Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

211results about How to "Guaranteed Performance Requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

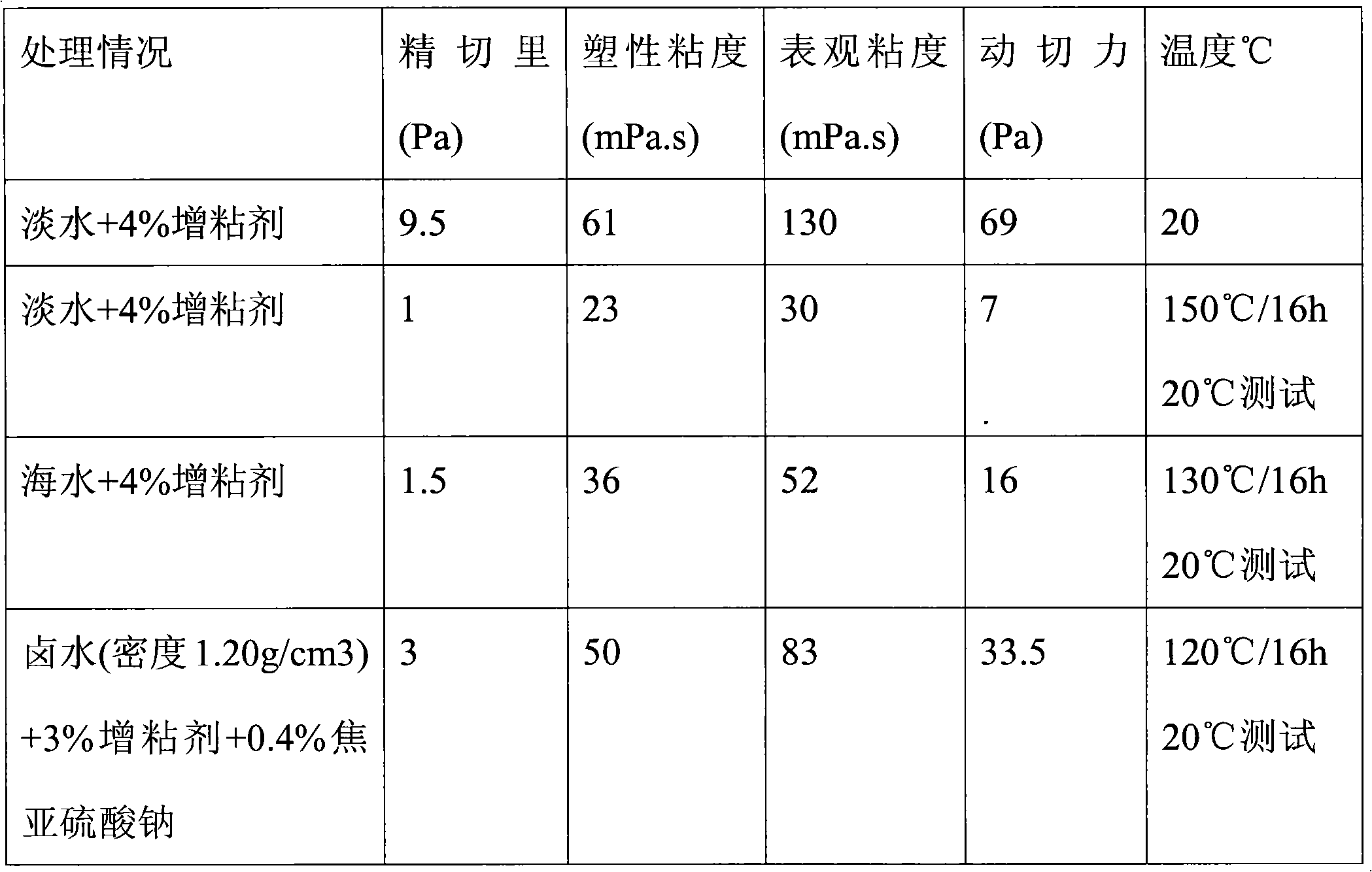

High-temperature resistance tackifier for drilling fluid and preparation method thereof

ActiveCN102127401AGood resistance to salt and viscosity increaseImprove temperature resistanceDrilling compositionTemperature resistanceSolvent

The invention relates to a petroleum drilling fluid, in particular to a high-temperature resistance tackifier for a drilling fluid and a preparation method thereof. The high-temperature resistance tackifier for the drilling fluid comprises the following components in parts by mass: 1 part of starch, 0.05-5 parts of guar gum, 0.01-2 parts of alkaline hydroxides, 0.02-6 parts of epoxide and 0-9 parts of alcohol solvent. The preparation method of the high-temperature resistance tackifier for the drilling fluid comprises the following steps of: adding the starch and the guar gum to a vessel, thenadding the epoxide and the alcohol solvent and stirring for 10-30min, then adding a water solution of alkaline hydroxides, continuously stirring and reacting for 20min-3h at 0-120 DEG C, discharging,drying and crushing to obtain a finished product. The tackifier prepared by adopting the preparation method disclosed by the invention achieves the purpose of improving the temperature resistance of a solid-free drilling fluid for a deep well and the viscosity and the shearing force of the drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

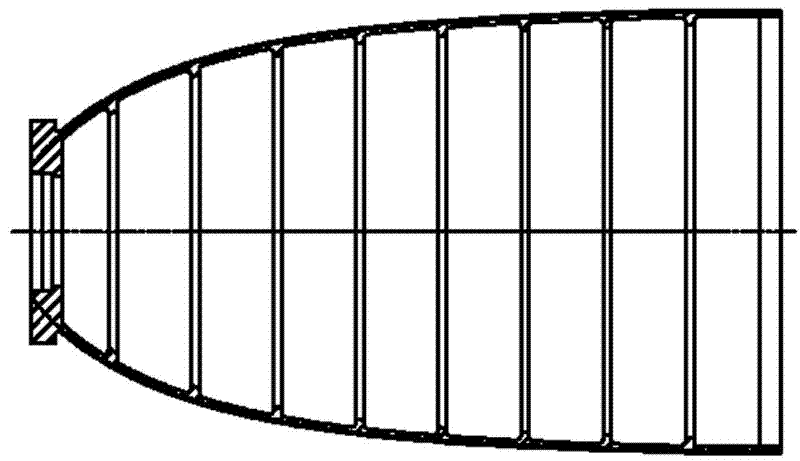

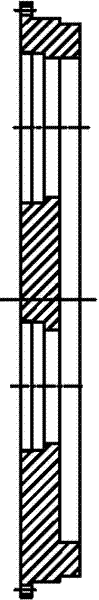

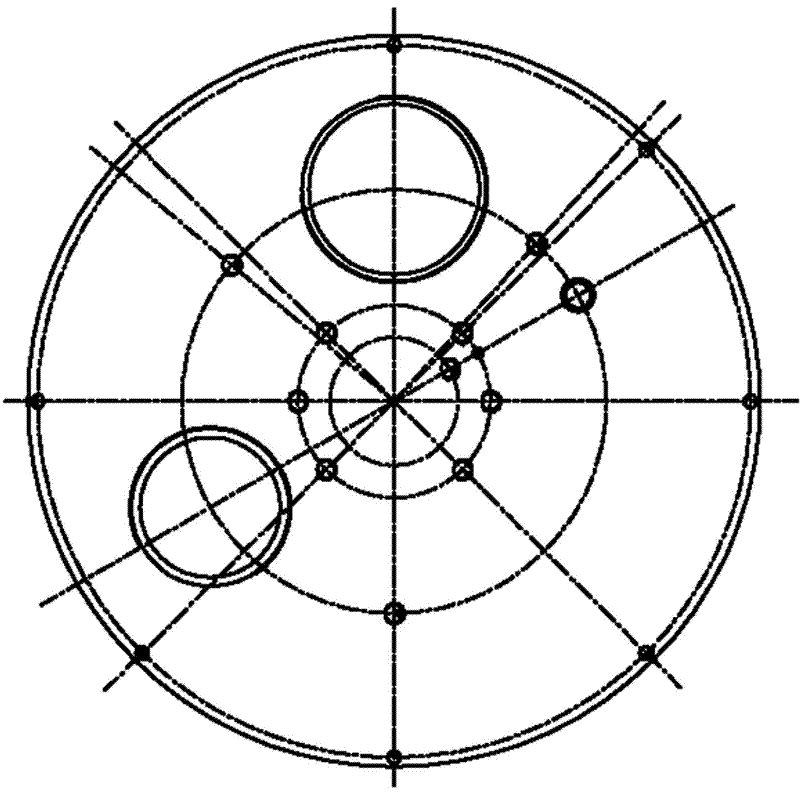

Processing method of thin and long aluminium alloy thin-walled cylinder

ActiveCN102513785AHigh material utilizationShort processing cycleNon-electric welding apparatusWeld seamThin walled cylinder

The invention provides a processing method of a thin and long aluminium alloy thin-walled cylinder and belongs to a mechanical processing method of a slewing structure, and the processing method is used for carrying out friction stir welding on a shell blank so as to process and mold the shell blank into a bent generatrix thin-walled cylinder shell. The method provided by the invention can be used for solving the problems of poor shell generatrix displacement, poor shell roundness, uneven wall thickness, clearance at welding seams, unqualified performance detection and incapability of ensuring use requirements in the existing processing method. The method comprises a part manufacturing step, a matching step, a caustic washing step, a trial assembly step, a positioned welding step, a friction stir welding step, a welding seam polishing step, a stress-relief annealing step, an X-ray detection step, a shape processing step, a ultrasonic flaw detection step and an end face hole processingstep. The method provided by the invention can be used for solving the problems of poor shell roundness, uneven wall thickness, clearances at the welding seams and unqualified performance detection in the existing processing method, improving the shell processing precision and reliably ensuring the product quality.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

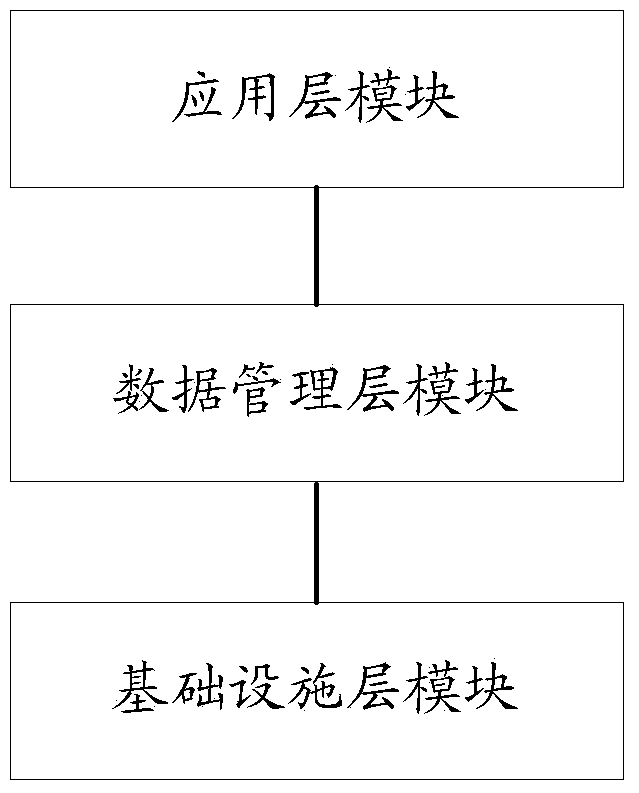

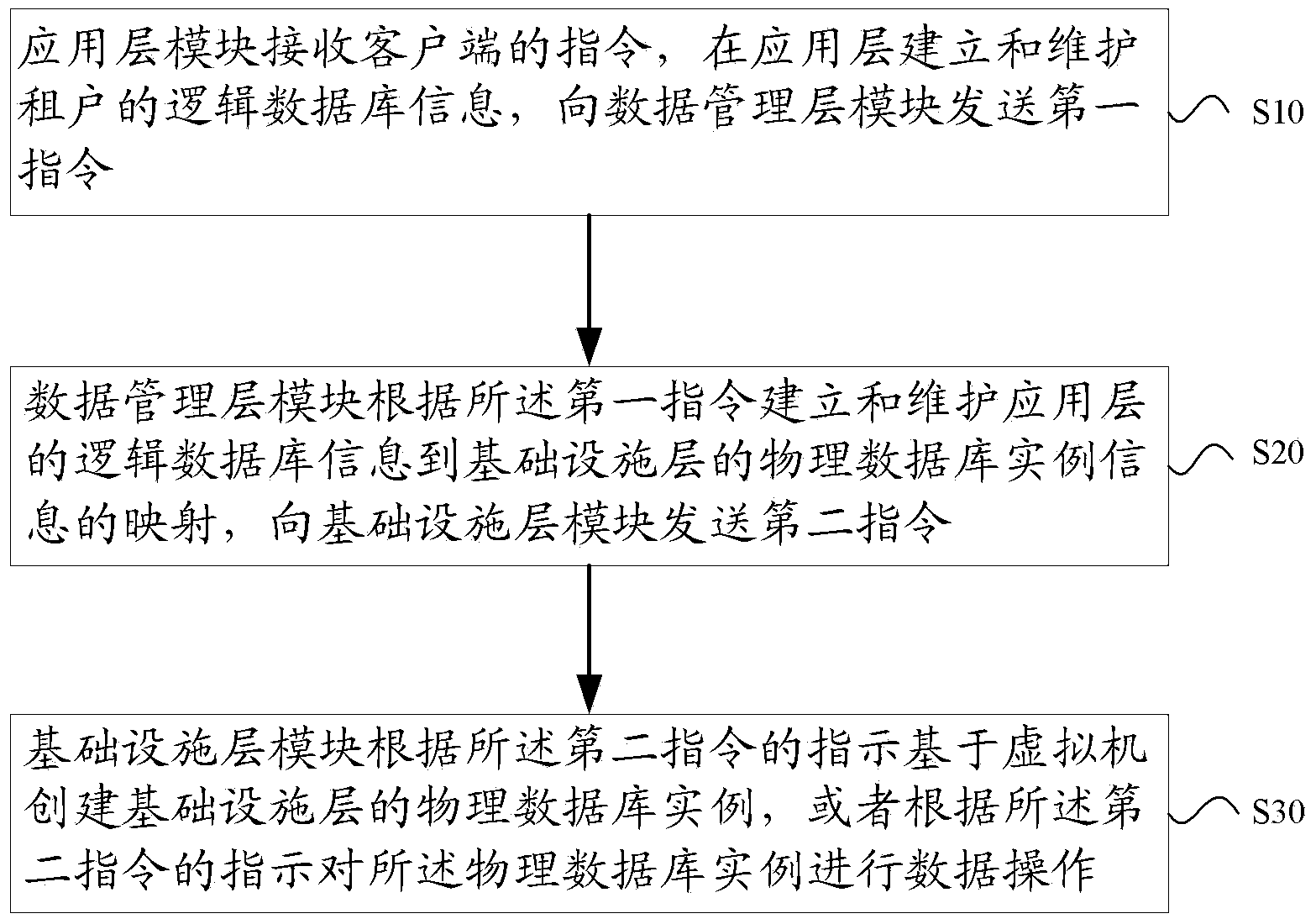

Multi-tenant database sharing method and multi-tenant database as-a-service system

ActiveCN103544319AGuaranteed performance requirementsAchieve performance isolationProgram controlSpecial data processing applicationsClient-sideVirtual machine

The invention discloses a multi-tenant database as-a-service system. The multi-tenant database as-a-service system comprises an application layer module for receiving a client-side instruction, establishing and maintaining logical database information of tenants and sending a first instruction to a data management layer module, the data management layer module for establishing and maintaining mapping of the logical database information of an application layer to physical database instance information of an infrastructure layer according the first instruction and sending a second instruction to an infrastructure layer module, and the infrastructure layer module for establishing physical database instances of the infrastructure layer according to indication of the second instruction based on a virtual machine or performing data operation on the physical database instances according to the indication of the second instruction. The multi-tenant database as-a-service system can achieve performance isolation of the tenants and ensures the performance demands of the tenants. The invention further provides a multi-tenant database sharing method.

