Technological mandrel and method for manufacturing squirrel-cage rotor by using same

A process and squirrel cage technology, applied in the field of process mandrels, can solve the problems of low surface flatness of the shaft hole, reduction of the cohesion area, and decreased reliability of the combination of the rotor core and the shaft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

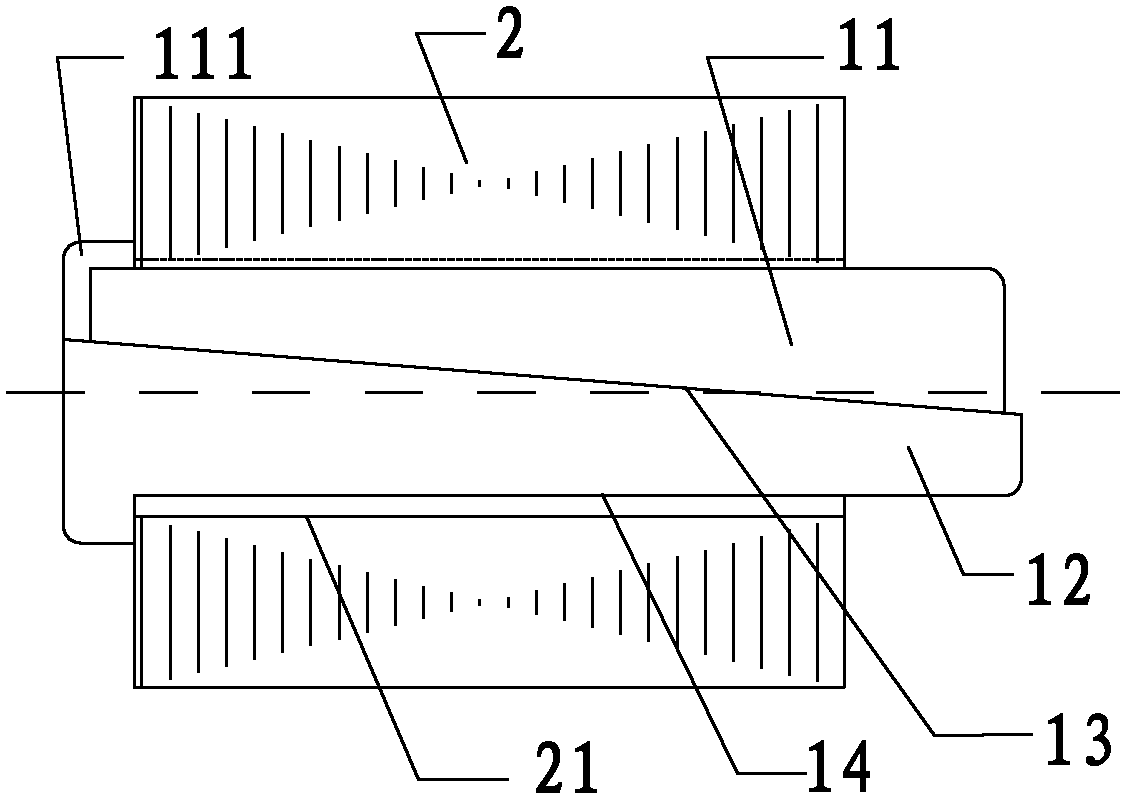

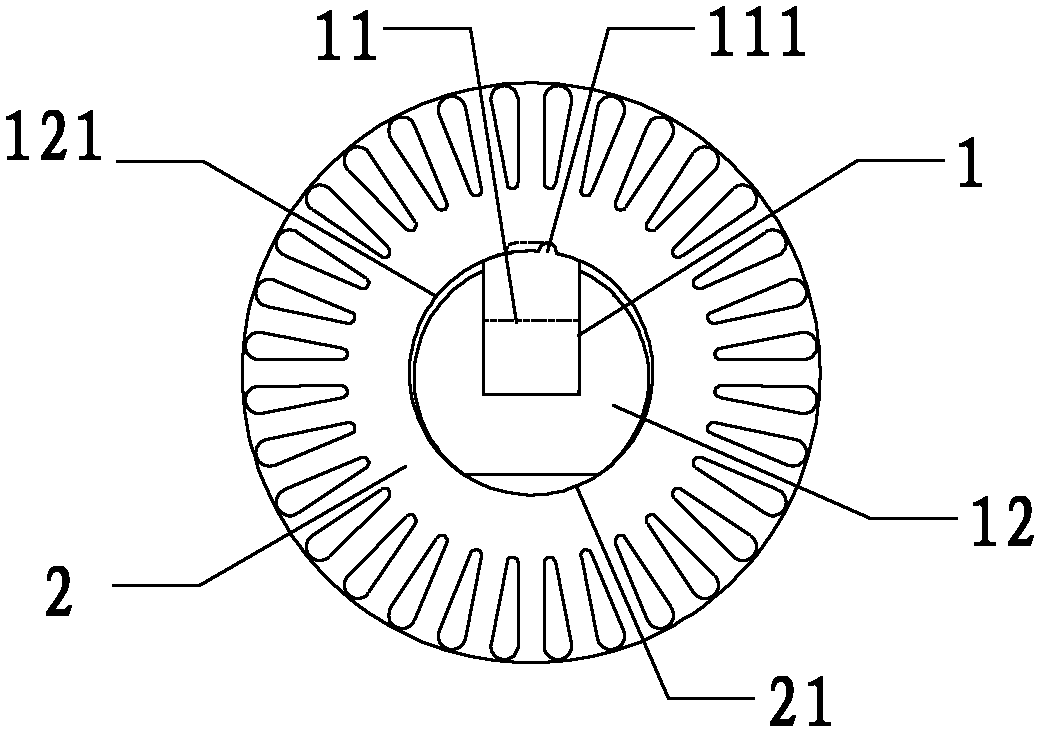

[0021] see figure 1 and figure 2 In order to better understand the technical solution of the present invention, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

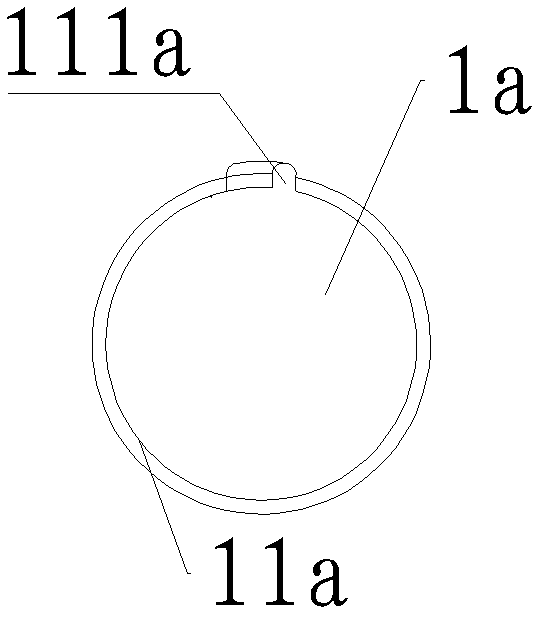

[0022] see figure 1 and figure 2 , the process mandrel 1 includes a "sub-mandrel" part 11 with a convex key part 111 and a "mother mandrel" part 12 with a smooth cylindrical surface, and the "sub-mandrel" part 11 and the "mother mandrel" The parts 12 are fitted together by grooves with wedge-shaped slopes 13 to form self-locking; the wedge-shaped slopes 13 are parallel to the axial direction of the process mandrel 1 .

[0023] In a preferred solution, the groove inclination angle of the wedge-shaped slope 13 between the "sub-spindle" part 11 and the "master mandrel" part 12 is about 10 degrees. The process mandrel is made of quenched and tempered structural steel.

[0024] The using method of described process mandrel is:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com