Method for excluding sodium oxalate and carbonate from Bayer process solution by adopting ultra-concentration method

A technology of sodium oxalate and Bayer process, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of reducing the agglomeration efficiency and the speed of crystal growth, the equipment cannot meet the load operation, and the production capacity is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

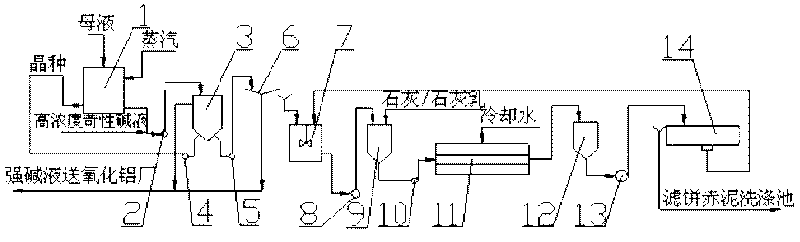

[0050] Embodiment 1: as figure 1 As shown, the mother liquor (Bayer process solution) in the alumina production system is first injected into the super concentrator 1 for super concentration. Finally, the concentration of causticized sodium oxide (Nk) in the mother liquor reaches 300g / l. Then the mother liquor (mixed liquid of mother liquor and high-concentration caustic lye) concentrated by the super-concentrator 1 to the specified value is transported to the separation and settling tank 3 through the super-concentration discharge pump 2, and the liquid is sent to the alumina production system through separation and overflow , the separated underflow (solid phase) is sent to the salt filter 6 through the underflow pump 5 for filtration, and the filtrate (liquid) is also sent to the alumina production system, and the solid phase (filter cake) is discharged into the water dissolution tank 7, and heated at 80°C Hot water or dilute alkali solution is dissolved into A solution wi...

Embodiment 2

[0051] Embodiment 2: as figure 1 As shown, the mother liquor (Bayer process solution) in the alumina production system is first injected into the superconcentrator 1 for superconcentration. When the mother liquor of the alumina system is concentrated, the temperature is 110 ° C, and the preferred temperature is 108 ° C. After being concentrated by the superconcentrator 1, the concentration of causticized sodium oxide (Nk) in the mother liquor reaches 370g / l. It is also possible to add an appropriate amount of high-concentration caustic lye (42-48% NaOH) at the outlet of the super-concentrator, so that the concentration of caustic oxide sodium (Nk) in the mother liquor and high-concentration caustic lye mixture reaches 370g / l; then the mother liquor (mixture of mother liquor and high-concentration caustic lye) that has been concentrated to a specified value by the super-concentrator 1 is transported to the separation and settling tank 3 through the super-concentration discharg...

Embodiment 3

[0052] Embodiment 3: as figure 1 As shown, the mother liquor (Bayer process solution) in the alumina production system is first injected into the super-concentrator 1 for super-concentration. Finally, the concentration of causticized sodium oxide (Nk) in the mother liquor reaches 360g / l. It is also possible to add an appropriate amount of high-concentration caustic lye (42-48% NaOH) at the outlet of the super-concentrator, so that the concentration of caustic oxide sodium (Nk) in the mother liquor and high-concentration caustic lye mixture reaches 360g / l; then the mother liquor (mixture of mother liquor and high-concentration caustic lye) that has been concentrated to a specified value by the super-concentrator 1 is transported to the separation and settling tank 3 through the super-concentration discharge pump 2, and the liquid separation overflow is sent to the alumina In the production system, the separated underflow (solid phase) is sent to the salt filter 6 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com