Owner:INSPUR BEIJING ELECTRONICS INFORMATION IND

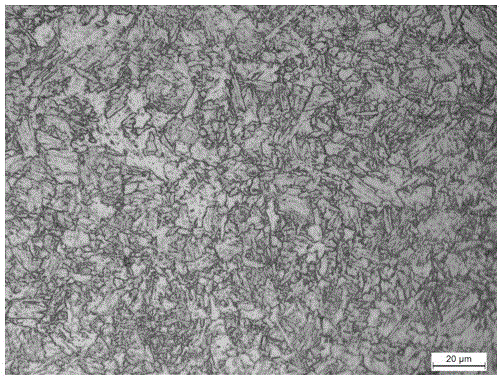

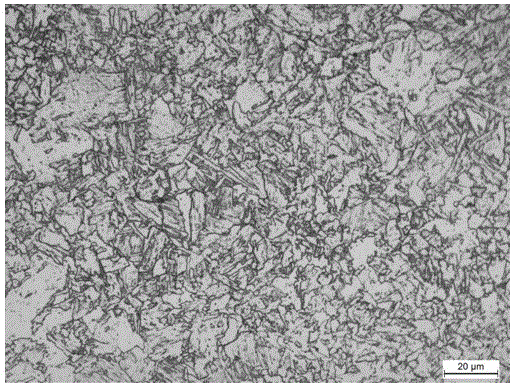

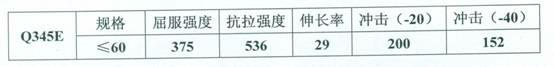

Steel plate for hardening and tempering type low temperature pressure vessel and method for producing steel plate

The invention discloses a steel plate for a hardening and tempering type low temperature pressure vessel with ultralimit thickness, low crack sensitivity and high strength and a method for producing the steel plate. The steel plate comprises the following chemical constituents according to percent by weight: 0.065-0.085% of C, 0.15-0.25% of Si, 1.30-1.50% of Mn, 0.40-0.45% of Ni, 0.15-0.25% of Cr, 0.20-0.25% of Mo, 0.035-0.045% of V, 0.030-0.045% of of Nb, 0.025-0.03% of Ti, 0.020-0.05% of Alt, 0.015% of P, 0.005% of S and the balance of Fe; and the method for preparing the steel plate comprises the steps that molten steel is smelted according to set constituents, the molten steel is cast into a casting blank, two stages of rolling, i.e. rough rolling and fine rolling are carried out after the heating, after quick cooling, a hardening and tempering technology is carried out for thermal treatment, matching of excellent strength, plasticity, cold bending and shock resistance can be achieved, and the requirement of the steel for the low temperature pressure vessel is satisfied.

Owner:NANJING IRON & STEEL CO LTD

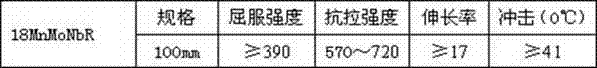

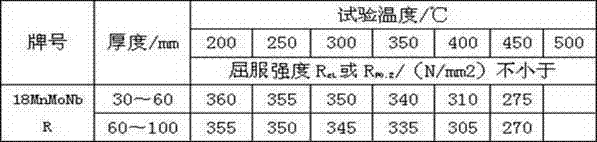

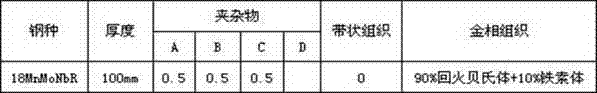

Steel 18MnMoNbR for pressure vessel and process for producing 18MnMoNbR steel plate with thickness of 100mm

The invention discloses steel 18MnMoNbR for a pressure vessel. The steel 18MnMoNbR comprises the following chemical components in percentage by weight (wt%): 0.16-0.20% of C, 0.25-0.45% of Si, 1.35-1.45% of Mn, 0.5-0.6% of Mo, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.015-0.040% of Als, 0.030-0.040% of Nb, 0.010- 0.020% of Ti and the balance of Fe and other residual elements, wherein the carbon equivalent of the chemical components is less than or equal to 0.04. Furthermore, the invention provides a process for producing an steel 18MnMoNbR plate with a thickness of 100mm. Due to the processes of pretreating molten iron by adopting the KR method, smelting by a converter, blowing argon, carrying out LF refining, carrying out VD refining, casting a die, heating, controlling rolling and cooling, cooling a pile and carrying out heat treatment, the content of harmful elements such as P and S which can affect the toughness of the steel 18MnMoNbR plate in steel can be controlled on the basis of guaranteeing the components of the steel 18MnMoNbR. In addition, by strictly controlling the heating cycle of the rolled steel, strictly controlling finishing rolling temperature, the reddening temperature and the cooling speed in the rolling process and cooling the steel-plate pile slowly, all the performance indexes of the steel 18MnMoNbR plate with the thickness of 100mm can meet the standard requirements.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

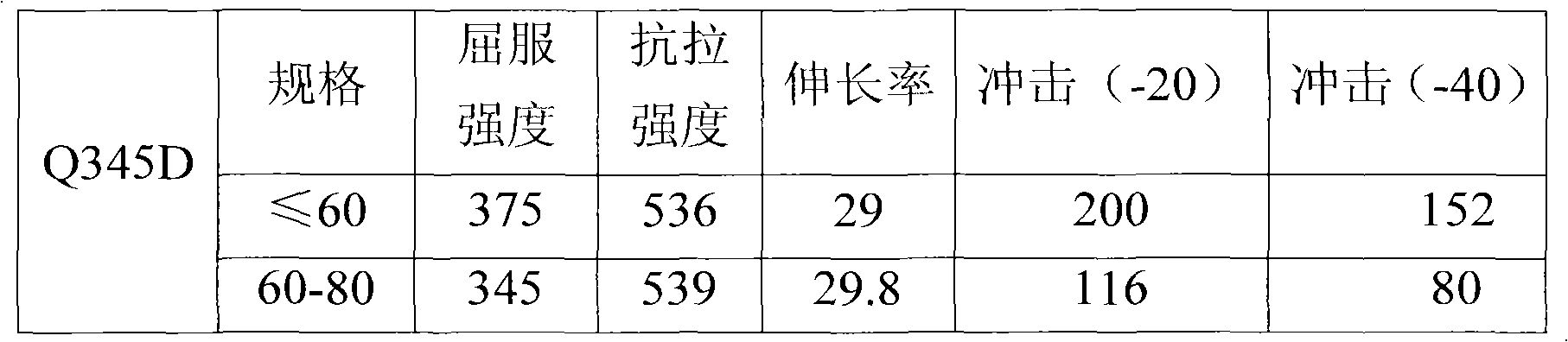

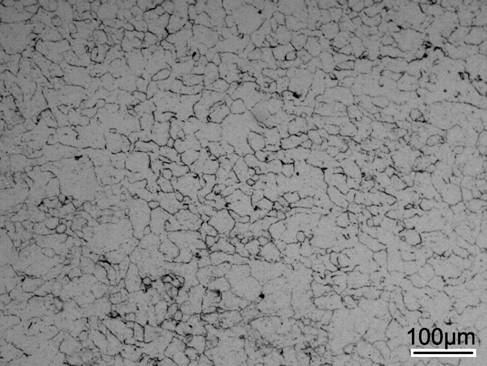

Low-alloy Q345D thick plate produced without adding micro-alloy elements and production method thereof

ActiveCN102080181AGuaranteed purityGuaranteed Performance RequirementsTemperature control deviceThick plateDegasser

The invention discloses a low-alloy Q345D thick plate produced without adding micro-alloy elements and a production method thereof. The method disclosed by the invention is characterized in that on the premise of not adopting vacuum decarburization equipment such as an RH and the like, through using the existing equipment such as a VD (vacuum degasser) and the like of enterprises, the requirements for smelting low-carbon steel plates and extreme low carbon steel plates are met, therefore, under the condition that the profits of the enterprises at the present stage are not high, a heavy investment in large-scale equipment replacement and remodeling is avoided, thereby saving the investment for the enterprises, completely using the existing equipment of the enterprises, greatly reducing the capital investment of the enterprises at the present stage, and providing abundant preparation time for equipment replacement after the market situation takes a favorable turn in the future and the profits of the enterprises are improved.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

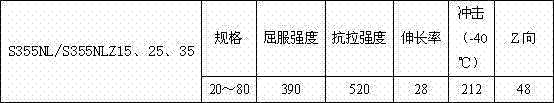

Weldable fine grain structural steel S355NL/S355NLZ35 steel plate and its production method

InactiveCN102345055AGuaranteed purityReduce performance requirementsTemperature control deviceWork treatment devicesHeating systemLadle furnace

The invention discloses a weldable fine grain structural steel S355NL / S355NLZ35 steel plate, which comprises the following chemical components by wt%: 0.10-0.18of C, 0.20-0.45 of Si, 1.20-1.45 of Mn, less than or equal to 0.018 of P, less than or equal to 0.005 of S, 0.015-0.050 of Als, 0.010-0.055 of V, 0.005-0.025 of Ti, and the balance Fe and residual elements. The production method consists of: KR molten iron pretreatment, converter smelting, argon blowing treatment, LF (ladle furnace) refining, VD (vacuum degassing) refining, continuous casting, heating, controlled rolling and controlled cooling, stack cooling, and normalizing. According to the invention, content and proportion of C, Mn and Nb alloy elements are adjusted properly, and content of harmful elements in steel like P and S etc. influencing the plasticity and toughness of the steel plate is strictly controlled, and meanwhile, the heating system of steel rolling is strictly controlled. The rolling process employs a mode of lowering finish rolling temperature, speeding up cooling after rolling, and conducting steel plate stacking and slowing cooling after rolling, thus guaranteeing all performance indexes of the weldable fine grain structural steel S355NL / S355NLZ35 steel plate meeting the standard requirements.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

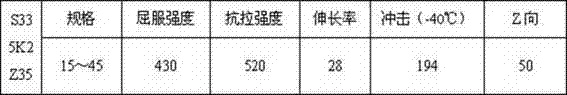

Hot-rolled structural steel ST52 medium-thick plate with thickness of 15-60mm and production method thereof

InactiveCN102345053AGuaranteed purityGuaranteed Performance RequirementsTemperature control deviceWork treatment devicesSlow coolingLadle furnace

The invention discloses a hot-rolled structural steel ST52 medium-thick plate with the thickness of 15-60mm. The thick plate comprises the following chemical components by weight percent (wt%): 0.10-0.16wt% of C, 0.25-0.45wt% of Si, 1.20-1.50wt% of Mn, less than or equal to 0.017wt% of P, less than or equal to 0.003wt% of S, 0.015-0.055wt% of Als, 0.020-0.040wt% of Nb, 0.010-0.020wt% of Ti and the balance of Fe and residual elements, wherein C equivalent amount [Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15] is less than or equal to 0.41. According to the invention, through KR molten iron pretreatment, converter smelting, argon blowing treatment, LF (ladle furnace) refining, VD (vacuum degassing) refining, continuous casting, heating, controlled rolling and controlled cooling and piling cooling processes and on the basis of ensuring the ST52 components, the contents of harmful elements such as P, S and the like, influencing the plasticity and toughness of the steel plate, in steel are strictly controlled, and simultaneously, the heating system of rolled steel is strictly controlled; and in the rolling process, final rolling temperature, red returning temperature and cooling speed are rigidly controlled, and methods such as steel plate stacking and slow cooling and the like are adopted, the various properties of the ST52 steel plate with the thickness of 15-60mm reach standard requirements.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

