Metal zinc negative electrode with uniform mesoporous structure coating and preparation method and application thereof

A mesoporous structure, metal zinc technology, applied in the direction of negative electrode, electrode manufacturing, structural parts, etc., can solve the problem of low utilization rate of zinc metal negative electrode, achieve the effect of reducing battery short circuit, reducing side reactions, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In an embodiment of the present invention, a method for preparing a metal zinc negative electrode with a uniform mesoporous structure coating comprises the following steps:

[0041] (1) The preparation of coated klZn negative electrode is the same as Comparative Example 2;

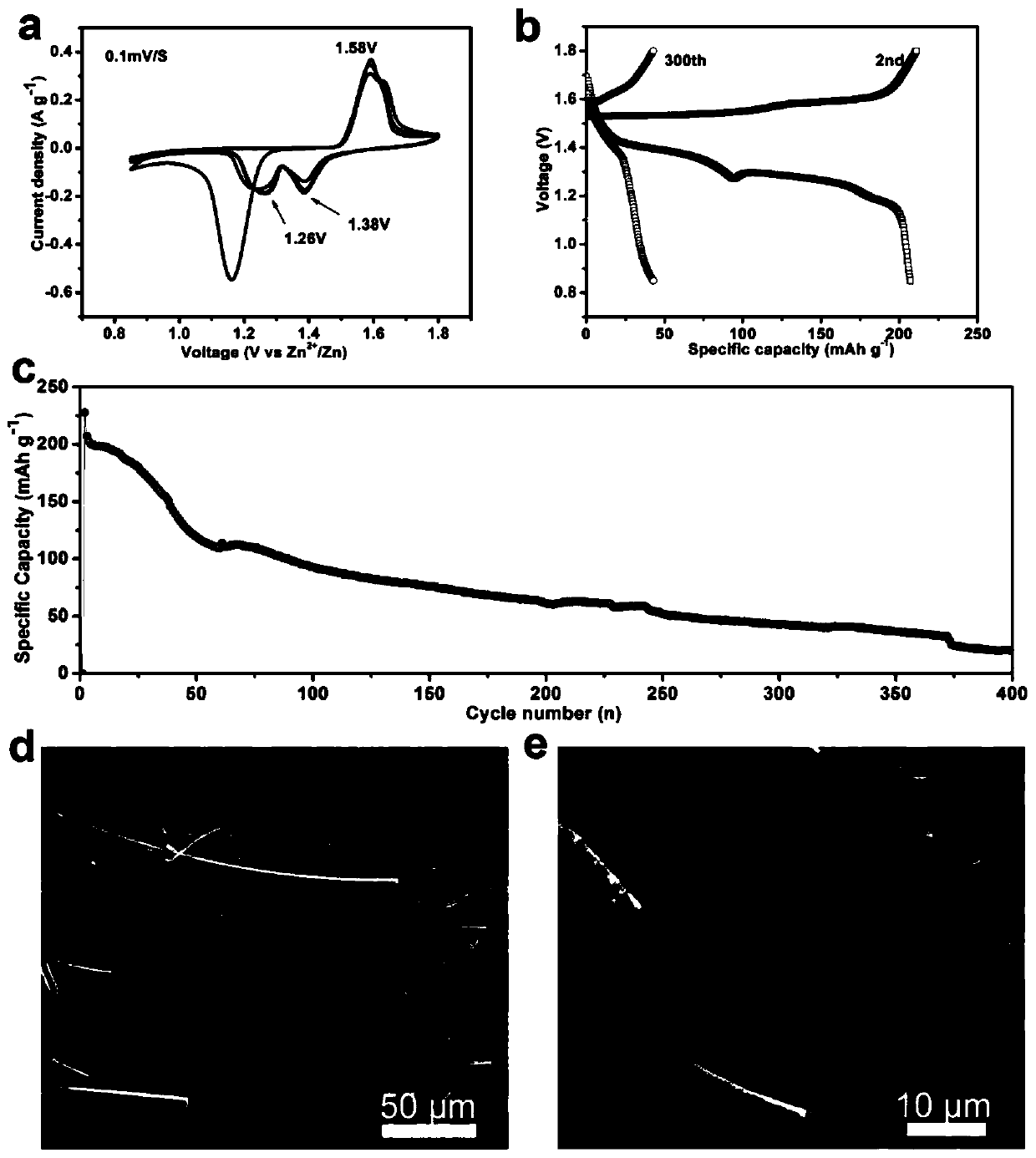

[0042] (2) The coated zinc foil (klZn) with a coating thickness of 21 μm was subjected to a trace zinc pre-deposition treatment, that is, the klZn was used as the positive electrode and the zinc foil was used as the negative electrode to assemble a button battery. -2 Discharge 15min under constant current, obtain the coated zinc foil (deposited klZn) of pre-deposited trace zinc; With this pre-deposited coated zinc foil as negative electrode, MnO 2 The pole piece is a positive electrode assembly button battery, and all the other conditions are the same as in Comparative Example 1, and the battery performance results are as follows: image 3 .

