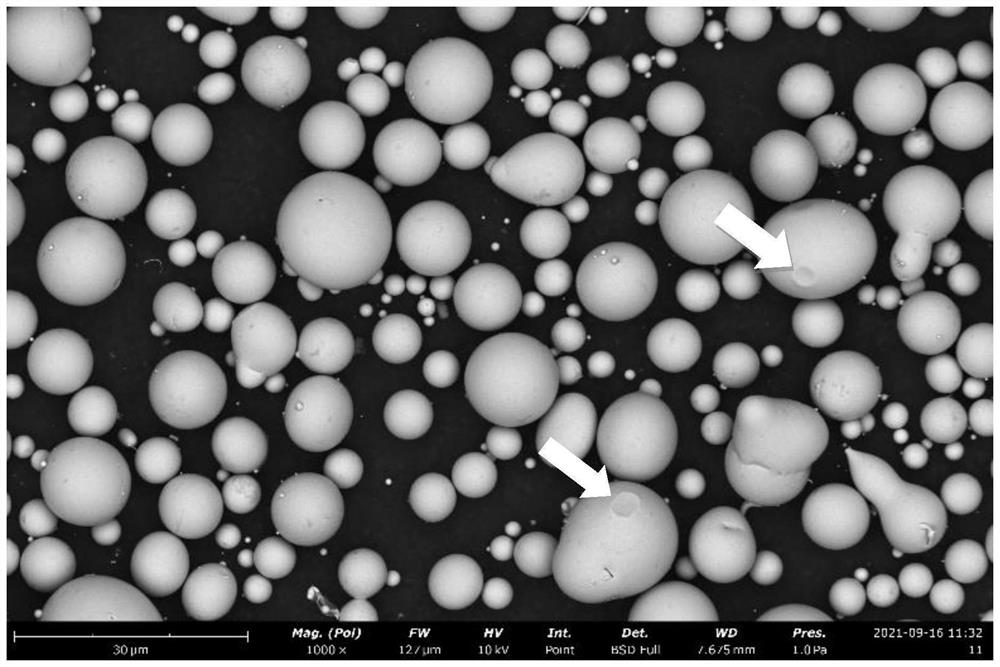

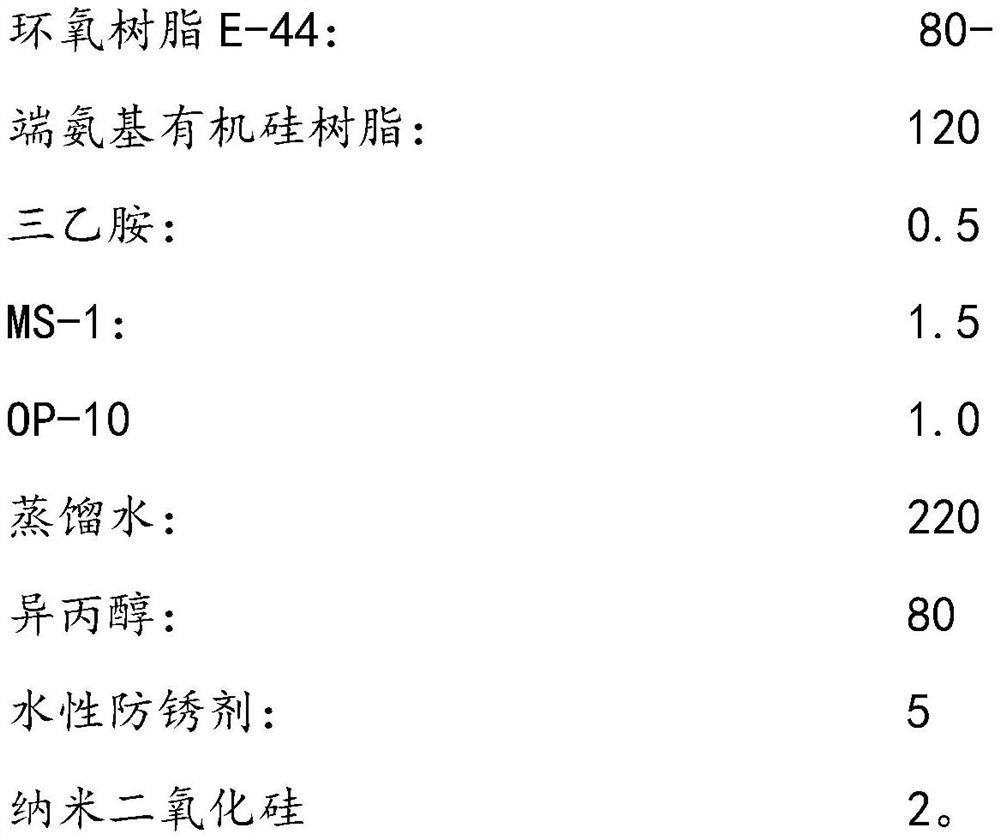

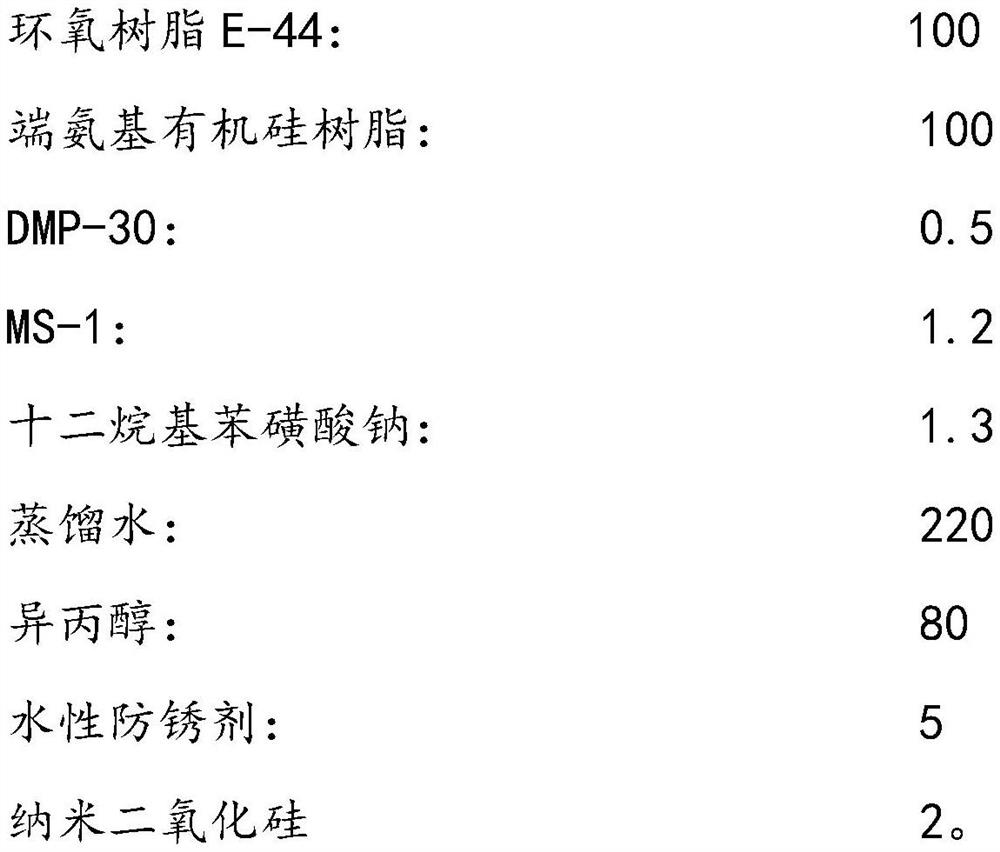

Atomized metal powder, insulating coating agent, magnetic powder core and preparation method of magnetic powder core

PendingCN114388214ASolve the problem of breakage and uneven coating of depressionsGuaranteed electromagnetic performanceTransformers/inductances detailsInductances/transformers/magnets manufactureEpoxyPhysical chemistry

The invention relates to the technical field of electromagnetism, in particular to atomized metal powder, an insulating coating agent, a magnetic powder core and a preparation method of the magnetic powder core. 0-5 pits exist on the particle surface of the atomized metal powder, an insulating coating layer is arranged on the particle surface of the atomized metal powder, and the coating layer is obtained by coating the atomized metal powder with an insulating coating agent; wherein the shape of each pit is similar to a hemisphere, the diameter of an opening is 0.2-10 microns, and the depth of the opening is 0.1-0.5 microns; the insulating coating agent includes: 200 parts by weight of a resin composition; wherein the resin composition is composed of epoxy resin and organic silicon resin, and the weight ratio of the epoxy resin to the organic silicon resin is (2: 3)-(3: 2); 2-3 parts by weight of an emulsifier; 200 to 240 parts by weight of water; 70-90 parts by weight of a cosolvent; and 1-3 parts by weight of nano silicon dioxide.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