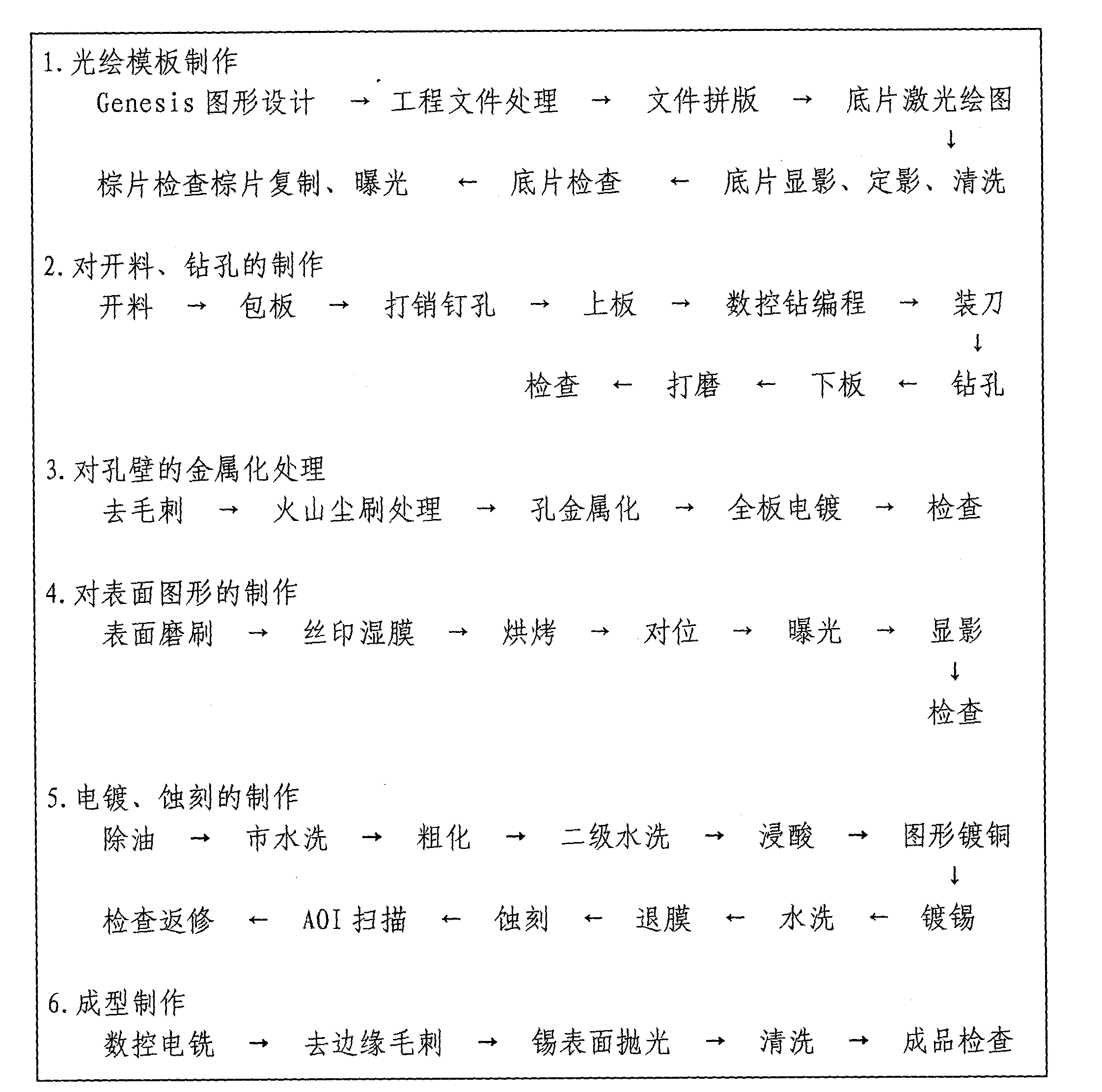

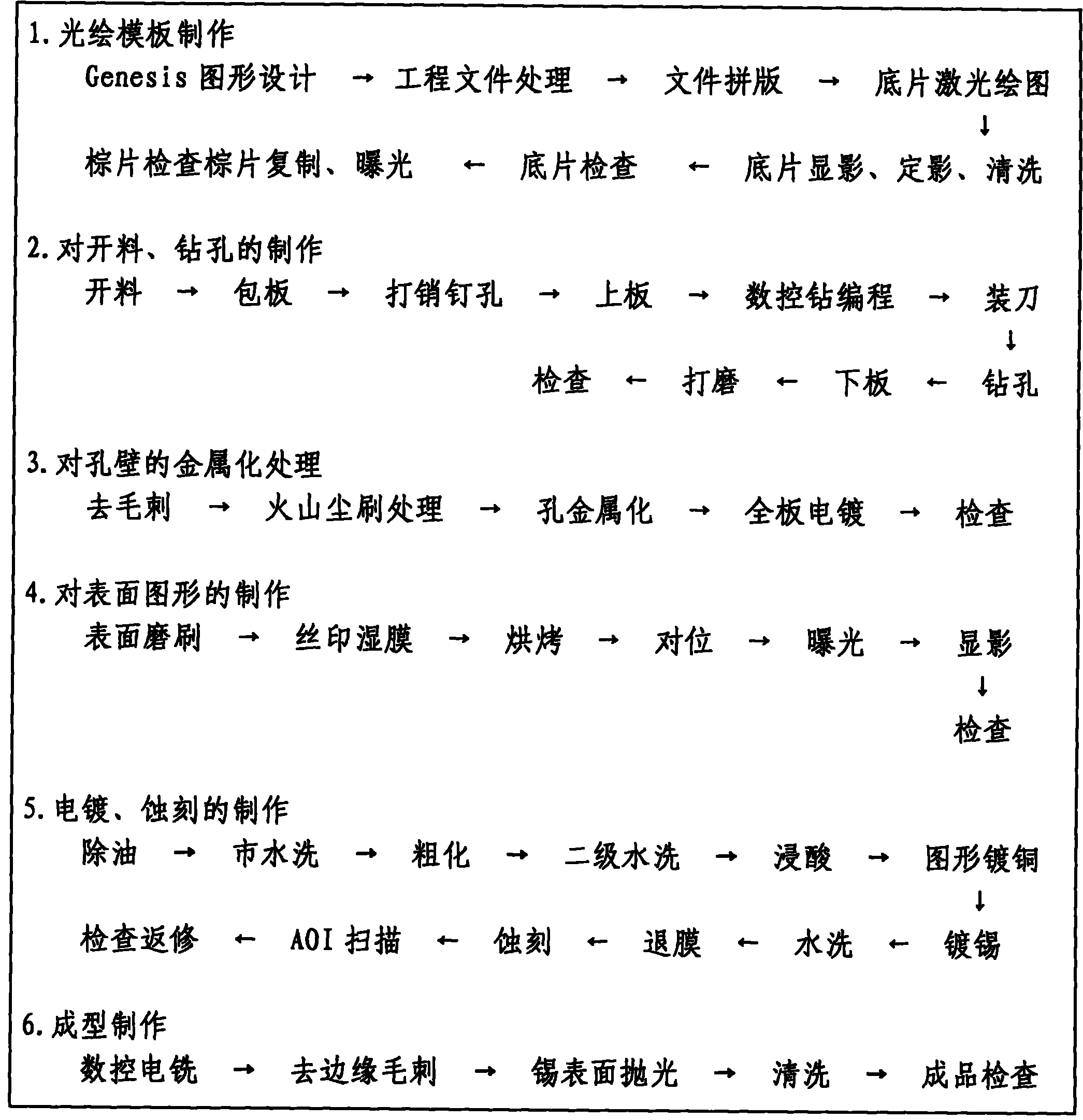

Method for manufacturing ultra-long microwave high-frequency circuit board

InactiveCN101808464AIncrease porosity densityImprove bindingConductive material chemical/electrolytical removalPrinted element electric connection formationMicrowaveEngineering

The invention discloses a method for manufacturing an ultra-long microwave high-frequency circuit board, comprising the following steps: (1) manufacturing a light potting template; (2) shearing to form an ultra-long combination board, and drilling holes on the ultra-long combination board; (3) metallizing the walls of the holes; (4) making patterns on the ultra-long combination board; (5) electroplating and etching the ultra-long combination board; and (6) forming the ultra-long combination board into the ultra-long microwave high-frequency circuit board. The method for manufacturing the ultra-long microwave high-frequency circuit board has high precision, and the ultra-long microwave high-frequency circuit board manufactured with the method has stable performance and can effectively improve the product quality and the work efficiency.

Owner:施吉连

Automotive transmission case and manufacturing method thereof

InactiveCN104561858AImprove wear resistanceHigh tensile strengthGearboxesTemperingCryogenic treatment

The invention relates to an automotive transmission case and a manufacturing method thereof. The automotive transmission case with high strength and high tenacity is obtained by preparing a mold for a specific component magnesium alloy; preparing materials, smelting, extruding and casting; quenching, carrying out cryogenic treatment, tempering and carrying out aging treatment.

Owner:邯郸市宝特铸造有限公司

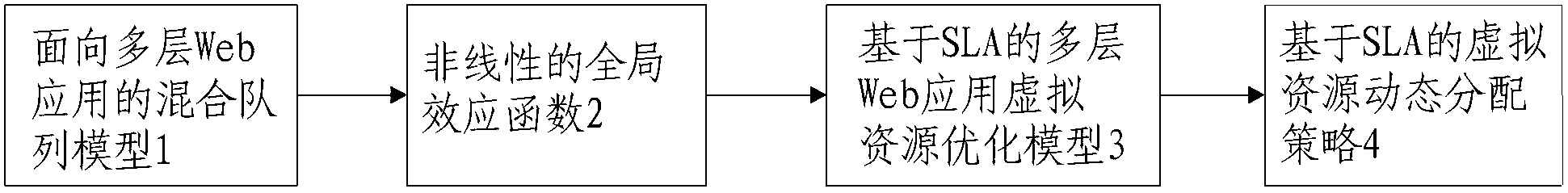

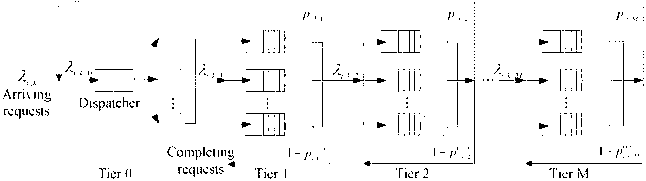

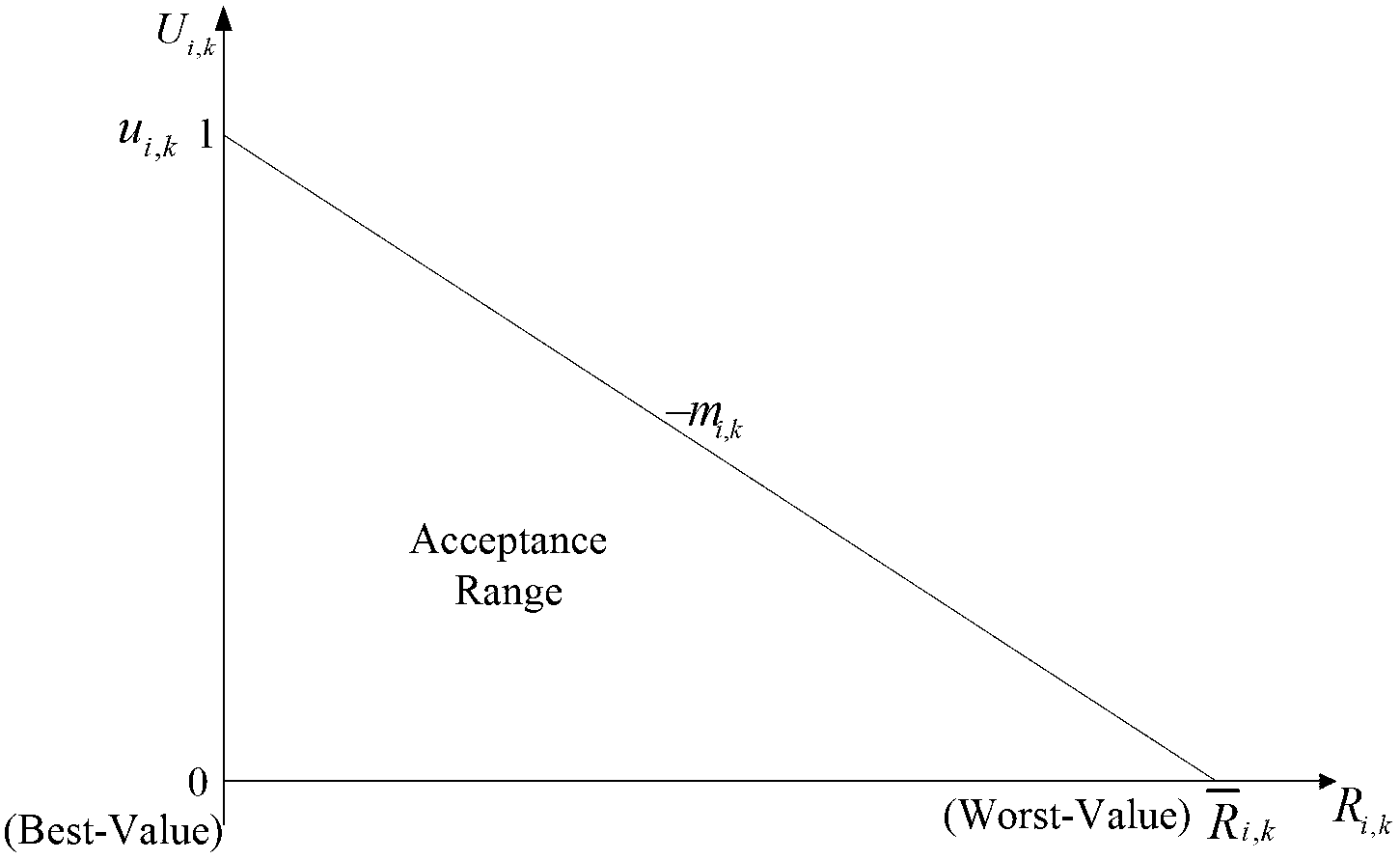

Resource optimizing method applied to multi-layer web application based on SLA (Service Level Agreement)

ActiveCN103064744AGlobal effect maximizationEasy to manageResource allocationUser needsService-level agreement

The invention relates to a resource optimizing method applied to a multi-layer web application based on a SLA (Service Level Agreement). A mixed queue module which is formed by an M / M / c model and an M / G / 1 model for the multi-layer web application based on a queuing theory is put forward according to virtual resources and user requirements. A non-linear overall-situation effect function is established for an infrastructure provider; the resource optimizing model of the multi-layer web application system based on the SLA is established; and dynamic distributing strategy of the virtual resources based on SLA is provided to obtain an optimal virtual resource allocation. The resource optimizing method applied to the multi-layer web application based on the SLA achieves optimizing of the virtual resources and maximization of inherent effects of the virtual resources simultaneously and satisfies performance requirements of web application users due to the fact that the infrastructure provider of the multi-layer web application needs to be in accordance with the SLA.

Owner:BEIJING SIMULATION CENT

Method for manufacturing high steel grade sulfur resistant drill pipe by laser cladding

ActiveCN101722403AIsolated contactImprove anti-H

<sub>2</sub>

S stress corrosion cracking performanceMetallic material coating processesLaser beam welding apparatusFriction weldingSulfur

The invention relates to a method for manufacturing a high steel grade sulfur-resistant drill pipe by laser cladding. In the method, in the condition of inert gas insulating air, nickel-base alloy anti-corrosion material is clad on the inner and outer pipe walls of an S135 steel grade drill pipe with conventional properties by laser, a nickel-base alloy anti-corrosion layer is clad on the non-thread area of a joint, threads are processed on the thread conical surface of the joint after a nickel-base alloy anti-corrosion layer is clad on the thread conical surface of the joint, and the end part of a pipe body is oppositely connected with the joint through friction welding; the output power of the laser is 3.5-4.5kW; laser beam spot size is not more than Phi 3mm; defocusing amount is 25-35mm; laser beam scanning line speed is 6.5-7.5mm / s; the inclined angle between the laser beam and the long axis direction of the pipe body is 40-50 degree; and the delivery rate of cladding wire material is 15-20g / s. The drilling pipe reaches the property of the S135 steel grade drilling pipe by the APE Spec standard. The cladding layer can effectively prevent a base body from contacting natural gas to improve the H2S-resistant stress corrosion cracking performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

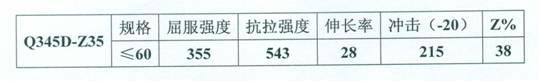

Low-alloy medium-thickness steel plate Q345D-Z35 and production process thereof

InactiveCN102041441AMatching strengthMatching plasticityTemperature control deviceSheet steelChemical composition

The invention discloses a low-alloy medium-thickness steel plate Q345D-Z35 produced without adding microalloy elements and a production process thereof. The steel plate contains the following chemical components in percentage by mass (with wt% as a unit): 0.10 to 0.18 percent of C, 0.20 to 0.45 percent of Si, 1.20 to 1.60 percent of Mn, less than or equal to 0.018 percent of P, less than or equal to 0.005 percent of S, 0.015 to 0.050 percent of Als and the balance of Fe and residual elements. The production method comprises the following steps of: pretreatment with high-quality molten iron or KP molten iron, blowing in a top and bottom combined blown converter, ladle furnace (LF) refining, vacuum degassing treatment, casting blank cooling in pile, treatment in a heating furnace, rolling, ACC (Active Calcium Carbonate) laminar cooling, treatment in a hot straightening machine, cooling in pile, finishing, external inspection, flaw detection and warehousing. The steel plate has the advantages that: compared with the traditional Q345D-Z35, under the conditions that the carbon equivalent is not changed and precious alloys of Nb, Ti and the like are not added, the various performance indexes of the Q345D-Z35 are ensured to meet the national standard requirements, and the production cost is greatly reduced.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

