Microelectronic element with elastic conductive projection and method of manufacture

A microelectronic component, elastic conductive technology, applied in the field of microelectronics, can solve problems such as increased connection resistance, short circuit, open circuit, etc., and achieve the effect of avoiding excessive connection resistance or even open circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

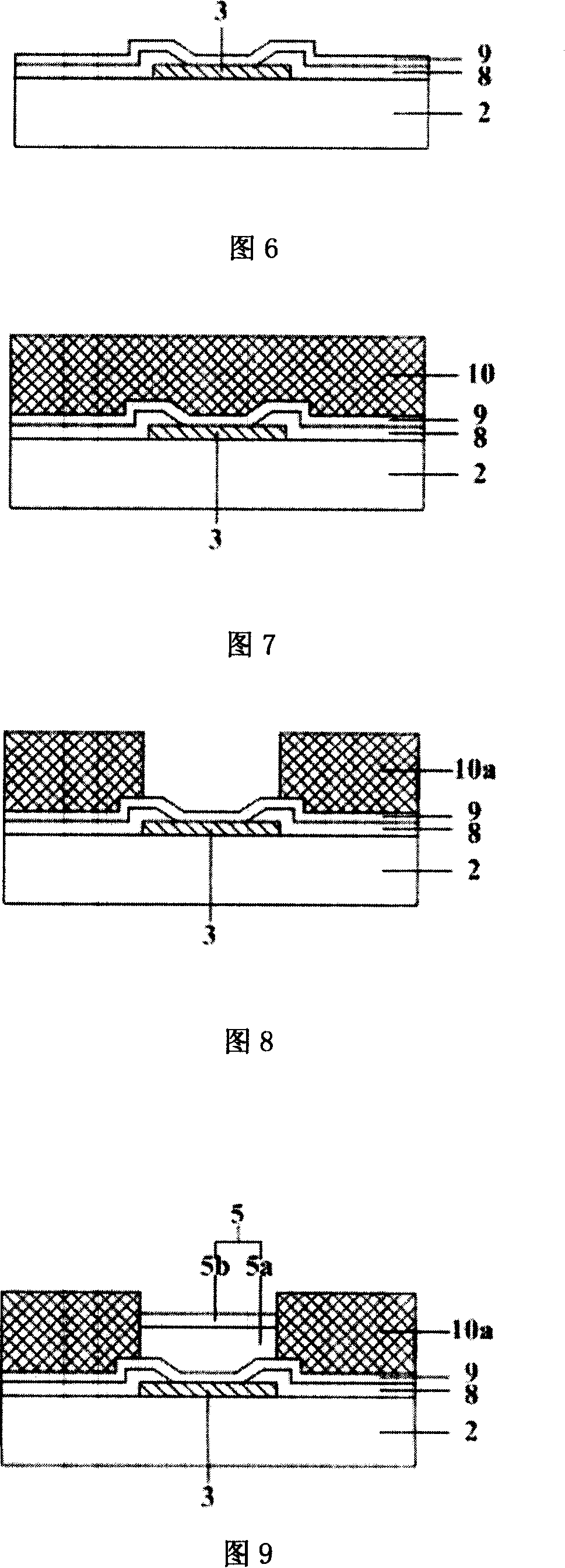

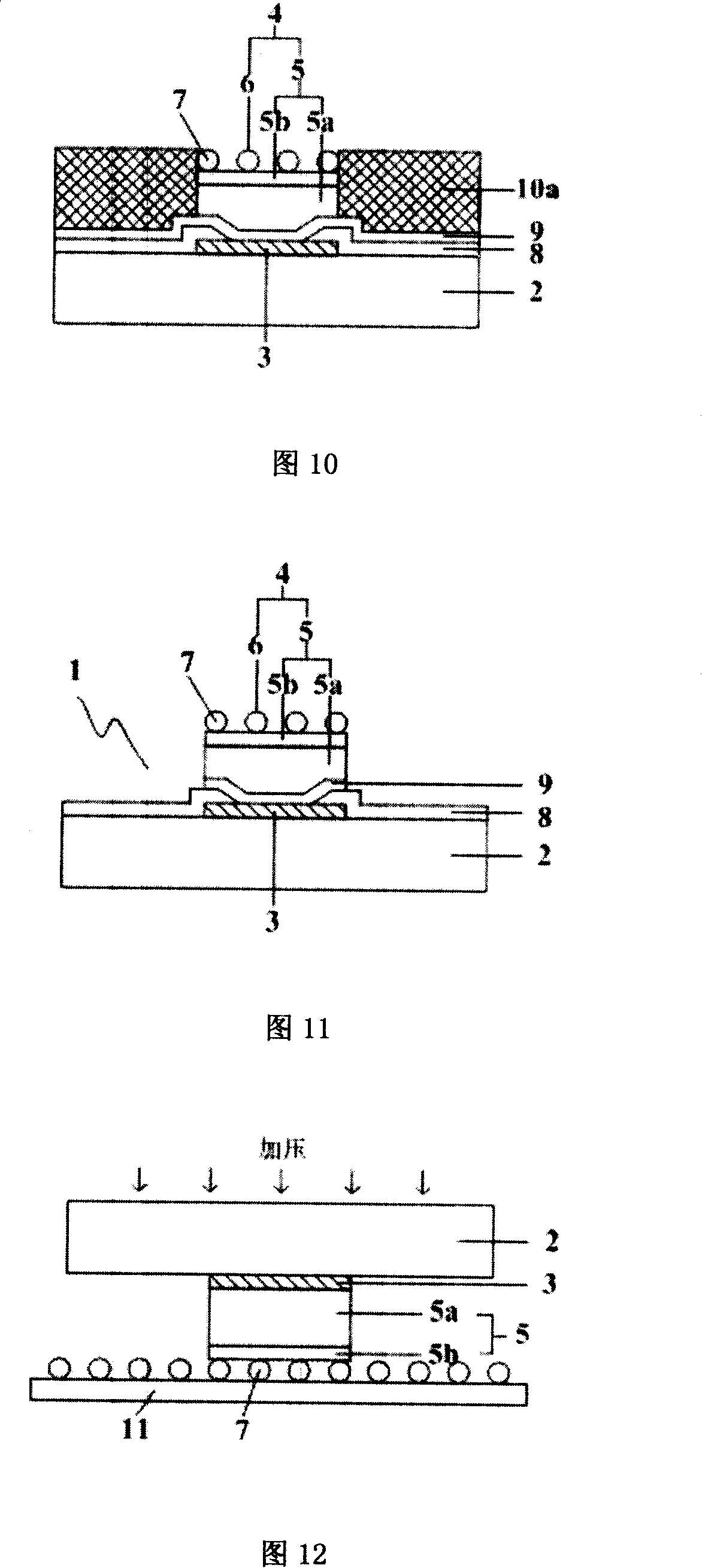

[0036] The present invention will be described more fully hereinafter with reference to the accompanying drawings, in which preferred embodiments of the invention are shown.

