Anode and lithium secondary battery comprising the same and method for preparation of the same

A positive electrode and battery positive electrode technology, applied in secondary battery, electrolyte battery manufacturing, electrode manufacturing, etc., can solve the problems of low overcharge safety and poor heat dissipation performance, so as to improve overcharge safety and reduce internal short circuit of the battery The probability of the heat dissipation is conducive to the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

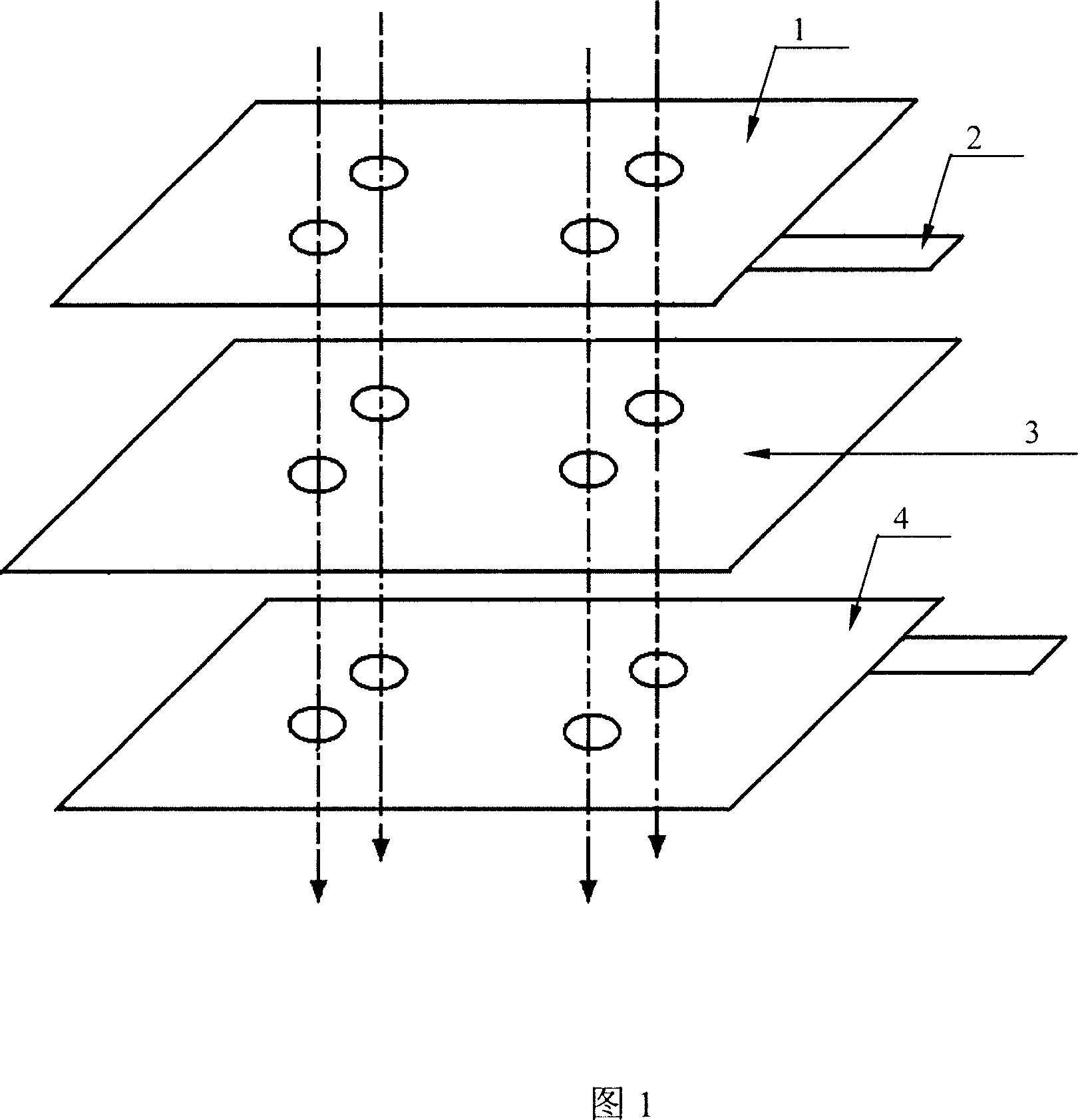

[0039] The present invention also provides a method for preparing the positive electrode of the above-mentioned battery, the method comprising coating the slurry containing the positive electrode material on the current collector, baking, calendering, coating after coating or after baking or after calendering The current collector of the upper positive electrode material is perforated, wherein the total area of the perforations is 0.5-50% of the area of the current collector, and the perforations are irregular. According to the present invention, the positive electrode must be perforated after coating, that is, the positive electrode can be perforated after coating, baking or calendering. If the positive electrode is perforated before coating, the positive electrode active material will be distributed in the holes when coating the positive electrode material, which will increase the potential danger. Because the positive electrode active material is more distributed in the...

Embodiment 1

[0049] This example illustrates the positive electrode provided by the present invention, batteries including the positive electrode and their preparation methods.

[0050] (1) Preparation of positive electrode

[0051] 90 grams of polyvinylidene fluoride (Atofina Company, 761#PVDF) were dissolved in 1350 grams of N-methyl-2-pyrrolidone (NMP) solvent to prepare a binder solution, and then the previously mixed 2895 gLiCoO 2 Add 90 grams of acetylene black powder into the above solution, stir and mix evenly to prepare positive electrode slurry.