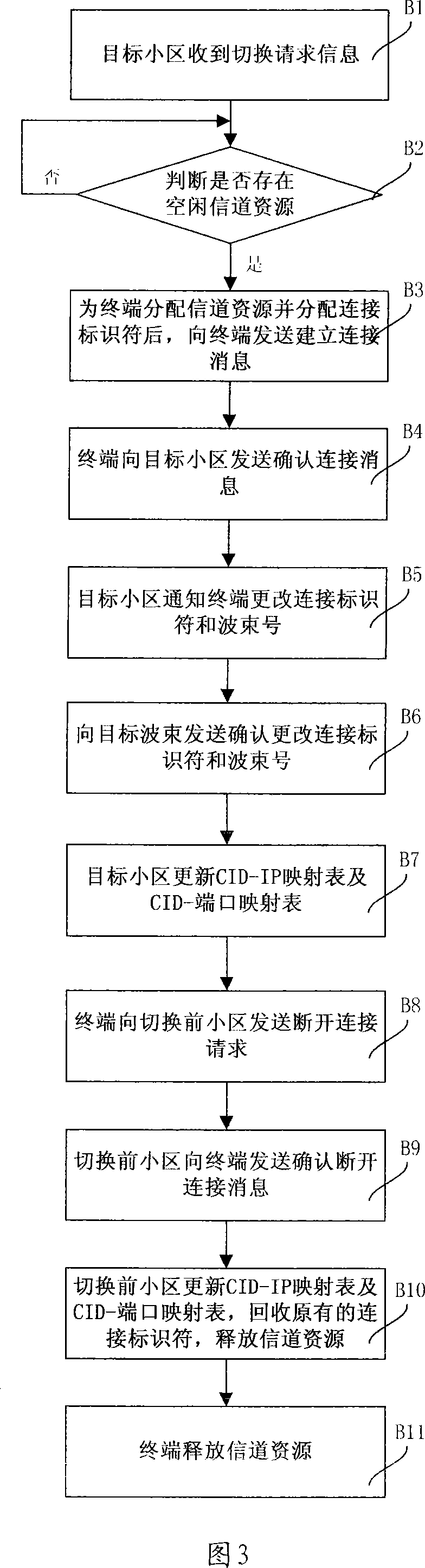

Planet-earth link switching method and planet-earth link switching mode selection processing device

InactiveCN101022668AGuaranteed Performance RequirementsReduce switching costsNetwork topologiesRadio/inductive link selection arrangementsMode selectionSatellite

A method for switching over link of satellite / ground includes selecting cell-in switching-over mode to carry out switching-over operation if current wave beam and object wave beam are in the same cell, selecting intercell switching-over mode to carry out switching-over operation if current wave beam and object wave beam are in the same satellite but not in the same cell and selecting intersatellite switching-over mode to carry out switching-over operation if current wave beam and object wave beam are not in the same satellite. The device used for realizing said method is also disclosed.

Owner:BEIHANG UNIV

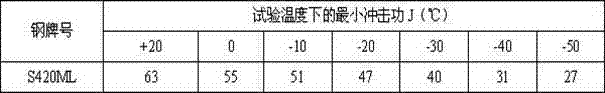

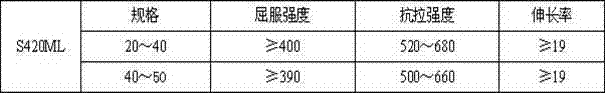

Structural steel S420ML medium and heavy plate and production method thereof

InactiveCN102345056AAvoid excessive grain growthGuaranteed purityRoll mill control devicesMetal rolling arrangementsHeating systemCooling speed

The invention discloses a structural steel S420ML medium and heavy plate comprising chemical components of, by weight: 0.12 to 0.15% of C, 0.25 to 0.40% of Si, 1.45 to 1.55% of Mn, no more than 0.017% of P, no more than 0.003% of S, 0.015 to 0.035% of Als, 0.030 to 0.040% of Nb, 0.010 to 0.020% of Ti, 0.010 to 0.020% of Ni, and balance of Fe and residual elements. The carbon equivalent is represented by that: [Ceq=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15]<=0.41. The production method of the plate comprises processes of KR hot metal pretreating, converter smelting, argon-blowing treating, LF refining, VD refining, continuous casting, heating, controlled rolling and controlled cooling, and stack cooling. During the processes, a TMCP rolling technology and a steel plate stacking and sustained-cooling technology are adopted. With the method provided by the invention, components in S420ML can be ensured; contents of harmful elements such as P and S can be strictly controlled; a heating system in the steel rolling process is strictly controlled; during a rolling process, a finishing temperature, a self-tempering temperature and a cooling speed are strictly controlled; and methods such as a steel plate stacking and sustained-cooling technology are adopted. Therefore, performance indexes of a 20-50mm hot-rolled weldable fine-grain structural steel S420ML medium and heavy plate can reach required standards.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

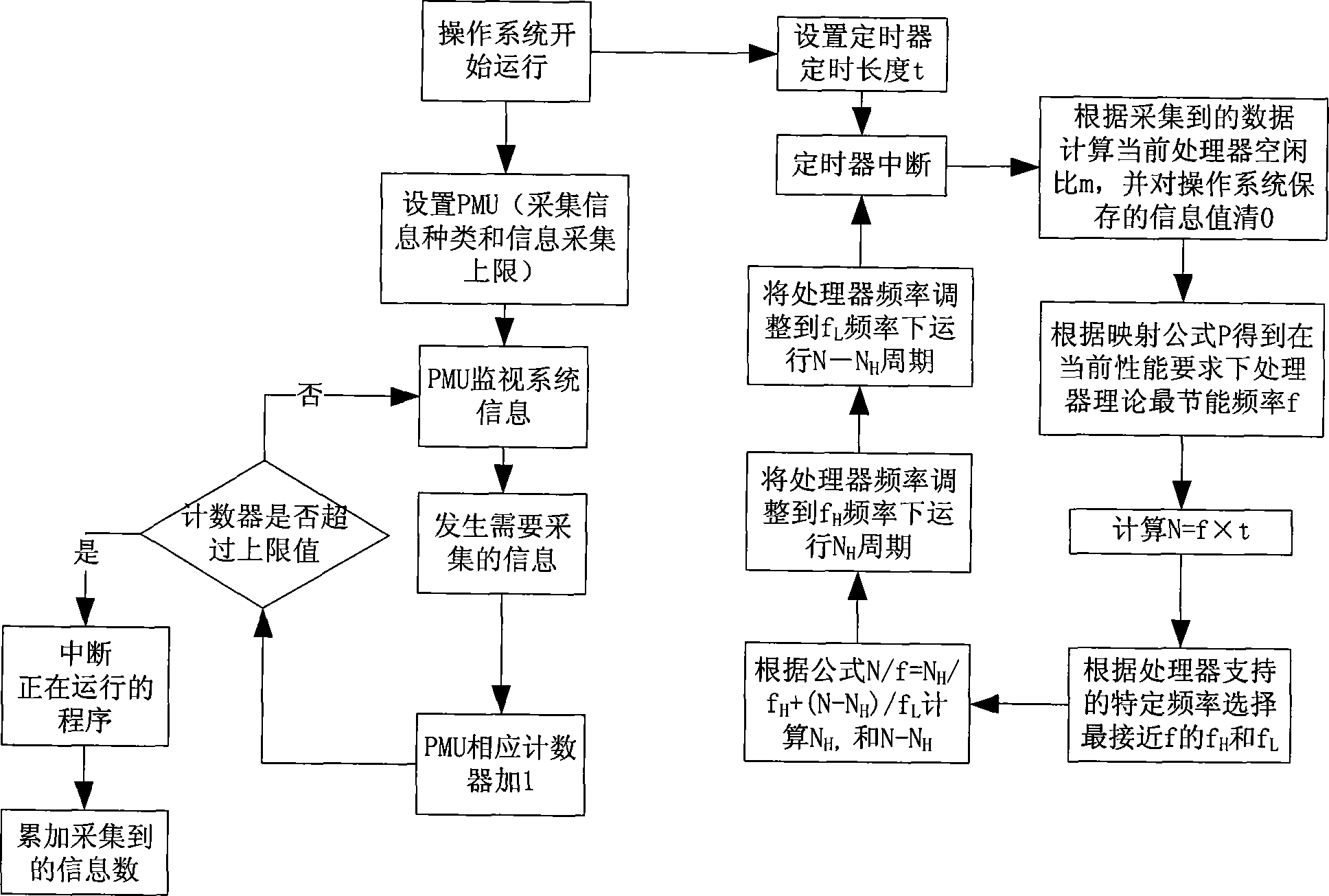

Embedded type low-power consumption operating system dynamic frequency regulation mapping method

InactiveCN101216727AGuaranteed performanceEnsure stabilityMultiprogramming arrangementsPower supply for data processingOperational systemProcessor frequency

The invention discloses a mapping method for adjusting the dynamic frequency in an imbedded low-power operating system and provides a new method and technology for modeling, addressing and optimizing the mapping issue during the dynamic adjustment of the processor frequency in an embedded low-power operating system. The invention uses the method that the operating frequency of the processor maps the most energy saving frequency of the theoretic processor upwards and downwards to the actual adjustable voltage in order to serve the energy saving purpose, and meanwhile to ensure the performance requirement for the system. The invention is based on a processor frequency mapping model, through which the most energy saving frequency of the theoretic processor is mapped to the actual adjustable processor frequency. When in operation, the operating system uses dynamic frequency and voltage modulation technology to determine the theoretically most energy saving operating frequency under current performance requirement according to the performance requirement and the operating status of the processor, and maps the most energy saving frequency to the actual processor frequency in order to serve the energy saving purpose.

Owner:ZHEJIANG UNIV

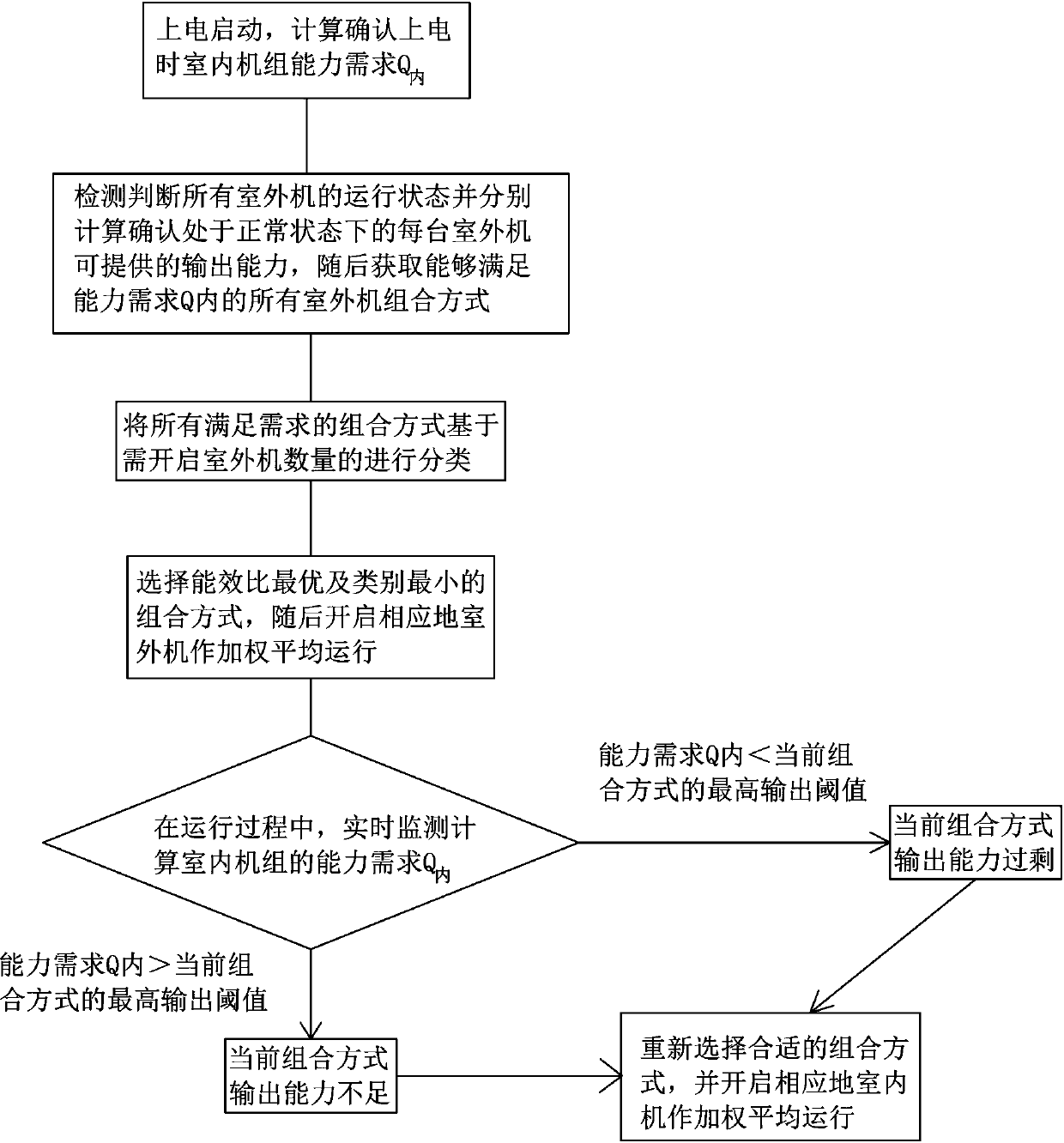

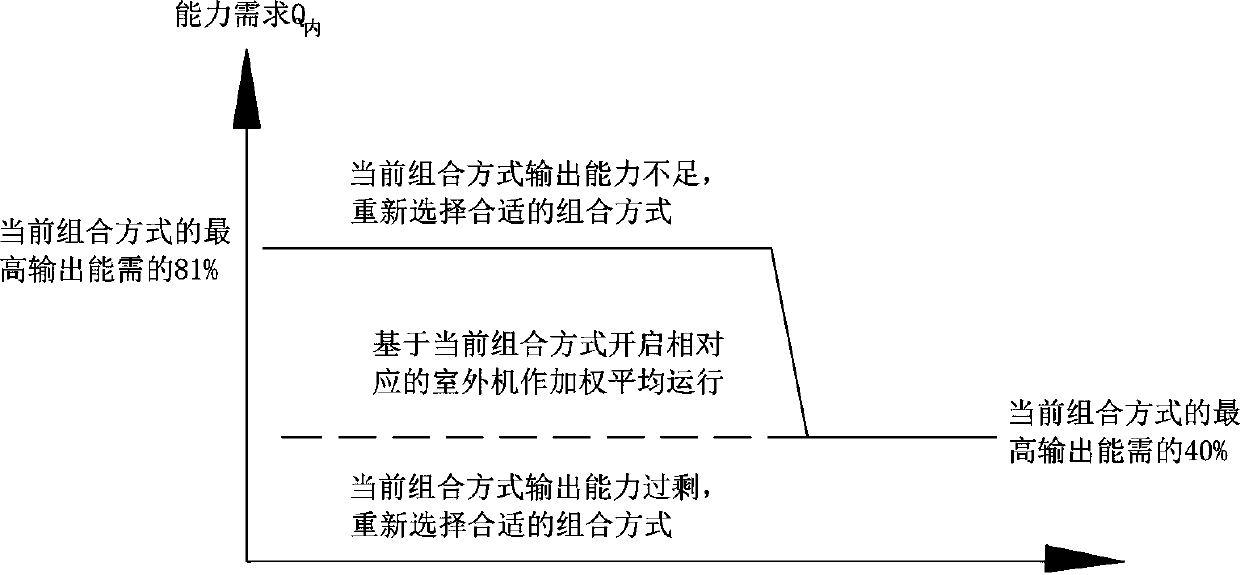

Dynamically-adjusted module type multi-split air conditioner control method

InactiveCN110319540AGuaranteed Performance RequirementsGuaranteed operational reliabilityMechanical apparatusSpace heating and ventilation safety systemsElectricityBusiness efficiency

