Method for producing scandium compound, and scandium compound

A manufacturing method and compound technology, applied in the field of scandium compound manufacturing, can solve problems such as cost increase, and achieve the effect of reducing effort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

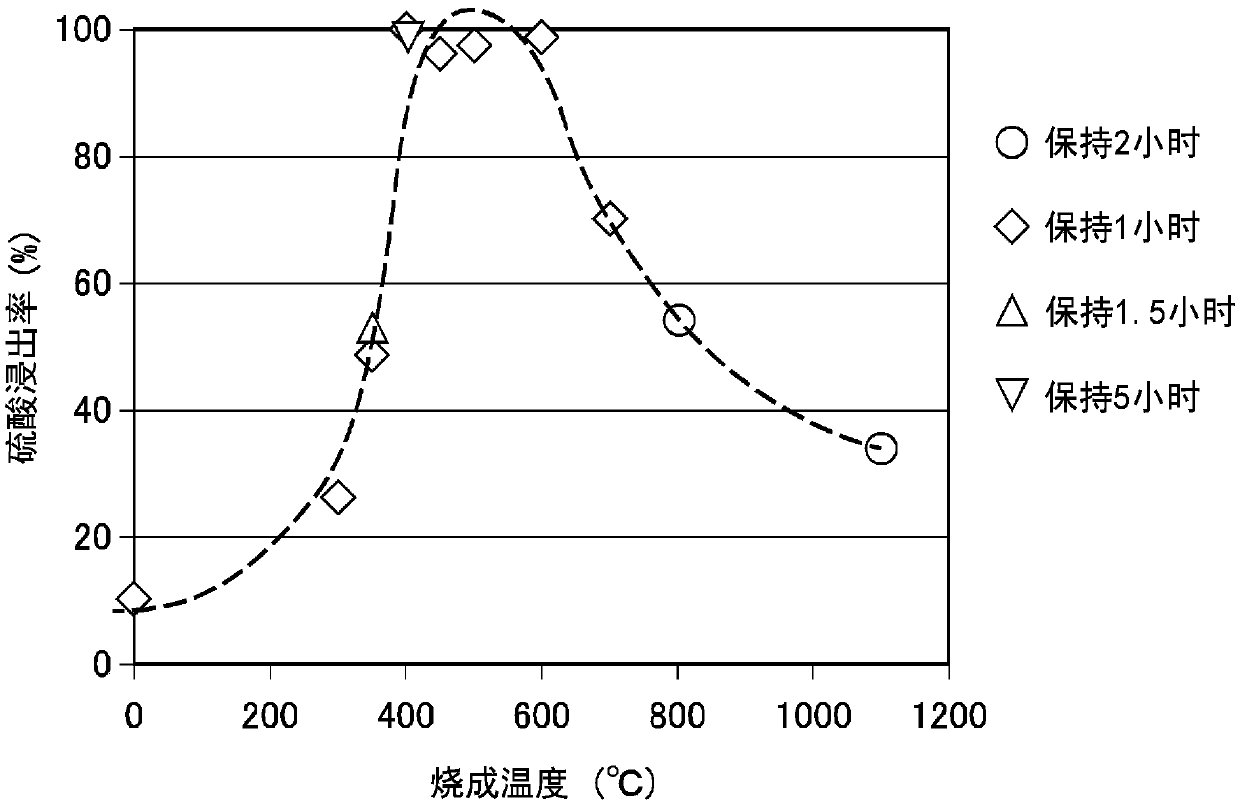

Image

Examples

Embodiment

[0082] Hereinafter, the present invention will be described more specifically by giving examples of the present invention. It should be noted that the present invention is not limited by the following examples.

[0083] (Wet smelting process of nickel oxide ore)

[0084] Nickel oxide ore is leached with sulfuric acid in an autoclave, and hydrated lime is added to the obtained leaching solution for neutralization. Thereafter, a sulfidizing agent was added to the obtained neutralized solution to cause a sulfidation reaction, nickel, cobalt, etc. were separated as sulfides, and a sulfided solution containing scandium was obtained.

[0085] (ion exchange treatment, neutralization treatment)

[0086] Next, the obtained vulcanized solution was subjected to ion exchange treatment using a chelate resin, and impurities in the solution were separated to obtain an eluate containing scandium eluted from the chelate resin (scandium eluate). Thereafter, a neutralizing agent is added to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com