Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

135results about How to "Coarse grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for manufacturing cold-rolled orientation-free electrical sheet

This is about the manufacturing method of cold-rolled non-oriented electrical steel, including the following steps: a) the continuous casting of blanks: the liquid steel is continuously cast into a blank of 120-170mm at a pulling speed of 2-3 m / min; b) hot rolling: the blanks are directly hot-rolled or heated into the hot-rolled plate of 900-1150 deg.C and the thickness of the blank is hot-rolled to 0.8-4mm with finishing temperature 800-900deg.C and coiling temperature 500-900deg.C; c) cold rolling: the hot-rolled band undergoes annealing or non annealing treatment and acidwashing, and then the first cold-rolling or the second cold-rolling with annealing until the goal thickness reaches. When the finishing annealing is carried out, the non-oriented electrical steel is produced.

Owner:BAOSHAN IRON & STEEL CO LTD

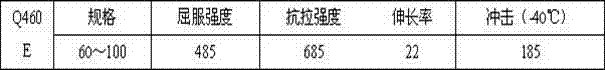

High strength and toughness Q460E structural steel thick plate and production method thereof

The invention discloses a high strength and toughness Q460E structural steel thick plate. The thick plate comprises the following chemical components by weight percent: 0.10-0.17% of C, 0.20-0.45% of Si, 1.30-1.65% of Mn, 0.018% or less of P, 0.007% or less of S, 0.015-0.050% of Als, 0.025-0.060% of Nb, 0.055-0.070% of V, 0.015-0.025% of Ti and the balance Fe and residual elements. The carbon equivalent [Ceq = C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15] is no more than 0.48. The production method comprises the following technologies: KR molten iron pretreatment, converter smelting, argon-blowing treatment, ladle furnace (LF) refining, vapor deposition (VD) refining, die casting, heating, controlled rolling and controlled cooling and stack cooling. On the basis of ensuring the original components of the high strength and toughness Q460E structural steel, the contents and ratio of the alloy elements in the Q460E steel, namely C, Mn and Nb are adjusted properly; the content of harmful elements in thesteel such as P and S which can influence the plasticity and toughness of the steel plate can be strictly controlled; the heating cycle of steel rolling is strictly controlled; and the rolling process adopts the ways of reducing the finish rolling temperature, increasing the cooling rate after rolling and perform stacking and slow cooling to the steel plate after rolling, thus each performance index of the steel plate meet the standard requirement.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

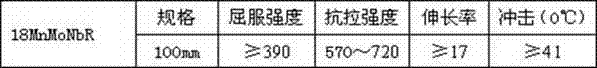

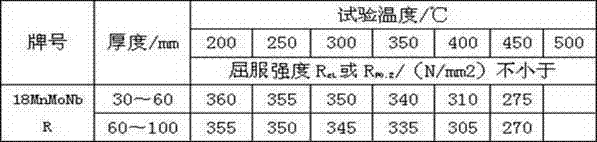

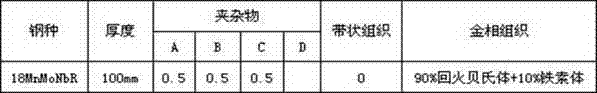

Steel 18MnMoNbR for pressure vessel and process for producing 18MnMoNbR steel plate with thickness of 100mm

The invention discloses steel 18MnMoNbR for a pressure vessel. The steel 18MnMoNbR comprises the following chemical components in percentage by weight (wt%): 0.16-0.20% of C, 0.25-0.45% of Si, 1.35-1.45% of Mn, 0.5-0.6% of Mo, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.015-0.040% of Als, 0.030-0.040% of Nb, 0.010- 0.020% of Ti and the balance of Fe and other residual elements, wherein the carbon equivalent of the chemical components is less than or equal to 0.04. Furthermore, the invention provides a process for producing an steel 18MnMoNbR plate with a thickness of 100mm. Due to the processes of pretreating molten iron by adopting the KR method, smelting by a converter, blowing argon, carrying out LF refining, carrying out VD refining, casting a die, heating, controlling rolling and cooling, cooling a pile and carrying out heat treatment, the content of harmful elements such as P and S which can affect the toughness of the steel 18MnMoNbR plate in steel can be controlled on the basis of guaranteeing the components of the steel 18MnMoNbR. In addition, by strictly controlling the heating cycle of the rolled steel, strictly controlling finishing rolling temperature, the reddening temperature and the cooling speed in the rolling process and cooling the steel-plate pile slowly, all the performance indexes of the steel 18MnMoNbR plate with the thickness of 100mm can meet the standard requirements.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