The invention discloses a dynamically-adjusted module type multi-split air conditioner control method. The method comprises the following steps that S1, when a multi-split air conditioner is electrified and started, the indoor unit capacity requirements Q-indoor unit generated in the electrifying process are calculated and confirmed; S2, the operation states of all outdoor units are detected and judged, the output capacity capable of being provided by each outdoor unit in the normal state is calculated and confirmed, then all the outdoor unit combination modes capable of meeting the capacity requirements Q-indoor unit are obtained, wherein each combination mode comprises at least one outdoor unit; S3, all the combination modes meeting the requirements are classified on the basis of the number of the outdoor units needing to be started; S4, the combination mode with the optimal energy efficiency ratio and the minimum category is selected, and then the corresponding outdoor units are started to perform weighted average operation; and S5, in the operation process, the indoor unit capacity requirements Q-indoor unit are monitored and calculated in real time, the indoor unit capacity requirements are dynamically monitored, the proper combination mode is dynamically selected, and the corresponding outdoor units are started to perform weighted average operation according to the reselected combination mode.

Owner:GUANGDONG CHIGO HEATING & VENTILATION EQUIP CO LTD

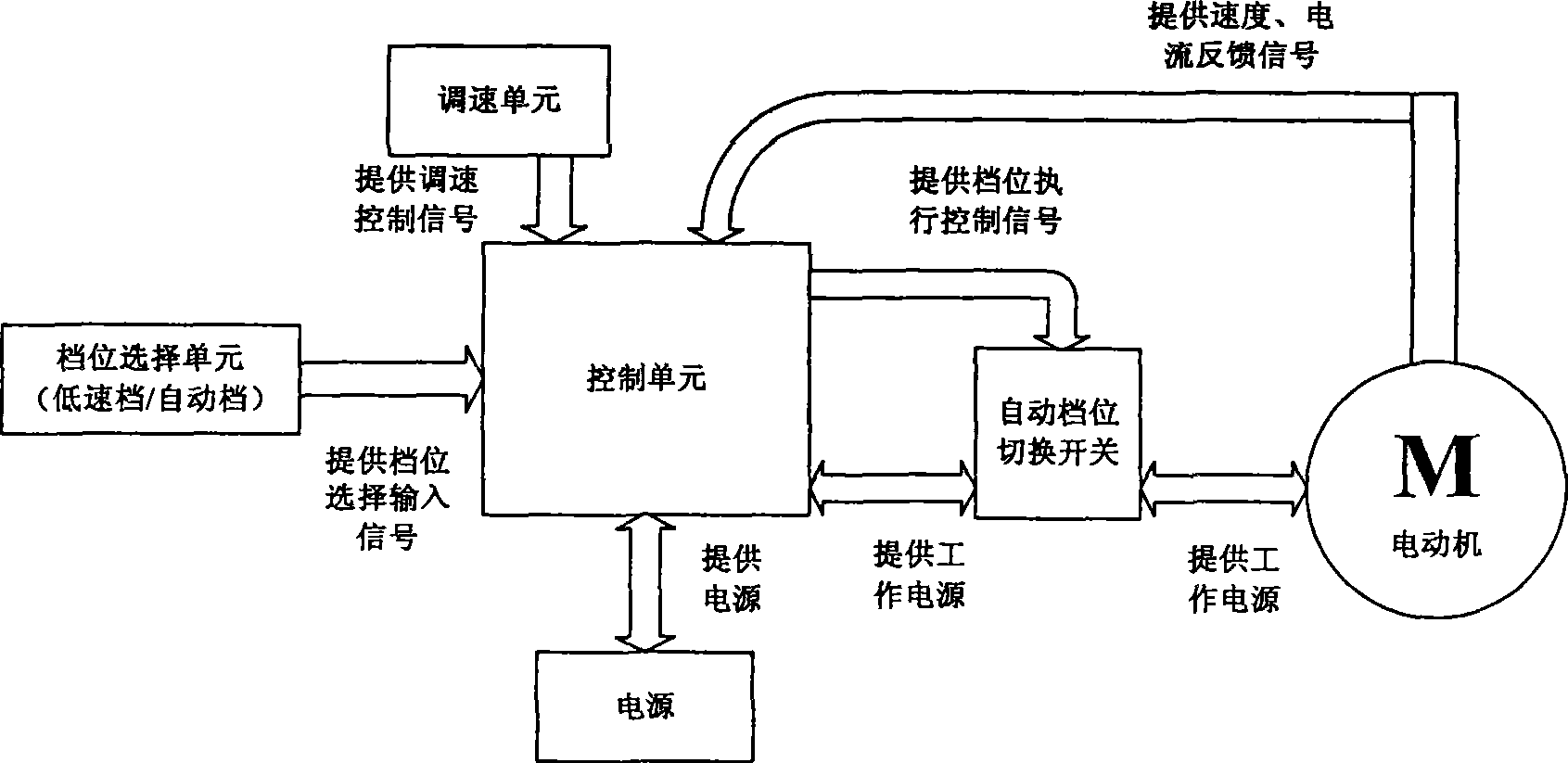

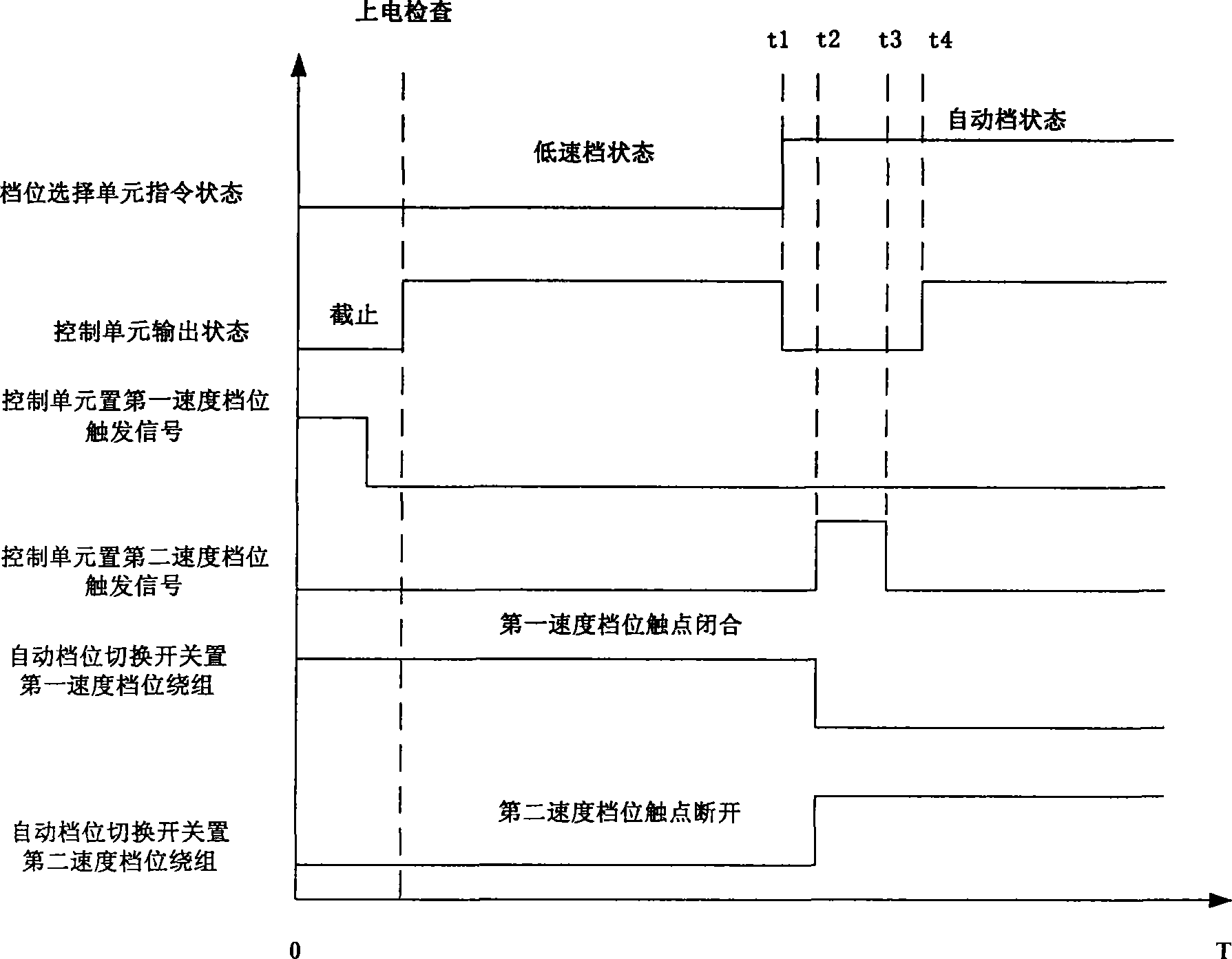

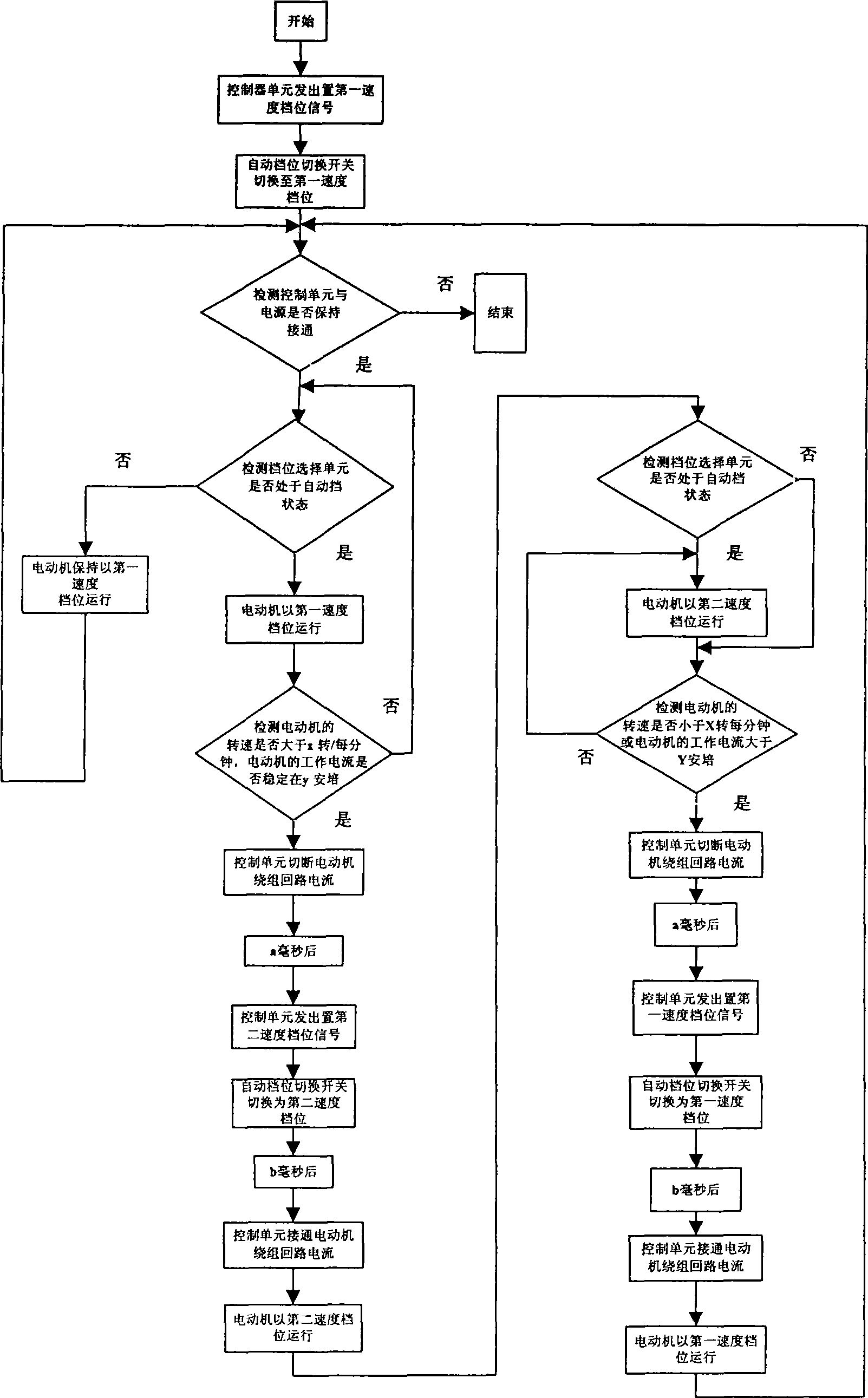

Shift control method for multi-stage motor

ActiveCN101505128AAvoid damageSimple preparation processSingle motor speed/torque controlField or armature current controlAuto regulationEngineering

The invention provides a gearshift control method for multi-gear motors. The method comprises the following steps: setting a plurality of speed gears, at least including a first speed gear and a second speed gear on an automatic gear switch, wherein the rotational speed value of a motor corresponding to the first speed gear is less than that of the motor corresponding to the second speed gear; placing the automatic gear switch in the first speed gear; confirming that a gear-selecting unit is in an automatic gear state; starting automatic gearshift function; and automatically regulating the rotational speed of the motor according to the load changes of the motor. The method also comprises the steps of confirming that the gear-selecting unit is in a low gear state, starting the function of running at uniform speed and placing or keeping the automatic gear switch in a preset speed gear. The gearshift control method for multi-gear motors has the advantages of adopting an electronic clutch mode, producing no arc during automatic gearshift, effectively solving the damage of arc to the automatic switch and automatically switching the gears of the motor according to the load changes.