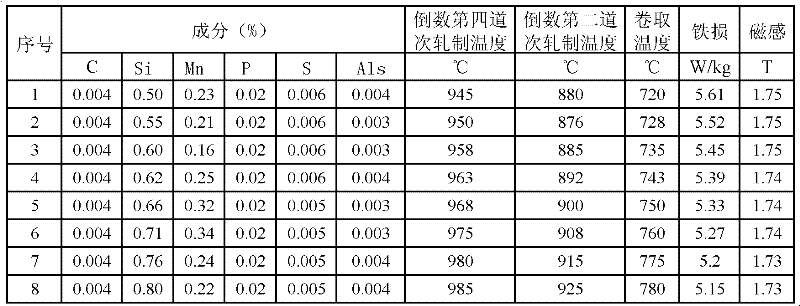

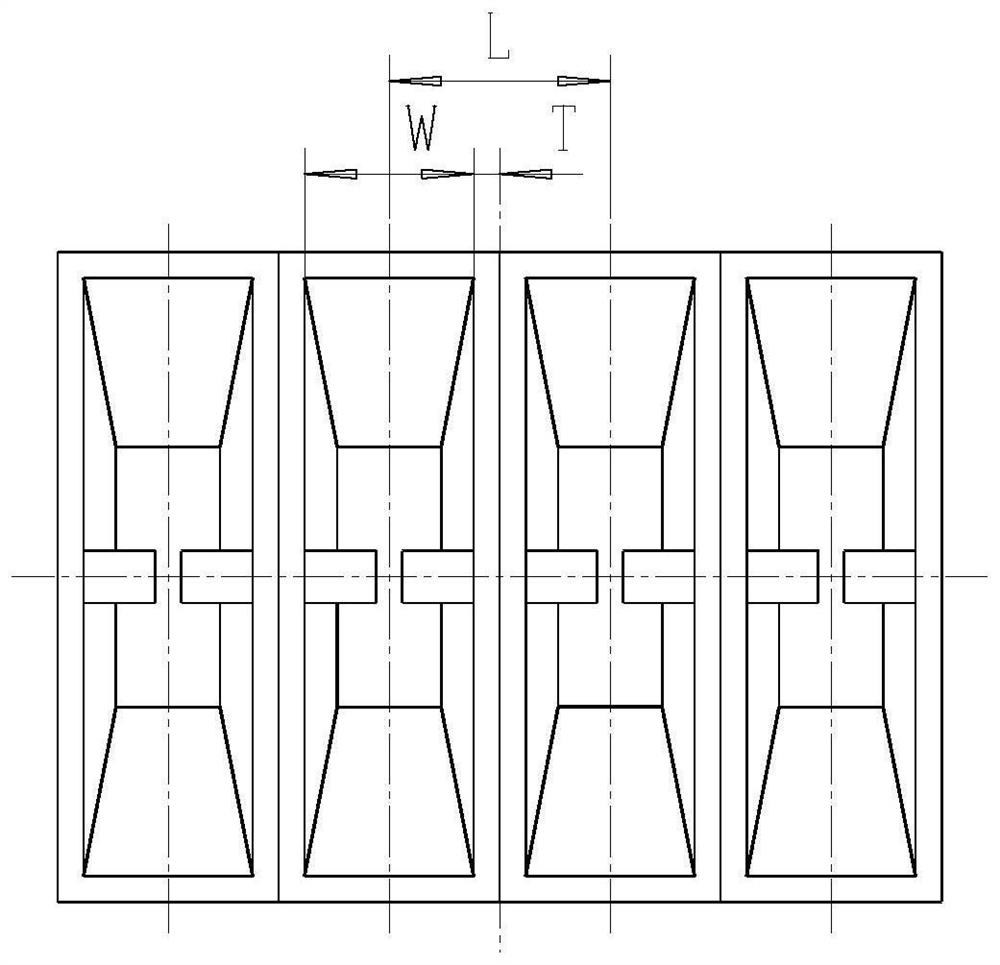

Hot rolling method of cold-rolled low-carbon low-silicon non-oriented electrical steel

InactiveCN101664758BGuaranteed rolling deformationEasy to produceTemperature control deviceMetal rolling arrangementsLower limitElectrical steel

