Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Oxalate crystals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

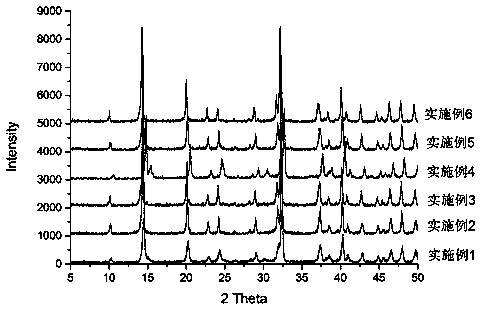

Method for preparing solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder

ActiveCN104124467ACalcination temperature is lowHigh sintering activitySecondary cellsElectrical batteryElectrochemistry

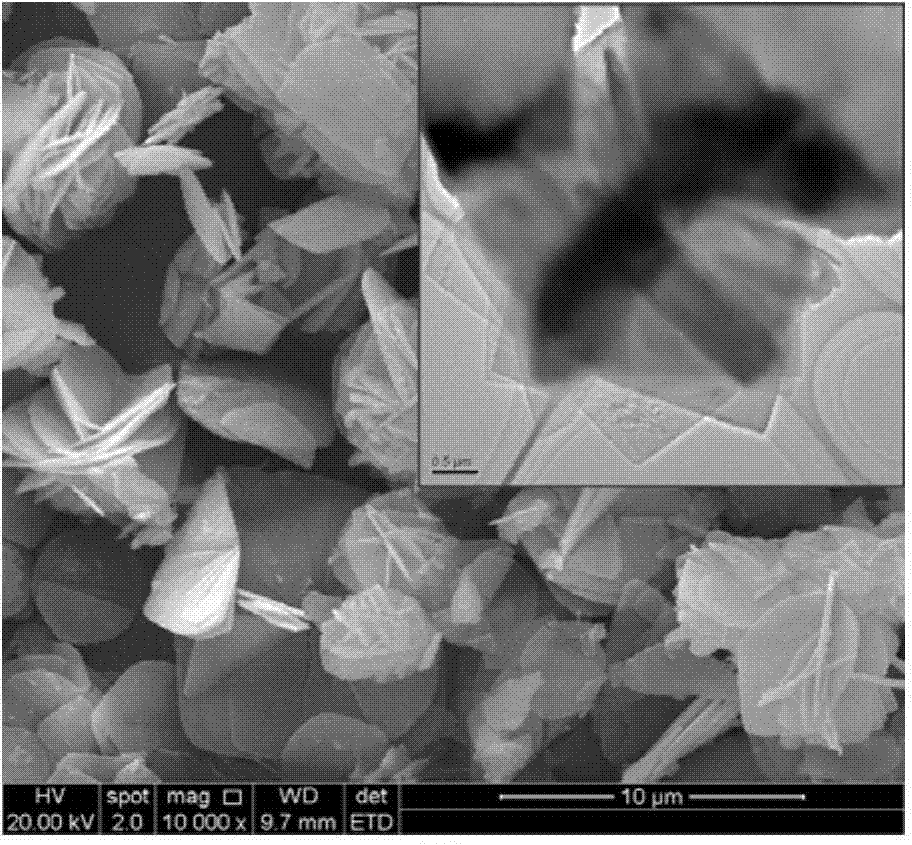

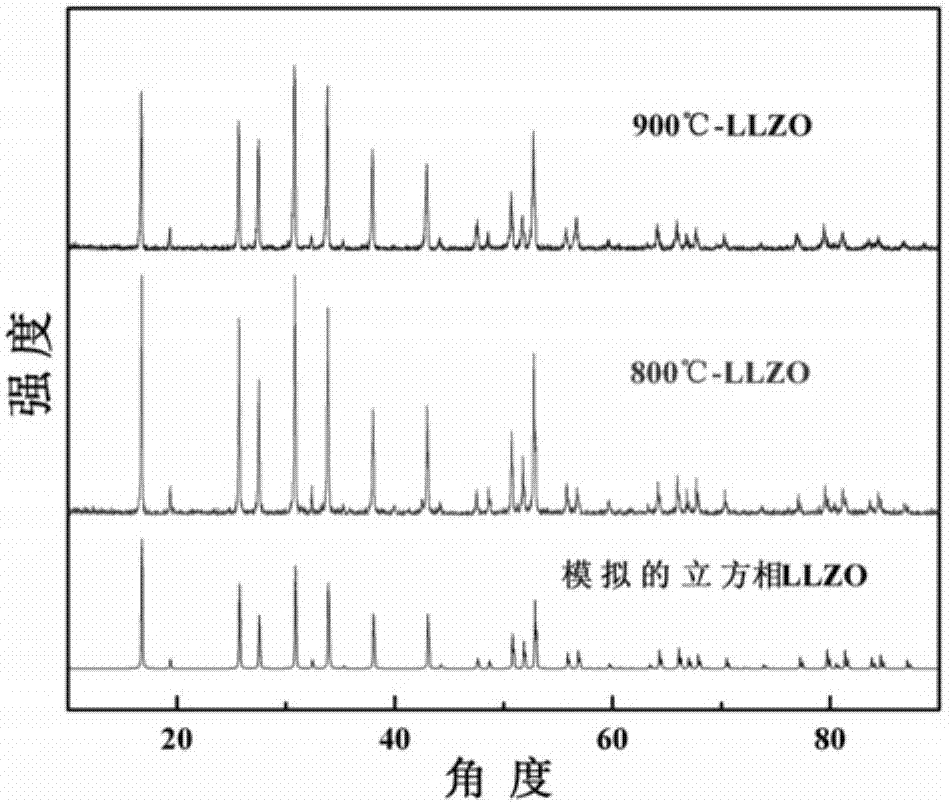

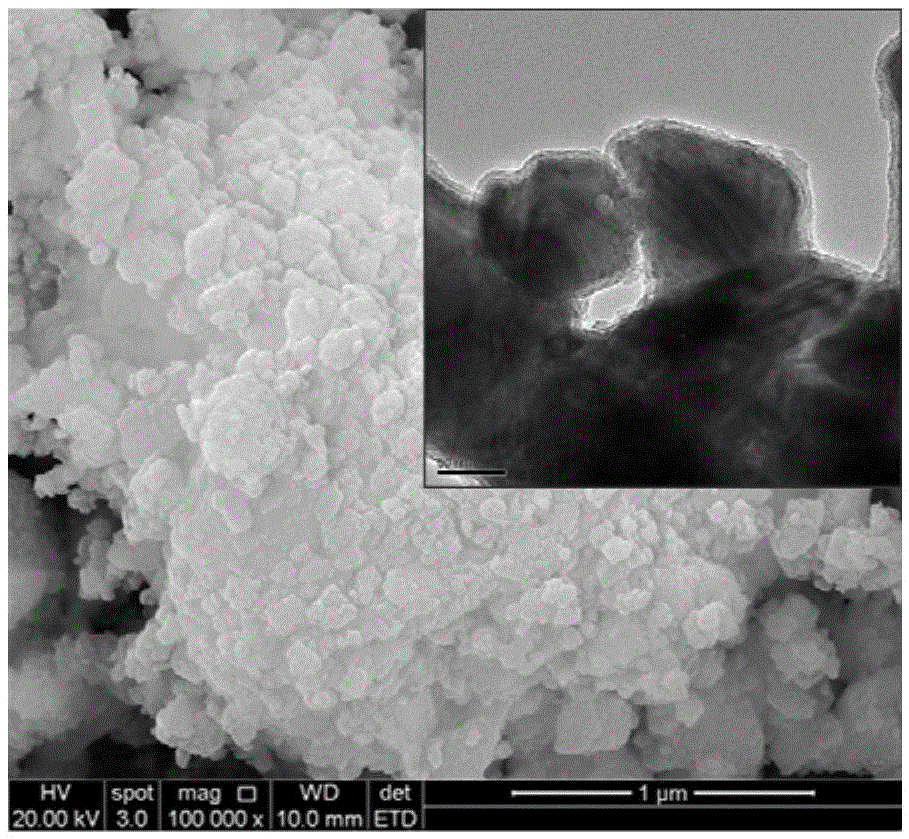

The invention discloses a method for preparing a solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder. The method specifically comprises the steps of dissolving a certain amount of lanthanum nitrate and zirconium nitrate into water, adding a precipitator, namely ammonium carbonate, controlling the pH value to ensure that La<3+> and Zr<4+> ions are simultaneously precipitated, and filtering and washing the precipitate; weighing a certain amount of lithium oxalate, dissolving lithium oxalate into water, adding the precipitate into the lithium oxalate solution, stirring, evaporating, crystallizing, and separating out lithium oxalate crystal on the surface of the precipitate to form precursor powder with a coated structure. The prepared powder has the advantages of uniform mixing, fine grains, high purity and the like; through the formed specific coated structure, the calcination temperature of the powder is low, the sintering time of the powder is short, and the room-temperature lithium ion electric conductivity of the sintered lithium lanthanum zirconium oxide is more than 2.2*10<-4>S / cm. According to the method, the process is simple, the cost is low, the preparation conditions are easy to control, and the prepared solid electrolyte is good in electrochemical stability and high in electric conductivity and can be used for preparing all-solid-state lithium ion batteries.

