Circuit board and processing method thereof

A processing method and circuit board technology, which is applied in the direction of assembling printed circuits with electrical components, printed circuits connected with non-printed electrical components, etc., can solve problems that limit product application and development, affect the electromagnetic performance of PCB products, and achieve guaranteed The effect of electromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

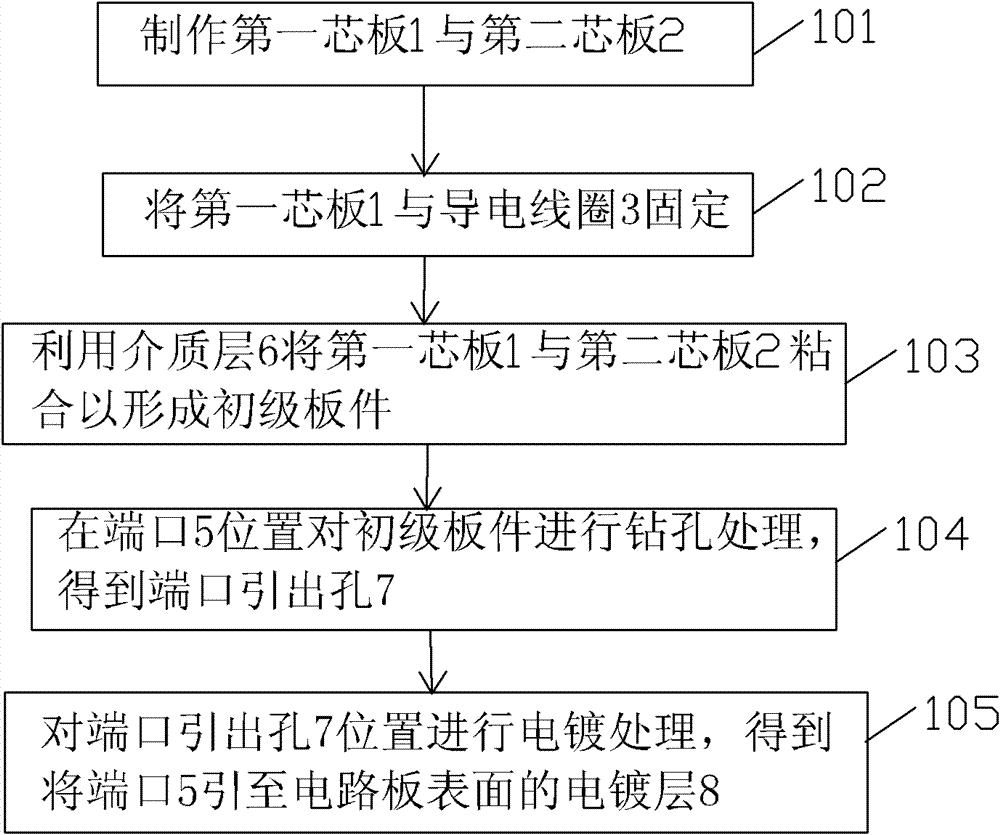

[0018] like figure 1 As shown, the embodiment of the present invention provides a circuit board processing method, which mainly includes:

[0019] 101, first make the first core board 1 and the second core board 2, the first core board 1 or the second core board 2 can be formed by cladding copper on the base material (single-sided or double-sided), which can include two layers or multi-layer lines;