Owner:JIANGSU XINRI E VEHICLE

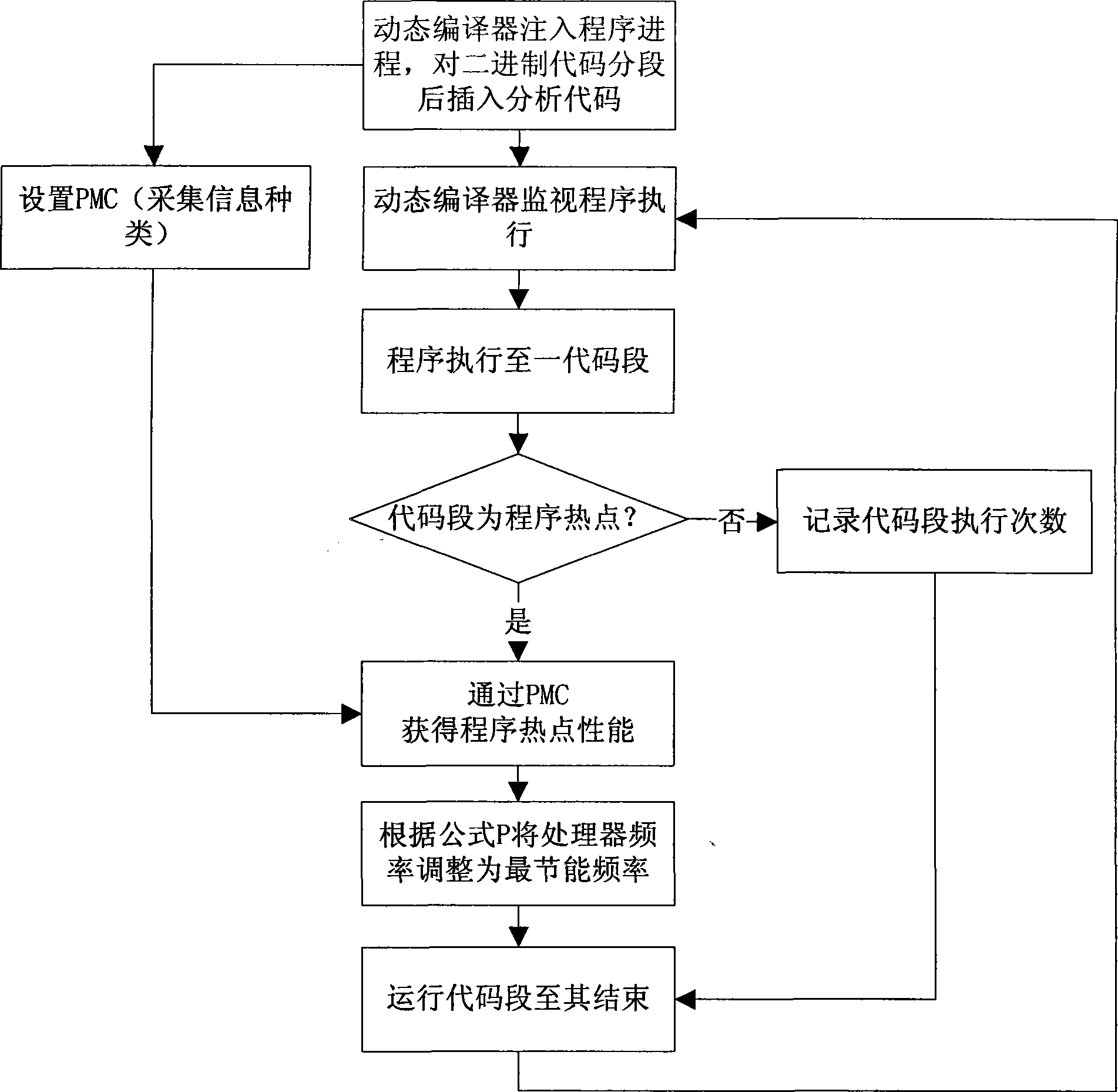

Method for controlling processor frequency when program operation by using dynamic compiler

InactiveCN101510115ATo achieve the purpose of energy savingGuaranteed Performance RequirementsEnergy efficient ICTPower supply for data processingProcessor frequencyPerformance tuning

The invention relates to the field of the energy-saving technology based on system software and aims at providing a method which can control the frequency of a processor by using a dynamic compiler when a program runs. The method includes the following steps: an analysis code is inserted; a hotspot of the program is dynamically determined when the program runs; the performance of the hotspot of the program is acquired; and the frequency of the processor is adjusted according to the performance of the hotspot of the program. By dynamically analyzing the performance of the program and using the frequency-adjusting function of the processor, the best energy-saving frequency of the program theory processor is mapped to an actual-adjustable voltage when the program runs so as to achieve the purpose of energy conservation and simultaneously ensure the performance requirements of the system. The invention is characterized by transparency, stability and practicability and the like.

Owner:ZHEJIANG UNIV

Information transmission method, terminal device and access network device

ActiveCN108282882AReduce performance lossAvoid reporting conflictsNetwork traffic/resource managementSignal allocationAccess networkComputer hardware

Embodiments of the application provide an information transmission method, a terminal device and an access network device. The information transmission method provided in the embodiments of the application may comprise the steps that: the terminal device determines N pieces of UCI that need to be transmitted in a same time unit, and transmits M pieces of UCI to the access network device on the basis of priorities of the N pieces of UCI, wherein N is an integer greater than or equal to 2, the N pieces of UCI include at least one of beam-forming information, buffer state report information and scheduling request information, the priorities of the M pieces of UCI are greater than that of the other N-M pieces of UCI in the N pieces of UCI, and M is a positive integer less than or equal to N. The embodiments of the application are capable of effectively preventing a conflict in reporting the UCI, ensuring the success rate of reporting the UCI, and effectively ensuring data transmission performance and service demand.

Owner:HUAWEI TECH CO LTD

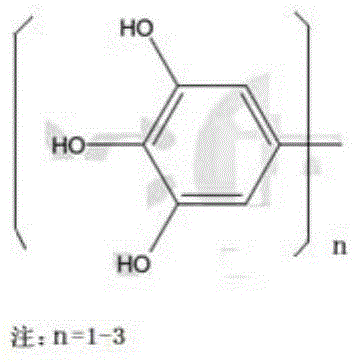

Phenol aldehyde molding compound for commutators

The invention discloses a phenol aldehyde molding compound for commutators, which is composed of a solid thermoplastic phenol aldehyde resin, a solid cardanol modified thermosetting phenol aldehyde resin, a solid melamine resin, a crystal whisker reinforcing material, a glass fiber reinforcing material, a mineral filler, a urotropine curing agent, a curing accelerator and a releasing agent. The material has higher toughness and higher dimensional stability under damp conditions. According to the phenol aldehyde molding compound, the cardanol modified thermosetting phenol aldehyde resin, thermoplastic phenol aldehyde resin and solid melamine resin are used as the adhesives, the crystal whisker and glass fiber are used as the reinforcing materials, the mineral is used as the filler, the urotropine is used as the curing agent, and the curing accelerator is also used, thereby ensuring the performance requirements of the material.

Owner:上海欧亚合成材料股份有限公司

Low-alloy Q345E medium plate and production process thereof

InactiveCN102041442AGuaranteed matching of strength and plasticityLow heating temperatureTemperature control deviceProcess efficiency improvementAlloy elementSteel plates

The invention discloses a low-alloy Q345E medium plate produced without adding micro-alloy element and a production process thereof. The low-alloy Q345E medium plate comprises the following chemical components in percentage by weight: 0.13-0.19% of C, 0.20-0.50% of Si, 1.30-1.60% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.015-0.050% of Als, and the balance of Fe and residual elements. The process disclosed by the invention comprises the following steps: KR (knotted reactor) hot metal pretreatment of high-quality hot metal, processing with a top-bottom combined blowing converter, LF ((ladle furnace) refining, casting blank stack cooling, processing with a heating furnace, rolling, ACC (accelerated cooling) laminar flow cooling, processing with a hot straightener, stack cooling, finishing, external inspection, flaw detection and storage. The invention has the beneficial effects that: compared with the traditional Q345E, precious alloys such as Nb, Ti and the like are not added without changing the carbon equivalent, all performance indexes of Q345E are guaranteed, and the production cost is remarkably reduced.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

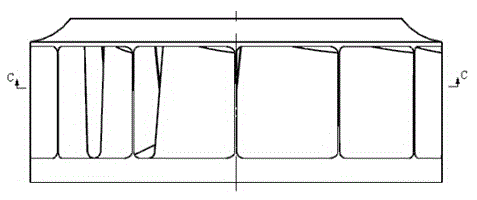

Manufacturing method of engine inlet

Provided is a manufacturing method of an engine inlet. The process method comprises the steps of uncapping subsection casting, casting pre-welding machining, vacuum electron jet assembling and welding, sizing destressing vacuum annealing, overall machining, hydrostatic testing and overall precise machining; an engine thin-wall titanium alloy component with the profile of a surface being less than or equal to 0.1mm, the surface roughness being less than or equal to Ra3.2, the dimensional precision being less than or equal to 0.2mm, and the form and location tolerance meeting design requirements is machined and manufactured. The manufacturing method overcomes defects in the prior art, meets all design requirements, resolves the problems of deformation, poor surface quality and poor dimensional precision which cannot be overcome by other machining methods, and is advanced and reasonable in technological process, smooth in technological production line, and especially suitable for developing and producing various engine thin-wall titanium alloy components.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

After-forging preheat treatment process of large turbine low-pressure rotor forging piece

InactiveCN102560039AGuaranteed Performance RequirementsShorten heat treatment process cycleAustenite grainTest sample

The invention discloses an after-forging preheat treatment process of a large turbine low-pressure rotor forging piece, and provides an after-forging preheat treatment process solving the problem of structural heredity of 26Cr2Ni4MoV steel or 30Cr2Ni4MoV steel used by the large turbine low-pressure rotor forging piece. The after-forging preheat treatment process comprises the steps of: firstly, carrying out 1250DEG C*1.5h roughening and 350DEG C*10h bainite treatment on an experimental material to ensure that rough austenite grains and needle-shaped bainite structures are obtained; and then carrying out high-temperature pre-tempering (660DEG C*20h) and critical region normalizing treatment (770 DEG C*3h) and normal normalizing treatment (950 DEG C*1h) on a test sample treated by the step. After the after-forging preheat treatment process is adopted, the refining effect of the grains is remarkable, the thermal treatment period is shortened, the heating temperature is reduced, the final use performance requirement is ensured, the problem of the structural heredity is solved in the practical production on the premise of ensuring the quality of a rotor, the process is simplified, and the reference basis is provided. The process can be applied in practical production.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +2