Owner:WUHAN UNIV OF TECH

Method for preparing zinc oxalate as zinc oxide powder precursor from middle/low-grade zinc oxide ore

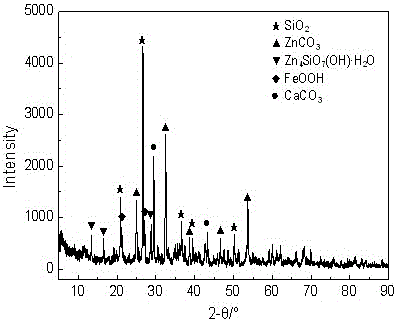

The invention relates to a method for preparing zinc oxalate as a zinc oxide powder precursor from middle / low-grade zinc oxide ore and belongs to the technical field of wet method metallurgy. The method comprises preparing a deep eutectic solvent-type ionic liquid from choline chloride and oxalic acid, fragmenting and fine grinding middle / low-grade zinc oxide ore, adding the middle / low-grade zinc oxide ore powder into the deep eutectic solvent-type ionic liquid, carrying out stirring leaching, adding distilled water into the leached ore pulp, carrying out stirring to obtain a uniform mixture, carrying out standing, carrying out solid-liquid separation to obtain a filtrate A and a zinc oxalate-rich filter residue B, preparing a deep eutectic solvent-type ionic liquid, adding the zinc oxalate-rich filter residue B into the deep eutectic solvent-type ionic liquid, carrying out leaching, carrying out solid-liquid separation to obtain a filtrate C and filter residue D, adding distilled water into the filtrate C, wherein the volume of the distilled water is 2-10 times that of the filtrate C, carrying out filtration after white precipitates are precipitated, washing the filter residue and carrying out drying to obtain zinc oxalate crystals. The method realizes effective utilization of middle / low-grade zinc oxide ore and provides a novel approach for deep eutectic solvent use.

Owner:KUNMING UNIV OF SCI & TECH

Method for producing ferrous oxalate from hematite

InactiveCN101085732ANo pollution in the processLow production costCarboxylic acid salt preparationPersulfateOxalate crystals

The invention relates to a method for producing ferrous oxalate taking bloodstone as raw material with acid- disslovation- irradiation reduction process. It is characterized in that it comprises following steps: disintegrating bloodstone, grinding, refining and getting mineral powder with TFe content larger than 65%; adding mineral powder into ferrous oxalate solution, stirring and extracting at 80- 85 Deg. C for 1- 6 hours; filtering at high temperature, stewing filterate under irradiation for 3d- 7d for reduction, getting light yellow ferrous oxalate crystal, separating crystal and getting vacuum drying it at 60 Deg. C and 13.3 Kpa for 1- 3 hours, getting ferrous oxalate. The invention employs bloodstone to replace ferric persulfate, employs oxalic acid to repalce ammonium oxalate. The invention is characterized by easy to get raw material, simple process, no environmental pollution and suitability for large- sacle industrial production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Scandium recovery method

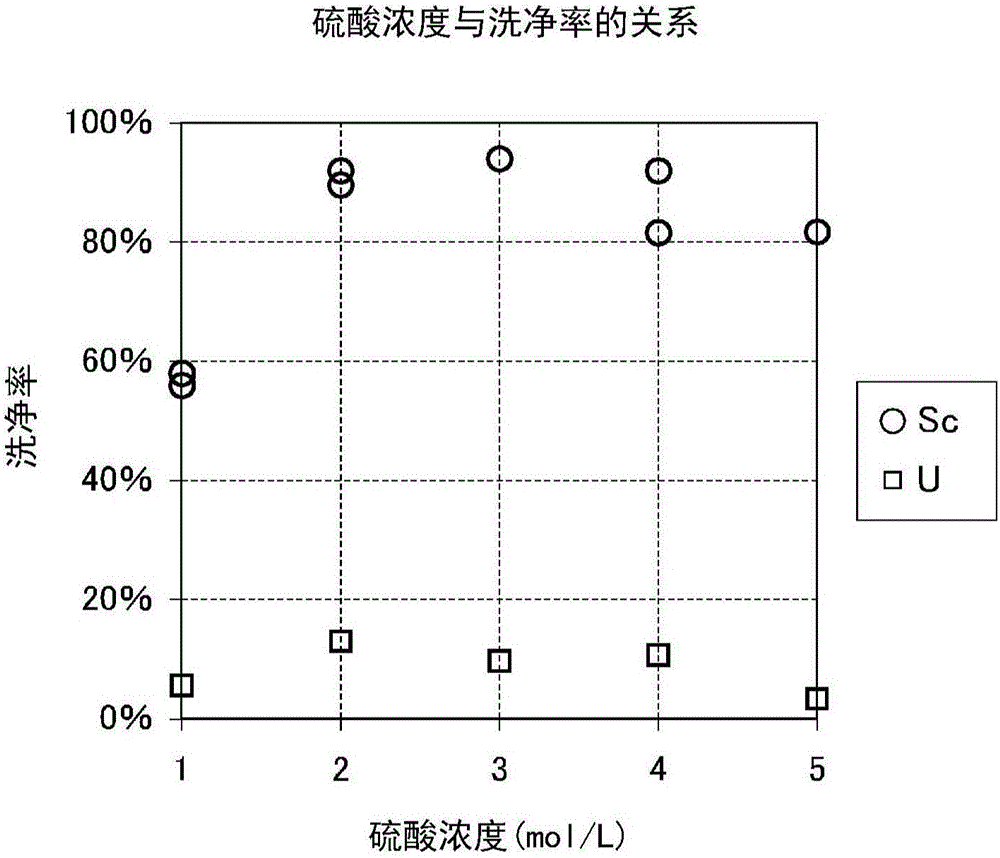

In order to recover high-quality scandium from nickel oxide ores efficiently, this method comprises: a leaching step (S1) for feeding Ni oxide ores and sulfuric acid into a pressure vessel, and subjecting the mixture to solid-liquid separation to form a leachate and a leach residue; a neutralization step (S2) for adding a neutralizing agent to the leachate, and thus forming a neutralization sediment and a post-neutralization fluid; a sulfurization step (S3) for adding a sulfurizing agent to the post-neutralization fluid, and separating the obtained mixture into Ni sulfide and a post-sulfurization fluid; an ion-exchange step (S4) for bringing the post-sulfurization fluid into contact with a chelating resin, making Sc adsorbed on the chelating resin, and forming an Sc eluate; a solvent extraction step (S6) for bringing the Sc eluate into contact with an extracting agent, adding a back-extraction agent to the extract, and thus forming back-extracted matter; and a roasting step (S8) for roasting the back-extracted matter, and thus forming Sc oxide. It is preferable that the method further includes, after the ion exchange step (S4), a concentration step (S5) for forming a sediment from the Sc eluate and dissolving the sediment in an acid, and includes, after the solvent extraction step (S6), an Sc precipitation step (S7) for dissolving the back-extracted matter in hydrochloric acid, adding oxalic acid to the obtained solution, and thus forming Sc oxalate crystals.

Owner:SUMITOMO METAL MINING CO LTD

Quinazoline derivative salt-type crystal forms and preparation method and application thereof

ActiveCN110343090AEffectively pass throughReduce the probability of outflowOrganic active ingredientsOrganic compound preparationTherapeutic effectBioavailability

The invention discloses quinazoline derivative salt-type crystal forms and a preparation method and application thereof. The quinazoline derivative salt-type crystal forms are specifically the hydrochloride crystal forms A, B, C, D, F, H, I, the sulphate crystal form A, the maleate crystal form A, the succinate crystal form A, the adipate crystal form A, the glycollate crystal form A, the malate crystal form A, the fumarate crystal form A, the benzene sulfonate crystal forms A, B, C, the benzoate crystal form A, the hippurate crystal form A and the oxalate crystal form A of a quinazoline derivative shown in a formula (I). The salt-type crystal form provided by the invention has good stability, can be applied to drugs for treatment of non-small cell lung cancer brain metastasis, meningeal metastases, primary brain cancer or glioma and the like, has good bioavailability, and has great significance for further study of the therapeutic effect of the solid drugs.

Owner:WEISHANG (SHANGHAI) BIO PHARMA CO LTD

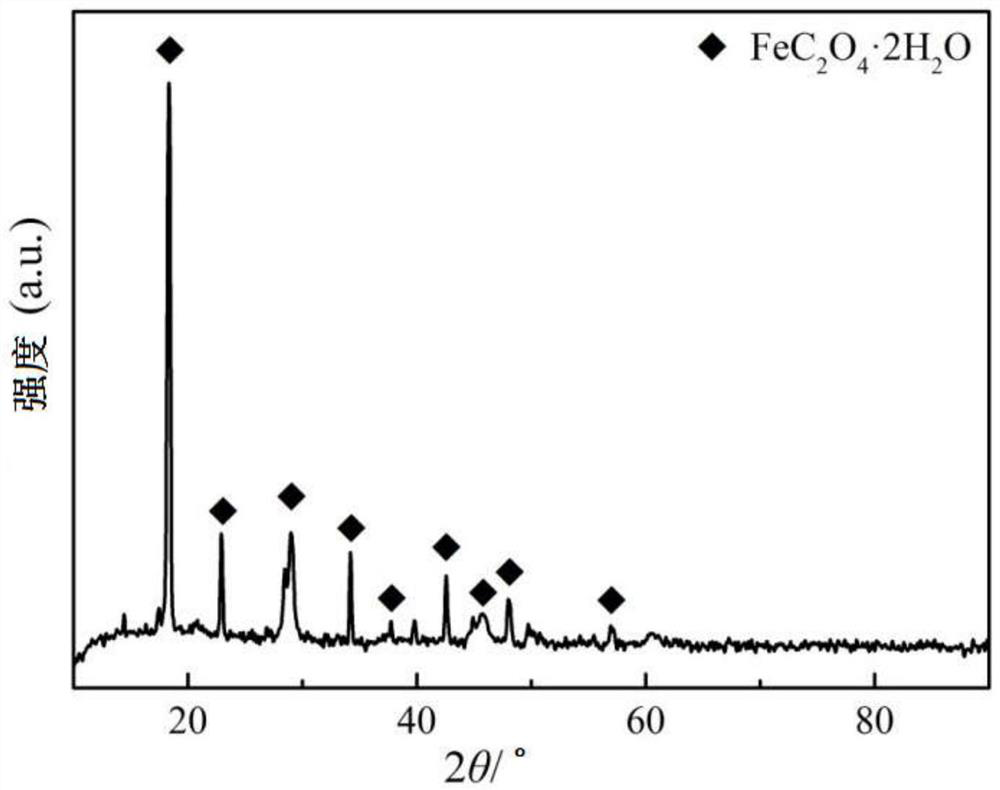

Iron oxalate crystal and preparation thereof

InactiveCN101462944APolycrystalline material growthCarboxylic acid salt preparationFerrous saltsOxalate crystals

