Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about "Scandium oxides/hydroxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

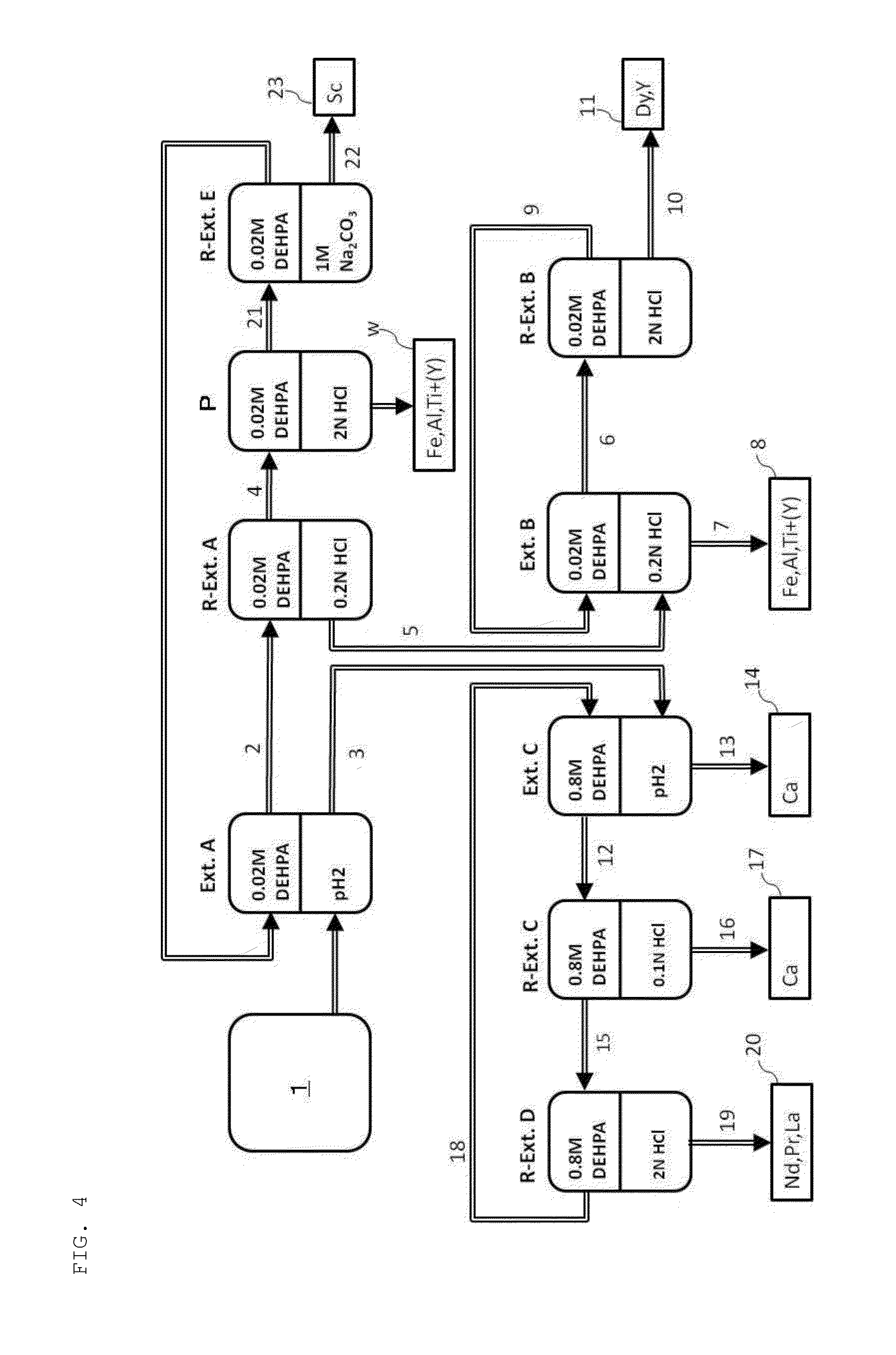

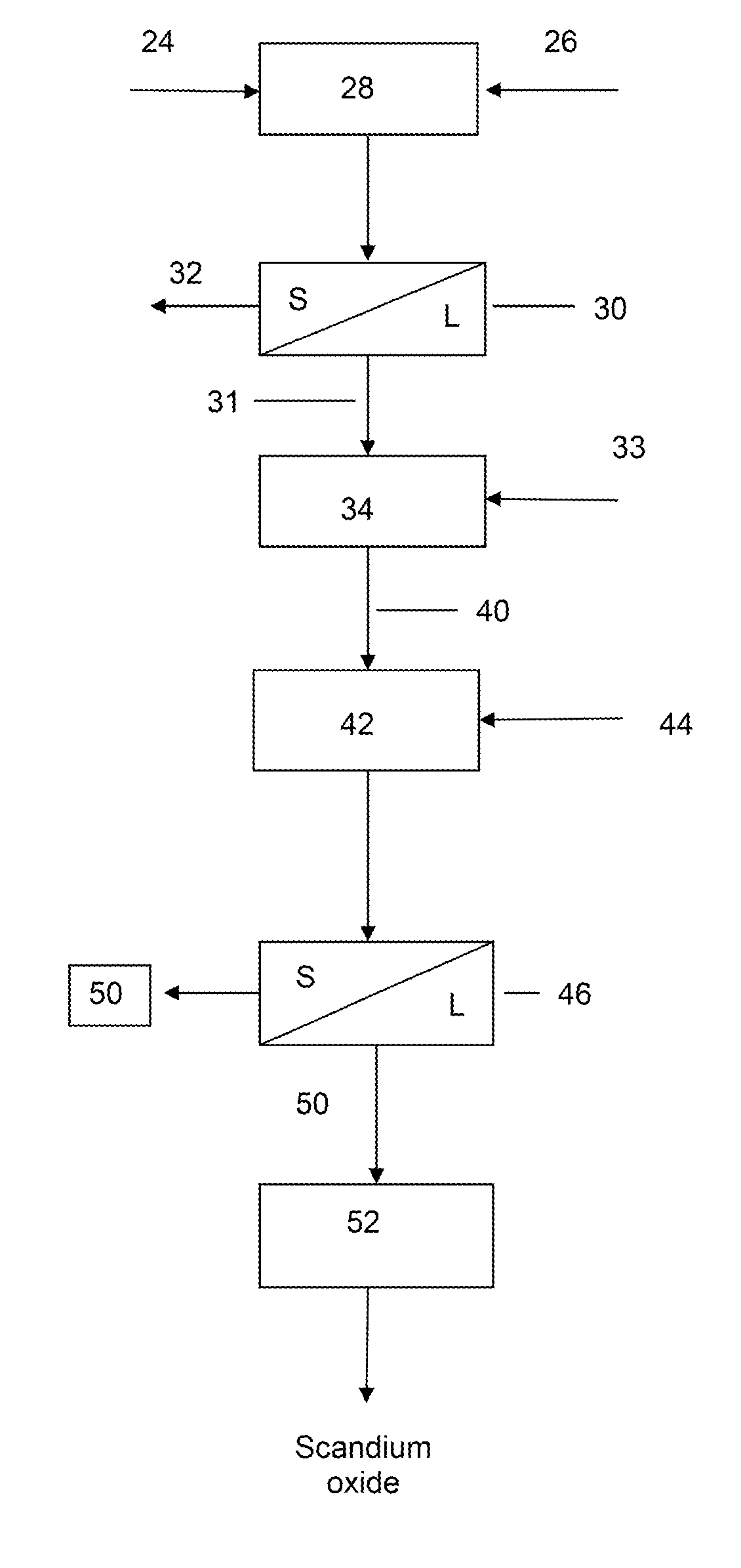

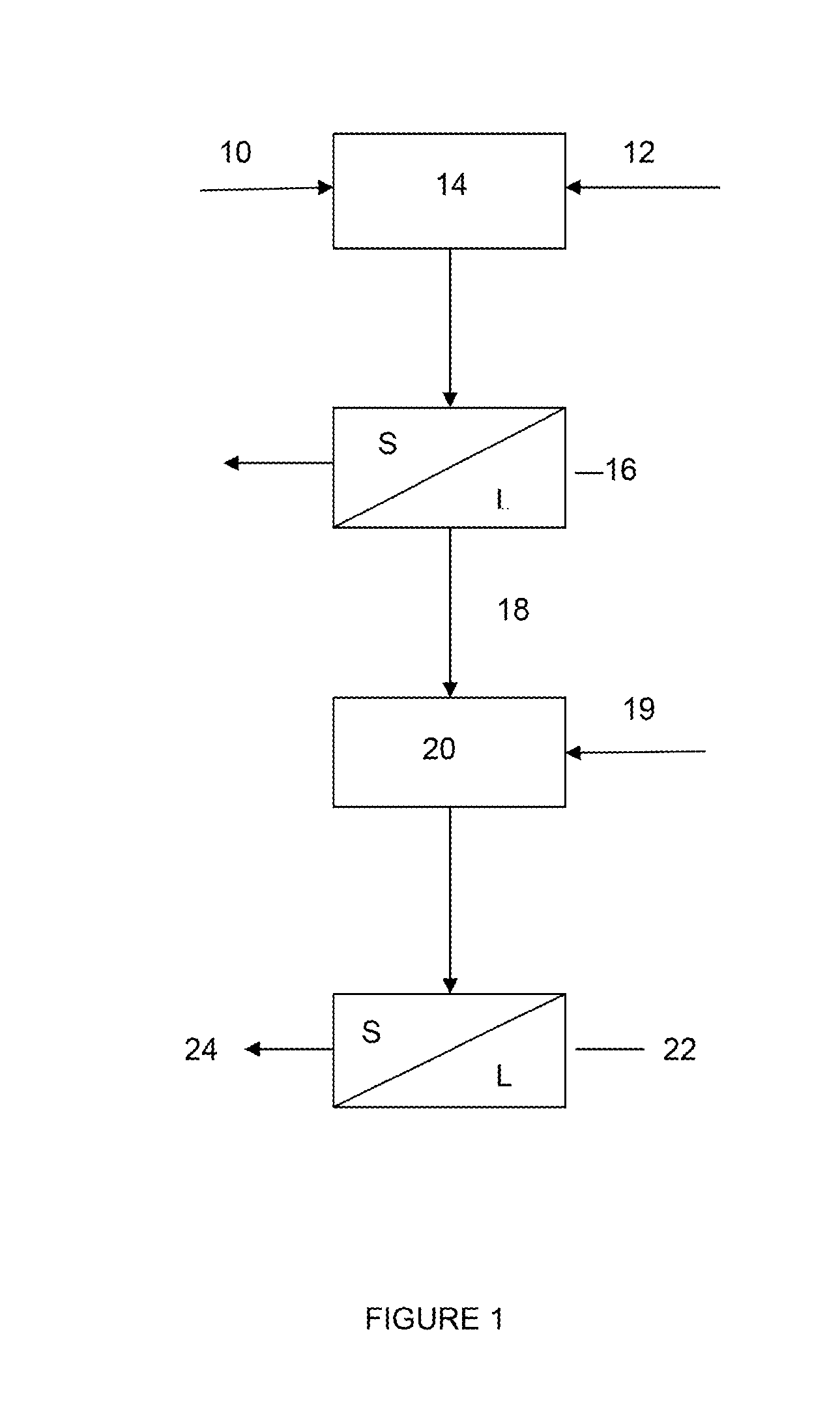