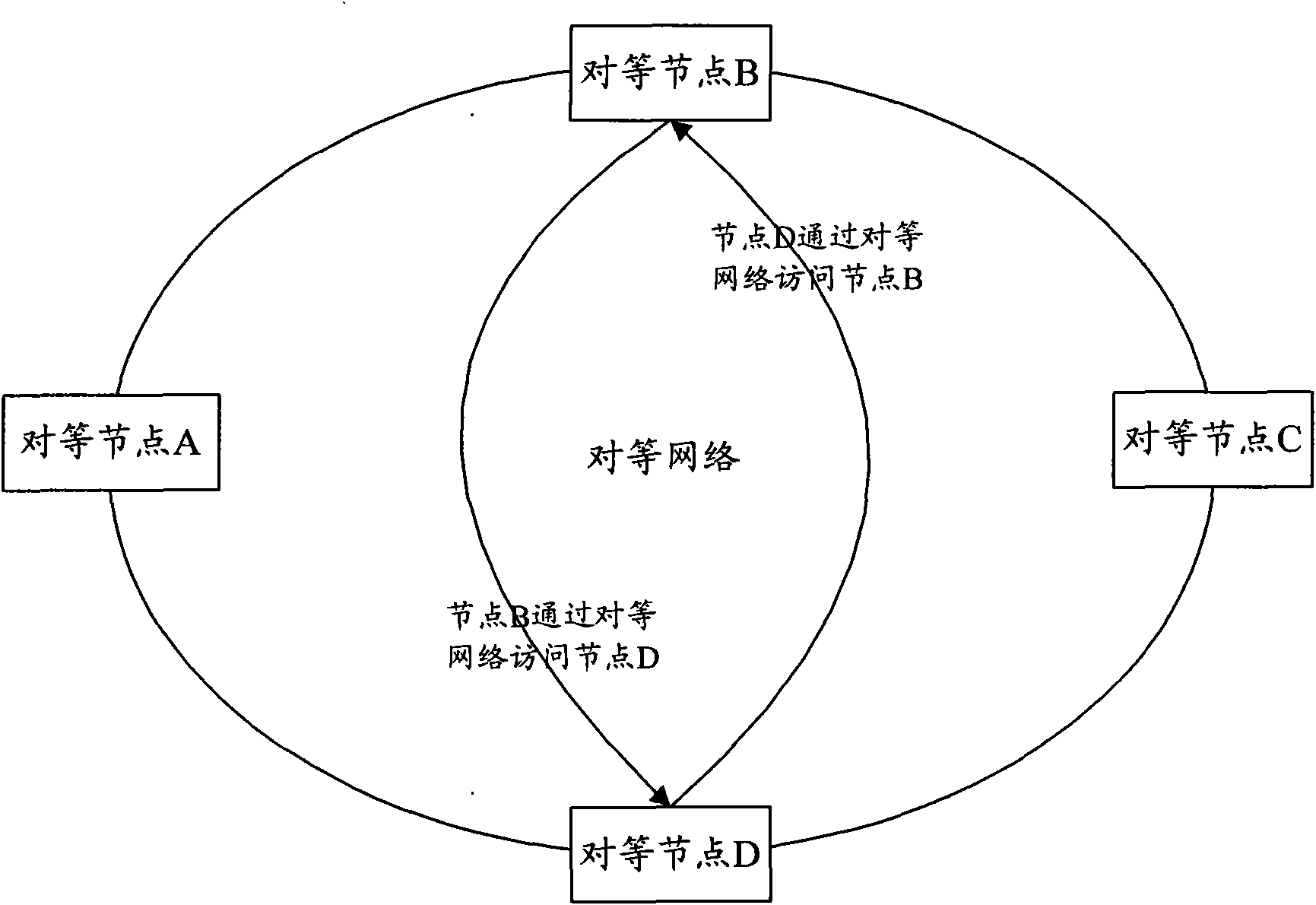

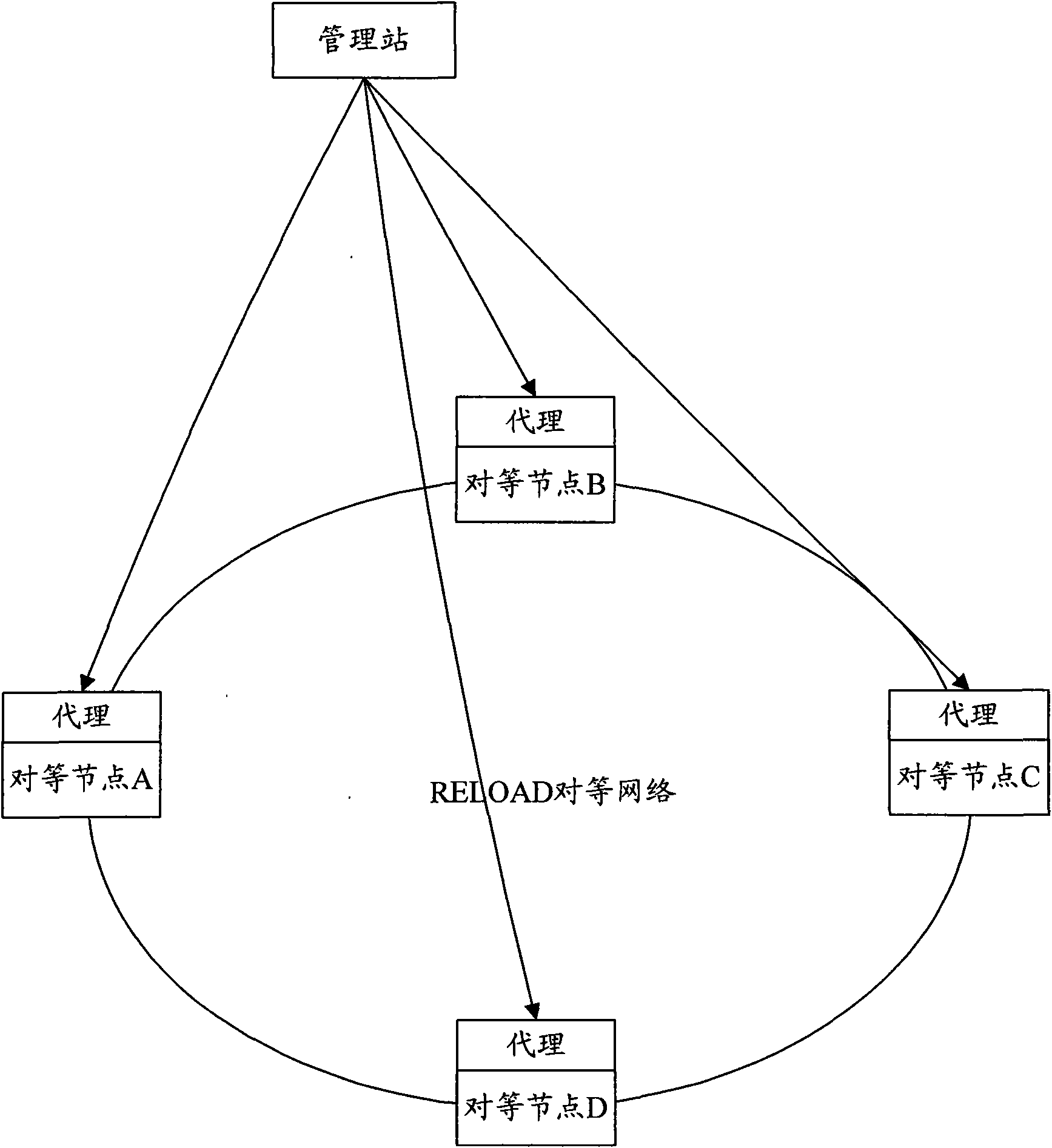

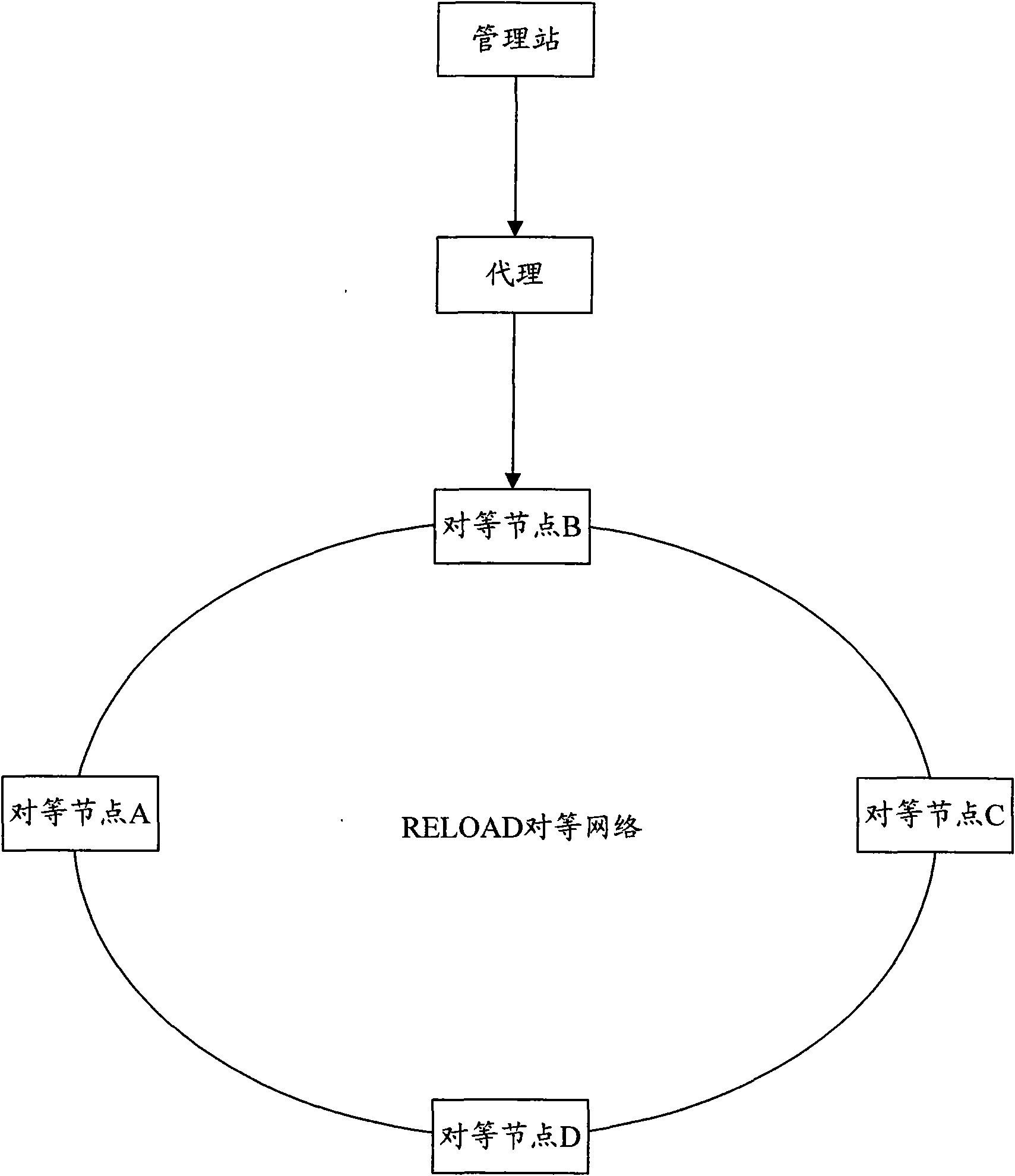

Peer-to-peer network management system and method

InactiveCN101989918AImprove work performanceImprove management efficiencyNetwork topologiesData switching networksWork performanceManagement efficiency

The invention provides a peer-to-peer network management system and method. The method comprises the following steps: a management station interacts with finite peer nodes in a peer-to-peer network through agent to obtain the related information from the peer-to-peer network or peer nodes adopting the resource locate and discovery (RELOAD) protocol; the peer-to-peer network or peer nodes are set or a management command is given to the peer-to-peer network or peer nodes; and the peer-to-peer network or peer nodes can instantly report the related information such as performance or alarm, and the performance requirement of the system is ensured. Therefore, the effective monitoring, diagnosis, debugging and other managements of the peer-to-peer network can be realized, the management efficiency of the peer-to-peer network can be increased, the working performance of the management station can also be increased and the timely management of the peer-to-peer network can be finally ensured, thus the normal operation of the peer-to-peer network can be ensured.

Owner:ZTE CORP

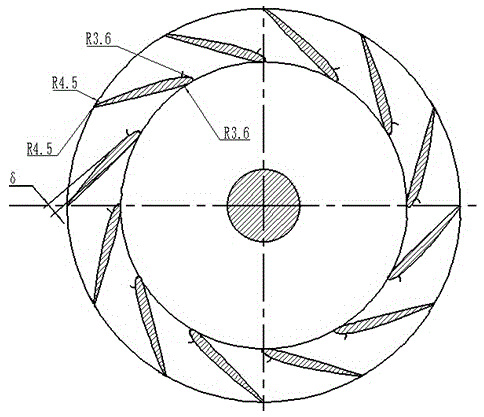

Process method for reducing corner-cleaning milling vibration of root part of integral closed impeller

InactiveCN104588750ARealize the improvement of manufacturing processGuarantee product qualityMilling cuttersWorkpiecesImpellerMilling cutter

The invention relates to a process method for reducing the corner-cleaning milling vibration of the root part of an integral closed impeller. According to the process method, milling processing is carried out on parts of various metal integral closed impeller systems, complex curved surface integral impellers and deep cavity curved surface system structures on five-shaft linked processing central equipment by adopting a rigid alloy milling cutter containing 0.2-0.8 micrometer superfine or extremely fine particles; and the process method is realized through the selection on a cutter structure, a cutter cutting locus, a cutter feeding method, a feeding direction, a cutting depth and a cutter shaft vector parameter, the setting of the processing allowance of rough processing and fine processing and the adoption of parameters. The process method disclosed by the invention can be used for carrying out the milling processing on the parts of the integral closed impeller systems, the complex curved surface integral impellers and the complex deep cavity curved surface system structures, thereby realizing the enhancement of a manufacturing process of a complex structural system part, ensuring the requirements for quality, property and design of a product and enhancing the stability of product property.

Owner:SHANGHAI INST OF TECH

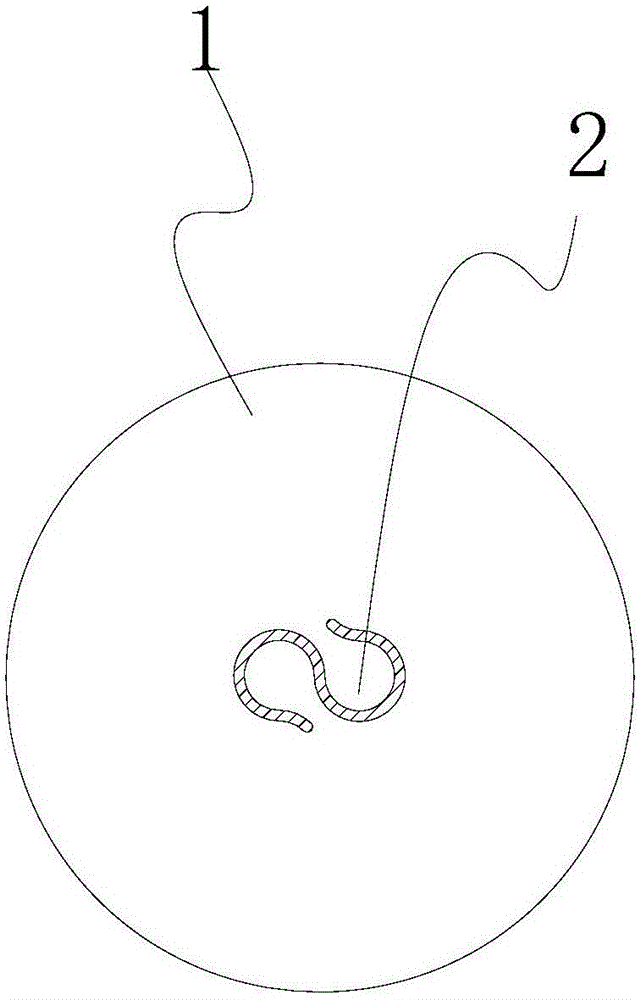

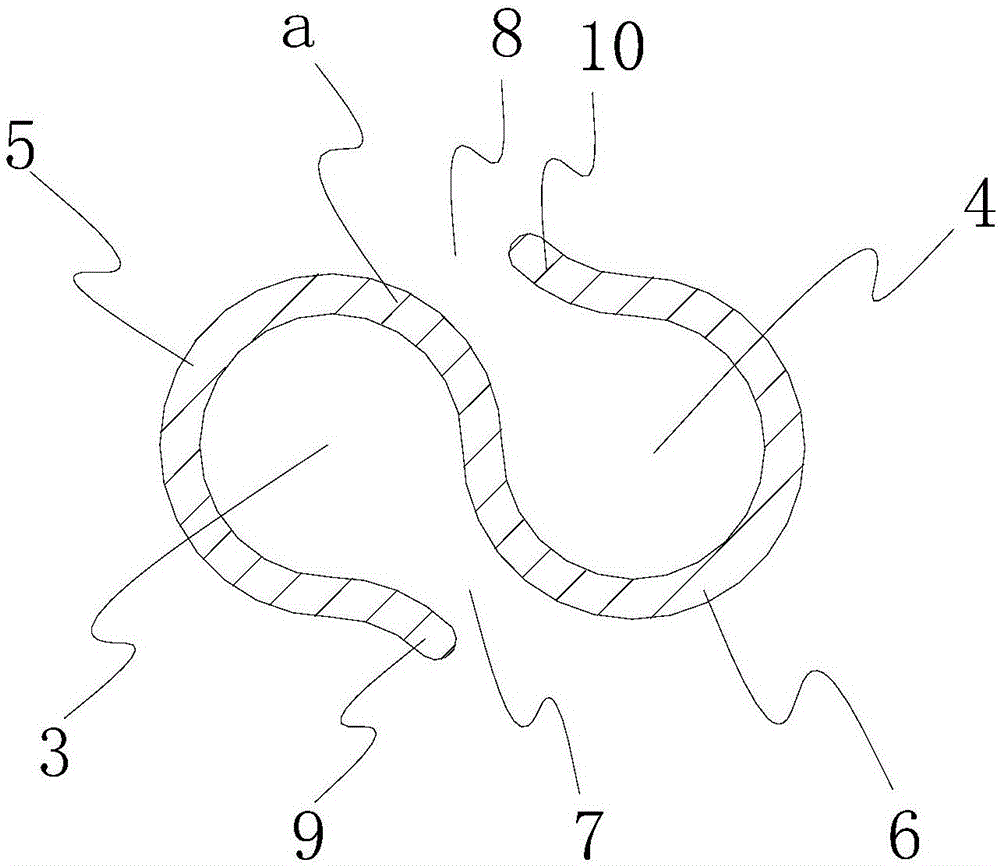

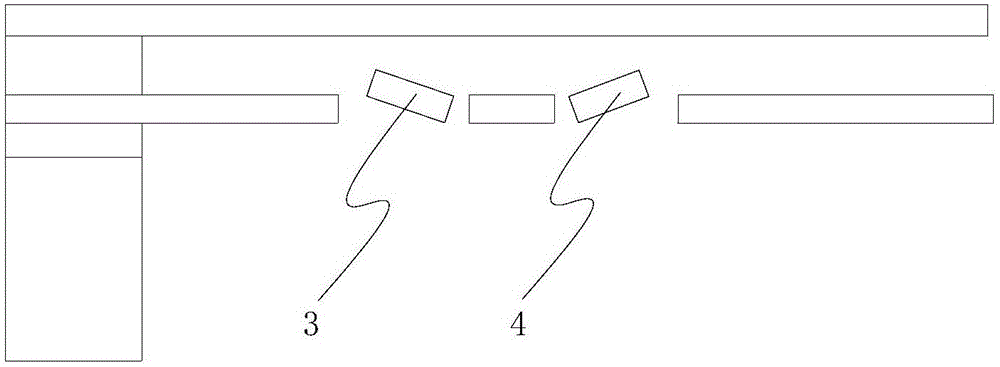

Vibration diaphragm in MEMS microphone, and MEMS microphone

ActiveCN106375912AGuaranteed Performance RequirementsAvoid damageMicrophonesLoudspeakersNeck partsEngineering

The invention discloses a vibration diaphragm in a MEMS microphone, and the MEMS microphone. The vibration diaphragm comprises a vibration diaphragm body and at least one pressure relief device; the at least one pressure relief device is on the vibration diaphragm body and formed by gaps; the gaps include at least two sections of circular arc-shaped gaps, which are continued together in sequence, wherein the whole of the adjacent two sections of circular arc-shaped gaps is S-shaped, and is centrosymmetric corresponding to a connection position; the pressure relief device comprises at least two valve clacks and neck parts; the at least two valve clacks are formed by at least two sections of adjacent circular arc-shaped gaps; and the neck parts are connected to the valve clacks and the vibration diaphragm body and shaped as constraint structures. When the vibration diaphragm disclosed by the invention is subjected to relatively high sound pressure due to mechanical shock, blowing, falling and the like, the at least two structure symmetrical valve clacks can upwarp upwardly or downwardly by taking respective neck parts as pivots; therefore, a effective pressure relief path is formed; and thus, the pressure relief purpose is achieved.