The invention relates to a preparation method of monoclinic ferrous oxalate crystal (FeC2O4.2H2O) with particlesize less than 3mum and the monoclinic ferrous oxalate crystal with particlesize less than 3mum obtained by adopting the method. A solid-liquid two-phase method is adopted and the reaction is controlled by controlling the feeding speed of solid oxalate and the temperature and concentration of bivalence ferrous salt solution, thus achieving the purpose of generating the ferrous oxalate crystals with specific crystal formation and particlesize. The method is characterized in that: the solid oxalate is added into the bivalence ferrous salt water solution with concentration of Fe2+ being 0.5-1.7mol / l at the temperature of 40-80 DEG C at the feeding speed of more than 500g / min for reaction by temperature preservation. The method has simple process and high yield. The ferrous oxalate crystal with particlesize less than 3mum is obtained by the method, and the crystal formation is the monoclinic crystal.

Owner:海宁市盐官工业投资有限公司

Drink composition capable of inhibiting urinary calculi formation and promoting litholysis and application of drink composition

InactiveCN107927498AInhibition formationReduce concentrationUrinary disorderNatural extract food ingredientsCalcium glucarateOxalate crystals

The invention relates to a drink composition capable of inhibiting urinary calculi formation and promoting litholysis and an application of the drink composition. The invention relates to a novel application of a garcinia cambogia extract, namely, an application of the garcinia cambogia extract in preparation of food or drugs for inhibiting urinary calculi formation and promoting litholysis. The invention also provides a drink capable of inhibiting urinary calculi formation and promoting litholysis. The drink has the advantages as follows: animal experiments find that the garcinia cambogia extract can inhibit urinary calculi formation and promote litholysis for the first time. The concentration of 24 h urinary oxalic acid and calcium ions in rats in a garcinia cambogia extract interventiongroup is significantly reduced as compared with a calculus induction group; dotted calcium oxalate crystals can be seen in kidney tubules in the garcinia cambogia extract intervention group, flaky calcium oxalate crystals are seldom seen, and the um oxalate crystal deposition and lumen expansion conditions are remarkably better than those in the calculus induction group.

Owner:南京伊登生物医学科技有限公司

Method for preparing ferrous oxalate by using vanadium slag

ActiveCN110256235AHigh puritySmall particle sizeOrganic compound preparationCarboxylic acid salt preparationSlagSolvent

The invention relates to a method for preparing ferrous oxalate by using vanadium slag, and belongs to the technical field of preparation of ferrous oxalate for batteries. The technical problem solved by the invention is to provide the method for preparing the ferrous oxalate by using the vanadium slag. The method includes the following steps: mixing quaternary ammonium salt with oxalic acid to form an eutectic solvent; and adding the vanadium slag into the eutectic solvent for leaching, carrying out solid-liquid separation to obtain a leachate, adding deionized water into the leachate, standing and filtering the mixture, and washing and drying obtained solid to obtain a ferrous oxalate crystal. The method of the invention uses the vanadium slag as a raw material to prepare the ferrous oxalate crystal with high purity and particle size of 0.5-2 [mu]m, which has the advantages of small particle size, uniform size and high purity and can be used as a raw material for synthesizing a lithium ion battery positive electrode material lithium iron phosphate, is low in equipment requirements, short in process flow and environmentally friendly, and can comprehensively utilize valuable metal resources of the vanadium slag. Moreover, the used eutectic solvent has the advantages of environmental protection, simple synthesis and low price.

