Atomized metal powder, insulating coating agent, magnetic powder core and preparation method of magnetic powder core

An atomized metal and insulating coating technology, applied in the electromagnetic field, can solve the problems of magnetic powder core electromagnetic performance decline, coating damage, atomized metal powder collision, etc. , The effect of improving the forming density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

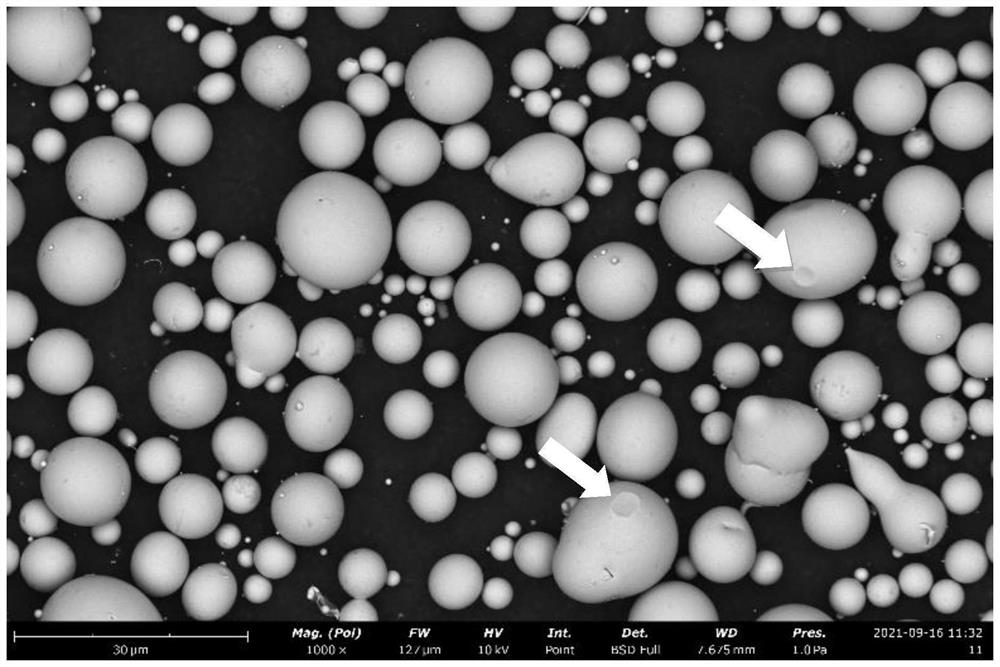

Image

Examples

Embodiment 1

[0036] The insulating coating agent is composed of 200 parts by weight of resin composition, 2.5 parts by weight of emulsifier, 220 parts by weight of water, 80 parts by weight of co-solvent, and 2 parts by weight of nano silicon dioxide. Wherein, the resin composition is composed of epoxy resin and silicone resin, and the weight ratio of epoxy resin and silicone resin is (2:3)-(3:2). In one example, the weight ratio of epoxy resin to silicone resin is 2:3. In another example, the weight ratio of epoxy resin to silicone resin is 1:1. The weight ratio of epoxy resin and silicone resin is 3:2.

[0037] The insulating coating agent in Example 1 can be prepared in the following manner.

[0038] Add 60 parts by weight of the resin composition, 40 parts by weight of co-solvent, 110 parts by weight of water, 1.25 parts by weight of emulsifier, and 2 parts by weight of nano silicon dioxide into a reaction container (such as a three-necked bottle). The reaction vessel was placed in ...