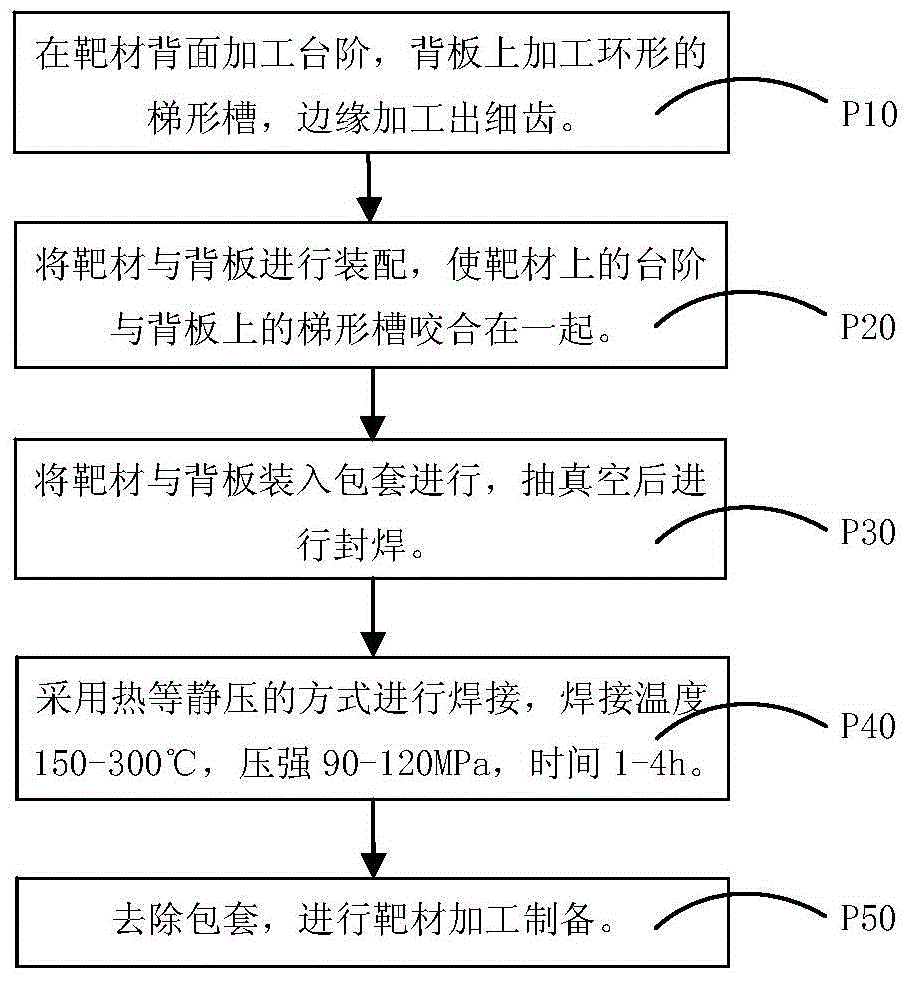

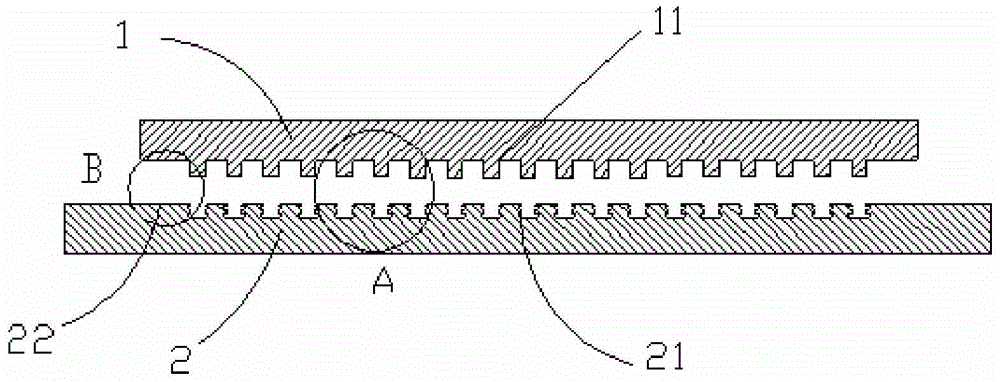

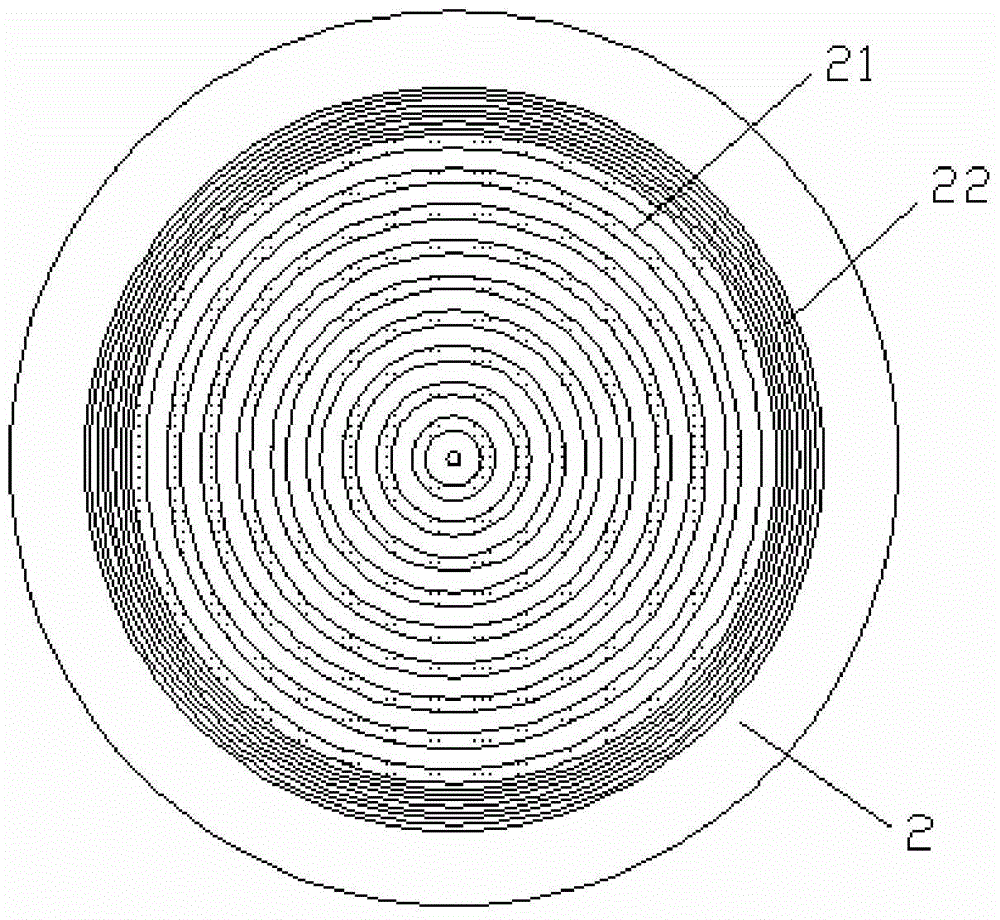

Welding method of aluminum alloy sputtering target material for integrated circuit package material

InactiveCN104625389AFine grainStrong reliabilityWelding/cutting auxillary devicesArc welding apparatusSputteringGrain growth

A welding method of an aluminum alloy sputtering target material for an integrated circuit package material comprises the steps that a protruding tooth of a certain shape and size is machined on the welding face of the target material, a corresponding groove is machined in a back plate, the target material and the back plate are put into a wrapping sleeve for carrying out vacuum seal welding after being assembled and combined, then a hot isostatic pressure method is adopted for enabling the groove to be completely filled with the material, and the target material is connected with the back plate. Due to the fact that welding temperature is low, aluminum alloy grain growth can be avoided, the welding intensity between the target material and the back plate is high, the target material is small in overall deformation, and subsequent machining is facilitated.

Owner:GRIKIN ADVANCED MATERIALS

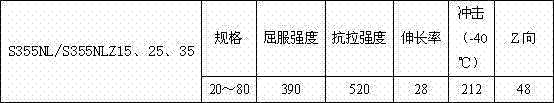

Weldable fine grain structural steel S355NL/S355NLZ35 steel plate and its production method

InactiveCN102345055AGuaranteed purityReduce performance requirementsTemperature control deviceWork treatment devicesHeating systemLadle furnace

The invention discloses a weldable fine grain structural steel S355NL / S355NLZ35 steel plate, which comprises the following chemical components by wt%: 0.10-0.18of C, 0.20-0.45 of Si, 1.20-1.45 of Mn, less than or equal to 0.018 of P, less than or equal to 0.005 of S, 0.015-0.050 of Als, 0.010-0.055 of V, 0.005-0.025 of Ti, and the balance Fe and residual elements. The production method consists of: KR molten iron pretreatment, converter smelting, argon blowing treatment, LF (ladle furnace) refining, VD (vacuum degassing) refining, continuous casting, heating, controlled rolling and controlled cooling, stack cooling, and normalizing. According to the invention, content and proportion of C, Mn and Nb alloy elements are adjusted properly, and content of harmful elements in steel like P and S etc. influencing the plasticity and toughness of the steel plate is strictly controlled, and meanwhile, the heating system of steel rolling is strictly controlled. The rolling process employs a mode of lowering finish rolling temperature, speeding up cooling after rolling, and conducting steel plate stacking and slowing cooling after rolling, thus guaranteeing all performance indexes of the weldable fine grain structural steel S355NL / S355NLZ35 steel plate meeting the standard requirements.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