Owner:PANZHIHUA UNIV +1

Production method of doped ferrous oxalate

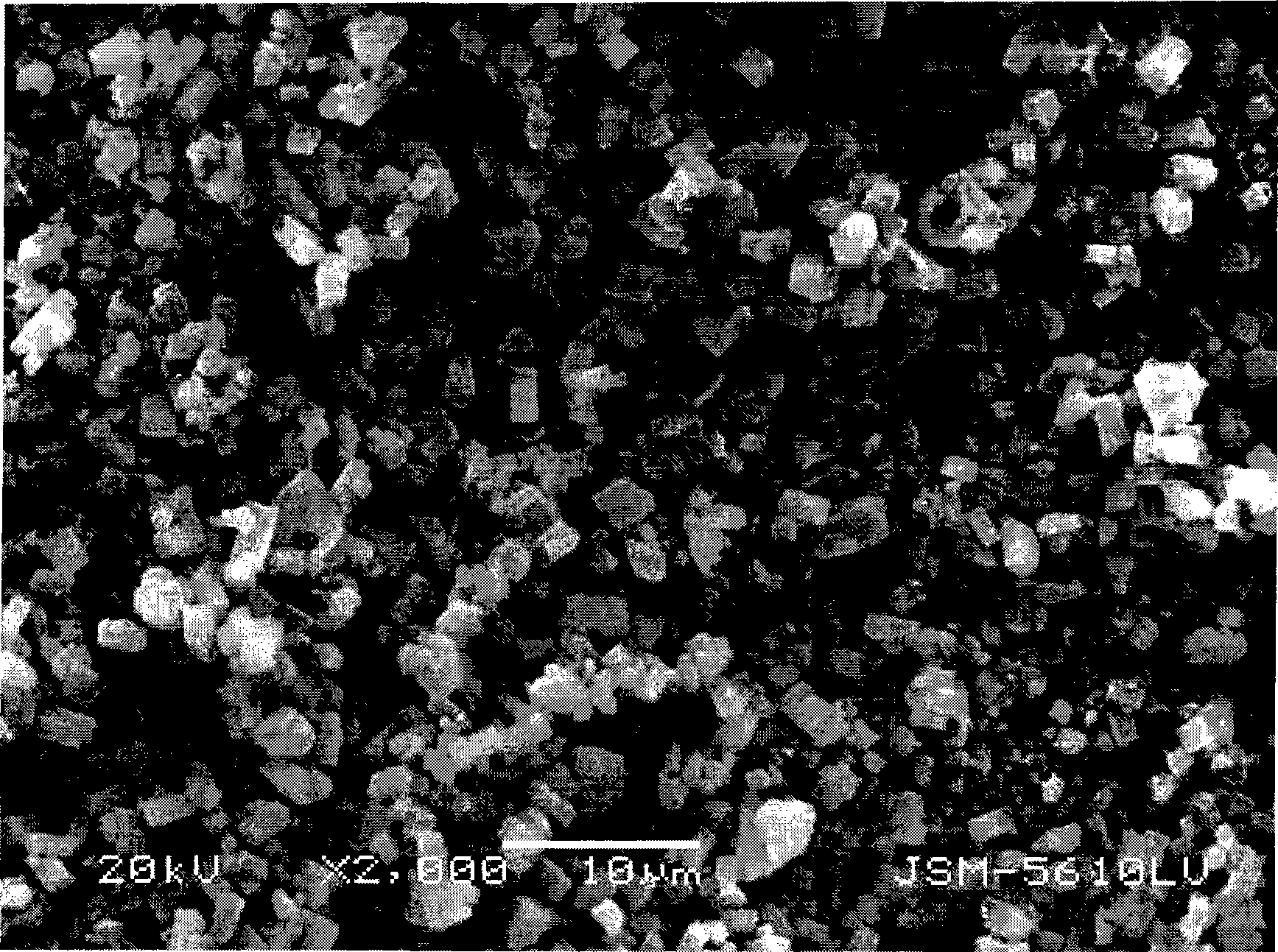

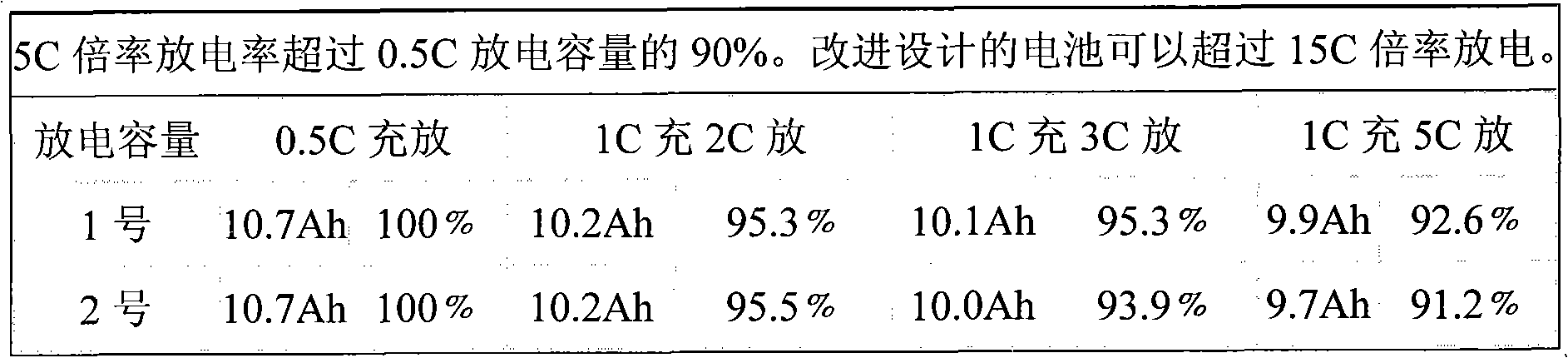

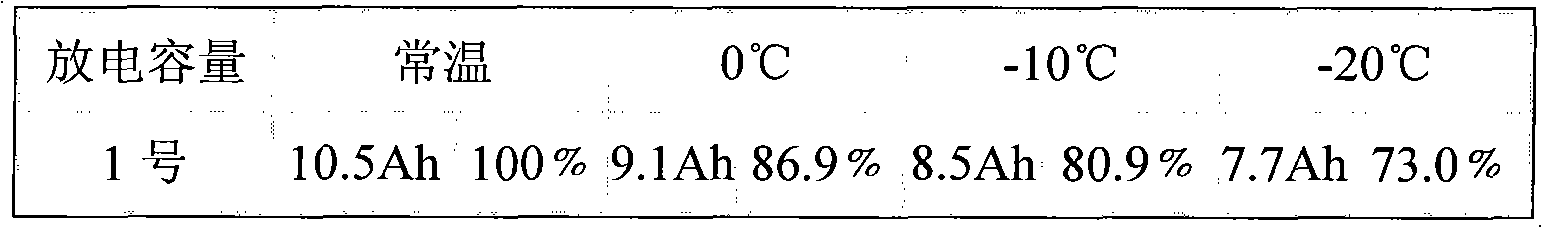

InactiveCN101811952AFast chargingImprove conductivityCarboxylic acid salt preparationMaterials processingOxalate crystals

The invention relates to a production method of doped ferrous oxalate, which takes ferrous sulfate and oxalic acid as raw materials, and comprises the steps of purifying, synthesizing, separating, washing and drying. The production method is characterized in that after purification, when the ferrous sulfate and the oxalic acid are synthesized in water solution, ammonium oxalate and metal salt are added into the solution at 60-140 DEG C and stirred for reaction for 5-40min, wherein the ammonium oxalate has the mass percent concentration of 0.2-1% in reaction liquid, and the adding quantity of the metal salt is 0.1-4% of the mass of the ferrous sulfate. The method leads 2500mu g / g of impurity ions to be doped into ferrous oxalate crystal, thus improving the electric conduction performance of LFP. A lithium battery processed by LFP cathode material prepared by the ferrous oxalate has good charging and discharging characteristics under different multiplying powers, and circulating performance at high and low temperature.

Owner:朱辰

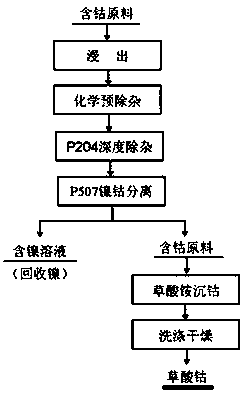

Method for preparing cobalt oxalate by ammonia-free oxalic acid precipitation

InactiveCN108069851AHarmful impact reductionImprove qualityOrganic compound preparationOrganic chemistry methodsOxalate crystalsEngineering production

A method for preparing cobalt oxalate by ammonia-free oxalic acid precipitation includes steps: subjecting cobalt-containing waste residues to leaching and decontaminating processes to obtain cobalt chloride solution performing precipitation with oxalic acid as a precipitant, and performing aging, leaching and washing under a stirring state to obtain mother liquor and cobalt oxalate crystal in granularity of 30micron and complete in crystal form. The method has advantages that adding of ammonium-containing compounds such as ammonium salt, ammonium hydroxide or the like is avoided, and ammonium-containing wastewater in a production process is avoided, so that ammonium removal treatment of wastewater in subsequent procedures is avoided, production cost is saved, environmental hazards are reduced, and valuable metal cobalt can be recycled to the utmost extent.

Owner:甘肃有色冶金职业技术学院

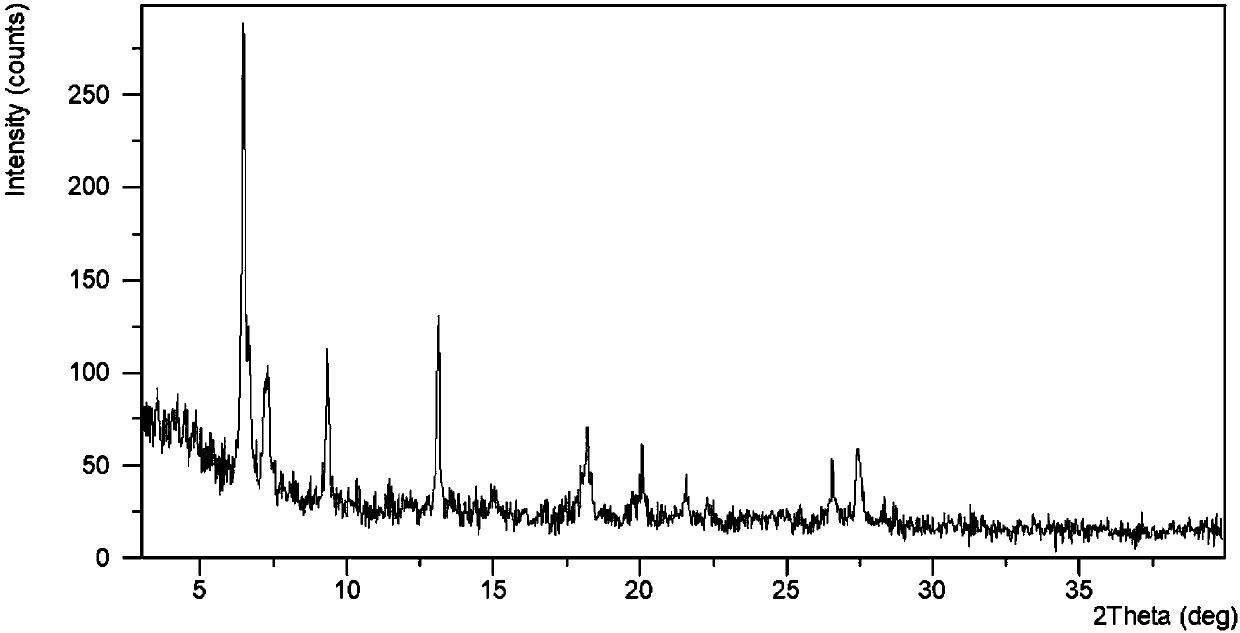

Valnemulin oxalate crystal and preparation method thereof

ActiveCN104130168AHigh purityHigh yieldOrganic chemistryOrganic compound preparationX-rayCrystallinity

The invention relates to a valnemulin oxalate crystal and a crystallization preparation method thereof. According to an X-ray powder diffraction pattern of the crystal, characteristic peaks appear at diffraction angle 2theta of 6.2, 8.0, 10.5, 11.2, 12.5, 13.2, 14.6, 15.0, 17.0, 18.0, 19.7 and 21.1 degrees. According to the invention, valnemulin is dissolved in an ester type solvent, wherein a solution concentration is 0.1-0.4g / mL; oxalic acid is added according to a molar ratio that oxalic acid to valnemulin is 1:1-1:2; under a stirring effect, a reaction is carried out under a temperature of 40-60 DEG C until the solution is clear; the temperature of the solution is reduced to 10-20 DEG C; and filtering, washing, and drying are carried out, such that a valnemulin oxalate crystal product is obtained. The crystallization process has a yield higher than 90%. The valnemulin oxalate product has high crystallinity, high purity, and low fly-off. The valnemulin oxalate product has good stability against light, heating, and moisture.