[0043] image 3 a is the charge and discharge curve o...

Embodiment 2

[0045] In an embodiment of the present invention, a method for preparing a metal zinc negative electrode with a uniform mesoporous structure coating comprises the following steps:

[0046] (1) The preparation of coated klZn negative electrode is the same as Comparative Example 2;

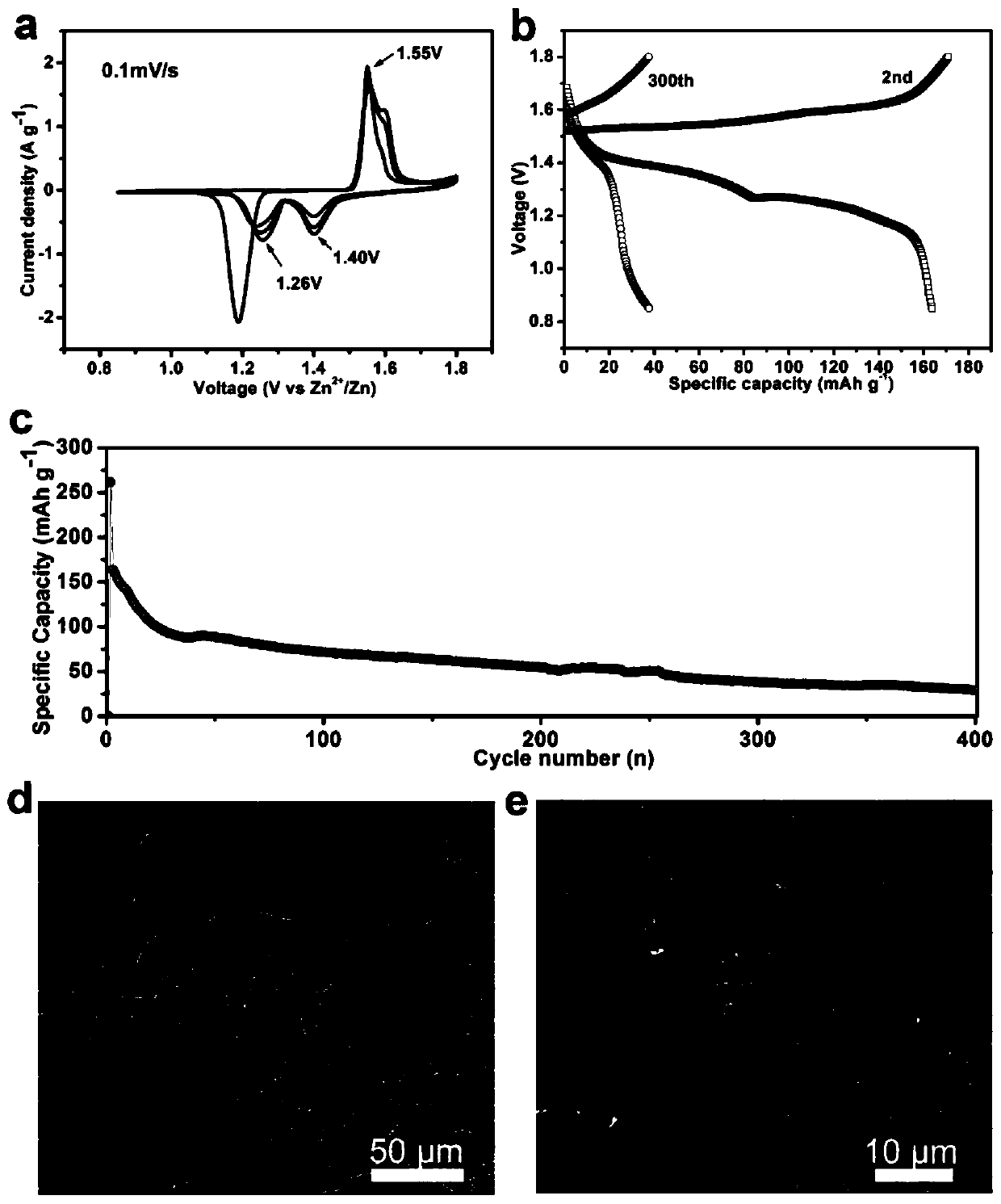

[0047] (2) The coated zinc foil (klZn) with a coating thickness of 21 μm is subjected to a trace zinc pre-deposition treatment, that is, a button battery is assembled with the klZn as the positive electrode and the zinc foil as the negative electrode, and the assembled battery operates at 10mA cm -2 Discharge 15min under the constant current, obtain the coated zinc foil (deposited klZn) of pre-deposited trace zinc, take this pre-deposited coated zinc foil as the negative electrode, MnO 2 The pole piece is a positive electrode assembly button battery, and all the other conditions are the same as in Comparative Example 1, and the battery performance results are as follows: Figure 4 .

