A kind of fe/zrh2 nanocrystalline composite particle and its preparation method and application

A nanocrystalline composite and nanocrystalline technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex magnetic permeability decrease, complex permittivity increase, etc., and achieve improvement Electromagnetic properties, guaranteed temperature resistance and electromagnetic properties, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

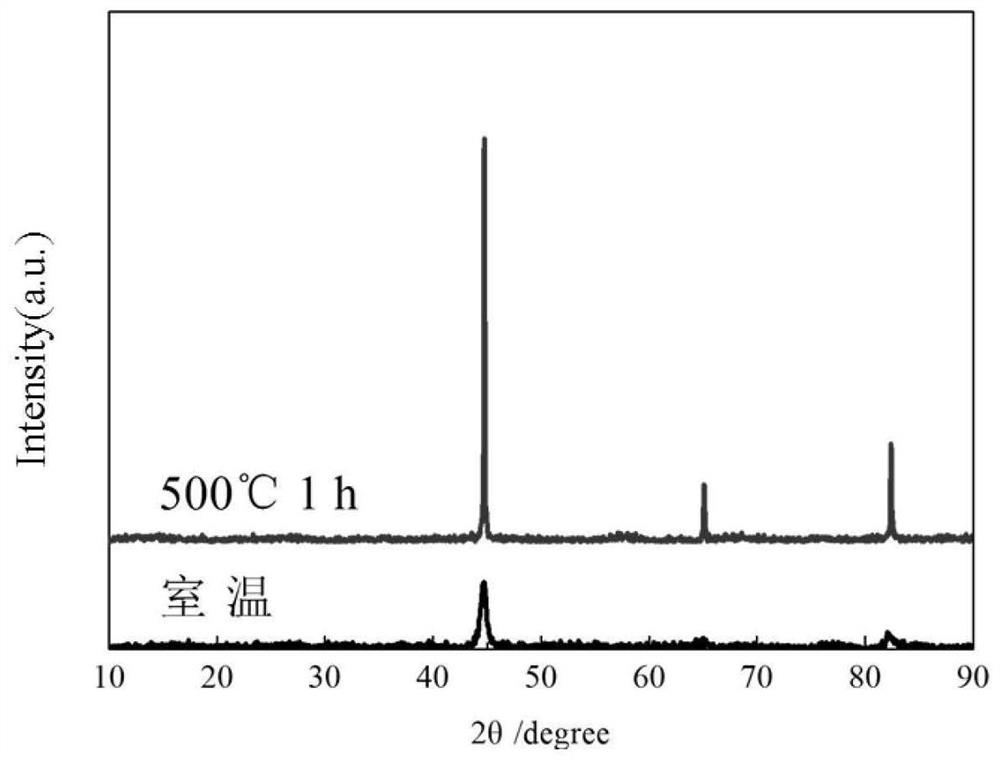

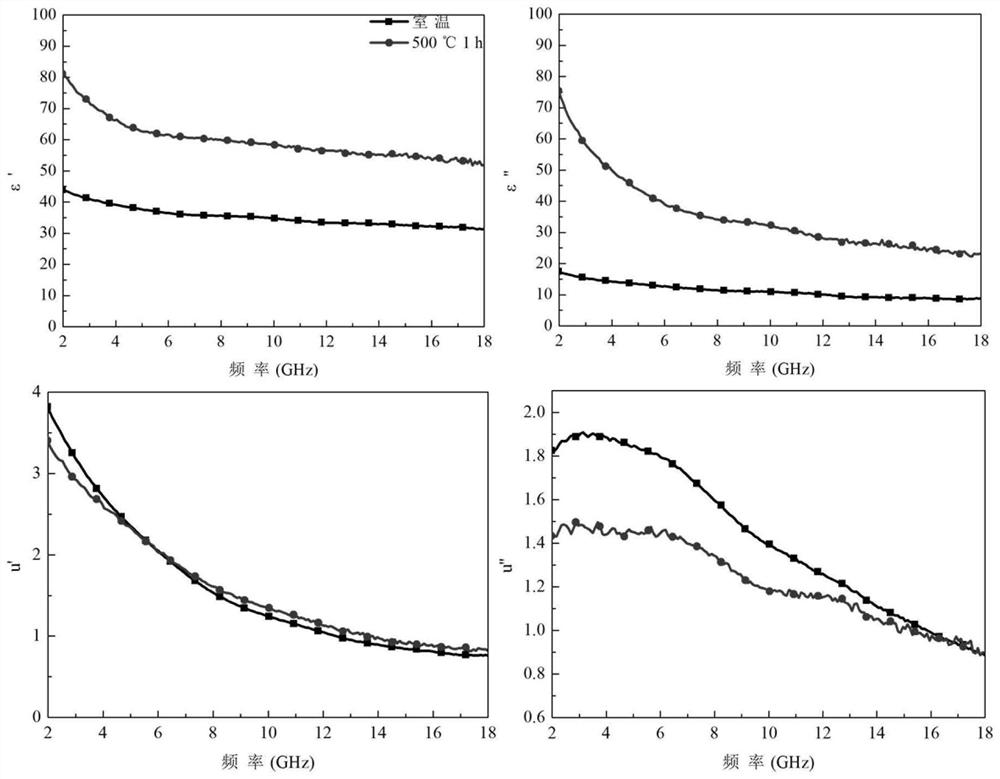

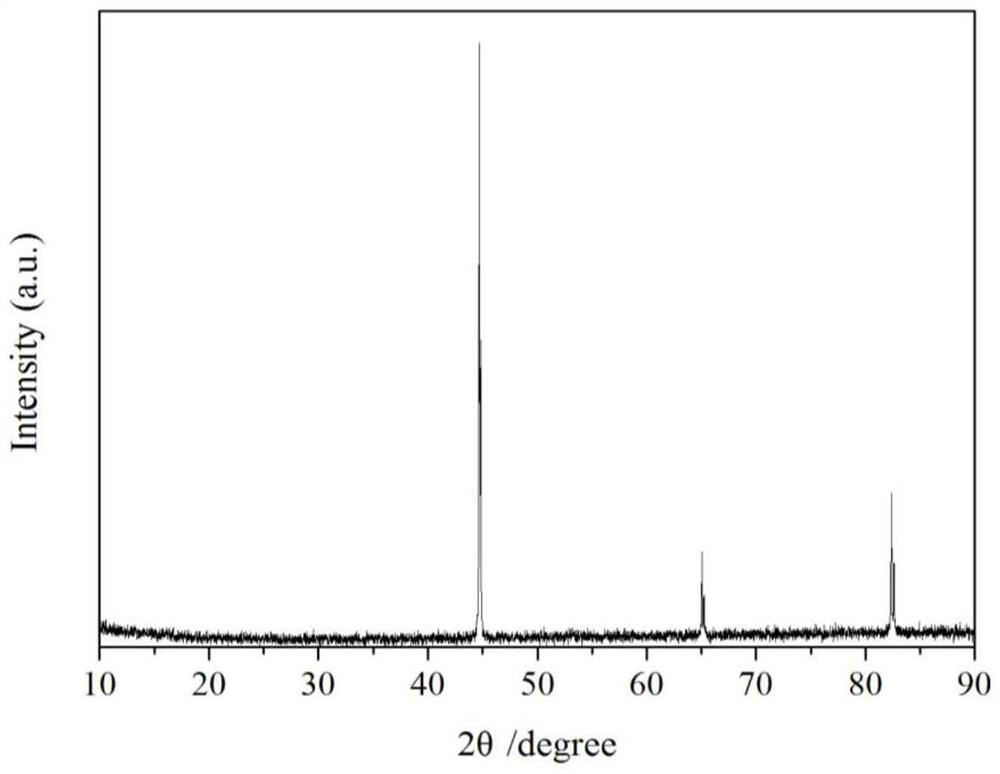

[0048] a Fe / ZrH 2 Nanocrystalline composite particle, its preparation method comprises the steps:

[0049] 1) 19.4g carbonyl iron powder and 0.6g ZrH 2 powder into the ball mill jar (ZrH 2 The mass fraction of particles in the composite powder is 3wt.%), weigh 10mm and 6mm stainless steel grinding balls according to the ball-to-material ratio of 20:1, and the ratio of large and small balls is 3:2; then add 10ml of analytically pure n-hexane As a dispersant; set the ball mill to the forward and reverse alternate mode, the cycle of each rotation is 5h, stop for 20min in the middle, set the ball milling time to 80h, and the speed to 260rpm / min; after the ball milling is completed, use a 300-mesh sieve to separate the balls with powder;

[0050] 2) Take 10g of the powder obtained in step 1), weigh zirconia balls with a diameter of 6mm at a mass ratio of 80:1 (ball-to-material ratio), put the powder and balls into a grinding tank, and add 100ml of ethanol to it As the grinding ...

Embodiment 2

[0059] a Fe / ZrH 2 Nanocrystalline composite particle, its preparation method comprises the steps:

[0060] 1) 18.4g carbonyl iron powder and 1.6g ZrH 2 powder into the ball mill jar (ZrH 2 The mass fraction of particles in the composite powder is 8wt.%), weigh 10mm and 6mm stainless steel grinding balls according to the ball-to-material ratio of 20:1, and the ratio of large and small balls is 3:2; then add 10ml of analytically pure n-hexane As a dispersant; set the ball mill to the forward and reverse alternate mode, the cycle of each rotation is 5h, stop for 20min in the middle, set the ball milling time to 100h, and the speed to 240rpm / min; after the ball milling is completed, use a 300-mesh sieve to separate the balls with powder;

[0061] 2) Take 10g of the powder obtained in step 1), weigh zirconia balls with a diameter of 6mm at a mass ratio of 80:1 (ball-to-material ratio), put the powder and balls into a grinding tank, and add 100ml of ethanol to it As a grinding m...

Embodiment 3

[0066] a Fe / ZrH 2 Nanocrystalline composite particle, its preparation method comprises the steps:

[0067] 1) 19g carbonyl iron powder and 1g ZrH 2 powder into the ball mill jar (ZrH 2 The mass fraction of the particles in the composite powder is 5 wt.%), weigh 10mm and 6mm stainless steel grinding balls according to the ball-to-material ratio of 20:1, and the ratio of large and small balls is 3:2; then add 15ml of analytically pure alkanes as a dispersant; set the ball mill to the forward and reverse alternating mode, the cycle of each rotation is 5h, stop for 20min in the middle, set the ball milling time to 60h, and the speed to 250rpm / min; after the ball milling is completed, use a 300-mesh sieve to separate balls and powder;

[0068] 2) Take 10g of the powder obtained in step 1), weigh zirconia balls with a diameter of 6mm at a mass ratio of 80:1 (ball-to-material ratio), put the powder and balls into a grinding tank, and add 100ml of ethanol to it As the grinding med...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com