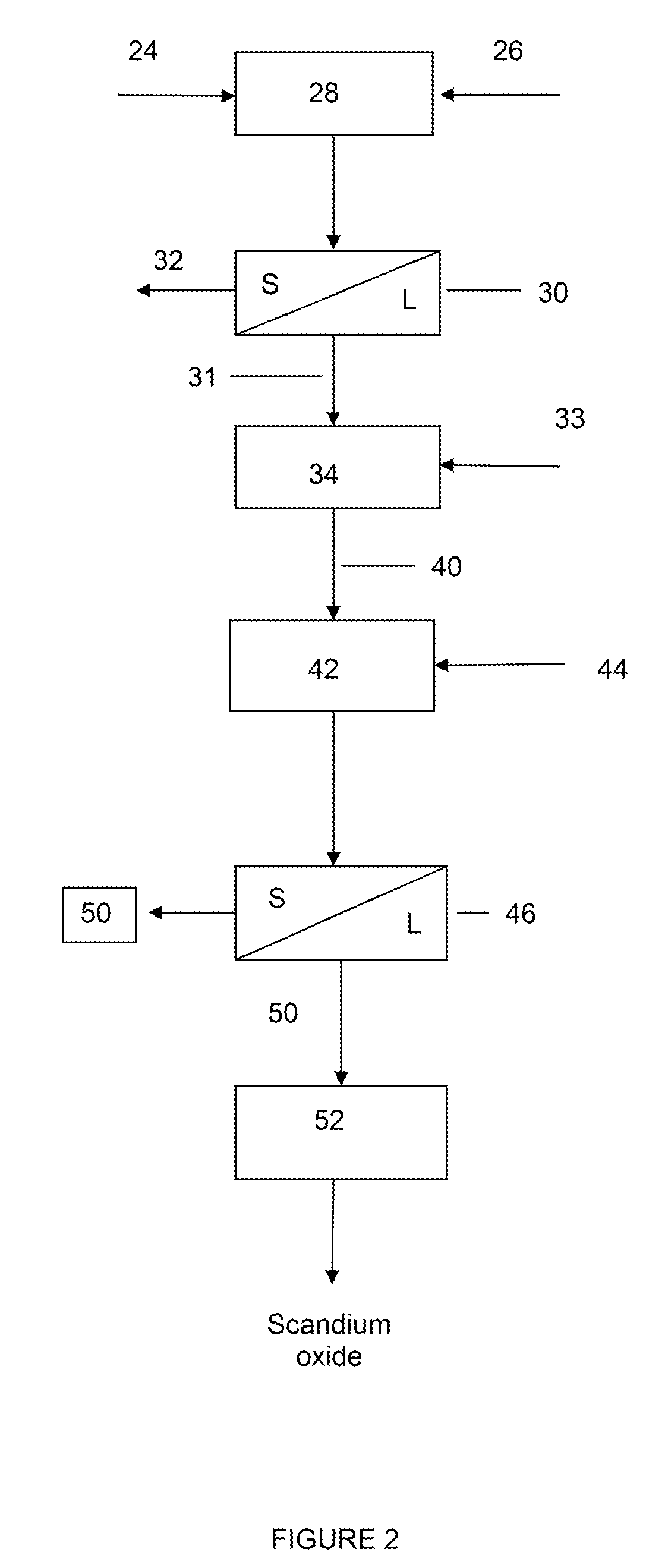

System and Method for Recovery of Scandium Values From Scandium-Containing Ores

InactiveUS20120207656A1Scandium oxides/hydroxidesProcess efficiency improvementScandiumMaterials science

