A kind of grain-oriented silicon steel and its preparation method

A technology of grain-oriented silicon steel and steel coil, applied in the field of grain-oriented silicon steel and its preparation, can solve the problem of lack of mass production, and achieve the effect of ensuring electromagnetic performance and improving suppression ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

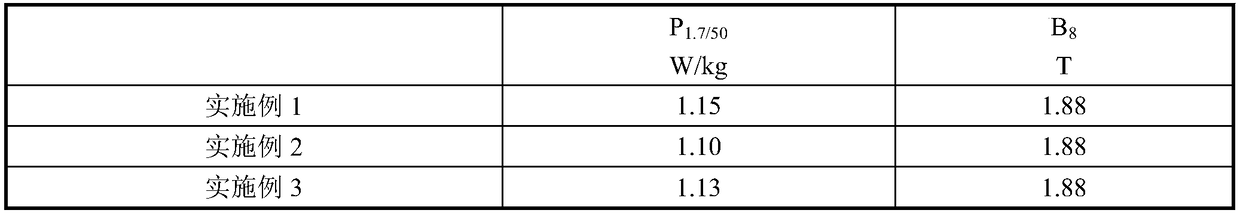

Examples

Embodiment 1

[0037] The preparation process steps of grain-oriented silicon steel are as follows:

[0038] 1) Continuous casting of molten iron pretreatment, converter steelmaking, and vacuum treatment into 230mm billets;

[0039] 2) Heating the billet to 1250°C for 280 minutes in the furnace, of which the effective holding time at 1250°C is 85 minutes;

[0040] 3) The cast slab is subjected to rough rolling for 3 passes, the thickness of the intermediate slab is 35mm, the starting temperature of the finishing rolling is controlled at 1080°C, the finishing rolling temperature is 950°C, the coiling temperature is 560°C, and the thickness after finishing rolling is 2.3mm;

[0041] 4) After the hot-rolled raw material is pickled, it is cold-rolled for the first time, with a thickness of 0.66mm;

[0042] 5) Decarburization annealing is performed on the primary cold-rolled coil, the decarburization annealing temperature is 830°C, the dew point is 35°C, the decarburization soaking time is 6min,...

Embodiment 2

[0049] The preparation process steps of grain-oriented silicon steel are as follows:

[0050] 1) The steel with the above chemical composition is continuously cast into a 250mm billet after molten iron pretreatment, converter steelmaking, and vacuum treatment;

[0051] 2) Heating the billet to 1280°C for 370 minutes in the furnace, of which the effective holding time at 1280°C is 110 minutes;

[0052] 3) The cast slab is subjected to 5 passes of rough rolling, the thickness of the intermediate slab is 45mm, the start rolling temperature of finish rolling is controlled at 1110°C, the finish rolling temperature is 980°C, the coiling temperature is 550°C, and the thickness after finish rolling is 2.3mm;

[0053] 4) After the hot-rolled raw material is pickled, it is cold-rolled for the first time, with a thickness of 0.70mm;

[0054] 5) Decarburization annealing is performed on the primary cold-rolled coil, the decarburization annealing temperature is 820°C, the dew point is 40°...

Embodiment 3

[0061] The preparation process steps of grain-oriented silicon steel are as follows:

[0062] 1) The steel with the above chemical composition is continuously cast into a 230mm billet after molten iron pretreatment, converter steelmaking, and vacuum treatment;

[0063] 2) Heating the billet to 1300°C for 410 minutes in the furnace, of which the effective holding time at 1300°C is 125 minutes;

[0064] 3) The cast slab is subjected to rough rolling for 3 passes, the thickness of the intermediate slab is 35mm, the starting temperature of the finish rolling is controlled at 1150°C, the finish rolling temperature is 980°C, the coiling temperature is 550°C, and the thickness after finish rolling is 2.0mm;

[0065] 4) After the hot-rolled raw material is pickled, it is cold-rolled for the first time, with a thickness of 0.63mm;

[0066] 5) Decarburization annealing is performed on the primary cold-rolled coil, the decarburization annealing temperature is 830°C, the dew point is 40°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com