Owner:TIANJIN UNIV +1

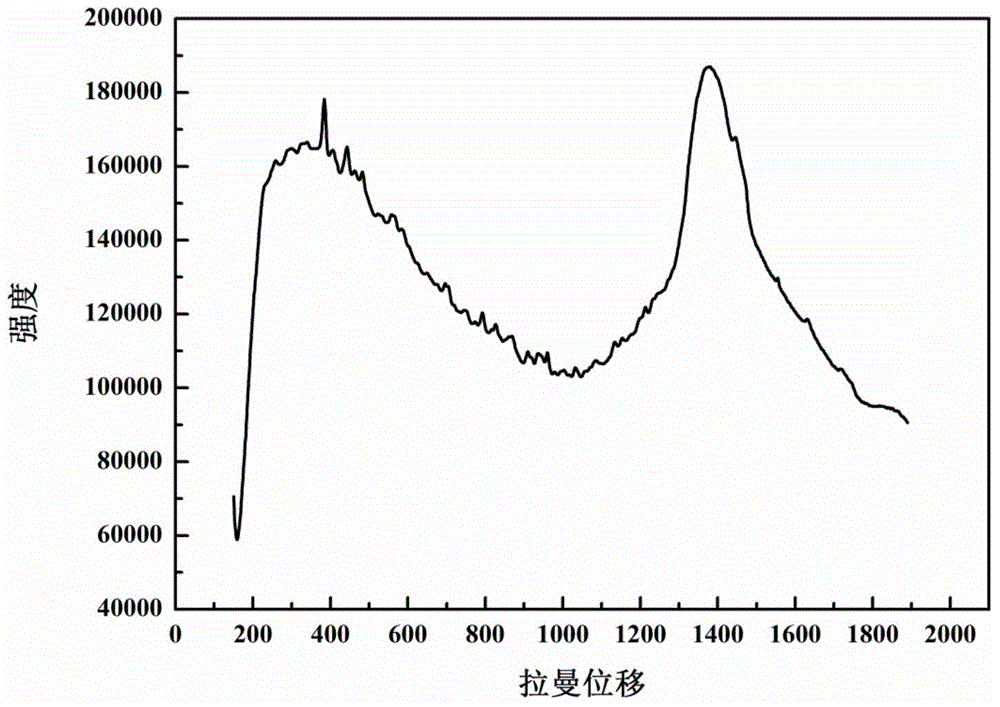

Plant source organic-inorganic compounding molluscicide fertilizer preparation and preparation method and application thereof

ActiveCN109197896AImprove performanceEasy to useBiocideBio-organic fraction processingAmaryllidaceaePlant Sources

The invention relates to a plant source organic-inorganic compounding molluscicide fertilizer preparation and a preparation method and application thereof, and relates to the technical field of biological pesticides. The plant source organic-inorganic compounding molluscicide fertilizer preparation comprises a needle-like calcium oxalate crystal and an inorganic fertilizer, wherein the needle-likecalcium oxalate crystal is obtained by separating and extracting from a plant of Araceae or Amaryllidaceae. The plant source organic-inorganic compounding molluscicide fertilizer preparation also preferably includes a plant fermented organic fertilizer. A suitable amount of chemical fertilizer is added to a needle-like calcium oxalate crystal extract contained in the plant of Araceae and Amaryllidaceae, and a plant extract residue fermented product is used as an organic fertilizer carrier to prepare the plant source organic-inorganic compounding molluscicide fertilizer preparation. The plantsource organic-inorganic compounding molluscicide fertilizer preparation can not only promote rice growth, increase yield, also has the effect of killing snails and achieve the double effect of killing Oncomelania hupensis to achieve the integration of double effects of molluscicide and fertilizing. In addition, the plant source organic-inorganic compounding molluscicide fertilizer preparation issimple in preparation method, the production cost is low, the use is convenient, and the plant source organic-inorganic compounding molluscicide fertilizer preparation is conductive to large-scale application and promotion in a rice field in a schistosomiasis epidemic area.

Owner:HUBEI UNIV

Method for removing oxalate during production of alumina

InactiveCN109292804AReduce concentrationImprove decomposition yieldAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAluminium hydroxideDecomposition

The invention provides a method for removing oxalate during alumina production and relates to the technical field of alumina production. The method specifically includes: adding a special crystallizing aid and a CGM crystallizing aid into essential oil, decomposing, filtering to obtain an aluminum hydroxide filter cake, and filtering underflow to obtain oxalate crystal; adjusting decomposing headtank temperature to 56-62 DEG C and decomposing tail tank temperature to 45-49 DEG C, wherein adding amount of the CGM crystallizing aid is 0-25ppm of essential liquid amount, adding amount of the special crystallizing aid is 5-30ppm of the essential liquid amount, and the special crystallizing aid comprises, by mass, 10-30% of oleic acid, 1-5% of C8-10 fatty acid and the balance of water. By adding the special crystallizing aid combined with the CGM crystallizing aid, oxalate is stably precipitated in a spherical form, the head tank temperature and the tail tank temperature are adjusted downwards to lower concentration of oxalate in a solution, and decomposition yield is increased.

Owner:GUANGXI HUAYIN ALUMINUM

Recycling method for acidic etching waste liquid

InactiveCN112080748ANo dischargeIncrease valueCarboxylic compound separation/purificationOil phaseEnvironmental engineering

The invention discloses a recycling method for an acidic etching waste liquid. The recycling method for the acidic etching waste liquid comprises the following steps that the pH value range of the acidic etching waste liquid is adjusted to be 1-2; extraction operations are performed on the acidic etching waste liquid by adopting an extracting agent solution, and an oil phase is obtained after still-standing layering; and back extraction operations are performed on the oil phase by adopting a solution containing oxalate ions to obtain copper oxalate. The technical scheme of the recycling methodfor the acidic etching waste liquid is low in operation cost and relatively easy to operate, no toxic waste gases are generated in the operation process, the safety is high, furthermore, no waste liquid and waste residues are discharged in the treatment process, and secondary pollution is not caused; and meanwhile, a product obtained by the recycling method for the acidic etching waste liquid isan ultrafine copper oxalate crystal, the particle size is regular and relatively uniform, the value is high, and hazardous waste transfer qualification is not needed during outward transportation.

Owner:深圳市祺鑫环保科技有限公司

A method for preparing solid electrolyte by coating powder with lithium lanthanum zirconium oxygen precursor

ActiveCN104124467BCalcination temperature is lowHigh sintering activitySecondary cellsCeriumElectrochemistry

The invention discloses a method for preparing a solid electrolyte by using lithium lanthanum zirconium oxide precursor coated powder. The method specifically comprises the steps of dissolving a certain amount of lanthanum nitrate and zirconium nitrate into water, adding a precipitator, namely ammonium carbonate, controlling the pH value to ensure that La<3+> and Zr<4+> ions are simultaneously precipitated, and filtering and washing the precipitate; weighing a certain amount of lithium oxalate, dissolving lithium oxalate into water, adding the precipitate into the lithium oxalate solution, stirring, evaporating, crystallizing, and separating out lithium oxalate crystal on the surface of the precipitate to form precursor powder with a coated structure. The prepared powder has the advantages of uniform mixing, fine grains, high purity and the like; through the formed specific coated structure, the calcination temperature of the powder is low, the sintering time of the powder is short, and the room-temperature lithium ion electric conductivity of the sintered lithium lanthanum zirconium oxide is more than 2.2*10<-4>S / cm. According to the method, the process is simple, the cost is low, the preparation conditions are easy to control, and the prepared solid electrolyte is good in electrochemical stability and high in electric conductivity and can be used for preparing all-solid-state lithium ion batteries.

Owner:WUHAN UNIV OF TECH

Oral composition for dissolving calcium oxalate calculus

InactiveCN108853170AEasy to control the dissolution timeConvenient time controlOrganic active ingredientsPharmaceutical non-active ingredientsCalcium oxalate calculusSide effect

The invention provides an oral composition for dissolving calcium oxalate calculus. The composition contains 0.1-10% of garcinia cambogia extract microcapsules or 0.1-10% of hydroxycitric acid or hydroxycitric acid derivative microcapsules. The composition contains garcinia cambogia extract microcapsules, hydroxycitric acid or hydroxycitric acid derivative microcapsules, so that calculus formed bycalcium oxalate crystals can be effectively dissolved; the materials of the garcinia cambogia extract microcapsules, hydroxycitric acid or hydroxycitric acid derivative microcapsules adopt organic polymer materials, which have certain dissolvability and are capable of conveniently controlling disintegration and dissolution time of the composition and protecting effective components in the composition to reach efficient absorption parts. The composition adopts natural extracts, is free of toxic and side effects on human body and excellent in calculus dissolving effect, can be orally taken by broad crowds, is free of strict restrictions on the crowds, and has broad application prospects.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV

Heterocyclic compound as well as preparation method and application thereof

ActiveCN114437084AStrong medicinal applicabilitySuppress cancerOrganic active ingredientsOrganic compound preparationHydrobromideOxalate crystals

The invention discloses a heterocyclic compound as well as a preparation method and application thereof. Specifically, the invention provides a free alkali crystal form, a hydrochloride crystal form, a sulfate crystal form, a maleate crystal form, a phosphate crystal form, a fumarate crystal form, a mesylate crystal form, an oxalate crystal form and a hydrobromide crystal form of the heterocyclic compound as shown in a formula I, a preparation method of each crystal form and application of the crystal forms in preparation of drugs. Wherein each crystal form has excellent physicochemical properties, so that the compound crystal form is particularly suitable for preparation development, especially as a medicine for treating cancers, and has a good patent medicine prospect. .