Owner:SCANDIUM INT MINING

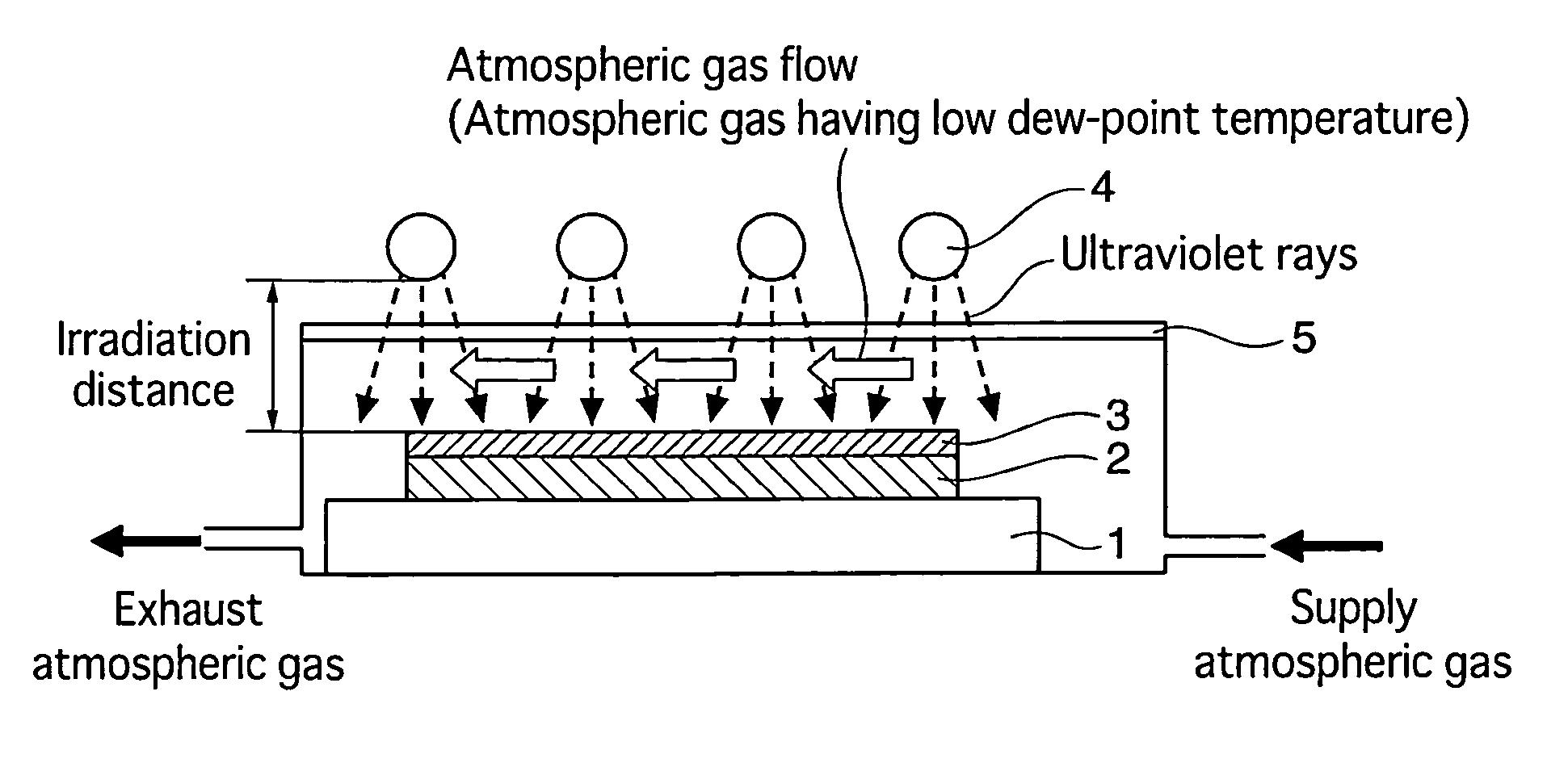

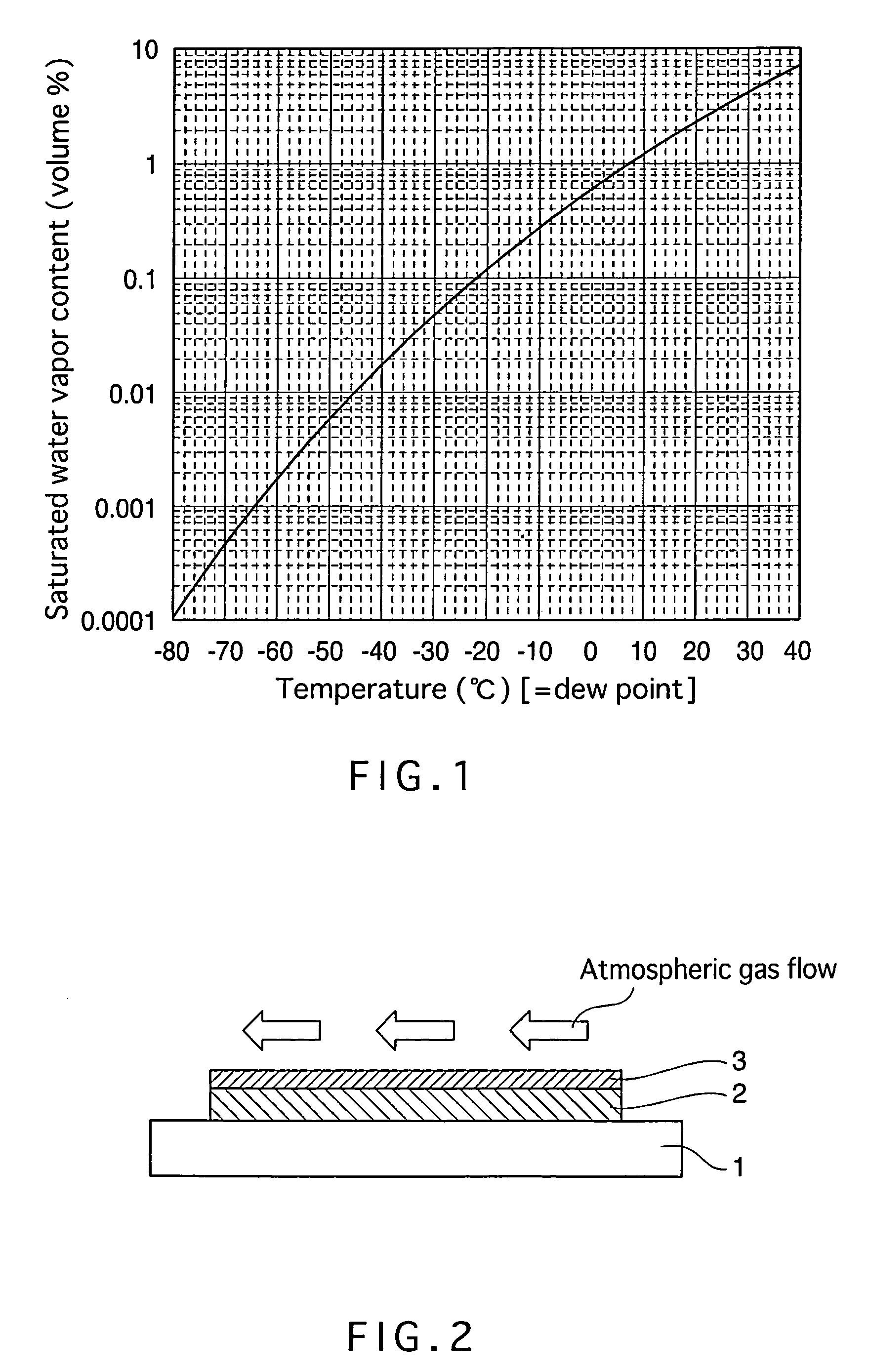

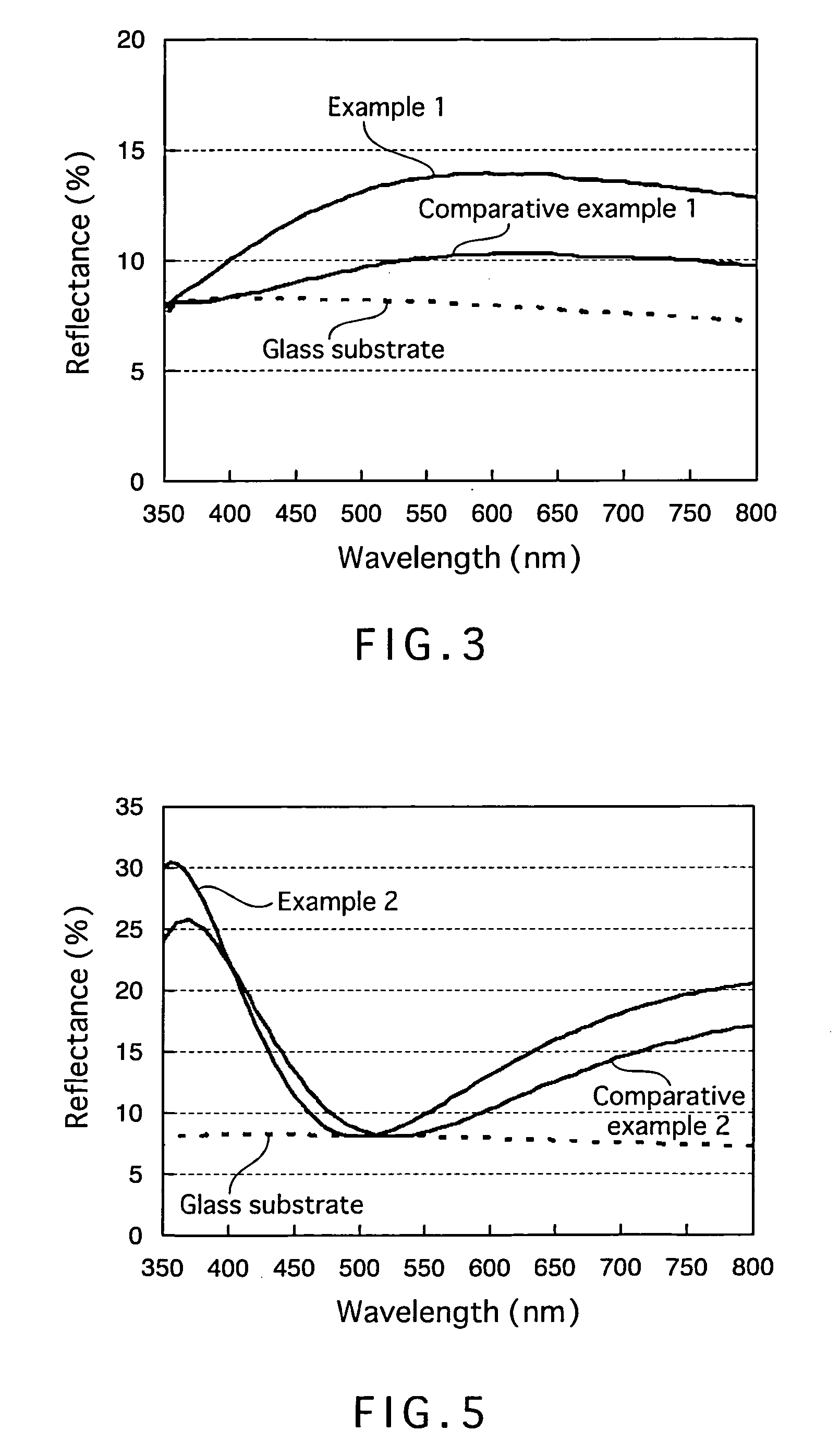

Method of manufacturing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

InactiveUS20130101867A1High densityHigh film strengthTantalum compoundsSemiconductor/solid-state device detailsOxygenMaterials science

