Rust-resistant carbonyl iron powder wave-absorbing material and preparation method thereof

A technology of carbonyl iron powder and wave-absorbing materials, which is applied in antennas, electrical components, magnetic field/electric field shielding, etc., and can solve problems such as changes in the electromagnetic properties of wave-absorbing materials, easy to rust, and failure to meet the needs of wave-absorbing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

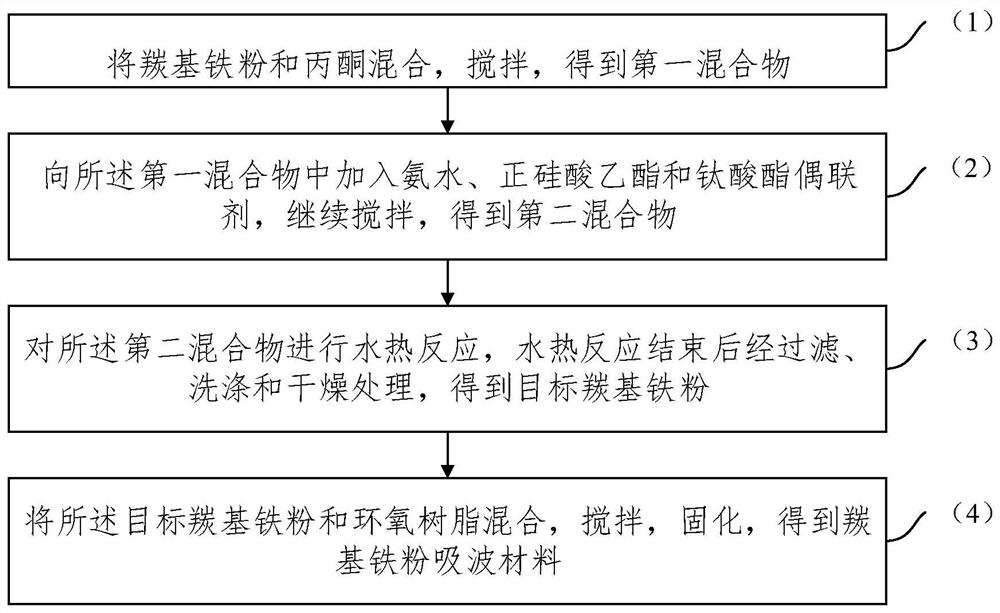

[0036] Such as figure 1 As shown, the embodiment of the present invention provides a method for preparing an anti-corrosion carbonyl iron powder absorbing material, the method includes the following steps:

[0037] In step (1), carbonyl iron powder and acetone are mixed and stirred to obtain the first mixture;

[0038] Step (2), adding ammonia water, tetraethyl orthosilicate and titanate coupling agent to the first mixture, and continuing to stir to obtain a second mixture;

[0039] In step (3), the second mixture is subjected to a hydrothermal reaction, and after the hydrothermal reaction is completed, it is filtered, washed and dried to obtain the target carbonyl iron powder;

[0040] In step (4), the target carbonyl iron powder and epoxy resin are mixed, stirred, and cured to obtain a carbonyl iron powder wave-absorbing material.

[0041] It should be noted that the stirring in step (1) is mechanical stirring; preferably, acetone is used, and ethanol can also be used for ...