Owner:ASCENTAGE PHARMA SUZHOU CO LTD +1

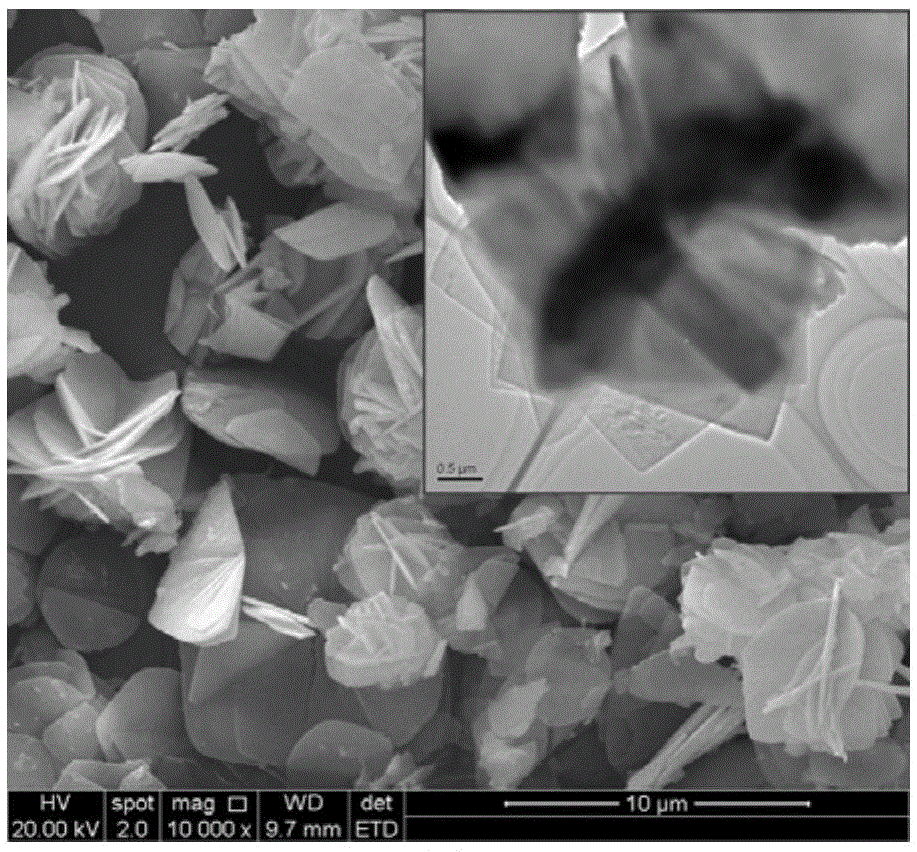

Preparation method of lithium ferrous oxalate ion battery negative electrode material with exposed specific oriented crystal faces

PendingCN113861015AImprove energy storage performanceLow costOrganic compound preparationCell electrodesFerric hydroxideElectrochemical response

The invention relates to a preparation method of a lithium ferrous oxalate ion battery negative electrode material with exposed specific oriented crystal faces. An iron hydroxide precursor is added into a mixed solution composed of additives such as ascorbic acid and oxalic acid in a specific proportion, and synthesis of a ferrous oxalate nano-material exposing different oriented crystal faces is achieved by controlling the reduction dissolution rate of iron hydroxide in the solution and coordinating the nucleation growth process of the ferrous oxalate material. According to the invention, ascorbic acid is adopted to strengthen reduction dissolution of an acidic oxalic acid solution on ferric hydroxide and regulate and control atomic coordination and an initial crystal stacking rate of ferrous oxalate; meanwhile, the atomic coordination environment and the surface energy of ferrous oxalate crystal particles are interfered by using an organic solvent; therefore, the preparation of the ferrous oxalate material with exposed specific oriented crystal faces is achieved. The ferrous oxalate material with the exposed specific oriented crystal face growth can give full play to the advantages of different types of electrochemical reaction ion diffusion microchannels constructed by arrangement of different crystal face atoms and the characteristic of close arrangement of different oriented crystal face atoms to adjust material stress distribution and energy storage catalytic sites, and the lithium storage performance of the ferrous oxalate material is enhanced.