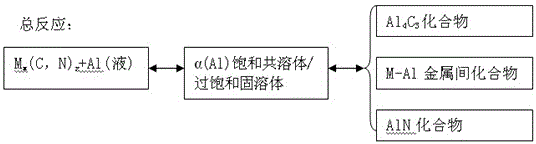

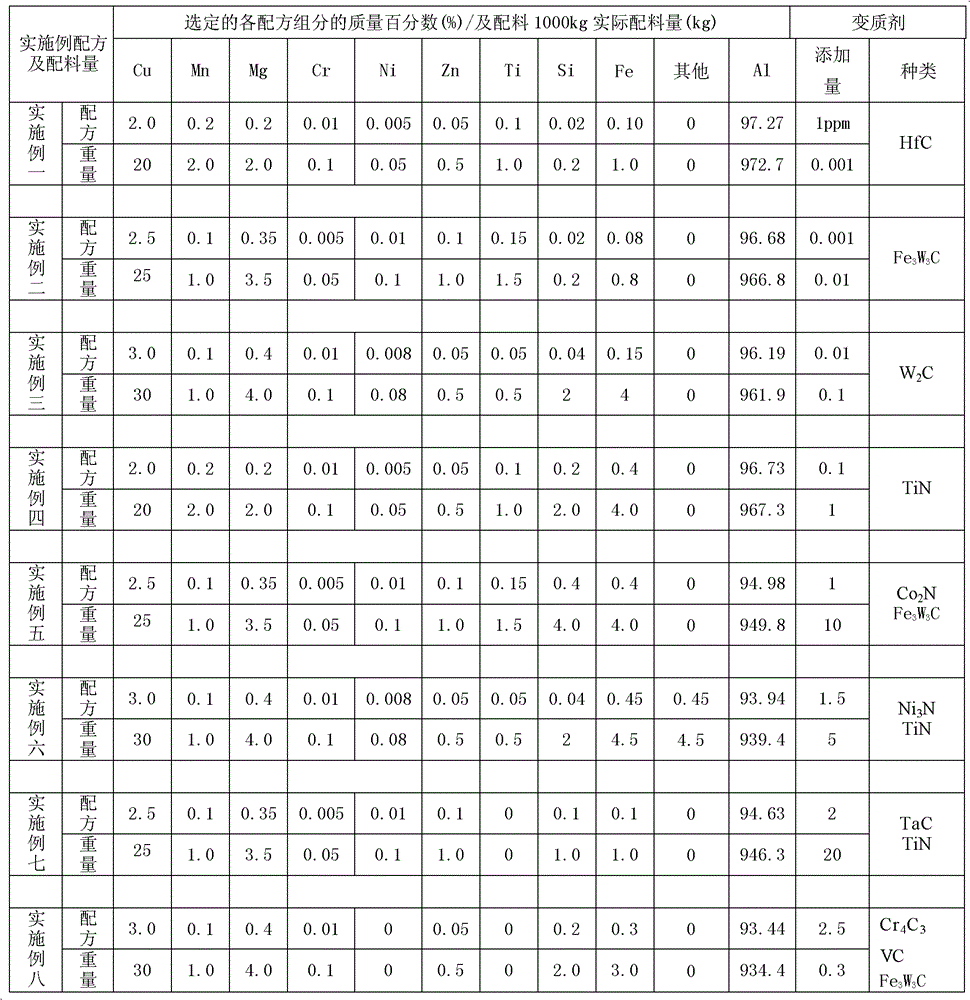

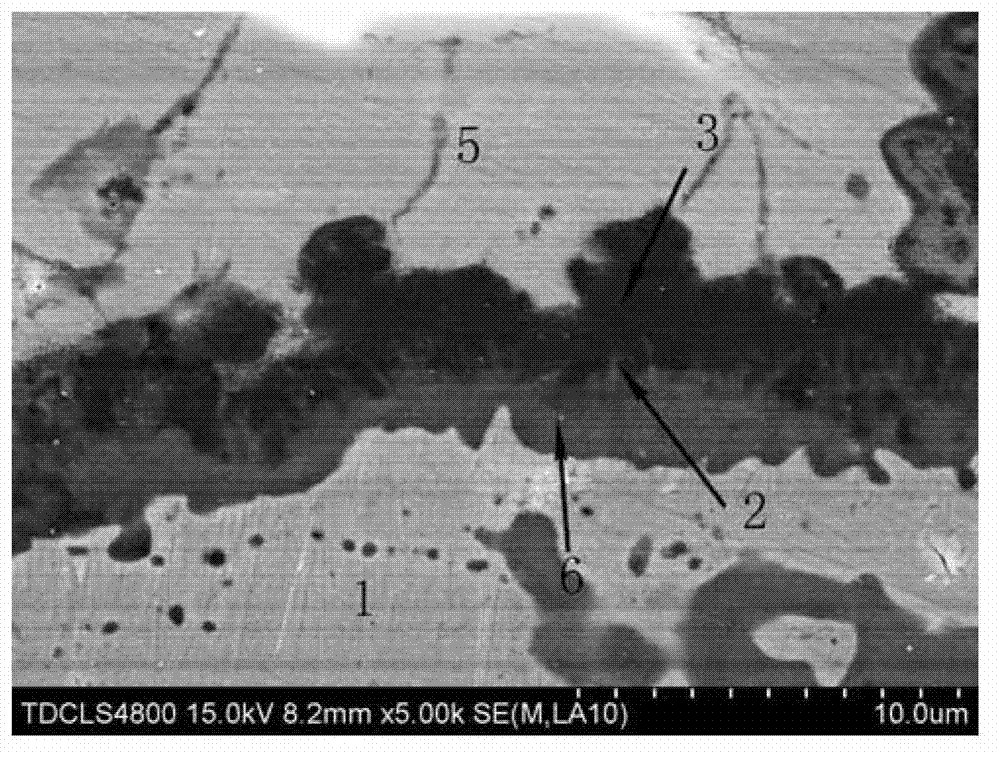

High-strength aluminum alloy subjected to carbonitride complex treatment and preparation method thereof

The invention discloses a high-strength aluminum alloy subjected to carbonitride complex treatment and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2.0-3.2 percent of Cu, less than or equal to 0.2 percent of Mn, 0.2-0.5 percent of Mg, less than or equal to 0.01 percent of Cr, less than or equal to 0.01 percent of Ni, less than or equal to 0.1 percent of Zn, less than or equal to 0.15 percent of Ti, less than or equal to 0.5 percent of Si, less than or equal to 0.5 percent of Fe, and the balance of Al and inevitable trace impurities, wherein the carbonitride MX(C,N)Y is 0.05-2.5 percent of total mass of the furnace burden. The aluminum alloy has the characteristics of high strength and good casting performance.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Metal inert gas (MIG) welding method of aluminum alloy thin plate for high speed train

InactiveCN103537784AReduce processIncrease productivityArc welding apparatusVehicle componentsSurface oxidationThin slab

The invention discloses a metal inert gas (MIG) welding method of an aluminum alloy thin plate for a high speed train. The method is characterized in that an ER5356 welding wire and 99.9% argon protective gas are selected to conduct single pass welding. The method includes the following steps: 1) surface machining of a workpiece to be welded; 2) MIG welding; 3) welding gap defect checking. The step 1) includes that the workpiece to be welded is not preheated, an organic solvent is directly adopted to remove grease dirt and dust on the surface of the workpiece to be welded, and a mechanical method is adopted to remove an oxidation film on the surface of the workpiece in a washing mode. The step 2) includes that weld heat input is controlled between 4.0KJ / cm and 5.0KJ / cm during MIG welding, and environment humidity is controlled to be smaller than or equal to 70%. The step 3) includes that pore defects of a welded workpiece are removed through a steel wire brush or an air chipper. The method has the advantage that thin plate aluminum alloy welding connector pore welding hot crack number can be greatly reduced, welding gap forming is good, welding deformation is small, welding connector strength is higher, the MIG welding quality of the aluminum alloy thin plate for the high speed train is effectively improved, and welding quality stability is ensured.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

Method for prolonging service life of engine thermal barrier coating by controlling components of thermal growth oxide layer

InactiveCN103160773ASuppress generationChange stateMolten spray coatingEfficient propulsion technologiesHigh energyThermal growth

The invention discloses a method for prolonging service life of an engine thermal barrier coating by controlling components of a thermal growth oxide layer. The thermal barrier coating utilizes high velocity oxy-fuel spray to prepare a bonding layer, utilizes low-energy power or high-energy power of atmospheric plasma to spray on a ceramic layer, then a combined technology of vacuum heat treatment and atmospheric diffusion heat treatment is carried out on the thermal barrier coating to restrain a premature appearance of spinel so that an edge of the thermal barrier coating is mainly alumina. Materials with a specific orientation of large grains are formed at the interface position of the alumina and the bonding layer to prevent oxygen from further largely intruding into the bonding layer and a base metal in a high-temperature service process. And the high-temperature service life of the thermal barrier coating is improved.

Owner:TIANJIN UNIV

Extrusion forming agent and preparation and use thereof

The invention discloses an extrusion forming agent, and preparation and use thereof, in particular to a forming agent for a tungsten-based alloy or hard alloy or ceramic powder extrusion forming process, and preparation and use thereof. The forming agent comprises 60 to 80 percent of solid and liquid paraffin wax, 3 to 8 percent of carnauba wax, 10 to 20 percent of high density polyethylene and ethylene-vinylacetate copolymer, 1 to 8 percent of plasticizer, 1 to 5 percent of stearic acid and the balance of modifier. In the invention, the drawbacks of long degreasing time, low degreasing conformality and more degreasing defects of extrusion blanks, particularly large-size extrusion blanks, are overcome, the raw materials are cheap and easy to purchase, the component compatibility of the prepared forming agent is high, the forming agent is used in a powder extrusion forming process, the micro structure of the forming agent is uniform, the forming agent has strong interaction force with powder, the formability is high, the quick and flawless degreasing of blanks with a thickness of 40 millimeters can be realize, the production efficiency is improved, and the development of extrusion forming industry is promoted greatly.