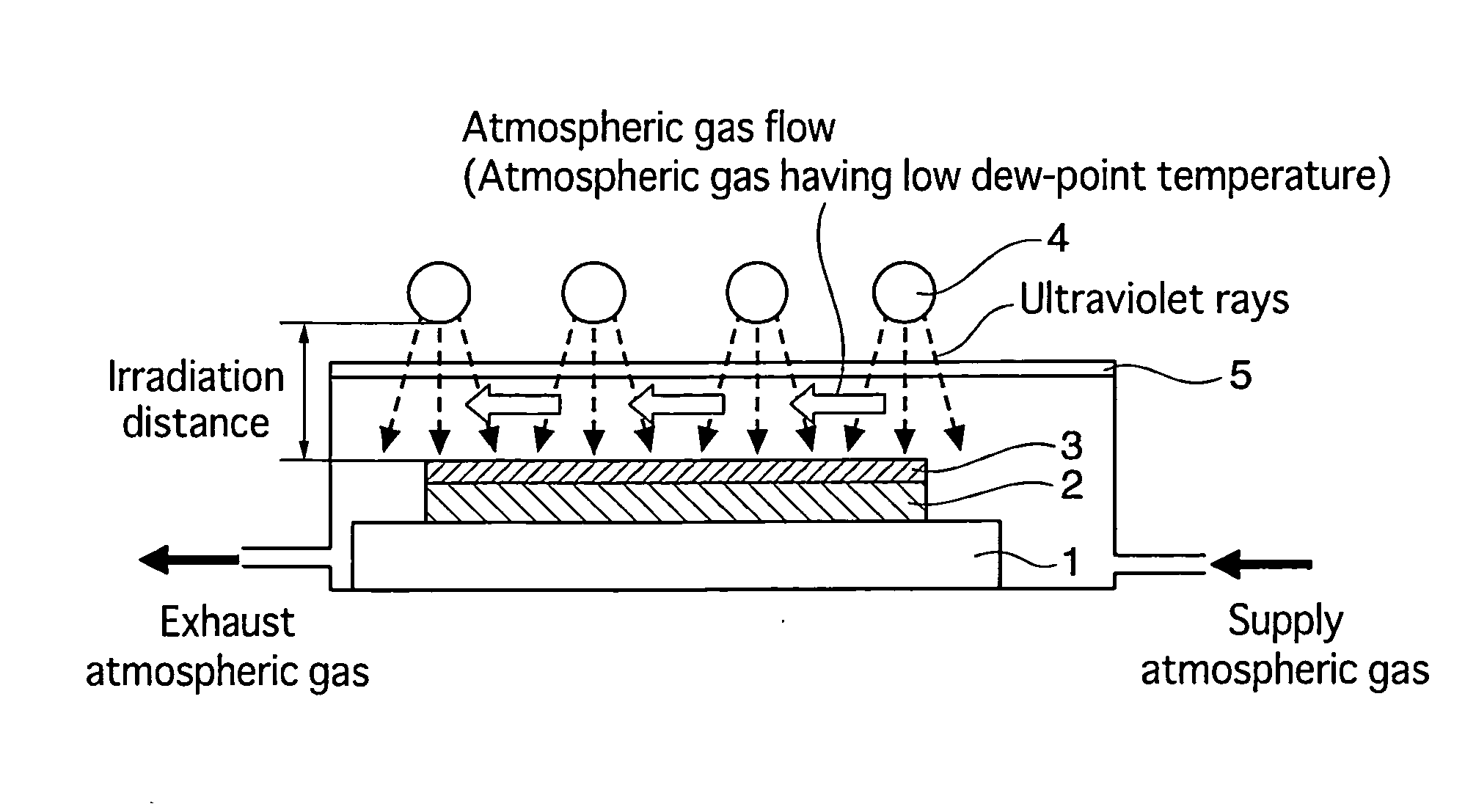

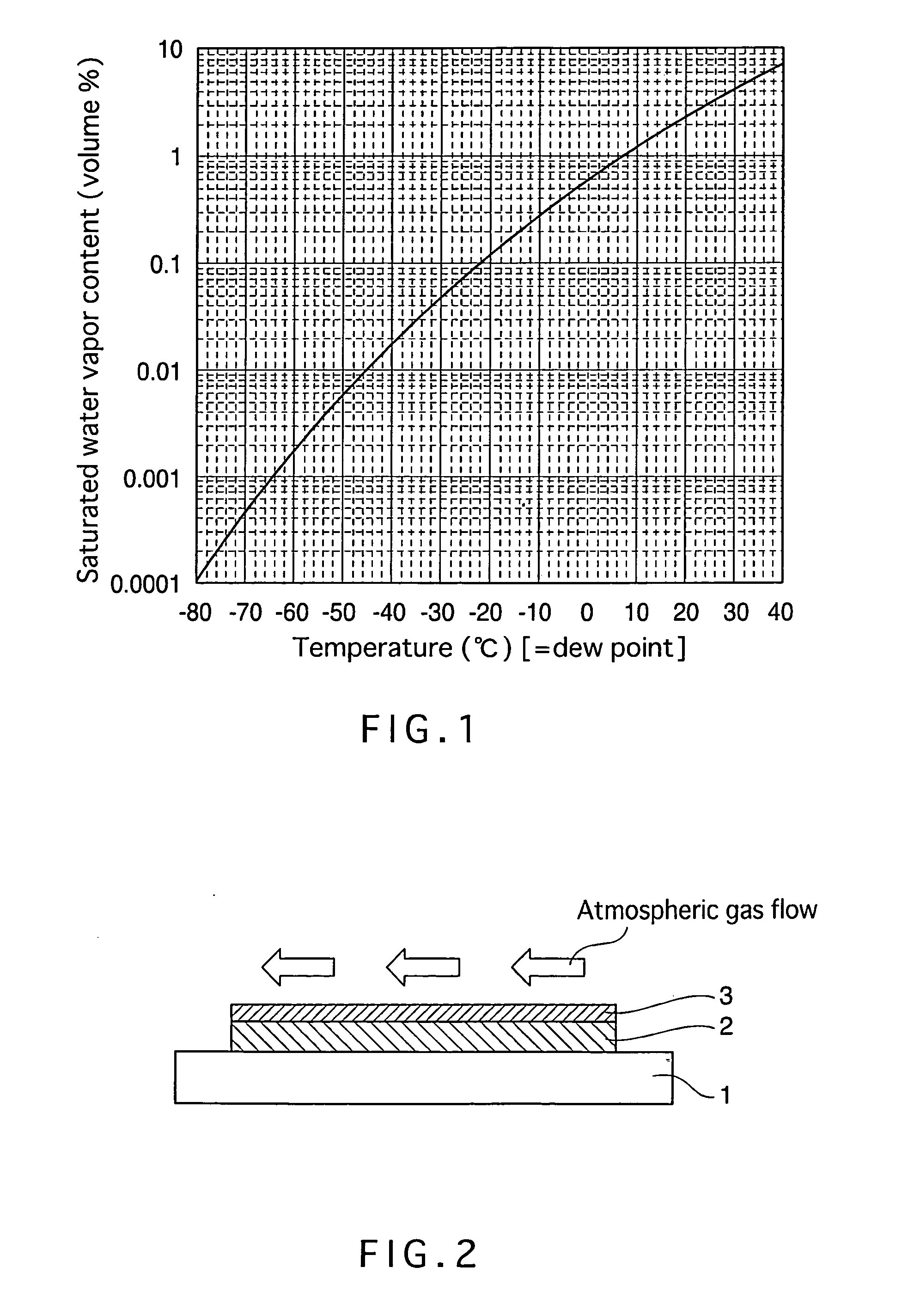

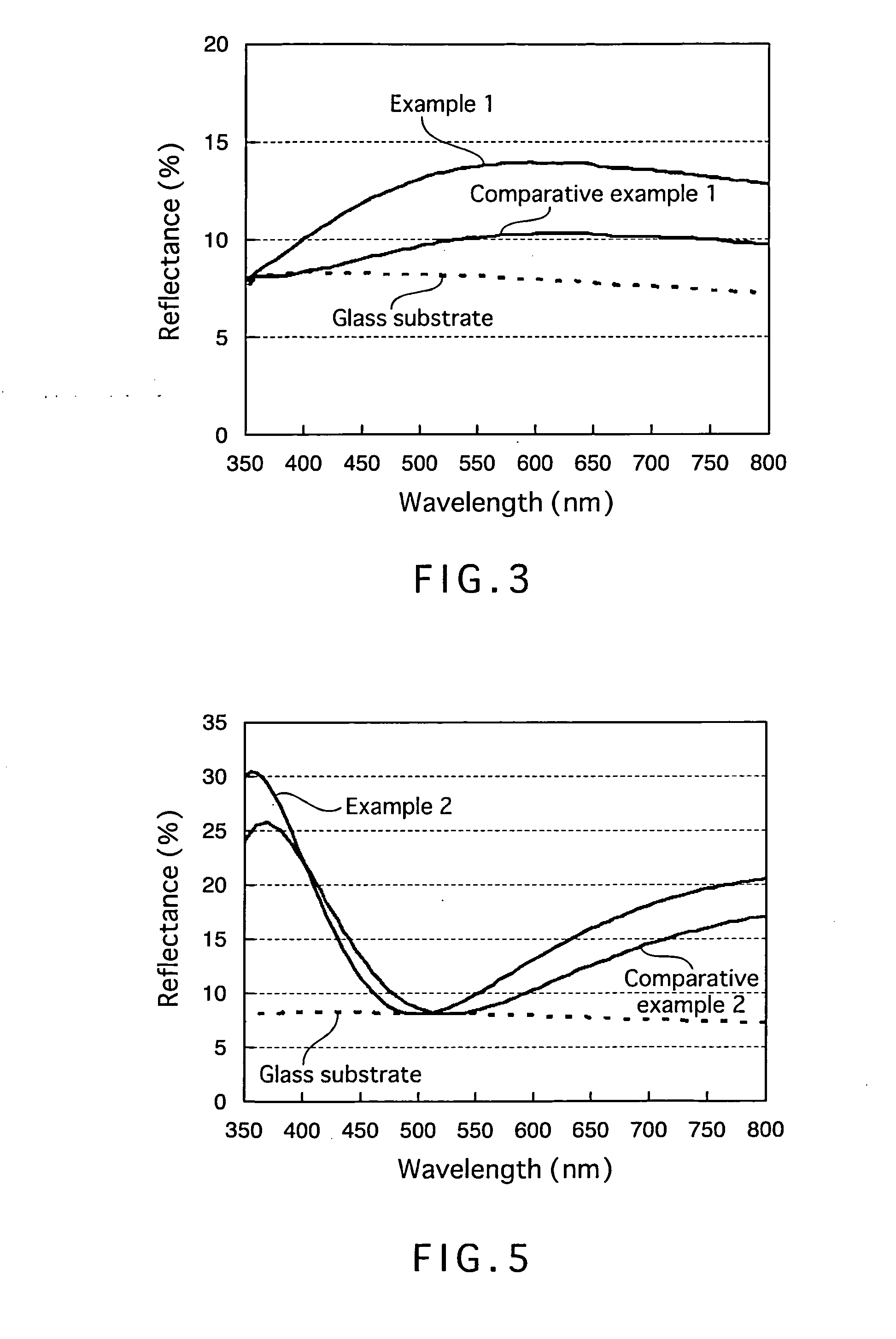

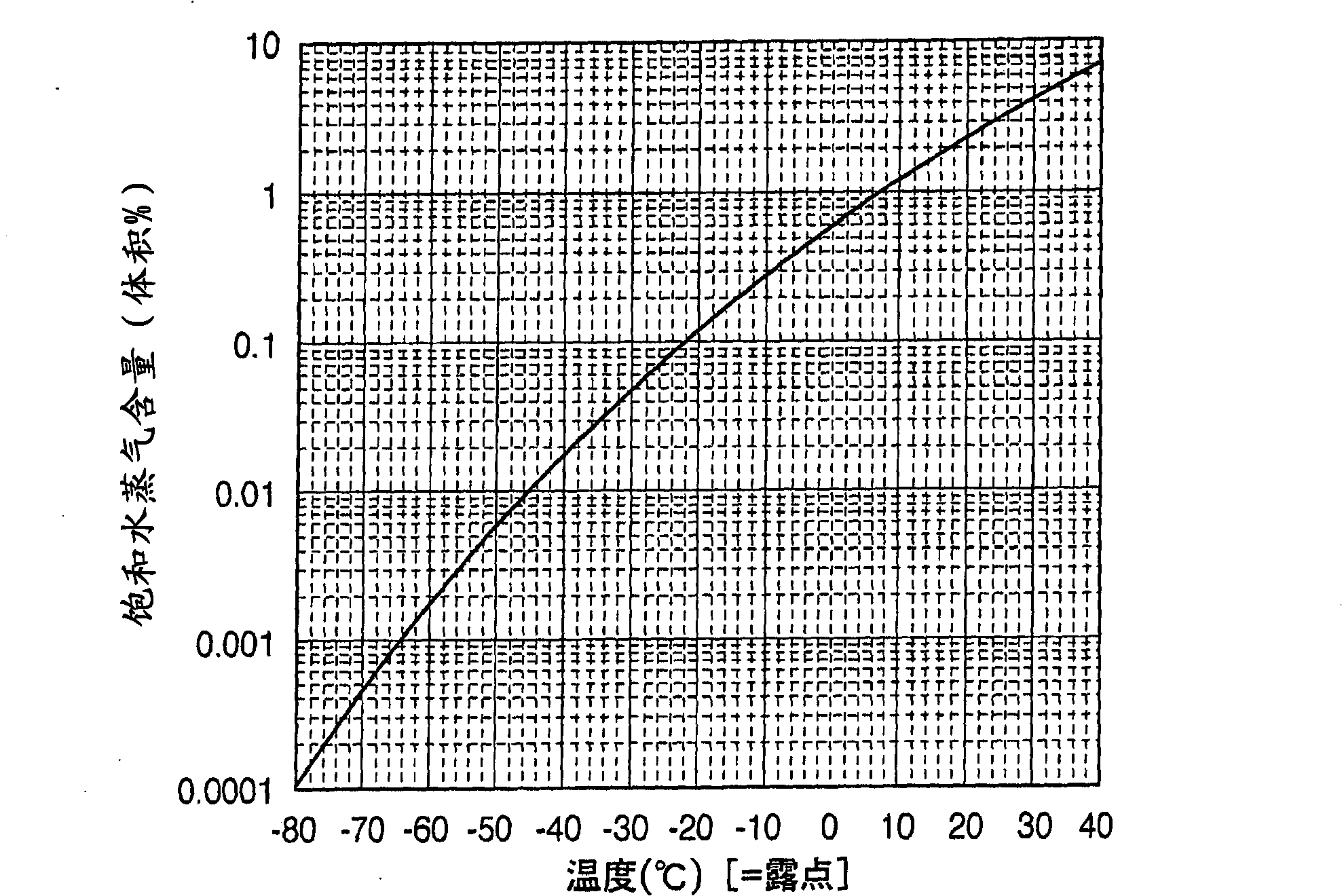

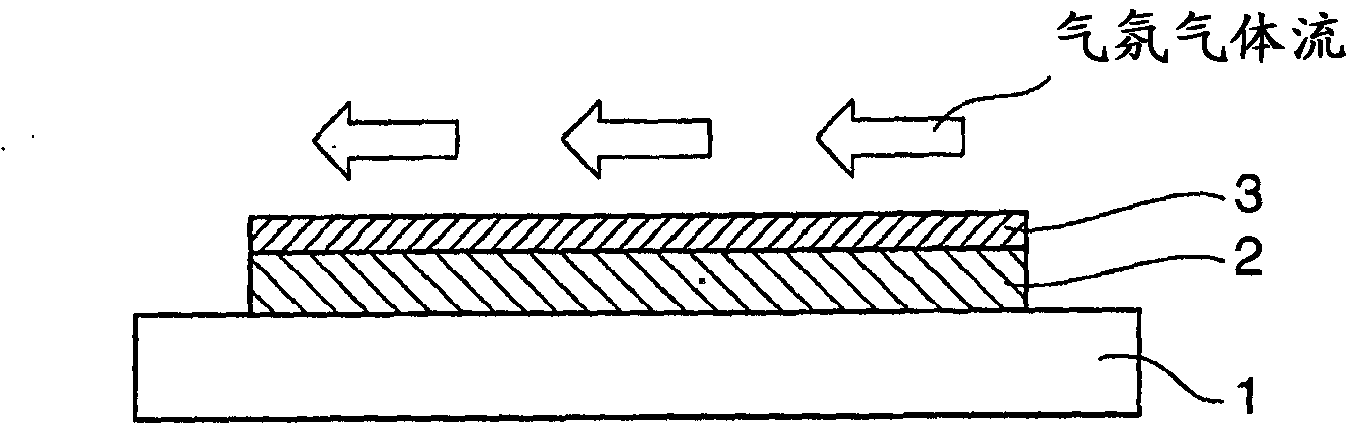