Owner:云南润久科技有限公司

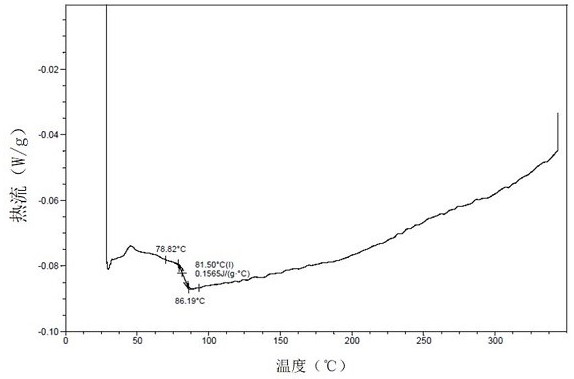

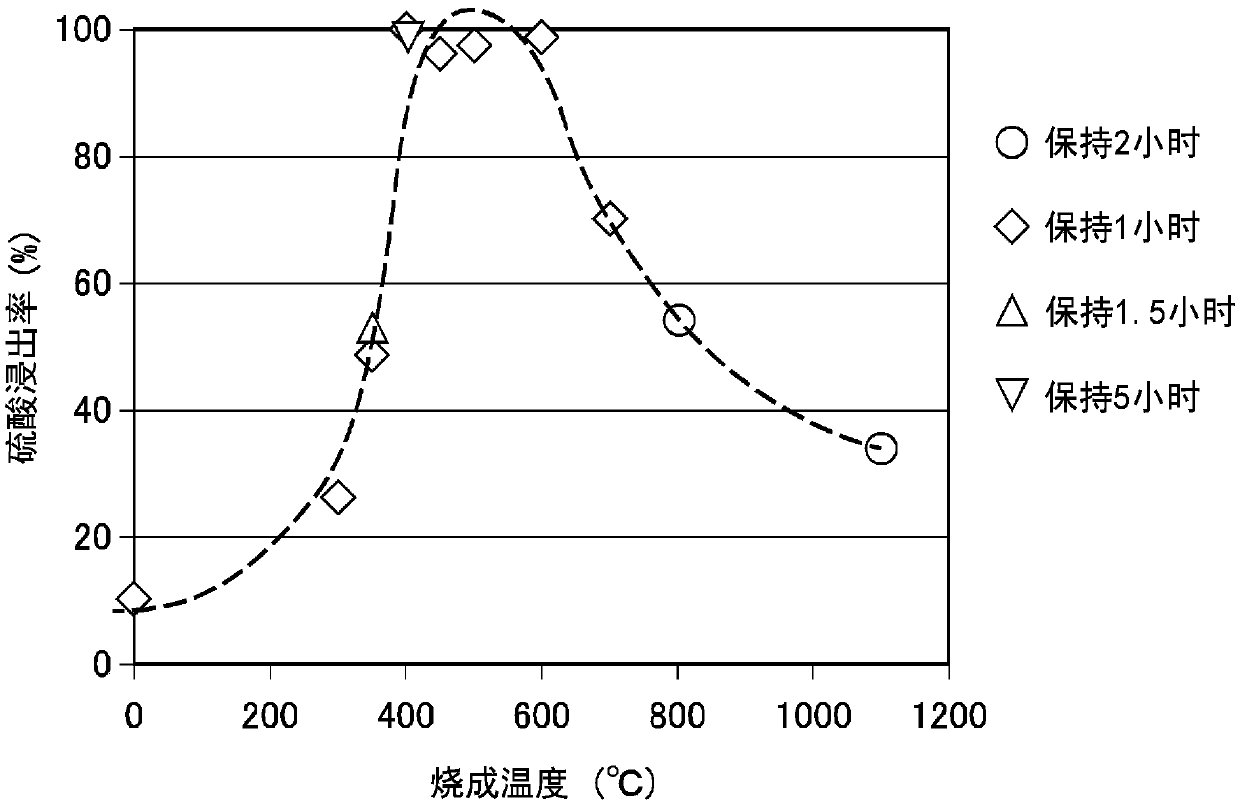

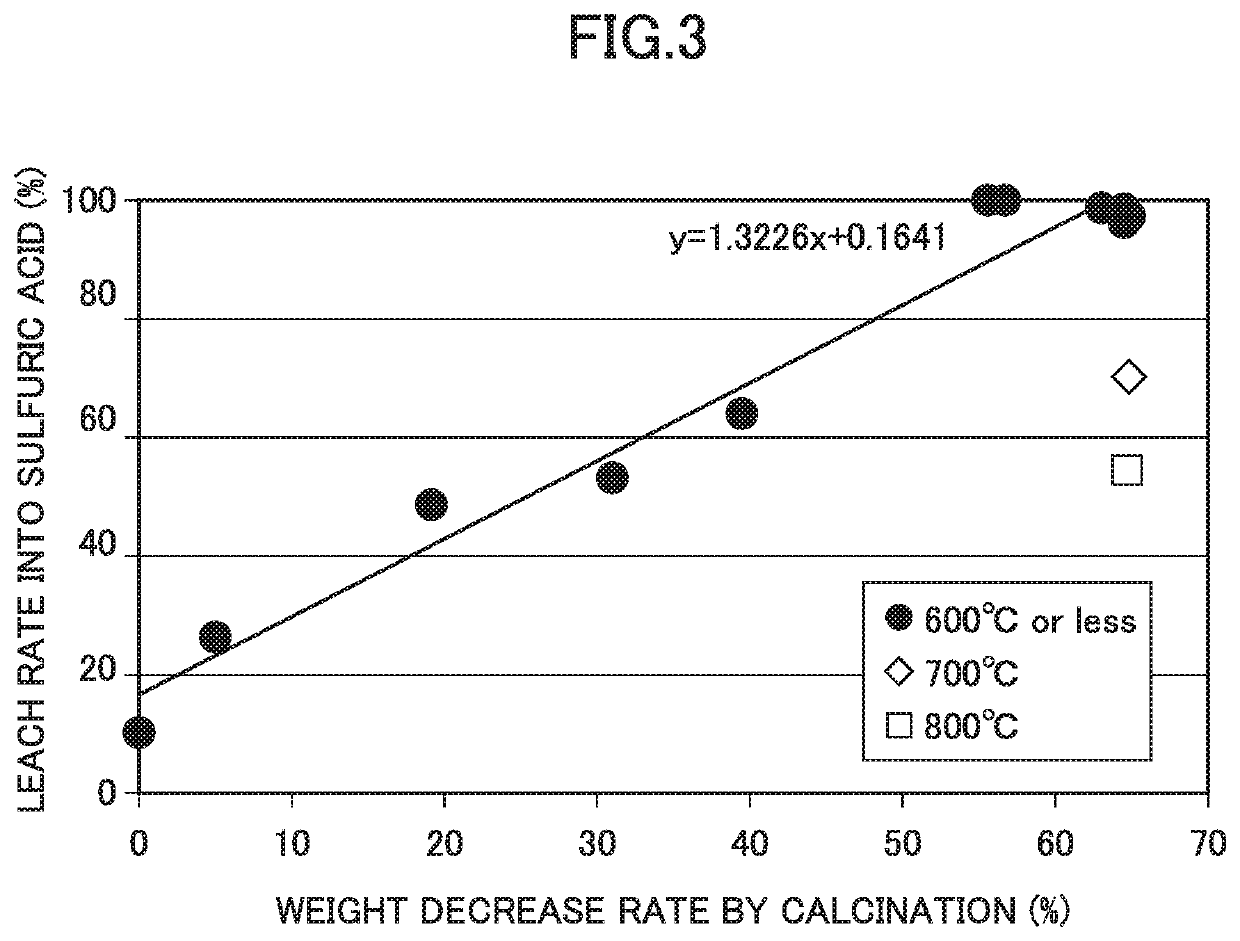

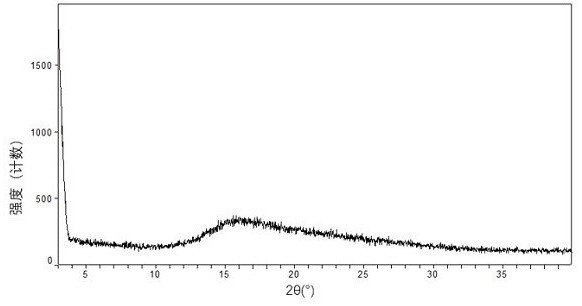

Method for producing scandium compound, and scandium compound

InactiveCN109563565ALow costSave effortScandium oxides/hydroxidesRare earth metal compounds preparation/treatmentAqueous solutionOxalate crystals

Provided is a method for producing, from scandium oxalate crystals obtained through an oxalate conversion process, a readily-soluble scandium compound that dissolves easily in an aqueous solution suchas an acid. This method for producing a scandium compound involves carrying out an oxalate conversion process using oxalic acid in a solution containing scandium, separating the product obtained through the oxalate conversion process into a liquid and scandium oxalate crystals, and obtaining a scandium compound by roasting the obtained scandium oxalate crystals at a temperature of 400 DEG C to 800 DEG C, preferably 400 DEG C to 600 DEG C.

Owner:SUMITOMO METAL MINING CO LTD

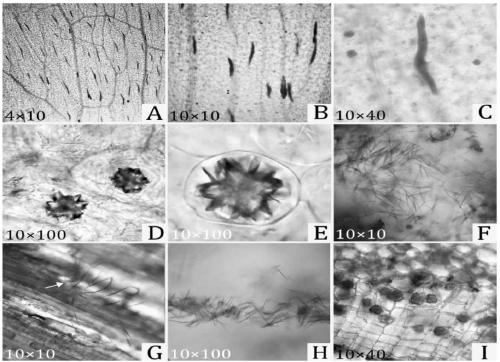

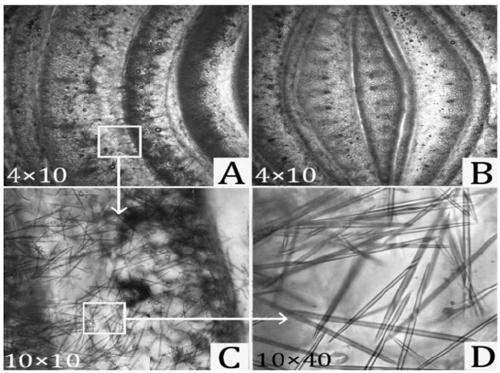

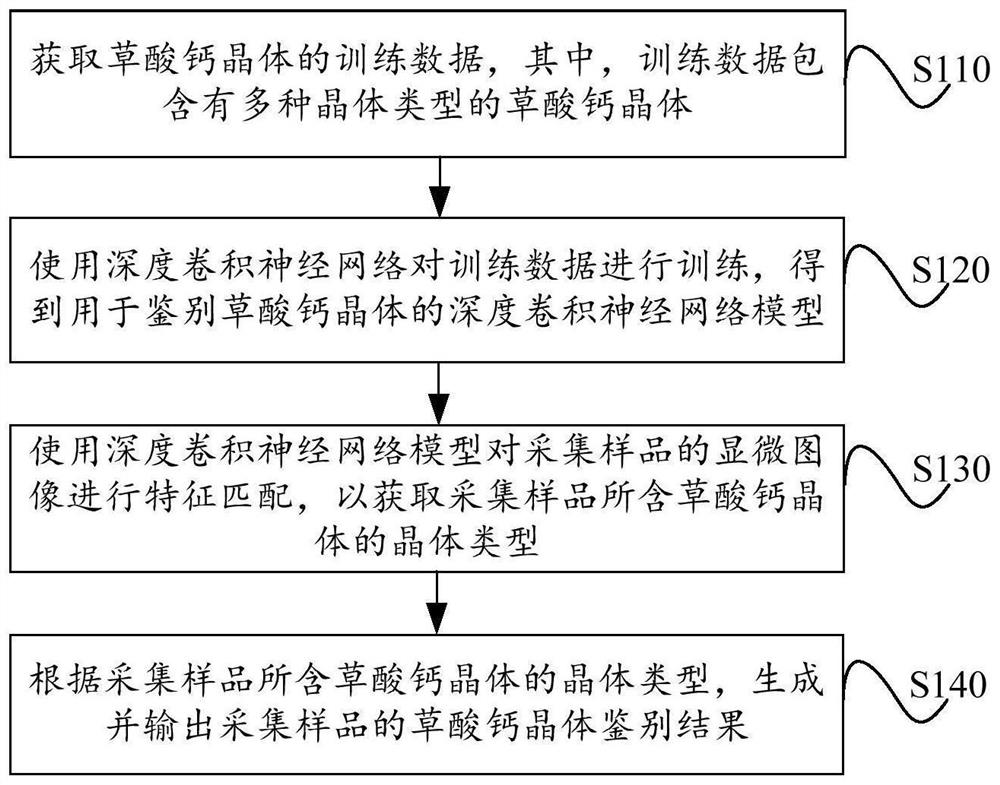

Intelligent identification method and system for calcium oxalate crystals based on microscopic images

PendingCN111709390ASolve the errorIt takes a long time to solve the drawingInvestigation of vegetal materialNeural architecturesMicroscopic imageOxalate crystals

The invention discloses an intelligent identification method and system for calcium oxalate crystals based on microscopic images, and the method comprises the steps: obtaining the training data of thecalcium oxalate crystals, wherein the training data comprises various types of calcium oxalate crystals; training the training data by using a deep convolutional neural network to obtain a deep convolutional neural network model for identifying calcium oxalate crystals; performing feature matching on the microscopic image of the collected sample by using a deep convolutional neural network modelto obtain the crystal type of the calcium oxalate crystal contained in the collected sample; and generating and outputting a calcium oxalate crystal identification result of the collected sample according to the crystal type of the calcium oxalate crystal contained in the collected sample. According to the technical scheme, the problems of large error, long consumed time and low working efficiencycaused by manual identification in the prior art can be solved.

Owner:SHANDONG INST FOR FOOD & DRUG CONTROL

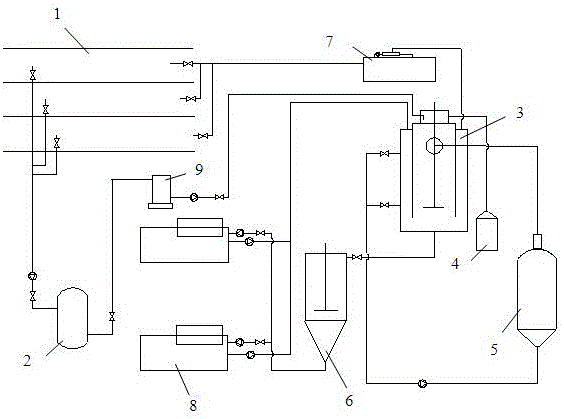

Plutonium oxalate cup-type continuous precipitation device

InactiveCN113058296AAvoid cloggingControl liquid levelOrganic compound preparationChemical/physical/physico-chemical stationary reactorsPhysical chemistryElectric machinery

The invention provides a plutonium oxalate cup-type continuous precipitation device. The plutonium oxalate cup-type continuous precipitation device comprises a precipitation tank, an inclined overflow weir, a stirring device, an end socket, a reaction tank, a precipitation channel, a conical buffer plate, a heat preservation jacket, a temperature sensor, a liquid level monitor, a feed port and a discharge port, The stirring device consists of a stirring shaft, a turbo type straight blade stirring paddle and a pump wheel, and is used for sucking and stirring mixed feed liquid under the driving of a motor. The reaction tank is arranged in the precipitation tank, and an inclined overflow weir is arranged at the top of the reaction tank, so that the precipitation slurry after reaction is smoothly discharged along the precipitation channel. The top of the precipitation tank is sealed by the end socket. The device has the beneficial effects that continuous precipitation is realized, the plutonium oxalate aging condition and time can be ensured in the equipment, and the quality of oxalate crystals is ensured while the high yield is ensured.