Embodiment 1

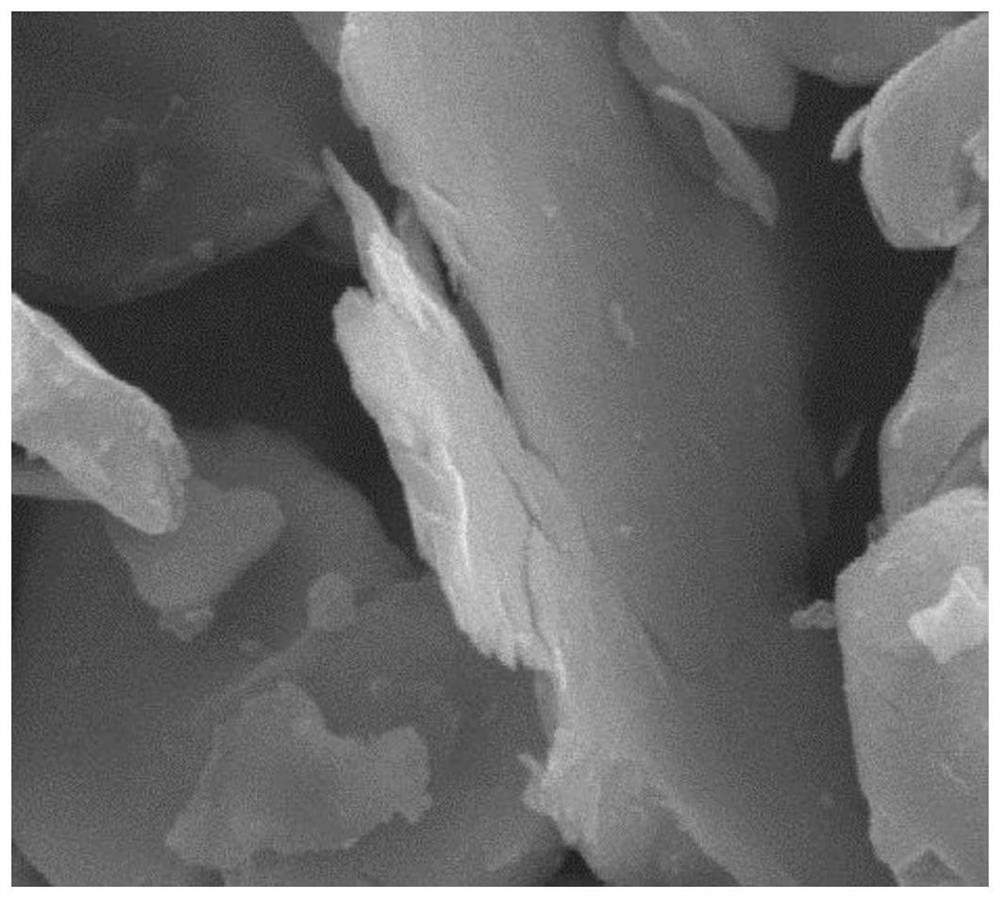

[0070] (1) Add 10 g of flaky carbonyl iron powder (with a particle size of 1-10 μm and a thickness of 0.5-3 μm) into acetone, and stir with mechanical stirring for 20 minutes to obtain the first mixture;

[0071] (2) Add 143 mL of ammonia water with a concentration of 1 mol / L, 5 g of tetraethyl orthosilicate and 5 g of titanate coupling agent TC-WT to the first mixture, and continue stirring to mix uniformly to obtain the second mixture;

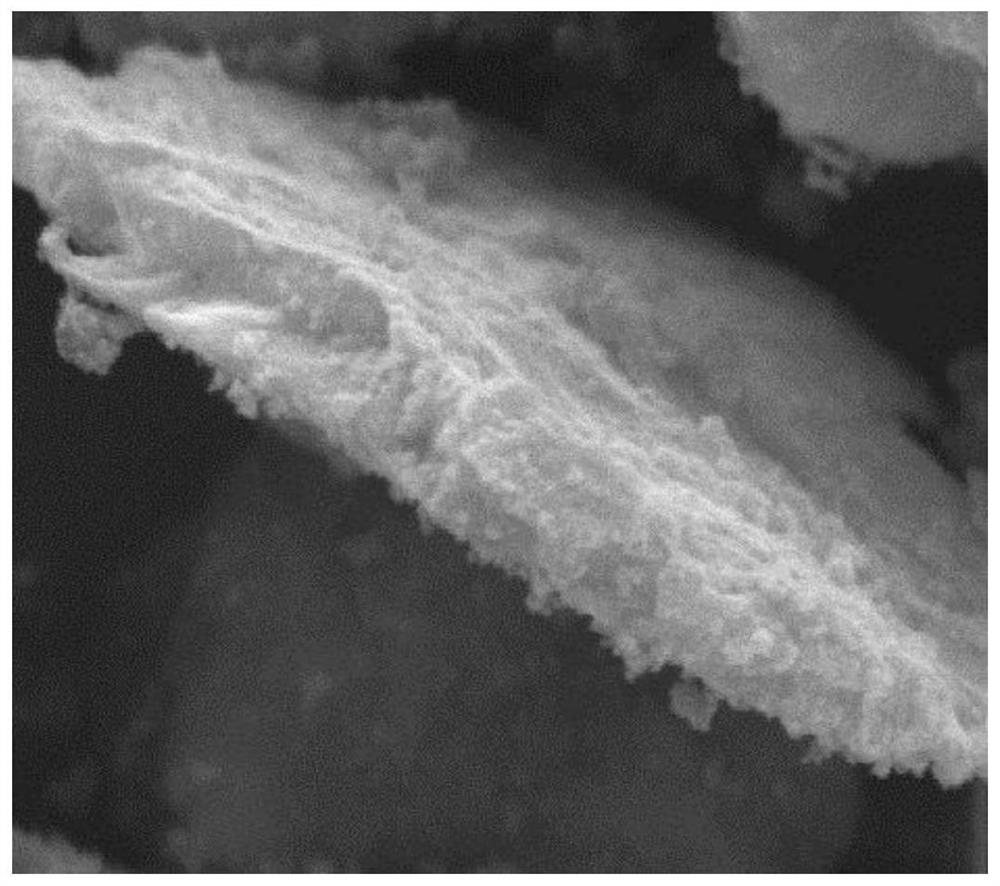

[0072] (3) Put the second mixture in a 90°C constant temperature water bath for 8 hours of hydrothermal reaction. After the hydrothermal reaction is completed, the solid product is obtained by filtration, and washed with ethanol and distilled water in sequence, and the washed solid product is placed at 50°C. Carry out drying in the vacuum oven, obtain target carbonyl iron powder;

[0073] (4) Mix 10 g of the target carbonyl iron powder with 2.5 g of epoxy resin, mechanically stir, place in a mold, and cure (put in an oven and heat to 120°C f...

Embodiment 2

[0076] Example 2 is basically the same as Example 1, except that 10 g of tetraethyl orthosilicate and 10 g of titanate coupling agent TC-WT are added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com