Owner:CENT SOUTH UNIV

Method for preparing alpha-type high-strength gypsum from phosphogypsum

The invention relates to a method for preparing alpha-type high-strength gypsum from phosphogypsum, belonging to the technical field of building materials. The method for preparing alpha-type high-strength gypsum from phosphogypsum is characterized by employing a semi-liquid-phase process and comprising the following steps: 1) blending phosphogypsum with quicklime with an amount identical to the sum of P2O5 and F in the phosphogypsum so as to neutralize the phosphogypsum and then carrying out aging for 1 d ; 2) weighing, on the basis of the total mass of the phosphogypsum, 0.01-0.5% of ternary organic acid and 0.5-2% of hypervalent sulfate, mixing the ternary organic acid and the hypervalent sulfate, and dissolving the obtained mixture in water with a temperature of 80-90 DEG C so as to prepare a composite crystal-type control agent; 3) adding the composite crystal-type control agent and water in a solid-liquid ratio of 4: 1 to 2: 1 into the neutralized phosphogypsum so as to form thick slurry; and 4) spreading the prepared slurry in an autoclave in layers, each layer being 5-15 mm thick, carrying out constant-temperature treatment at 120-150 DEG C for 3-6h, and then carrying out drying and ball-milling so as to obtain alpha-type high-strength gypsum powder. With the method in the invention, the prepared alpha-type high-strength gypsum is in the form of a short-column-like crystal with stable quality, and has 2-hour flexural strength of 4.9 MPa and drying compressive strength of 32.3 MPa; and obvious social, environmental and economic benefits are obtained.

Owner:湖北远固新型建材科技股份有限公司

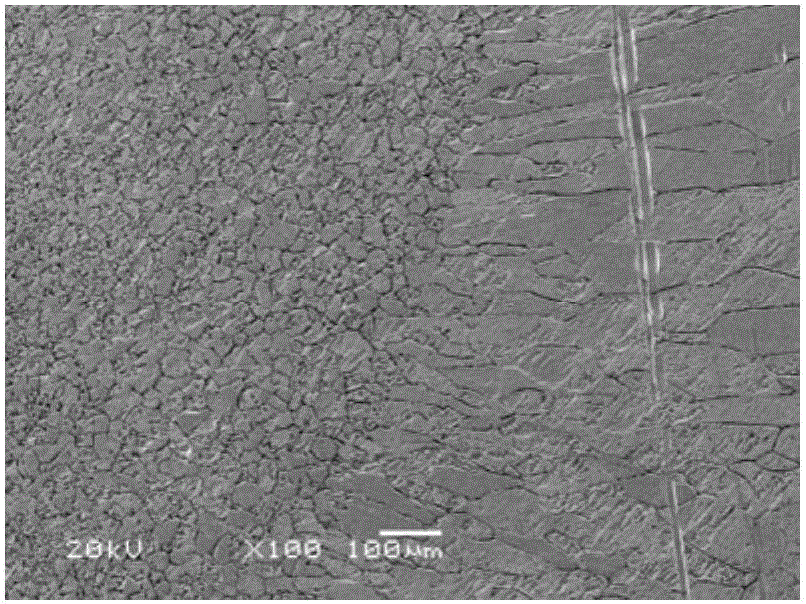

Method for producing metal powder and metal powder, and electroconductive paste and monolithic ceramic capacitor

InactiveUS6863708B2Efficient removalCoarse grainFixed capacitor electrodesMetal chlorideCeramic capacitor

Metal chloride vapor and reducing gas are brought into contact to form metallic powder, the metallic powder is washed in carbonic acid aqueous solution, and the metallic powder is classified in a liquid phase. In this way, metallic powder, such as nickel powder, in which the content of chloride components is extremely small and the coarse particle content is small, can be efficiently produced.

Owner:TOHO TITANIUM CO LTD

Graphite mould casting method for precise forming of low expansion alloy

ActiveCN102527936ASolve the problem of prone to thermal cracksSolve the problem of thermal crackingFoundry mouldsFoundry coresGraphite electrodeIngot

The invention provides a graphite mould casting method for precise forming of low expansion alloy. The method comprises the following steps: firstly preparing a part casting mould by using a graphite electrode, and adding 1-3% of shrinkage amount in a mould cavity of the casting mould; preparing a paint by using 325-mesh electric melting aluminum oxide powder, electric melting yttrium oxide powder and zirconium acetate at a mass ratio of (1-2.5):(1-2.5):1; then spraying the prepared paint on the surface of the mould cavity of the casting mould to form a coating with the thickness of 0.2-0.5mm, and shaping and pouring, wherein a 4J36 or 4J32 alloy ingot can be used as a consumable electrode for pouring; and finishing the pouring, thus obtaining the cast product. The method provided by the invention can be used for solving the problems that the 4J36 or 4J32 alloy has high melting point, the graphite chilling action is strong, the grains are coarse and the casting can generate hot crackseasily, and improving the quality and production efficiency of the 4J36 or 4J32 low expansion alloy casting.

Owner:SHENYANG RES INST OF FOUNDRY

Silicon-aluminum alloy and preparation method thereof

The invention discloses a silicon-aluminum alloy, belonging to the technical field of metal materials. The silicon-aluminum alloy disclosed by the invention contains the following components in percentage by weight: 6-10% of magnesium, 8-16% of silicon, 0.05-0.15% of iron, 0.05-0.2% of copper, 0.02-0.15% of manganese, 0.06-0.25% of chromium, 0.08-0.22% of nickel, 0.1-0.2% of titanium, and the balance of aluminum. Compared with the traditional aluminum alloy, the silicon-aluminum alloy disclosed by the invention is steady in component, good in quality, free from segregation, more uniform in tissue, uniform in grain size and better in performance.

Owner:ZUNYI FENGHUA ELECTROMECHANICAL FITTINGS CO LTD

Method for improving self-feeding capacity of high and thick large-cross section casting blank

ActiveCN102161090AAchieving radial self-feedingImprove the interface heat transfer coefficientState of artDiameter ratio

The invention relates to the field of casting blank manufacturing, in particular to a method for improving the self-feeding capacity of a high and thick large-cross section casting blank, and can solve the problems that the center quality of the thick large-cross section casting blank is poor, cracks are generated on the surface of the thick large-cross section casting blank, and the rejection rate is high in the prior art. The method comprises the following steps of: controlling external cooling conditions of different solidification stages of the casting blank to quickly solidify the outer surface of the casting blank to form a shell, establish strength and prevent surface cracks from being generated; performing heat preservation and slow cooling on the surface of the casting blank to keep a large area of a core part in a pasty area, wherein a solidification layer on the outer surface of the casting blank is kept at a higher temperature so that plastic deformation is realized; and performing simultaneous solidification and solid-phase movement in the subsequent solidifying and shrinking process of the casting blank to fulfill the aim of radial self-feeding of a deformable metal at a high temperature so as to eliminate the internal shrinkage cavities and surface cracks of the casting blank and obviously improve the looseness until the internal looseness of the casting blank is eliminated. The method is applicable to the high and thick large-cross section casting blank, particularly to a thick large-cross section casting round blank and a thick large-cross section casting square blank of which the height-diameter ratio is high and the axial looseness cannot be improved through riser feeding.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

