Method for manufacturing high steel grade sulfur resistant drill pipe by laser cladding

A technology of laser cladding and steel grade, which is applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of sensitive drill pipe material strength, drill pipe strength that cannot meet the actual drilling needs, and brittle fracture, etc., to achieve Improve the H2S stress corrosion cracking resistance, ensure the overall performance requirements, and increase the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

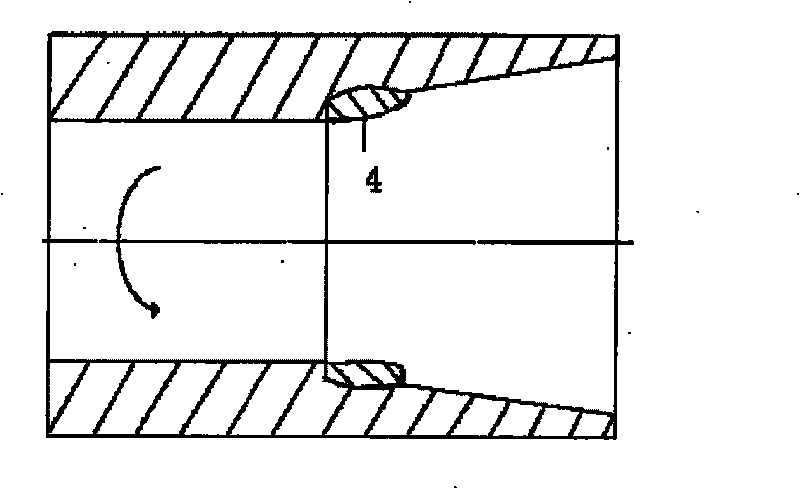

[0026] Under the condition of inert gas and air isolation, the nickel-based alloy corrosion-resistant material is clad on the inner and outer pipe walls 1 and 2 of the S135 steel grade drill pipe with conventional performance by laser, and nickel is coated on the inside and outside of the non-threaded area of the drill pipe joint 7 base alloy corrosion-resistant layer, and then apply a nickel-based alloy corrosion-resistant layer on the taper surface of the joint thread 3 and 4, and then process the thread 5, and then the end of the pipe body 6 and the joint 7 are formed by friction welding.

[0027] The output power of the laser is 3.5-4.5kw;

[0028] Laser beam spot (melt pool) size ≤ φ3mm;

[0029] The defocus amount is 25-32mm;

[0030] Laser beam scanning line speed is 6.5-7.5mm / s;

[0031] The angle between the laser beam and the long axis of the tube is 40-50°;

[0032] The delivery rate of cladding wire is 15-20g / s;

[0033] During the cladding process, the steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com