[0037] The embodiments will be described with reference to a liquid crystal display driver chip (hereinafter simply referred to as a driver chip) as a microelectronic element, the characteristics of which will be described by way of example.

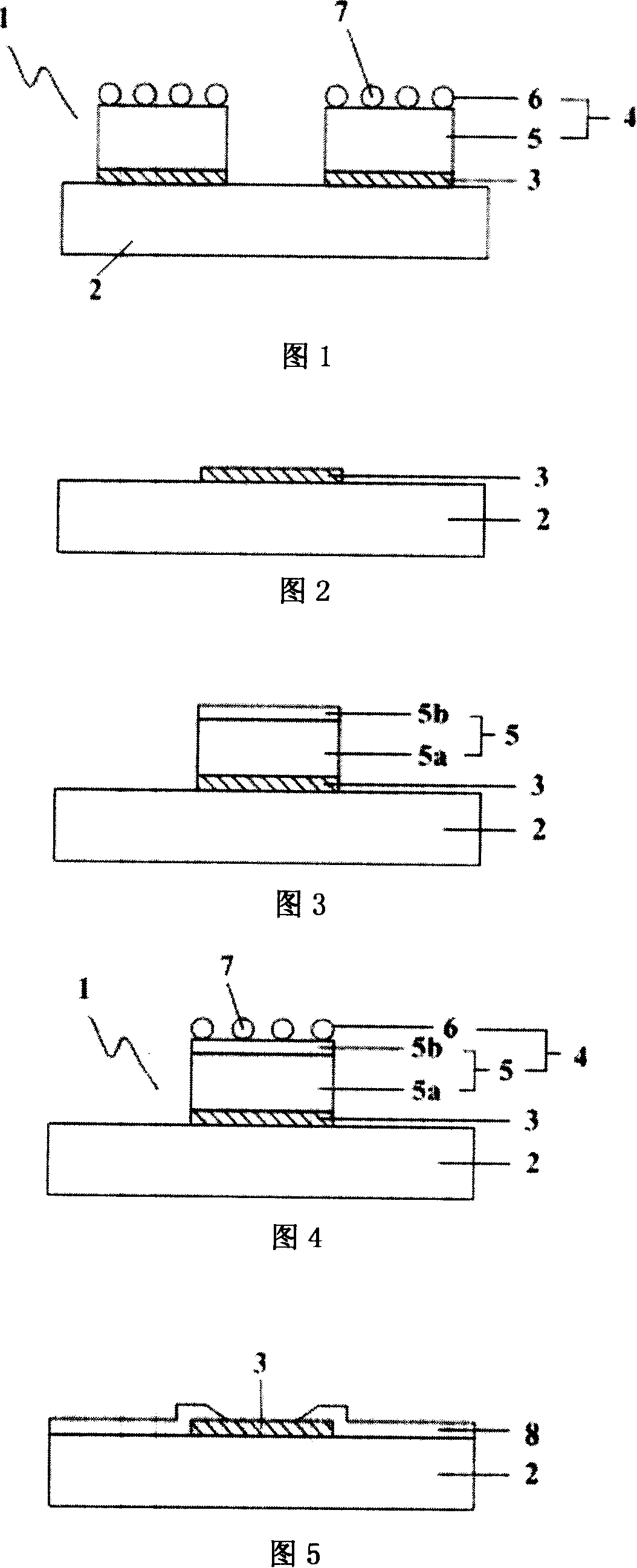

[0038] FIG. 1 is a schematic structural diagram of a driver chip with elastic conductive bumps according to an embodiment of the present invention.

[0039] In view of the previous description of the problems faced by the current packaging structure using ACF for flip-chip interconnection, an embodiment of the present invention provides a driving chip 1 with elastic conductive bumps 4, including a semiconductor chip 2 and a The elastic conductive bump 4 on the bonding pad 3 on the surface of the semiconductor chip. It is characterized in that the elastic conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com