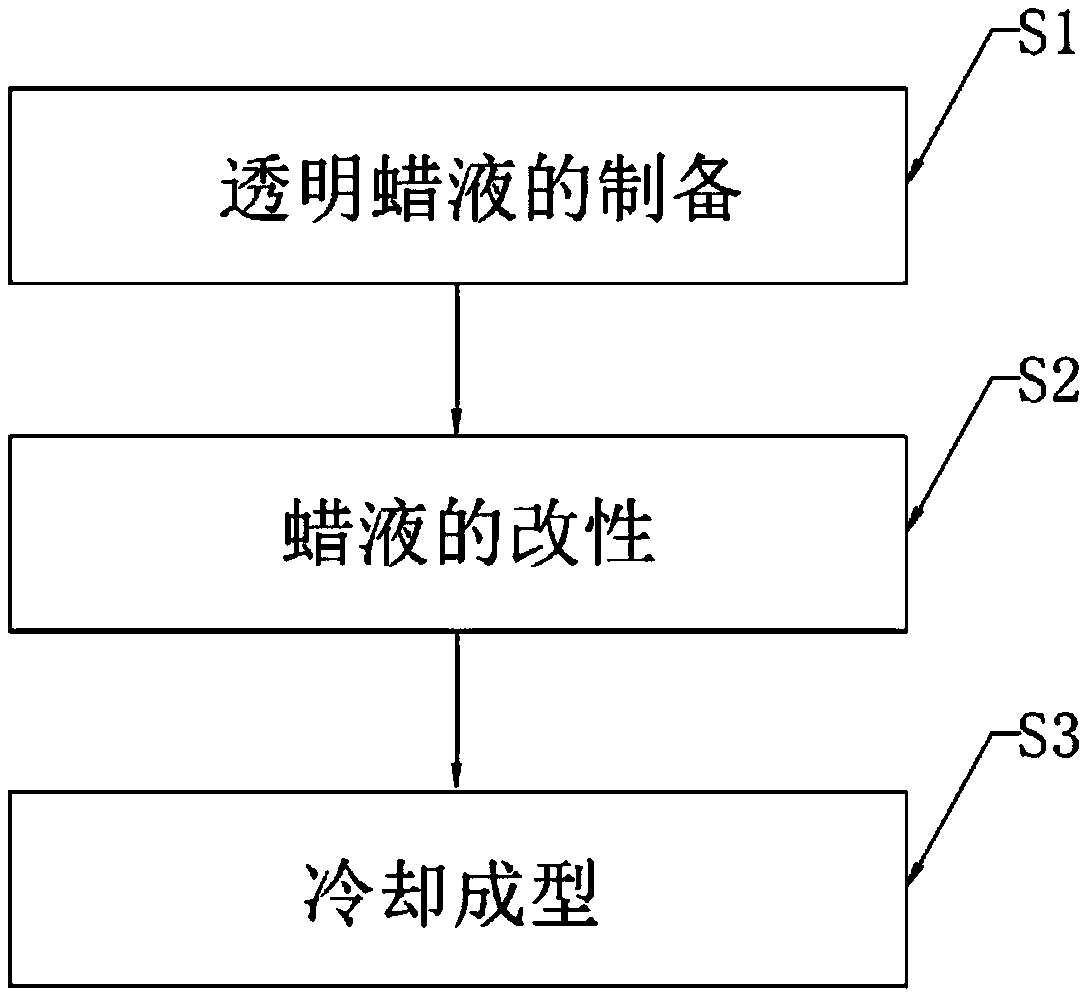

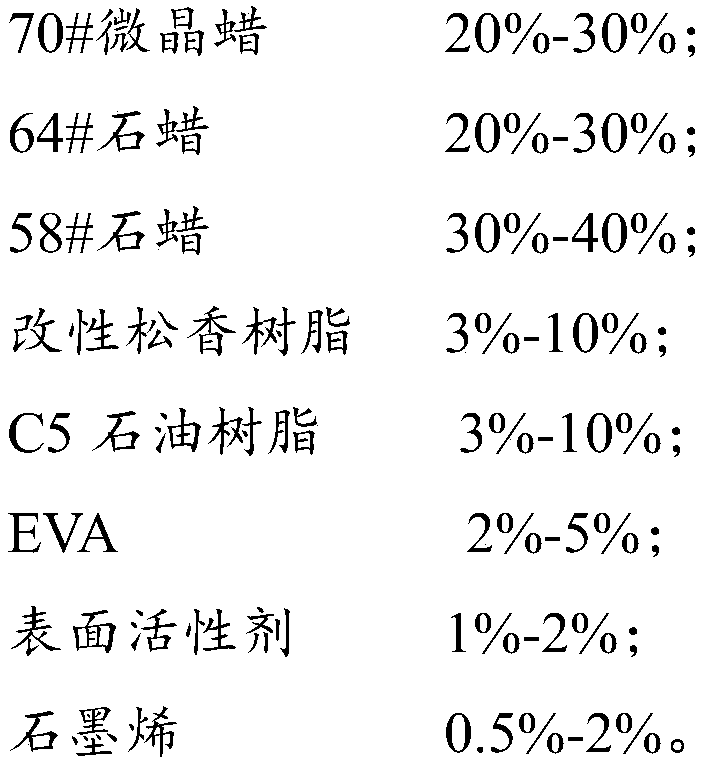

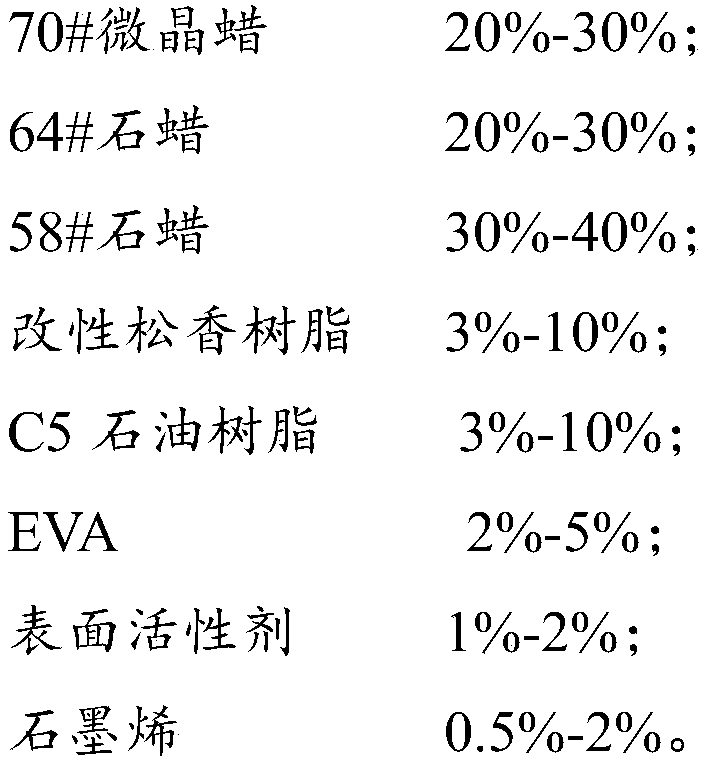

Graphene-based 3D printing non-photocuring model wax and synthesis method thereof

InactiveCN108676370AHigh strengthImprove toughnessAdditive manufacturing apparatusHeat-exchange elementsParaffin waxSynthesis methods

The invention discloses graphene-based 3D printing non-photocuring model wax and a synthesis method thereof. The model wax comprises the following components in percentage by mass: 20-30% of #70 microcrystal wax, 20-360% of #64 paraffin, 30-40% of #58 paraffin, 3-10% of a modified rosin resin, 3-10% of a C5 petroleum resin, 2-5% of EVA (Ethylene Vinyl Acetate), 1-2% of a surfactant and 0.5-2% of graphene. After printing of a 3D printer, the non-photocuring model wax for 3D printing, which is disclosed by the invention, can be directly used as a cast mold of the field of precise casting of fired molds, has the advantages of being high in precision, excellent in mechanical property, good in surface property, good in stability, good in non-photocuring molding, and the like, and is simple andcontrollable in process; cast molds can be manufactured in a large scale; manufacturing procedures of wax molds can be greatly simplified; and demands of practical production can be well met.