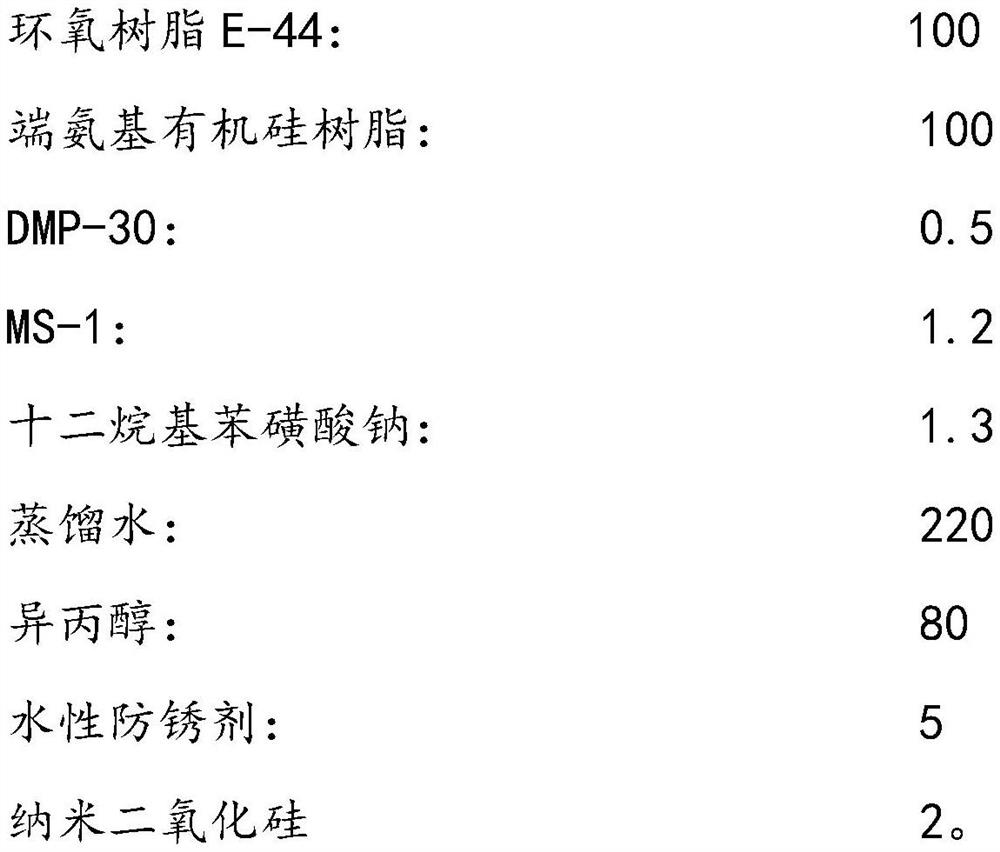

Embodiment 2

[0041] The insulating coating agent consists of 200 parts by weight of resin composition, 2.5 parts by weight of emulsifier, 220 parts by weight of water, 80 parts by weight of cosolvent, 2 parts by weight of nano silicon dioxide, and 5 parts by weight of water-based rust inhibitor composition. Wherein, the resin composition is composed of epoxy resin and silicone resin, and the weight ratio of epoxy resin and silicone resin is (2:3)-(3:2).

[0042] The insulating coating agent in Example 2 can be prepared in the following manner.

[0043] Add 60 parts by weight of resin composition, 40 parts by weight of cosolvent, 110 parts by weight of water, 1.25 parts by weight of emulsifier, 2 parts by weight of nano silicon dioxide, 5 parts by weight of water-based rust inhibitor. The reaction vessel was placed in a water bath, and the temperature of the water bath was adjusted to 80°C-90°C, and the stirring speed was set to 800r / min for thorough mixing for 30min.

[0044] Then, at a...

Embodiment 3

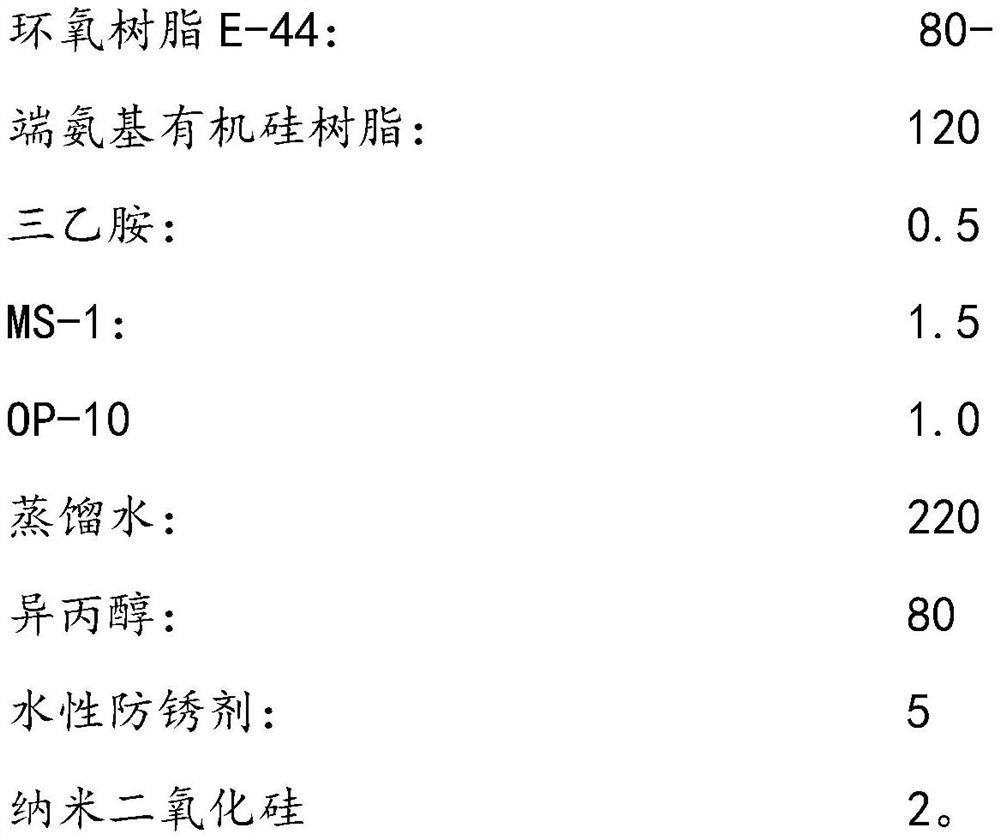

[0046] The insulating coating agent consists of 200 parts by weight of resin composition, 2.5 parts by weight of emulsifier, 220 parts by weight of water, 80 parts by weight of cosolvent, 2 parts by weight of nano silicon dioxide, 0.5 parts by weight of reaction accelerator, 5 parts by weight of water-based antirust agent. Wherein, the resin composition is composed of epoxy resin and silicone resin, and the weight ratio of epoxy resin and silicone resin is (2:3)-(3:2).

[0047] The insulating coating agent in Example 3 can be prepared in the following manner.

[0048] Add 60 parts by weight of resin composition, 40 parts by weight of cosolvent, water of 110 parts by weight, emulsifier of 1.25 parts by weight, reaction accelerator of 0.25 parts by weight, 2 parts by weight of Nano silica, 5 parts by weight of water-based antirust agent. The reaction vessel was placed in a water bath, and the temperature of the water bath was adjusted to 80°C-90°C, and the stirring speed was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com