[0048] Fig...

Embodiment 3

[0050] In an embodiment of the present invention, a method for preparing a metal zinc negative electrode with a uniform mesoporous structure coating comprises the following steps:

[0051] (1) The preparation of coated klZn negative electrode is the same as Comparative Example 2;

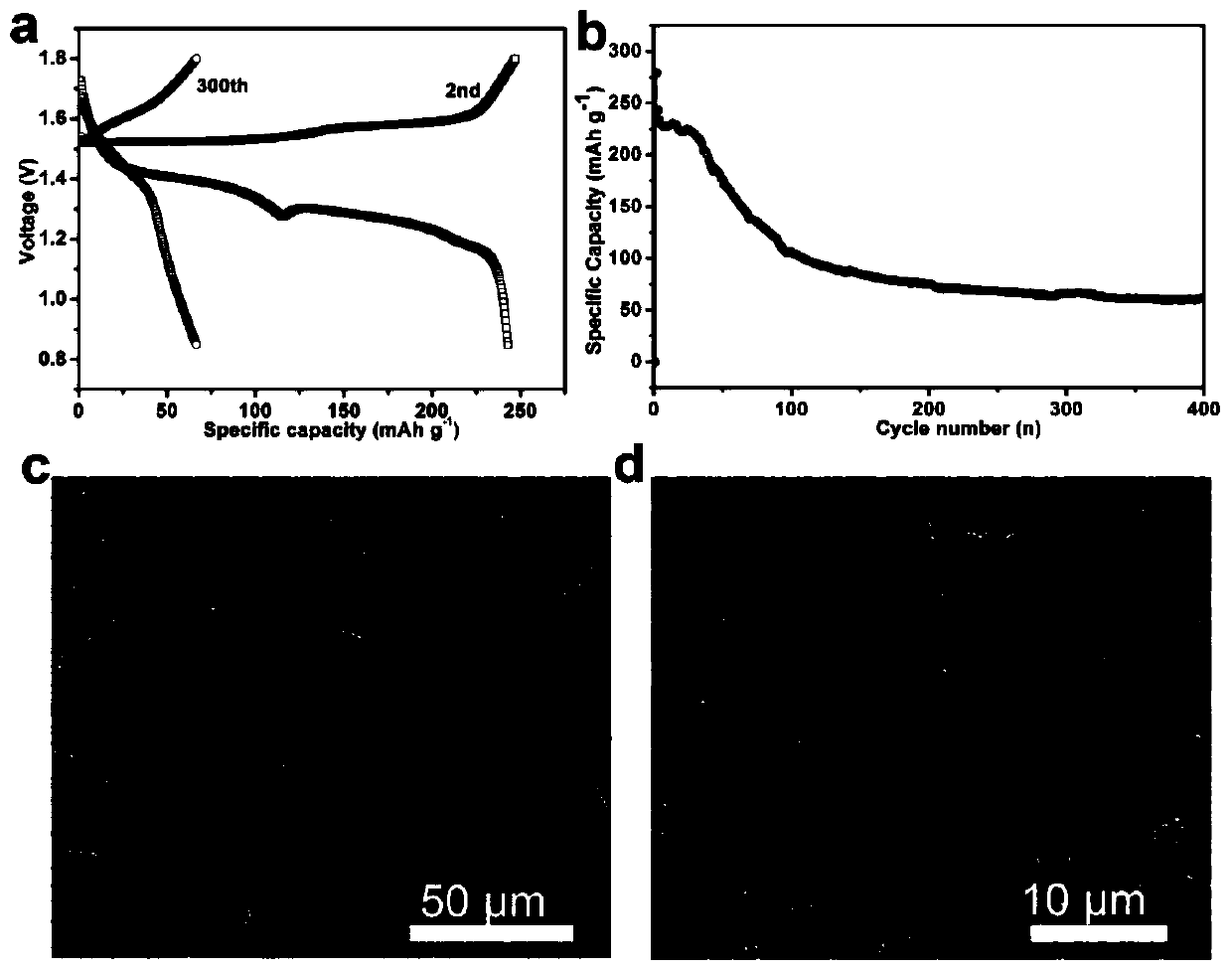

[0052] (2) The coated zinc foil (klZn) with a coating thickness of 21 μm was subjected to a trace zinc pre-deposition treatment, that is, a button battery was assembled with the klZn as the positive electrode and the zinc foil as the negative electrode, and the assembled battery operated at 20mA cm -2 Discharge 15min under constant current, obtain the coated zinc foil (deposited klZn) of pre-deposited trace zinc; With this pre-deposited coated zinc foil as negative electrode, MnO 2 The pole piece is a positive electrode assembly button battery, and all the other conditions are the same as in Comparative Example 1, and the battery performance results are as follows: Figure 5 .

[0053] Figure 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com