The invention relates to a manufacturing method of cold-rolled non-oriented electrical steel, in particular to a hot rolling method of cold-rolled low-carbon low-silicon non-oriented electrical steel, which comprises the steps of finish rolling and reeling after finish rolling; the plate blank is rolled for at least three passes at the finish rolling process; the upper limit of the temperature ranges of two phase areas of austenite and ferrite of the plate blank is lower than 945 DEG C, and the lower limit thereof is higher than 925 DEG C; the rolling temperature of the first pass in the three continuous passes of the finish rolling of the plate blank is higher than 945 DEG C, the second pass does not conduct rolling, the rolling temperature of the third pass is lower than 925 DEG C, and the plate blank is cooled forcibly between the first and the third passes in the three continuous passes. The hot rolling method leads a common finishing mill group to be applicable for the productionof the cold-rolled low-carbon low-silicon non-oriented electrical steel, simplifies the control method, reduces the production cost, and is beneficial to the production and promotion of the cold-rolled low-carbon low-silicon non-oriented electrical steel.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

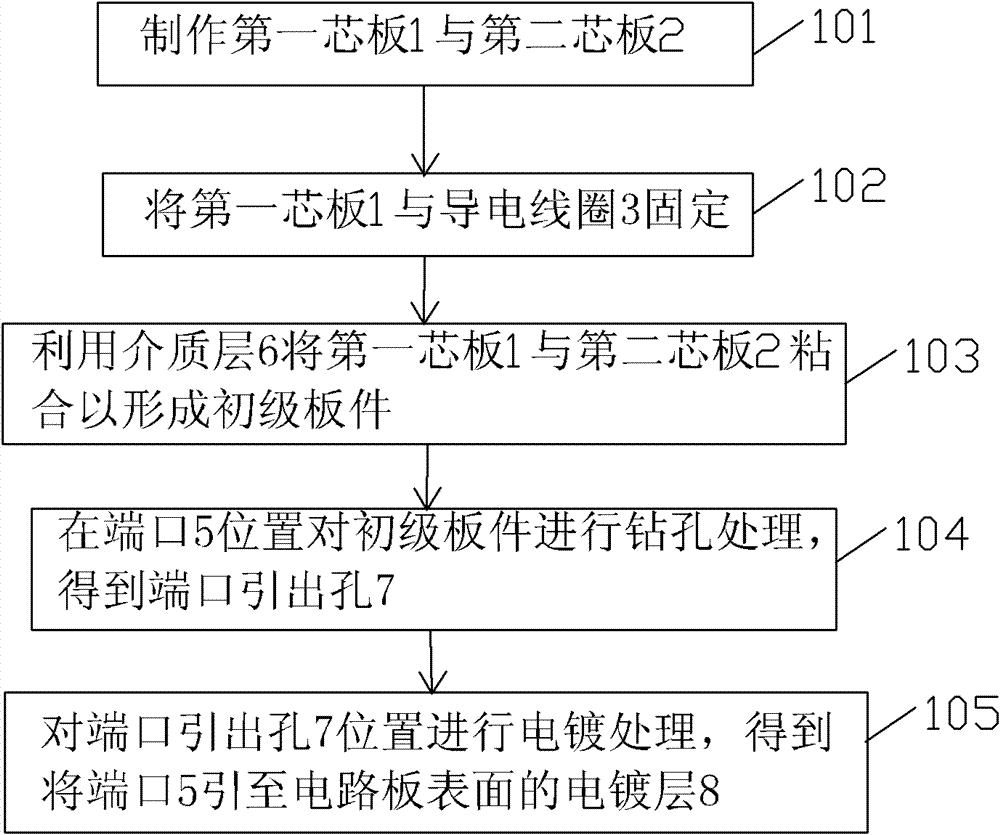

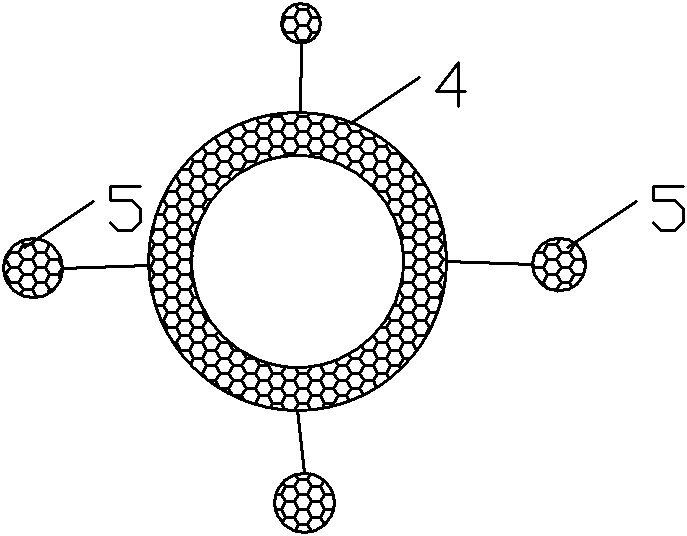

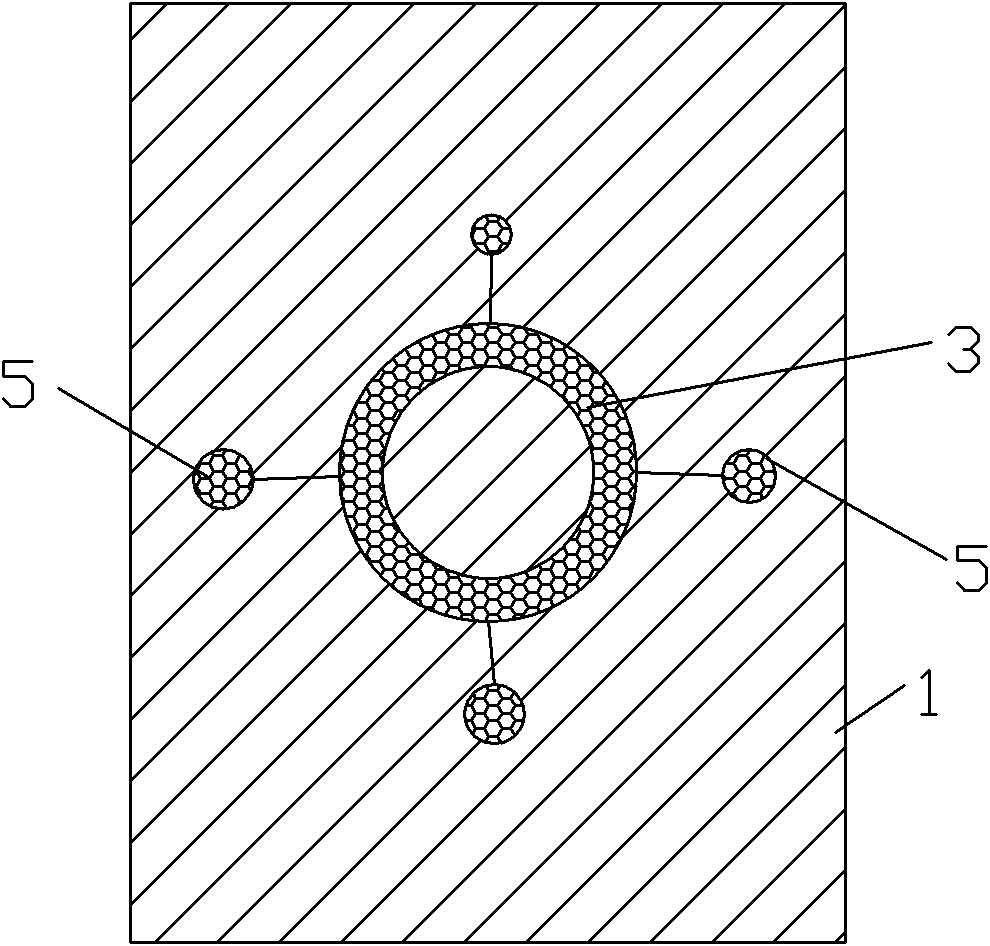

Circuit board and processing method thereof

ActiveCN102186311BGuaranteed electromagnetic performancePrinted circuit assemblingPrinted circuit non-printed electric components associationPower flowEngineering

The embodiment of the invention relates to a circuit board processing method, comprising the following steps of: fixing a conductive coil on a first core board, arranging the conductive coil between the first core board and a second core board, and for leading the ports of the conductive coil out of the surface of the circuit board, drilling at the position of the ports, and electroplating at thepositions of port leading-out holes to obtain an electroplated layer for leading the ports out of the surface. The embodiment of the invention also provides a corresponding circuit board. Thus, the conductive coil is embedded in the circuit board and is not exposed on the surface of the circuit board, no loss is produced when current is introduced as the conductive coil is not exposed in the air,the electromagnetic properties of PCB (Printed Circuit Board) products are guaranteed, and especially the invention can be widely applied in the power supply industry with high requirement for current density.

