Method for preparing heavy basic copper carbonate

A copper carbonate and heavy alkali technology, applied in chemical instruments and methods, copper compounds, inorganic chemistry, etc., can solve the problems of inability to achieve water balance, difficulty in sales, and large labor for cleaning copper powder, and achieve the goal of being conducive to separation and purification. The effect of washing, solving air pollution problems and improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

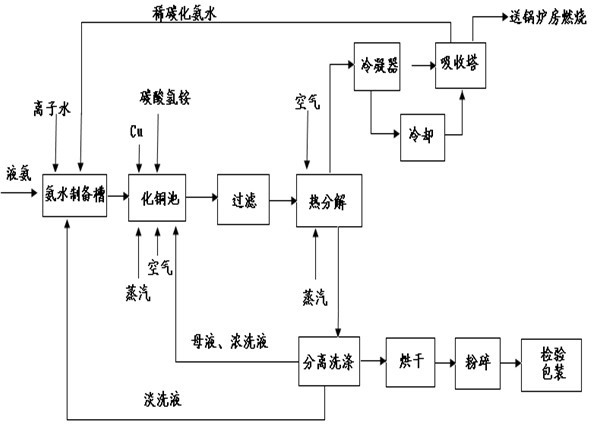

[0022] Example 1: Referring to accompanying drawing, technological process of the present invention is as follows:

[0023] (1) Preparation of concentrated ammonia water: prepare ammonia water with a concentration of 11% by using deionized water and liquid ammonia (or recovering dilute carbonized ammonia water from the absorption tower and separating light washing liquid).

[0024] (2) Synthesis reaction of leaching: put the concentrated ammonia water in step (1) into the copper pool equipped with copper wire, press NH 4 HCO 3 / NH 3 Molar ratio = 2 Add ammonium bicarbonate, blow in air with an air compressor, and then use steam to control the reaction temperature to 60°C, so that the reaction solution meets the sulfuric acid test (that is, the reaction is good).

[0025] The sulfuric acid test is: take about 5ml of the clear liquid, and add sulfuric acid reagent without producing red precipitate.

[0026] Detection principle: Cu(NH 3 ) 2 CO 3 +H 2 SO 4 →CuSO 4 Blue ...

Embodiment 2

[0038] Example 2: The main process method is the same as example 1, wherein, the second step is by NH 4 HCO 3 / NH 3 Ammonium bicarbonate is added at a molar ratio of 3, the reaction temperature is 70°C, the thermal decomposition heating temperature of the fourth step is 100°C, and the fifth step is to separate, wash, dry, Crush and pack after passing the inspection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com