Vinpocetine special-purpose crystallization pot

A vinpocetine and crystallizing tank technology is applied in the field of vinpocetine special crystallizing tanks, which can solve the problems of troublesome operation, inability to use together, low crystallization rate, etc., and achieve the effects of convenient operation and simple setting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

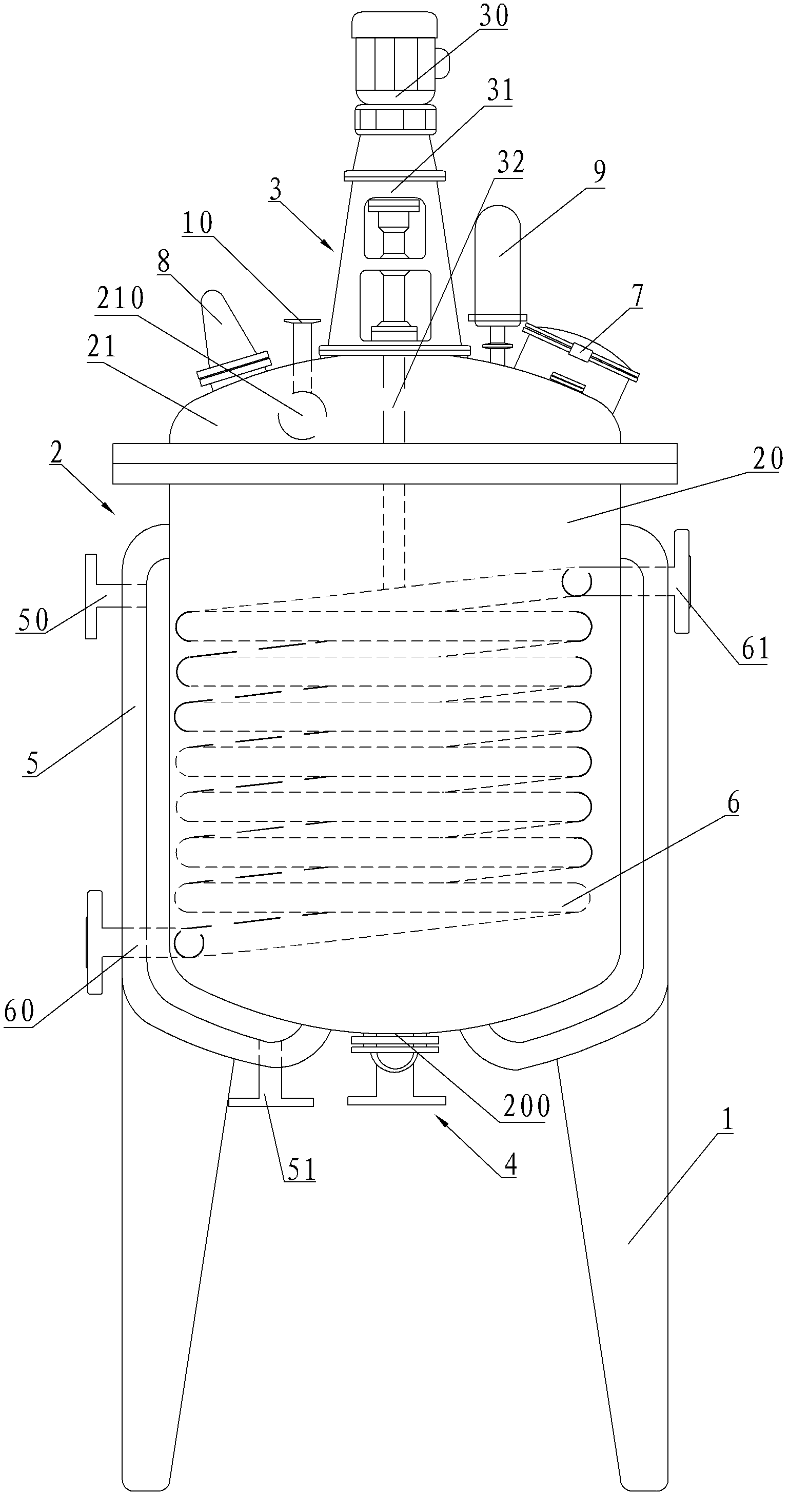

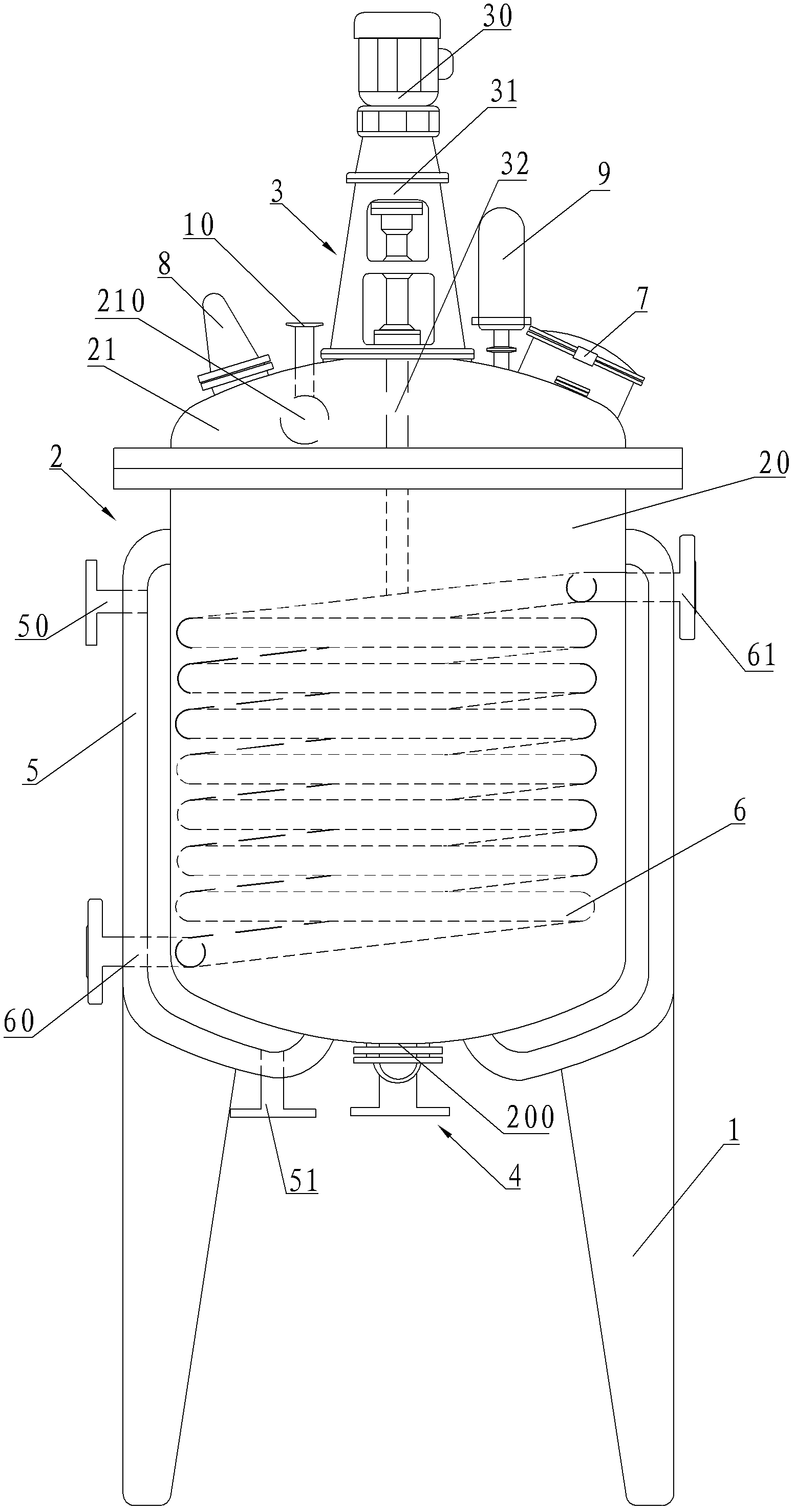

[0017] like figure 1 Shown, according to a kind of vinpocetine special-purpose crystallization tank of the present embodiment, it comprises tank frame 1, the tank body 2 that is arranged on the tank frame 1 and stirring device 3, wherein tank body 2 comprises tank body 20 and tank body 20 sealed connection tank cover 21, the bottom of the tank body 20 is provided with a discharge port 200, and a discharge valve 4 is provided at the position of the discharge port 200, the tank cover 21 is provided with a feed port 210, and at the feed port 210 The position is connected with the feed pipe 10, and the outer periphery of the tank body 20 is also provided with a thermal insulation jacket 5 with a steam inlet 50 and a condensed water outlet 51. The crystallization tank also includes a condensation coil 6 arranged in the tank body 20. The condensation coil The pipe 6 has a condensate inlet 60 and a condensate outlet 61 protruding from the tank body 2. In addition, for practical ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com