Owner:SHENNAN CIRCUITS

Long-stator linear machine electromagnetic performance off-line testing device

InactiveCN1238730CGuaranteed electromagnetic performanceFulfil requirementsForce measurementMagnetic property measurementsPull forceTransformer

Owner:TONGJI UNIV +2

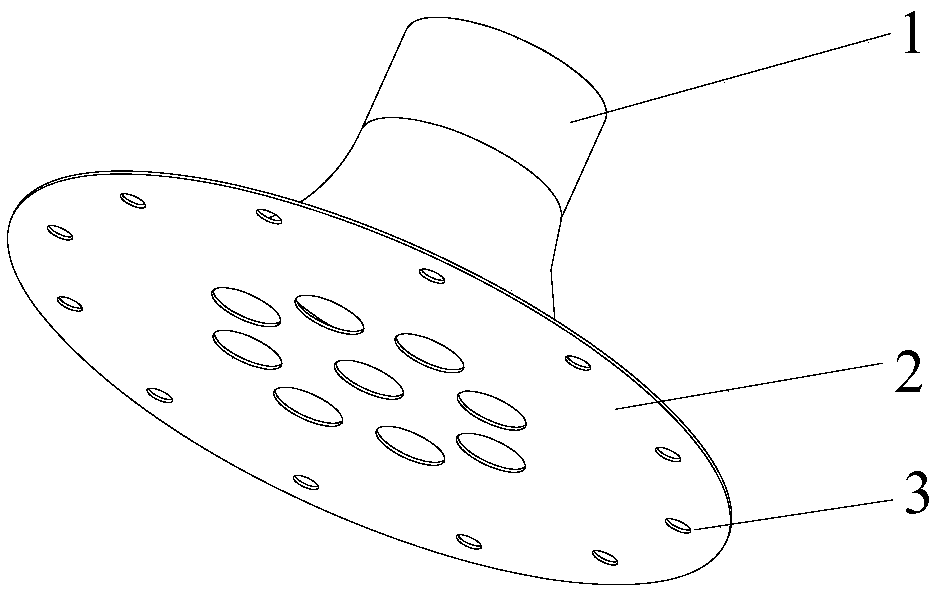

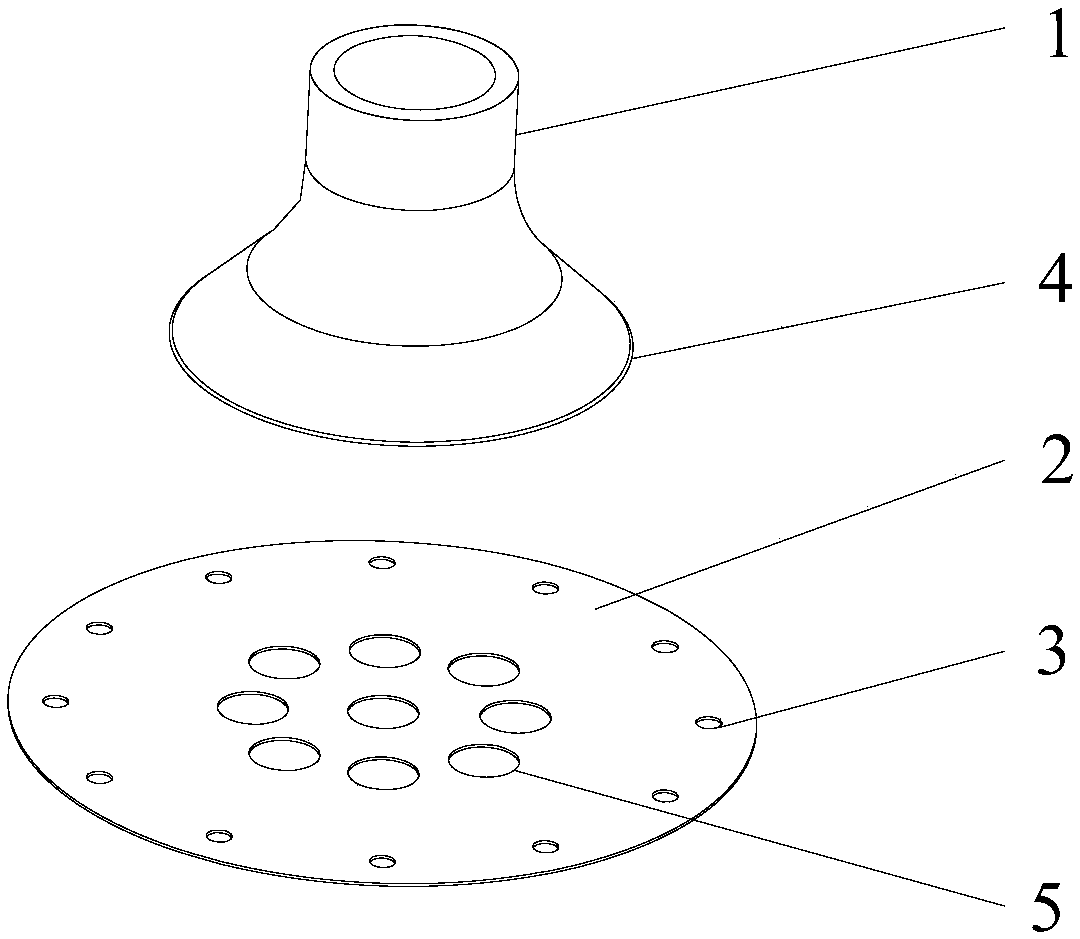

Exhaust device

InactiveCN108860630AGuaranteed electromagnetic performanceReduced ventilation resistanceFuel tank safety measuresStraight tubeFuel tank

The invention discloses an exhaust device. The exhaust device includes multiple diffuser tubes and a mounting plate, each diffuser tube is composed of a straight tube segment and a horn opening, eachstraight tube segment is connected with a fuel tank venting pipe, each horn opening is fixedly connected to the mounting plate, and multiple vent holes communicated with the diffuser tubes are formedin the mounting plate. The diameter of each vent hole is smaller than 5 mm. The exhaust device fits the surface skin of an airplane to achieve connection with the fuel tank venting pipe, and the circulation area of the combined vent holes is far more greater than the sectional area of the fuel tank venting pipe, low resistance of gas circulation is ensured, the problem that the venting functionaldesign of existing fuel tanks needs vent holes to stretch out of the surface skin of airplanes is solved, and meanwhile the electromagnetic performance requirements for the vent holes can be guaranteed.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Hot rolling method of cold-rolling low-carbon non-oriented electrical steel

The invention relates to a manufacture method of cold-rolling non-oriented electrical steel, in particular to a hot rolling method of cold-rolling low-carbon non-oriented electrical steel, comprising a finishing step and a coiling step after the finishing step. At least two passes of rolling are carried out on a plate blank in the finishing step; two phase regions of the austenite and the ferriteof a plate blank have a temperature range with an upper limit lower than 900 DEG C and a lower limit higher than 850 DEG C; and the plate blank is forcefully cooled between two adjacent passes in thefinishing step and has a rolling temperature higher than 900 DEG C in the prior pass and a rolling temperature lower than 850 DEG C in the later pass. The hot rolling method enables a common finishing mill group to be suitable for the production of the cold-rolling low-carbon non-oriented electrical steel, simplifies the control method, decreases the production cost and is beneficial to the production and the popularization of the cold-rolling low-carbon non-oriented electrical steel.