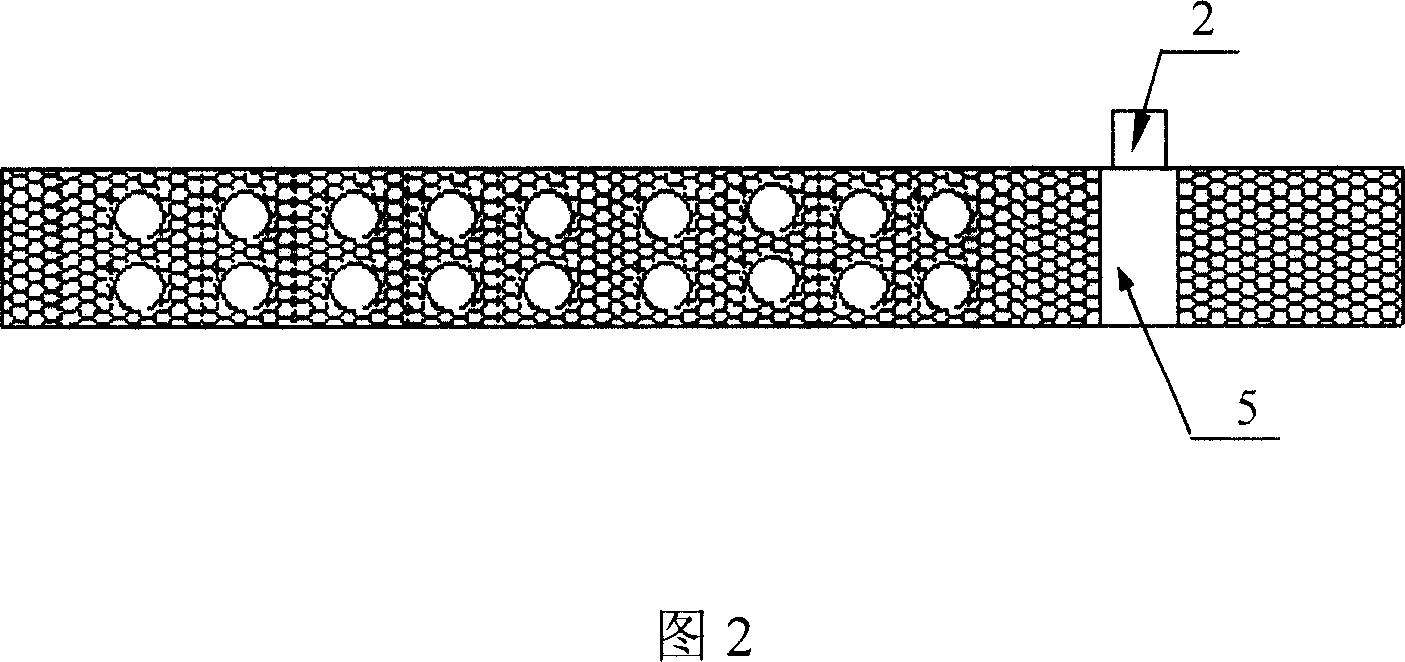

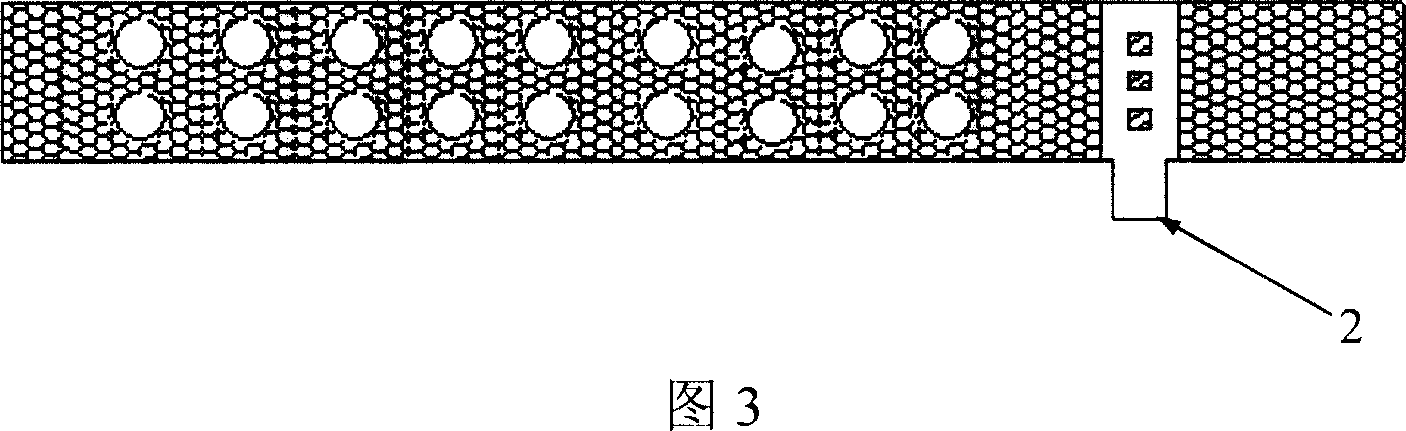

[0052] Use a pulper to coat the positive electrode slurry on both sides of an aluminum foil with a thickness of 20 microns at intervals, heat and dry under vacuum at 120°C for 1 hour, and perforate with a laser to make the perforated shape irregular. The front and back sides of the positive electrode are shown in Figure 4 As shown in Figure 5, the shaded part is the surface of the current collector coated with the positive electrode m...

Embodiment 2-4

[0061] Prepare battery positive electrode and lithium secondary battery according to the method of embodiment 1, difference is the timing of laser perforation, the ratio of the total area of perforation to the current collector area and the positive active material (LiCoO2) on each positive electrode. 2 ) content is different, as shown in Table 1 below. Wherein, the front and back sides of the positive pole obtained in Example 2 are shown in Figure 6 and Figure 7 respectively; the front side and back side of the positive pole obtained in Example 3 are shown in Figure 8 and Figure 9 respectively; the front side of the positive pole obtained in Example 4 and the reverse side are shown in Figure 10 and Figure 11, respectively.

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com