Owner:DONGGUAN HENGTIAN NEW MATERIAL CO LTD

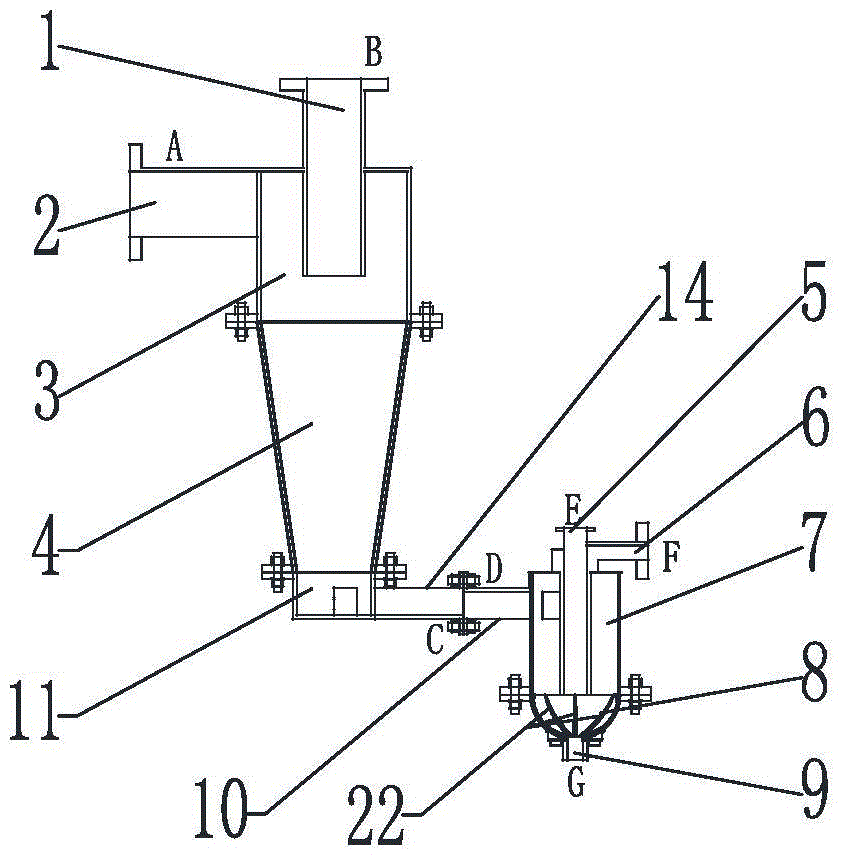

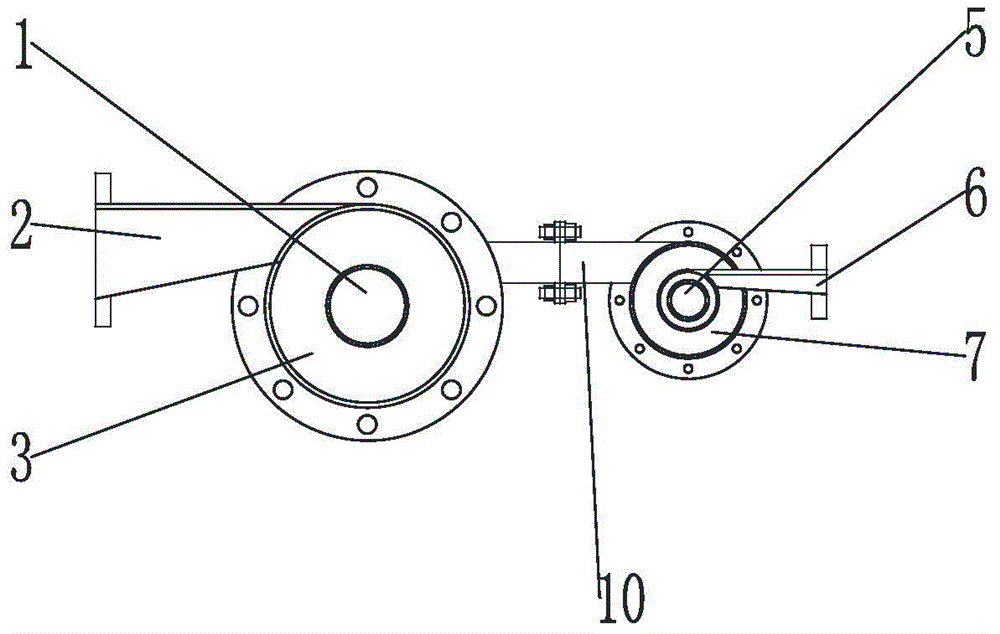

Coal slime recovery device and process

ActiveCN104307624AIncrease ashFine particleReversed direction vortexWet separationCycloneHigh density

The invention discloses a coal slime recovery device and process. The coal slime recovery device comprises a two-stage cyclone separation device, a flotation device, a high-frequency vibrating screen and a spiral separator; the two-stage cyclone separation device comprises a pre-stage cyclone and a post-stage cyclone; a first overflow port and a first underflow port are formed in the pre-stage cyclone, and a second overflow port, a third overflow port and a second underflow port are formed in the post-stage cyclone; a first granular material is obtained at the first overflow port, a second granular material is obtained at the second overflow port, a third granular material is obtained at the third overflow port, and a second underflow product is obtained at the second underflow port. The coal slime recovery device and process have the benefits that a small quantity of fine coal is obtained after the first granular material and the second granular material are floated, the third granular material has the characteristics of fine particle and high ash content and also has good ash reduction effect and large fine coal recovery rate after being further treated by the high-frequency vibrating screen, the second underflow product has the characteristics of high density and low ash content, and a small quantity of fine coal can be recovered after the second underflow product is further treated by the spiral sorter.

Owner:SHANDONG UNIV OF SCI & TECH

Carbide residue and waste water treating process

InactiveCN1986458AHighlight substantiveSignificant progressMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationIndustrial waste waterCarbide

The carbide residue and waste water treating process includes the following steps: pumping carbide residue with a slurry pump from acetylene producing shop to a settler, standing and separating water and precipitate; pumping the precipitate to wet ball mill and milling into 300 mesh below slurry; pressure filtering the slurry, water washing the filter cake to eliminate soluble impurity and collecting water; treating water through adding desulfurizing agent and returning to the acetylene producing shop for reuse; and pulping the filter cake to form slurry, which may be used as slaked lime for treating acid industrial waste water or sulfur containing boiler fume, building lime paste or material for producing high quality calcium carbonate.

Owner:梁永洪 +1

Method for preparing large-grain ingot polycrystal silicon

InactiveCN102425008ACoarse grainExtend your lifePolycrystalline material growthSingle crystal growth detailsBorideBoron nitride

The invention relates to a method for preparing large-grain ingot polycrystal silicon. The directional growth of polycrystal silicon grains is induced by adopting a large-grain film with a high melting point in the method. The large-grain film is made of metallic high-purity oxide, nitride, nitric oxide, carbide or boride, or high-purity silicon nitride, boron nitride, silicon carbide or boron carbide; the melting point is more than 1,480 DEG C, the purity is more than or equal to 99.9 percent, the thickness of the film is 0.01 to 500 mu m, and the diameter of the grains is 10 to 400 mm; and in the horizontal direction, the crystal face of the grains can be effectively matched with a certain crystal face of the crystal silicon, so that the growth of the crystal silicon grains is induced. The ingot polycrystal silicon crystal prepared by the method has the characteristic of thick grains, the average granularity of the grains is more than 20 mm, the service life of minority carriers of a silicon chip is over 30 percent longer than that of the ingot polycrystal prepared by adopting the same ingot casting technology and grown without film induction, and the absolute value of the conversion efficiency of a photovoltaic cell sheet prepared from the ingot polycrystal silicon is 0.5 to 1.5 percent higher than that of the ingot polycrystal silicon prepared by adopting the same ingot casting technology and grown without film induction.

Owner:TRINA SOLAR CO LTD

Copper alloy for contact line and application thereof

InactiveCN101684529ACoarse grainUniform size distributionMetal rolling arrangementsInduction furnaceWater pipe

The invention relates to copper alloy for a contact line and the application thereof; the copper alloy for the contact line at least contains tin with the content of 0.01-0.4 percent (weight percentage); a method for manufacturing copper alloy wires by the copper alloy is that: high-purity cathode copper is added in an induction furnace and the temperature of melted copper in the furnace is 1100-1160 DEG C; tin-chromium, tin-zirconium or tin-chromium-zirconium master alloy is added in a tundish continuously by a charging device, and the temperature of the tundish is controlled to be 1080-1150DEG C; the alloy is injected in a belt-type casting machine with 750-900rpm of rotating speed by a water pipe, cooing water pressure is controlled to be 0.05-0.35MPa,andthen a casting blank is obtained after cooling, solidification and formation; the casting blank is fed in a rolling mill with 600-800rmp of running speed to be rolled continuously after being milled and finished, and the temperature of the casting blank which is fed in the rolling mill is controlled to be 700-850 DEG C, and the casting blank is rolled and deformed by multiple passes to be formed into copper alloy wire blanks with various specifications. The copper alloy has the advantages that: the developed copper alloy for the contact line has high elongation percentage and tensile strength, is in accordance to the application requirements of high-speed railways and is particularly suitable for electrified trains with more than 300km / h of running speed; the manufacturing method of the lead wires is simple, has low cost and is easy to realize industrialization.