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Millimeter wave frequency band rectangular horn antenna substructure and N-element antenna array

ActiveCN113904128AGuaranteed wall thicknessReduce manufacturing difficultyWaveguide hornsWaveguide mouthsEngineeringHorn antenna

The invention provides a millimeter wave frequency band rectangular horn antenna substructure and an N-element antenna array. The substructure comprises a main body structure, the bottom end of the main body structure is V-shaped, the two sides of the main body structure are respectively a ridge cover side and a ridge box side, the ridge cover side is provided with a straight waveguide section and a rear cover plate, the rear cover plate is installed on any side of the V-shaped main body structure, the straight waveguide section extends to the rear cover plate from the side top end of the ridge cover, a blind hole is formed in the tail end of the straight waveguide section located at the rear cover plate, a through hole is formed in the rear cover plate, and the through hole corresponds to the blind hole in position; the ridge box side comprises a groove and a straight waveguide section arranged in the groove, and the straight waveguide section of the ridge box side extends from the top end of the ridge box side to the side, without the rear cover plate, of the V shape at the bottom end of the main body structure. According to the scheme, the wall thickness of the horn mouth part is kept to the maximum extent, the manufacturing difficulty of the horn mouth part is effectively reduced, the horn mouth part is particularly suitable for structural design and manufacturing of a small-size and high-precision rectangular horn antenna array of a millimeter wave frequency band, and arraying of any number of unit antennas can be achieved.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

A kind of low-temperature rapid sintering soft ferrite and its preparation method

ActiveCN107200571BGuaranteed initial permeabilityReduce manufacturing costInorganic material magnetismInductances/transformers/magnets manufactureAir atmospherePolyvinyl alcohol