Owner:HARBIN ENG UNIV

Online hydrochloric acid cyclic utilization method and device on steel acid pickling line

The invention discloses an online hydrochloric acid cyclic utilization method on a steel acid pickling line. The method includes the following steps that firstly, acid pickling liquid on the acid pickling line is collected and filtered and is conveyed to a vapor-liquid separator; secondly, oxalic acid is added into the vapor-liquid separator through a chemical adding device; thirdly, mixed liquid is forcefully cycled between the vapor-liquid separator and an acid-resisting and high-temperature-resisting heating evaporation device, acid vapor and a super-saturated solution containing ferrous oxalate crystals are formed, and the acid vapor is conveyed to the acid pickling line; fourthly, a crystallizing tank is used for separating out ferrous oxalate and conveying the ferrous oxalate to a second filtering device; fifthly, the ferrous oxalate crystals are filtered through the second filtering device; and sixthly, the above steps are repeated. According to the online hydrochloric acid cyclic utilization method on the steel acid pickling line, low-concentration hydrochloric acid obtained after acid pickling is converted into high-concentration hydrochloric acid which can be cyclically used through the oxalic acid and is conveyed to the acid pickling line again, meanwhile, due to the reaction of the oxalic acid and ferrous chloride, the ferrous oxalate is generated and can also be used as a raw material of lithium batteries and the like, cost is saved, and profits are generated.

Owner:TIANJIN RUNJIE INNOVATION ENVIRONMENTAL PROTECTION TECH

On-line hydrochloric acid recycling method and device on steel pickling line

Owner:TIANJIN RUNJIE INNOVATION ENVIRONMENTAL PROTECTION TECH

Method for producing scandium compound, and scandium compound

InactiveUS20210284546A1Improve solubilityLow costScandium oxides/hydroxidesRare earth metal compounds preparation/treatmentOXALIC ACID DIHYDRATEOxalate crystals

Provided is a method for producing, from scandium oxalate crystals obtained through an oxalate conversion process, a readily-soluble scandium compound that dissolves easily in an aqueous solution such as an acid. This method for producing a scandium compound involves carrying out an oxalate conversion process using oxalic acid in a solution containing scandium, separating the product obtained through the oxalate conversion process into a liquid and scandium oxalate crystals, and obtaining a scandium compound by roasting the obtained scandium oxalate crystals at a temperature of 400° C. to 800° C., preferably 400° C. to 600° C.

Owner:SUMITOMO METAL MINING CO LTD

A kind of method utilizing vanadium slag to prepare ferrous oxalate

ActiveCN110256235BHigh puritySmall particle sizeOrganic compound preparationCarboxylic acid salt preparationOXALIC ACID DIHYDRATESlag

Owner:PANZHIHUA UNIV +1

Heterocyclic compounds and their preparation methods and applications

ActiveCN114437084BStrong medicinal applicabilitySuppress diseaseOrganic active ingredientsOrganic compound preparationHydrobromideOxalate crystals

The invention discloses a heterocyclic compound and a preparation method and application thereof. Specifically provide a free base crystal form, hydrochloride salt crystal form, sulfate crystal form, maleate crystal form, phosphate crystal form, fumarate crystal form, Mesylate crystal form, oxalate crystal form and hydrobromide salt crystal form, as well as the preparation method of each crystal form and the application in the preparation of medicine. Wherein each crystal form has excellent physical and chemical properties, so that the crystal form of the compound is particularly suitable for formulation development, especially as a drug for treating cancer, and has a good drug prospect. .

Owner:ASCENTAGE PHARMA SUZHOU CO LTD +1

Method for sealing carbon dioxide

ActiveCN109516912ATo achieve the effect of storageAvoid consumptionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsCarbon dioxide productionSorbent

The invention discloses a method for sealing carbon dioxide. According to the method, carbon dioxide is captured and absorbed by virtue of inorganic base and is directly applied to the production of oxalate, oxalate is taken as a detergent aid to be applied to a clothes detergent, and ucalcium oxalate crystals are formed by oxalate and calcium ions in water, so that the utilization and mineralization sealing of carbon dioxide are realized. Carbon dioxide is absorbed through carbonate and is directly applied to the production of oxalate, so that the loss of a large number of energy sources is avoided in the regeneration process of an adsorbent, and the zero release can be realized in the whole flow; and oxalate prepared during the production of carbon dioxide is taken as the detergent aid,oxalate is combined with the calcium ions so as to generate calcium oxalate precipitates in the washing process of clothes, so that the mineralization sealing of carbon dioxide is realized, and the greenhouse effect is relieved.

Owner:TAIYUAN UNIV OF TECH

A method for preparing zinc oxide powder precursor zinc oxalate by utilizing middle and low grade zinc oxide ore

The invention relates to a method for preparing zinc oxalate as a zinc oxide powder precursor from middle / low-grade zinc oxide ore and belongs to the technical field of wet method metallurgy. The method comprises preparing a deep eutectic solvent-type ionic liquid from choline chloride and oxalic acid, fragmenting and fine grinding middle / low-grade zinc oxide ore, adding the middle / low-grade zinc oxide ore powder into the deep eutectic solvent-type ionic liquid, carrying out stirring leaching, adding distilled water into the leached ore pulp, carrying out stirring to obtain a uniform mixture, carrying out standing, carrying out solid-liquid separation to obtain a filtrate A and a zinc oxalate-rich filter residue B, preparing a deep eutectic solvent-type ionic liquid, adding the zinc oxalate-rich filter residue B into the deep eutectic solvent-type ionic liquid, carrying out leaching, carrying out solid-liquid separation to obtain a filtrate C and filter residue D, adding distilled water into the filtrate C, wherein the volume of the distilled water is 2-10 times that of the filtrate C, carrying out filtration after white precipitates are precipitated, washing the filter residue and carrying out drying to obtain zinc oxalate crystals. The method realizes effective utilization of middle / low-grade zinc oxide ore and provides a novel approach for deep eutectic solvent use.

Owner:KUNMING UNIV OF SCI & TECH

A plant-derived organic-inorganic compound snail-killing fertilizer preparation and its preparation method and application

ActiveCN109197896BImprove performanceEasy to useBiocideBio-organic fraction processingBiotechnologyLycoris radiata

The invention relates to a plant source organic-inorganic compounding molluscicide fertilizer preparation and a preparation method and application thereof, and relates to the technical field of biological pesticides. The plant source organic-inorganic compounding molluscicide fertilizer preparation comprises a needle-like calcium oxalate crystal and an inorganic fertilizer, wherein the needle-likecalcium oxalate crystal is obtained by separating and extracting from a plant of Araceae or Amaryllidaceae. The plant source organic-inorganic compounding molluscicide fertilizer preparation also preferably includes a plant fermented organic fertilizer. A suitable amount of chemical fertilizer is added to a needle-like calcium oxalate crystal extract contained in the plant of Araceae and Amaryllidaceae, and a plant extract residue fermented product is used as an organic fertilizer carrier to prepare the plant source organic-inorganic compounding molluscicide fertilizer preparation. The plantsource organic-inorganic compounding molluscicide fertilizer preparation can not only promote rice growth, increase yield, also has the effect of killing snails and achieve the double effect of killing Oncomelania hupensis to achieve the integration of double effects of molluscicide and fertilizing. In addition, the plant source organic-inorganic compounding molluscicide fertilizer preparation issimple in preparation method, the production cost is low, the use is convenient, and the plant source organic-inorganic compounding molluscicide fertilizer preparation is conductive to large-scale application and promotion in a rice field in a schistosomiasis epidemic area.

Owner:HUBEI UNIV

A kind of warnemulin oxalate crystal and preparation method thereof

ActiveCN104130168BHigh purityHigh yieldOrganic chemistryOrganic compound preparationX-rayCrystallinity

The invention relates to a valnemulin oxalate crystal and a crystallization preparation method thereof. According to an X-ray powder diffraction pattern of the crystal, characteristic peaks appear at diffraction angle 2theta of 6.2, 8.0, 10.5, 11.2, 12.5, 13.2, 14.6, 15.0, 17.0, 18.0, 19.7 and 21.1 degrees. According to the invention, valnemulin is dissolved in an ester type solvent, wherein a solution concentration is 0.1-0.4g / mL; oxalic acid is added according to a molar ratio that oxalic acid to valnemulin is 1:1-1:2; under a stirring effect, a reaction is carried out under a temperature of 40-60 DEG C until the solution is clear; the temperature of the solution is reduced to 10-20 DEG C; and filtering, washing, and drying are carried out, such that a valnemulin oxalate crystal product is obtained. The crystallization process has a yield higher than 90%. The valnemulin oxalate product has high crystallinity, high purity, and low fly-off. The valnemulin oxalate product has good stability against light, heating, and moisture.

Owner:TIANJIN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com