Owner:YUNNAN COPPER CO LTD +1

Nano-matrix-combined high-performance fused magnesium calcium brick and manufacturing method thereof

The invention provides a nano-matrix-combined high-performance fused magnesium calcium brick and a manufacturing method thereof. The fused magnesium calcium brick is prepared from 8-5mm high-calcium fused magnesium calcium sand, 5-2mm high-calcium fused magnesium calcium sand, 2-0mm high-calcium fused magnesium calcium sand, <=0.074mm high-calcium fused magnesium calcium sand, 8-5mm fused magnesite, 5-2mm fused magnesite, 2-0mm fused magnesite, <=0.074mm fused magnesite fine powder, nano sea water magnesia fine powder and a binder paraffin. The manufacturing method comprises the following steps: fine powder premixing, integral compounding, molding, drying, firing and the like. The product has the advantages of compact microstructure, fewer low-melting-point minerals, higher erosion resistance, higher scour resistance, higher stripping resistance and higher hydration resistance. The furnace life is prolonged by 30% above on average. Thus, the product satisfies the requirements of high efficiency, long service life and high cleanness for stainless steel and special steel smelting, and lowers the cost for the steel enterprises.

Owner:LIAONING ZHONGMEI HIGH TEMPERATURE MATERIAL CO LTD

Process for producing food grade saleratus by double decomposition

The invention relates to a process for producing food grade saleratus by double decomposition. The food grade saleratus is produced through a double decomposition reaction of natural brine and ammonium bicarbonate by using the process comprising the following steps: brine refining, double decomposition reaction, thickening, filtering, centrifugal separation and drying. A three-stage reaction process is adopted for the double decomposition reaction, and a kettle type machine is used for stirring a reaction barrel; a vacuum belt type filter is used for filtration washing, and washing water can be utilized for multiple times. The food grade saleratus product has good quality, easy control of the double decomposition reaction, small washing water quantity and low production cost.

Owner:湖南裕华科技集团股份有限公司

Method for preparing CuW/Cu/CuCrZr integrated contact through electron beam welding

InactiveCN105057873AImprove connection strengthImprove high temperature mechanical propertiesElectron beam welding apparatusWelding/soldering/cutting articlesButt jointCopper

The invention provides a method for preparing a CuW / Cu / CuCrZr integrated contact through electron beam welding and belongs to the field of production and manufacturing of high-voltage switch electrical contacts. One side of the electrical contact is made of a base material CuW / Cu, and the other side of the electrical contact is made of a base material CuCrZr. The method comprises the following steps that 1, the base material CuW / Cu on one side of the electrical contact is manufactured in a connection mode through a sintering method; and 2, the CuW / Cu subjected to sintering treatment and the CuCrZr are subjected to direct electron beam welding, a welding surface is made of Cu and the CuCrZr, a welded joint is a square butt joint, the joint gap value is zero, welding filling materials are not filled, a weld forming a 45-degree angle with the axis of the contact is adopted for electron beam welding, and thermal treatment is not needed after welding. Compared with the prior art, the high-temperature mechanical performance of chromium-copper can be improved, and the high welding strength can be achieved; moreover, it can be guaranteed that a Cu base is not annealed or softened; meanwhile, the stress of a vertical weld heat-affected zone is small, the sectioned contact cannot deform after being pulled and inserted for many times, and the contact finger force is stable.

Owner:SHENYANG JINCHANG LANYU NEW MATERIAL CO LTD

Forging die set and forging method of large-scale thin-wall barrel type flange plate

ActiveCN109648029AOmit the punching stepSave materialForging/hammering/pressing machinesWheelsPunchingEngineering

The invention discloses a forging die set and forging method of a large-scale thin-wall barrel type flange plate. The die set comprises a shaping die and a forging die for preforming a blank. The forging die comprises an upper die and a lower die, and cavities for pre-forming the blank are formed in the upper die and the lower die. A punch pin is arranged on the upper die. The cavities comprise afirst cavity and a second cavity which are formed in the lower die. A first through hole communicating with the second cavity is formed in the lower end of the lower die. The upper die is provided with a third cavity, wherein a flange portion of the pre-formed blank is formed by the third cavity and the first cavity. Both the second cavity and the punch pin have pattern drafts. The shaping die isused for expanding and shaping an inner hole of the pre-formed blank. The forging method is implemented by adopting the die. Firstly, the blank is pressed into a cake-shaped blank; and then the middleportion of the cake-shaped blank is pressed to form a pit; and the upper die is matched with the lower die to forge the flange plate with a barrel body. The forging die set and forging method of thelarge-scale thin-wall barrel type flange plate have the beneficial effects that the step of punching in traditional tire film forging is omitted, materials can be saved, and the production efficiencyis improved.

Owner:CHONGQING CHANGZHENG HEAVY IND

Quenching machine accelerated cooling method for improving strength of normalized steel plate with thickness specification of being greater than or equal to 50 mm

InactiveCN105154631AGood water cooling uniformityIncrease nucleation rateFurnace typesHeat treatment process controlFree coolingUltimate tensile strength

The invention discloses a quenching machine accelerated cooling method for improving the strength of a normalized steel plate with the thickness specification of being greater than or equal to 50 mm. The quenching machine accelerated cooling method comprises the following steps: the normalized steel plate enters a quenching machine along a quenching machine roller way after being discharged from a quenching furnace to be subjected to water cooling, four or six low-pressure sections are confirmed to be opened according to steel varieties and specifications, and the opening degrees, the upper and lower opening degree ratios and the roller way speeds of the areas of the low-pressure sections are adjusted, so that the steel plate is naturally cooled after the 'self-tempering' temperature reaches 580-630 DEG C, wherein the water yield control parameters are as follows: the opening degree of a flow control valve at the 15 area of the low-pressure sections is 30-40%, and the opening degree of a flow control valve at the 16 area of the low-pressure sections is 35-50%; the opening degree of a flow control valve at the 17 area of the low-pressure sections is 40-50%, and the opening degree of a flow control valve at the 18 area of the low-pressure sections is 45-60%; the opening degree of a flow control valve at the 19 area of the low-pressure sections is 60-70%, and the opening degree of a flow control valve at the 20 area of the low-pressure sections is 65-80%; the steel plate cooling speed is controlled to be 8-10 DEG C / S. The water cooling uniformity is good, the plate form after the cooling is good, and the strength of the normalized steel plate can be greatly improved through water cooling.

Owner:SHANDONG IRON & STEEL CO LTD

Method for decomposing scheelite through pressurizing by adopting phosphorus-sulfur mixed acid

The invention relates to a method for decomposing scheelite through pressurizing by adopting phosphorus-sulfur mixed acid. According to the main improved point, in the process of extracting the tungsten from the scheelite by using the mixed acid of phosphoric acid and sulfuric acid, pressurization treatment is carried out on a reaction system, so that the temperature of the reaction system is higher than 100 DEG C. According to the method, pressurized high-temperature treatment is carried out on the reaction system of extracting the tungsten from the scheelite by the phosphoric acid and the sulfuric acid, under the condition that the extraction rate of the tungsten is guaranteed, the addition amount of the phosphoric acid and the sulfuric acid is reduced, and the addition of calcium sulfate crystal seeds is omitted; and compared with an existing non-pressurization method, the method still has the advantages of being high in decomposition rate, free of generation of hazardous waste decomposition slag and low in decomposition cost.

Owner:CENT SOUTH UNIV

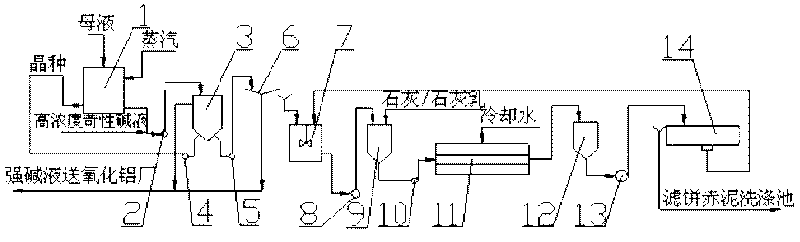

Method for excluding sodium oxalate and carbonate from Bayer process solution by adopting ultra-concentration method

ActiveCN101734694AIncrease crystallization ratePromote crystallizationAluminium oxides/hydroxidesRed mudDissolution

The invention discloses a method for excluding sodium oxalate and carbonate from Bayer process solution by adopting an ultra-concentration method. The method comprises the steps of: concentrating the mother liquor of an alumina system, sending liquor in the concentrated mother liquor to an alumina production system, and then send to a first segment causticization tank for causticizing for 2 to 4 hours to obtain seriflux B after solid phase dissolution; cooling the seriflux B to 50 to 70 DEG C and send to a second segment causticization tank for causticizing for 1.5 to 3 hours at 50 to 70 DEG C to obtain seriflux C; sending the seriflux C into a separating and washing machine, sending washed liquid to the alumina production system, and sending residues an alumina red mud washing system. The invention not only has the advantages of good excluding effect, simple process, less investment and low production and operation cost, but also achieves less loss of alumina, and has good use value and economic value.