The invention discloses low-temperature rapidly sintered soft magnetic ferrite and a preparation method thereof. The preparation method comprises the following steps: S1, weighing the following components in parts by mole: 60-80 parts of ferric oxide, 40-60 parts of zinc oxide, 30-50 parts of copper oxide and 15-20 parts of manganese carbonate, and performing mixing ball-milling till the average particle size is 5-30 [mu]m so as to obtain mixed powder; S2, pre-sintering the mixed powder at 900-1000 DEG C so as to obtain a pre-sintered material; S3, weighing yttrium oxide, aluminum oxide and lithium carbonate as doping materials; S4, adding the doping materials weighed in the step S3 into the pre-sintered material, performing secondary ball-milling for 6-8 hours, drying, adding polyvinyl alcohol, and performing pelletizing so as to obtain a granular material; S5, heating the granular material to sintering temperature in the presence of an air atmosphere, and performing warm-keeping sintering, thereby obtaining the low-temperature rapidly sintered soft magnetic ferrite, wherein the sintering temperature meets the equation that T=1454 / [1g(X+2Y+Z)+t]. Due to mutual cooperation of the main material and the doping materials, a preparation process is optimized, the sintering temperature is reduced, and meanwhile the electromagnetic properties of the ferrite are ensured.

Owner:ZHONGDE ELECTRONICS

Hot rolling method of cold-rolling low-carbon non-oriented electrical steel

The invention relates to a manufacture method of cold-rolling non-oriented electrical steel, in particular to a hot rolling method of cold-rolling low-carbon non-oriented electrical steel, comprising a finishing step and a coiling step after the finishing step. At least three passes of rolling are carried out on a plate blank in the finishing step; two phase regions of the austenite and the ferrite of a plate blank have a temperature range with an upper limit lower than 900 DEG C and a lower limit higher than 850 DEG C; and the plate blank has a rolling temperature higher than 900 DEG C in the first pass, no temperature in the second pass and a rolling temperature lower than 850 DEG C in the third pass of the three continuous passes in the finishing step and is forcefully cooled between the first pass and the third pass of the three continuous passes. The hot rolling method enables a common finishing mill group to be suitable for the production of the cold-rolling low-carbon non-oriented electrical steel, simplifies the control method, decreases the production cost and is beneficial to the production and the popularization of the cold-rolling low-carbon non-oriented electrical steel.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

A kind of fe/zrh2 nanocrystalline composite particle and its preparation method and application

ActiveCN110270683BGrowth retardationPinned grain boundariesMaterial nanotechnologyTransportation and packagingIron powderBall mill

The invention discloses a Fe / ZrH 2 Nanocrystalline composite particles, which are composed of carbonyl iron powder and ZrH 2 Particles are the main raw material, which is easily prepared by ball milling + stirring milling. The present invention works by combining ZrH 2 The stabilization of particles on the microscopic grain boundaries of carbonyl iron powder, the control technology of Zr element content and the control technology of Zr distribution, to obtain Fe / ZrH with temperature resistance 2 composite particles; the Fe / ZrH 2 After heat treatment at 500 °C for 1 h, the grain size of the composite particles is within 20 nm, the electromagnetic parameters of 2-18 GHz do not change significantly, and the composite particles have good temperature resistance.

Owner:武汉双虎涂料股份有限公司

Orthogonal dual-polarized metal slot antenna array structure and antenna array containing the structure

ActiveCN109904587BGuaranteed accuracyGuaranteed electromagnetic performanceAntenna supports/mountingsRadiating elements structural formsEngineeringRadiating element

The invention discloses an orthogonal dual-polarized metal slot antenna array structure and an antenna array containing the structure, and solves the problem in the prior art that high-temperature welding formation is adopted to cause poor antenna precision, resulting in reducing the yield, limiting by the welded aluminum alloy material and reducing the mechanical strength of the antenna, or the assembly formation of spare parts is adopted, resulting in increasing the weight of the antenna, reducing the mechanical strength of the antenna and increasing the number of structural parts that are independent of electromagnetic properties, so as to narrow the scope of application. The antenna array structure comprises an antenna bottom plate, and a sub-structure unit mounted on the antenna bottom plate and interposed by horizontal radiating unit pieces and vertical radiating element pieces. The antenna array includes an antenna array structure. The antenna array structure and the antenna array have the advantages of simple structure, scientific and reasonable design and convenient use, and can effectively ensure the accuracy of the antenna to improve the production yield, effectively improve the mechanical structure strength, reduce the weight of the antenna, and ensure the electromagnetic performance of the antenna array to expand the applicable range.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com