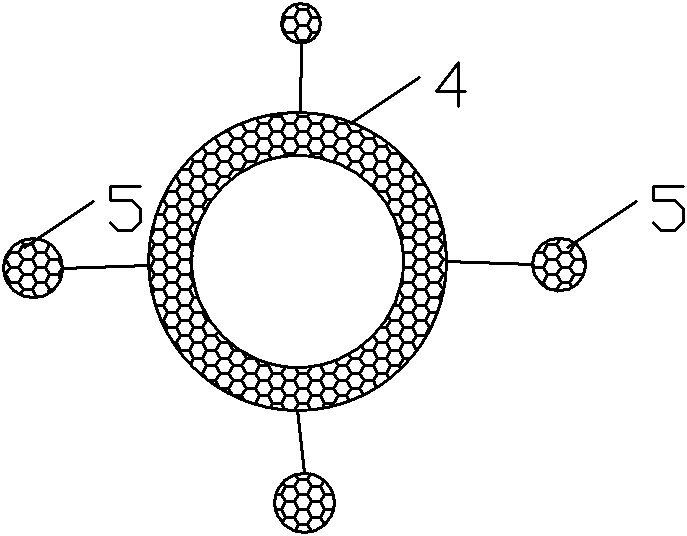

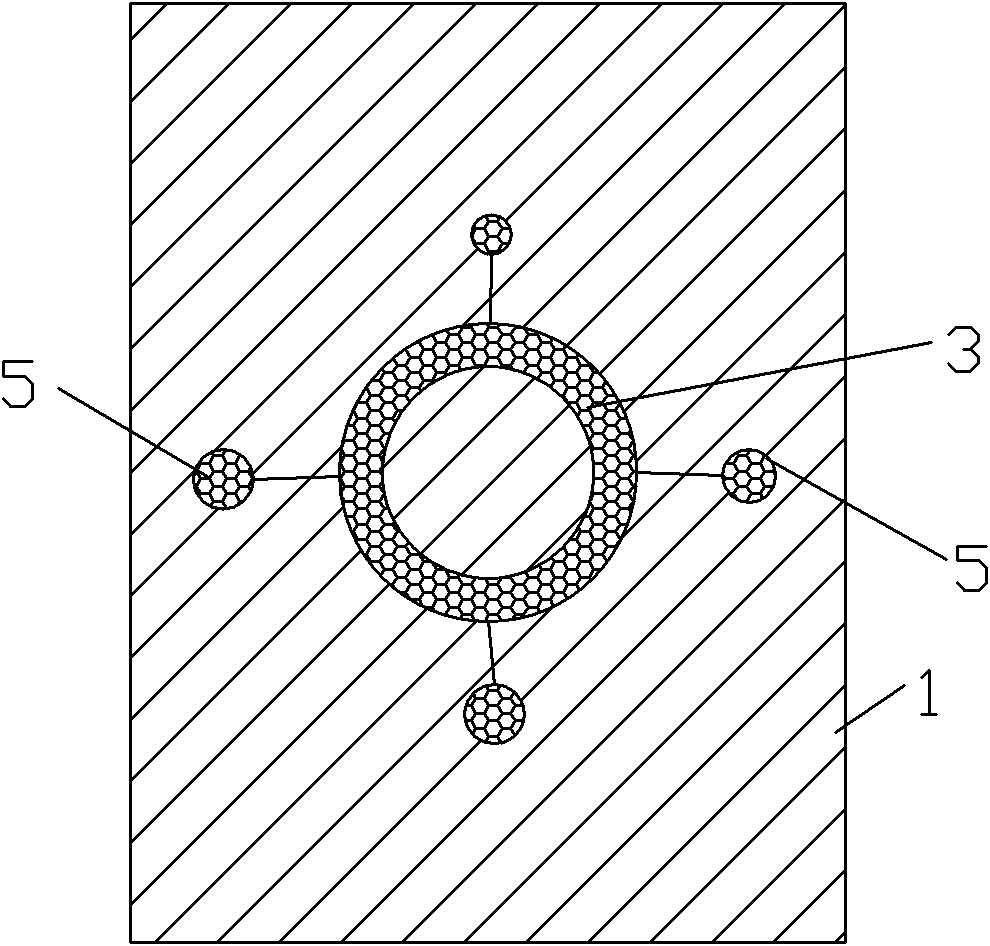

[0020] 102. Fix the first core board 1 and the conductive coil 3 with the port 5 in a certain way, and the conductive coil 3 can be as follows figure 2 As shown, it includes one or more turns of conductive wire 4 and port 5. The conductive wire 4 can be copper wire, gold wire, silver wire or aluminum wire, or it can be made of a mixture of various metals in copper, gold, silver and aluminum. Specifically, the conductive coil 3 can be welded to the first core board 1, and the conductive paste used for welding can be solder paste, copper paste or silver paste, etc., or the conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com