Owner:GUIYANG AL-MG DESIGN & RES INST

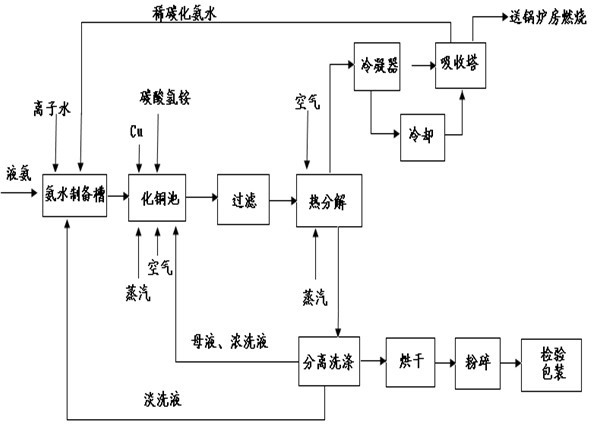

Method for preparing heavy basic copper carbonate

InactiveCN102531027ASolve pollutionNo escapeCopper compoundsBasic copper carbonateEnvironmental engineering

The invention discloses a method for producing heavy basic copper carbonate by a new secondary oxidation copper removal and air stripping process. Copper, ammonia and ammonium bicarbonate are taken as raw materials, and the method comprises the following steps of: performing leaching synthesis reaction, filtering, performing thermal decomposition, separating, washing, drying, crushing, packaging after inspection, and the like. By the preparation method, the decomposition reaction speed is improved, byproducts and waste materials are avoided, the utilization rate of the raw materials is high, environmental pollution is avoided, a problem of water balance in the production process is solved, and the method accords with a sustainable development policy and belongs to a clean production process.

Owner:樊余杰

Aluminum alloy capable of digesting high-hardness compounds and smelting method of aluminum alloy

The invention discloses an aluminum alloy capable of digesting high-hardness compounds and a smelting method of the aluminum alloy. The method comprises the following steps of: heating aluminum ingots or molten aluminum till complete melting; adding Si, Fe, Cu, Mn, Mg, Cr, Zn and Ti, and completely dissolving and melting the elements; preserving the heat at the temperature of between 700 and 1,000 DEG C after refining, and obtaining an alloy melt; performing degassing purification operation on the alloy melt by using nitrogen or inert gas or mixed gas of the nitrogen and the inert gas in a random ratio, and continuously introducing the gas till the reaction is finished; adding LaH3 powder into the alloy melt in a fluidized form together with the gas; stirring to make the LaH3 distributed uniformly in the alloy melt and fully reacted with the alloy melt; and standing, regulating the temperature to 680-730 DEG C, and discharging the molten alloy for casting. By the method, the defects of the properties of the conventional aluminum alloy can be overcome, the toughness, the forming property and the hardening capacity of the aluminum alloy are improved, and a high-end base material is provided for efficient deep processing.

Owner:GUIZHOU ALUMINUM MATERIALS ENG TECHRES CENT

PVC composite plate and preparation method thereof

InactiveCN108239356ALow densityHigh compressive strengthSynthetic resin layered productsAgricultural engineeringComposite plate

The invention discloses a PVC composite plate. The PVC composite plate is of a composite layer structure and comprises outer panel layers and an inner panel layer arranged between the outer panel layers, wherein the outer panel layers contain the following components in parts by weight: 47-58 parts of PVC resin, 32-38 parts of nano-light calcium carbonate, 5-7 parts of a calcium-zinc stabilizer, 0.98-1.42 parts of an inner lubricant, 1-1.5 parts of a PVC foaming modifier, 0.18-0.22 part of ACR-401 and 1-1.5 parts of titanium dioxide. The invention further discloses a preparation method of thePVC composite plate. According to the PVC composite plate provided by the invention, the density of the PVC composite plate is reduced, the integral strength of a product is enhanced, and light and pressure-proof effects are achieved.

Owner:湖南五祥新材料科技有限公司

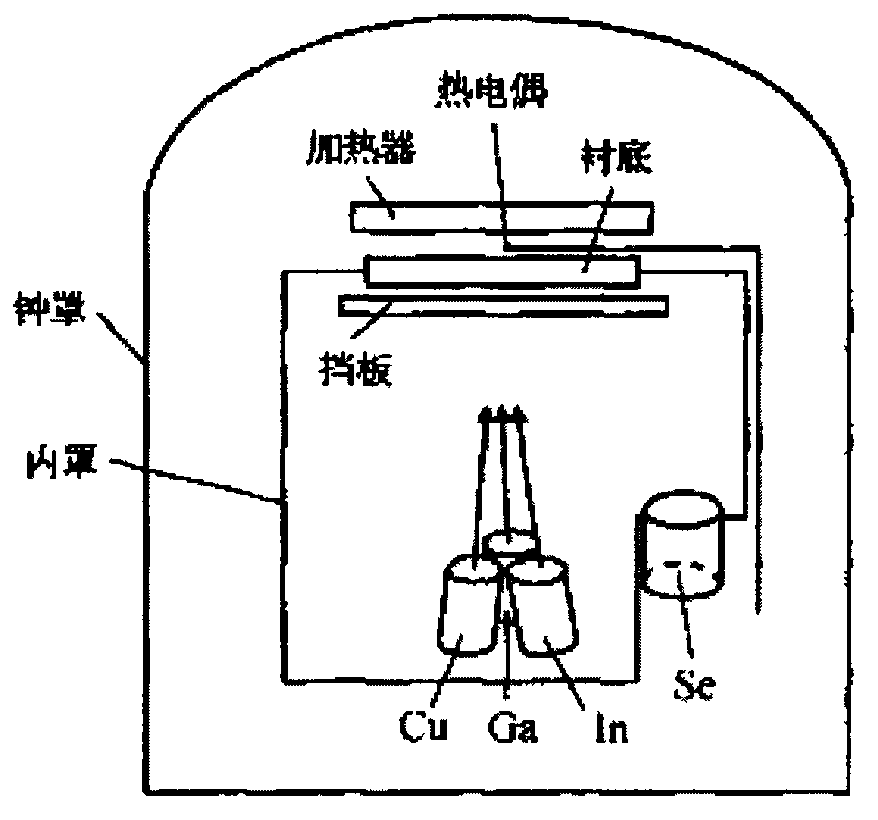

Sodium-doped copper indium gallium diselenide solar cell device and manufacturing method thereof

InactiveCN104716217AExcellent electrical propertiesImprove performanceFinal product manufacturePhotovoltaic energy generationGlass compositesIndium

A polyimide film-soda glass composite substrate based sodium-doped copper indium gallium diselenide solar cell device is characterized in that a substrate is composed of soda glass and a polyimide film growing on the surface of the substrate, and copper indium gallium diselenide solar cells are manufactured on the surface of the composite substrate. The sodium-doped copper indium gallium diselenide solar cell device has the advantages that the polyimide film-soda glass composite substrate based copper indium gallium diselenide film is excellent in adhesion property and good in crystallization quality, crystalline grains are large, and the defects are few; after the whole copper indium gallium diselenide solar cells are manufactured, the solar cells are separated from the soda glass to form the flexible copper indium gallium diselenide solar cells using the polyimide film as the substrate, and the flexible cells are manufactured by using the rigid substrate; a manufacturing method is simple and easy to implement, and the solar cell device is suitable for large-scale popularization and application and especially has very wide application prospect in a space occasion and special occasions.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com