Owner:GOERTEK MICROELECTRONICS CO LTD

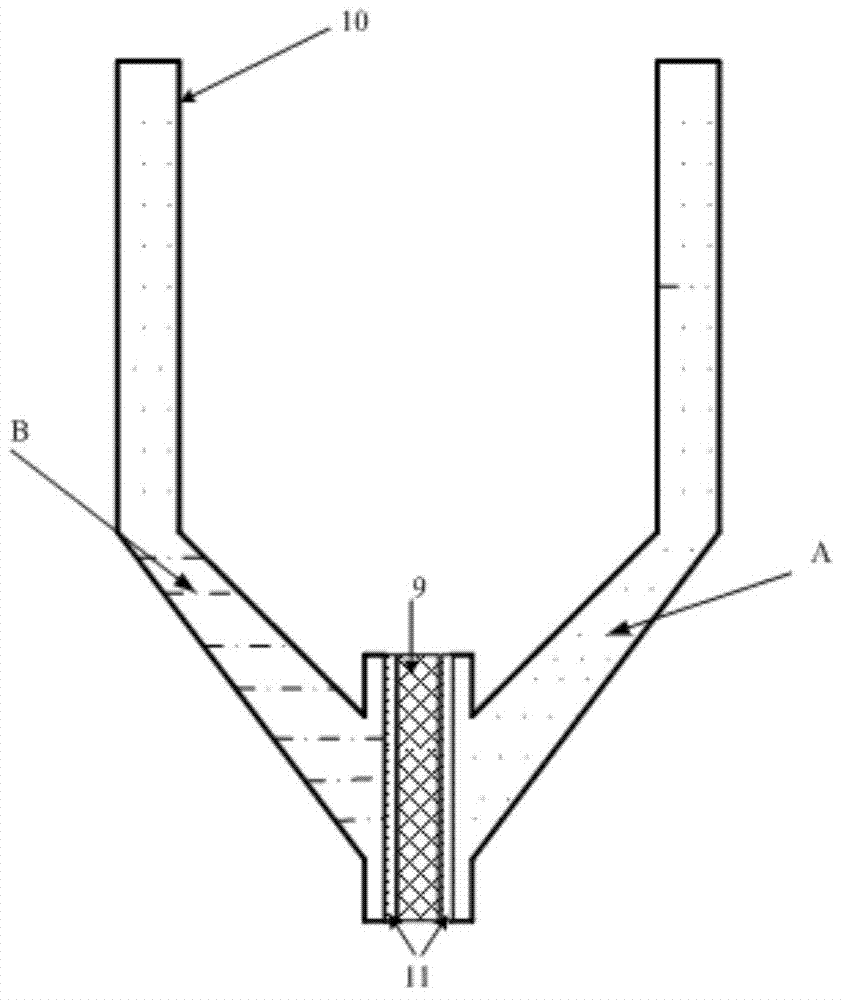

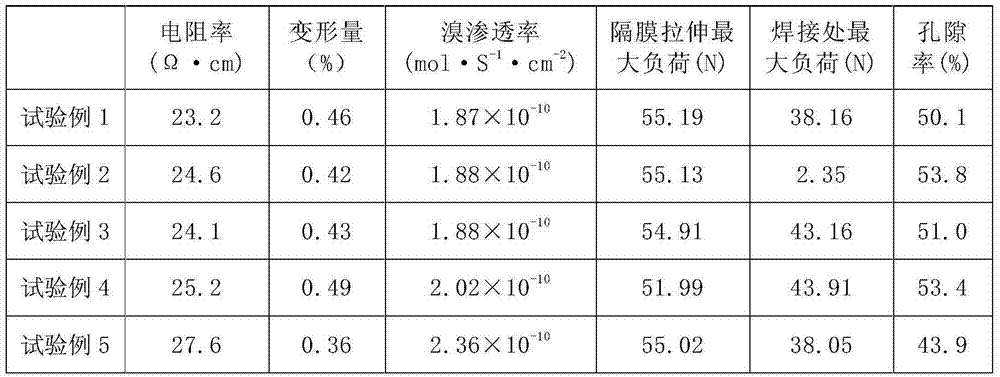

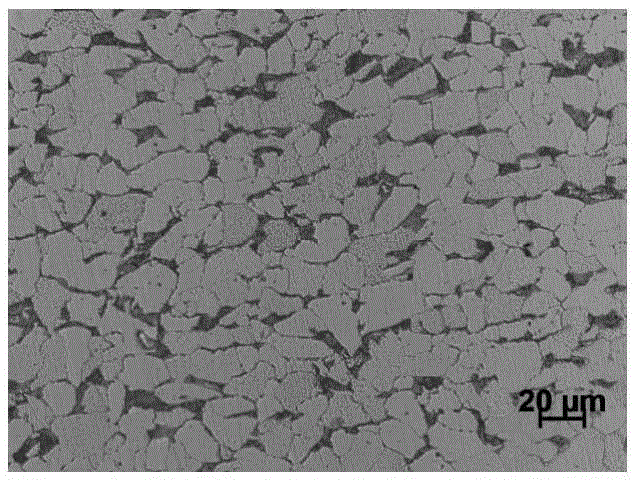

Zinc-bromine flow battery diaphragm applicable to laser welding, and preparation method thereof

ActiveCN103618057AImprove long-term stabilityThe effect of bromine transmission rateCell seperators/membranes/diaphragms/spacersFuel cellsElectrical batteryPlasticizer

The invention discloses a zinc-bromine flow battery diaphragm applicable to laser welding, and a preparation method thereof. The zinc-bromine flow battery diaphragm is prepared by mixing the following active ingredients in parts by weight: 10-35 parts of silica, 25-65 parts of plasticizer, 10-40 parts of PE (polyethylene) raw materials, 1-5 parts of color master batch with laser energy of 900-1000nm, and 1-2 parts of antioxidant. Compared with the prior art, by adding a certain amount of color master batch absorbing infrared rays into active ingredients, not only is the zinc-bromine flow battery diaphragm endowed with the laser welding capability, but also no obvious adverse influence on the physical properties of bromine transmittance, resistance and the like exists, and the performance requirement of the diaphragm can be guaranteed; in addition, the zinc-bromine flow battery diaphragm and a bipolar plate as well as a frame are laser-welded, so that the sealing property of a zinc-bromine battery can be effectively promoted, and the long-term stability of the battery can be enhanced.

Owner:江苏恒安储能科技有限公司

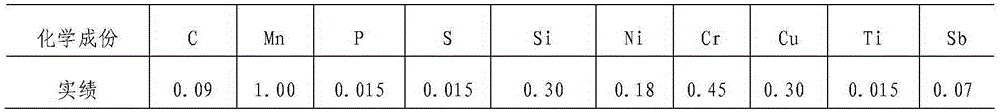

Low-cost Nb-free thin-gauge sulfuric acid dew point corrosion resisting steel and production method thereof

InactiveCN105349911AGuaranteed Performance RequirementsGuaranteed production costHigh pressure waterHigh pressure

The invention provides low-cost Nb-free thin-gauge sulfuric acid dew point corrosion resisting steel. The steel is characterized by comprising the following elements in percentage by mass: smaller than or equal to 0.12% of C, smaller than or equal to 0.55% of Si, 0.75% to 1.20% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.025% of S, 0.50% to 1.2% of Cr, 0.20% to 0.50% of Cu, smaller than or equal to 0.25% of Ni, 0.05% to 0.15% of Sb, smaller than or equal to 0.025% of Ti, smaller than or equal to 0.010% of V, 0.020% to 0.050% of Alt and 0.0005% to 0.0035% of Ca. The tissues of the steel disclosed by the invention are ferrite and pearlite; the heating temperature is increased; generation of relatively thick iron oxide scale is facilitated; transient temperature reduction of the surface iron oxide scale is increased during descaling of high-pressure water, so that shrinkage of the surface iron oxide scale is intensified, the iron oxide scale is easier to remove from a base body, the descaling efficiency is improved, and iron oxide scale residues are fundamentally reduced.

Owner:NANJING IRON & STEEL CO LTD

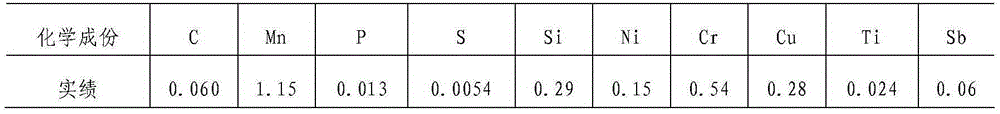

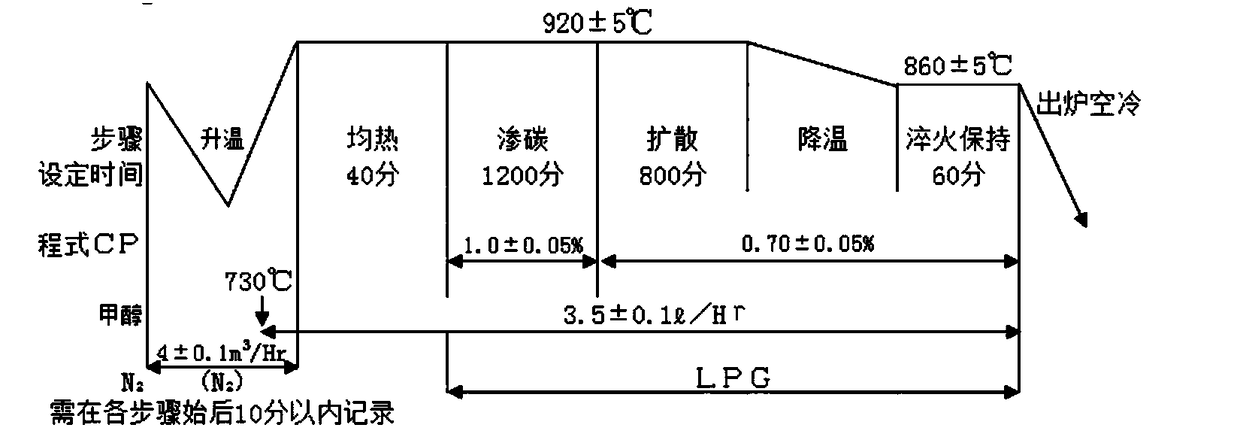

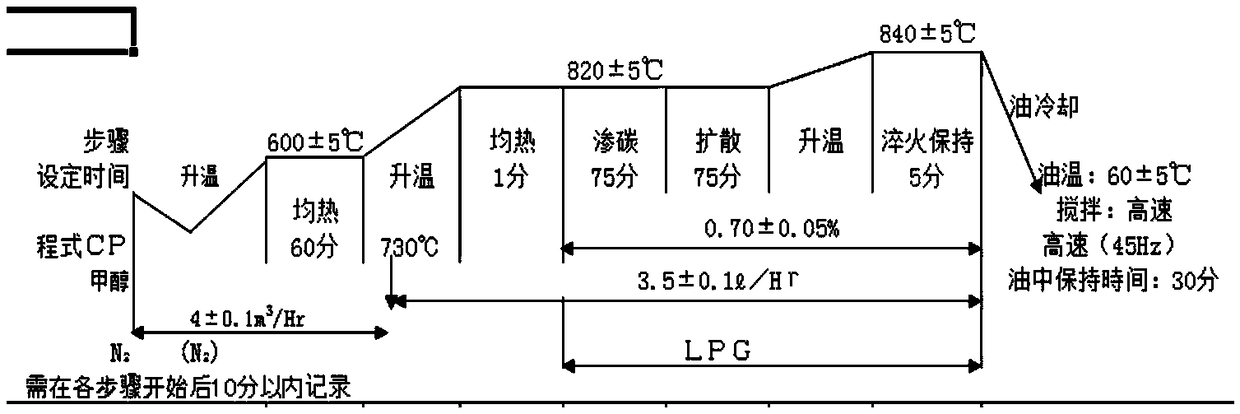

Thermal treatment method for carrying out carburizing and quenching on low-carbon alloy steel workpiece

ActiveCN108277449AReduce distortionGuaranteed Performance RequirementsSolid state diffusion coatingCarbon layerCarbide

The invention discloses a thermal treatment method for carrying out carburizing and quenching on a low-carbon alloy steel workpiece. The thermal treatment method comprises the steps that (1) after thesurface of the workpiece is cleaned, non-working surfaces of the workpiece are subjected to anti-seepage treatment; (2) after the workpiece is heated to a certain temperature, the temperature is maintained for a certain time, and then, the workpiece is subjected to carburizing treatment and diffusion treatment at the temperature; (3) then, the workpiece is cooled, and quenching is maintained; (4)a part is directly discharged and air-cooled; (5) after carbon layer turning and stress release tempering, the workpiece is quenched; (6) the workpiece is quenched in oil; and (7) finally, secondarylow-temperature tempering is carried out. According to the thermal treatment method, the workpiece processed and manufactured through low-carbon alloy steel is subjected to surface carburizing treatment, so that surface hardness of the workpiece is improved, carbide of a product is decreased, and the service life of the product is prolonged; besides, the carburizing and quenching technology of theproduct is improved, so that utilization performance of the product is improved; and the problem that the service life and utilization performance of the product are affected as carbide is redundantand too large in a traditional thermal treatment technology is solved, retained austenite on the surface of the product is decreased as much as possible under the precondition that performance of theproduct is guaranteed, and deformation of the product is controlled.

Owner:湖南特科能热处理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com