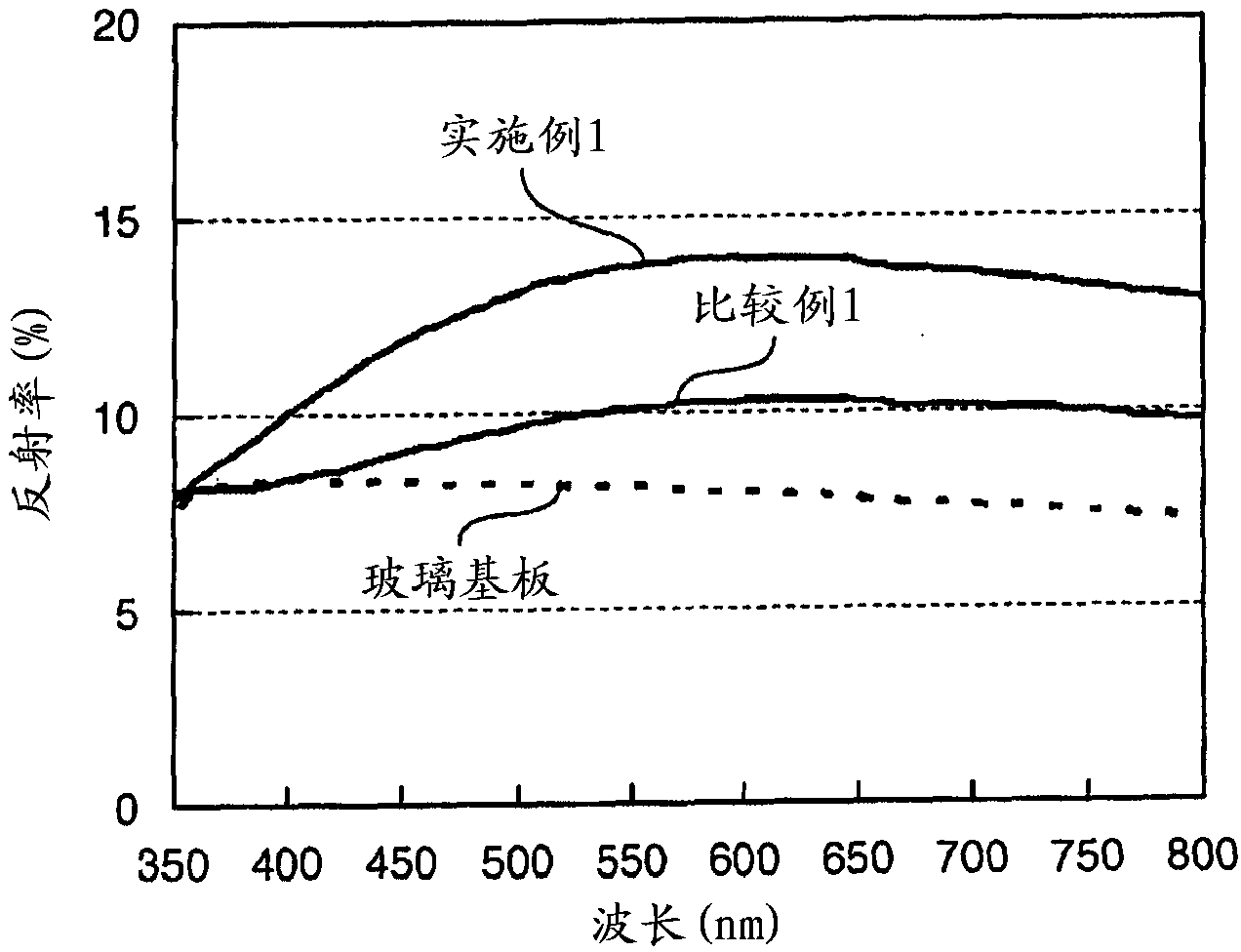

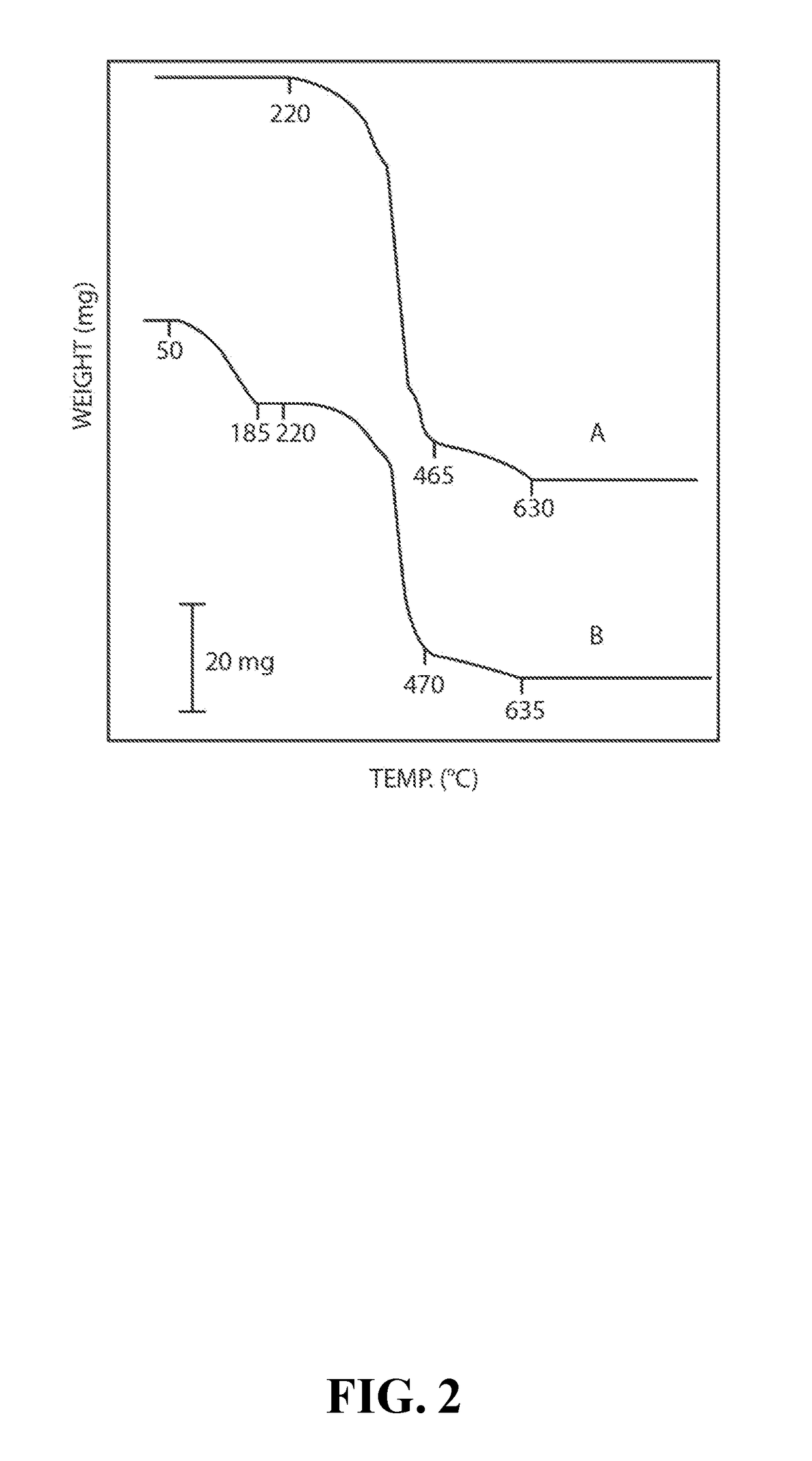

Provided is a method of manufacturing a metal oxide film to be formed through the following processes: a coating process of forming a coating film on a substrate by using a coating liquid for forming metal oxide film containing any of various organometallic compounds; a drying process of making the coating film into a dried coating film; and a heating process of forming an inorganic film from the dried coating film under an oxygen-containing atmosphere having a dew-point temperature equal to or lower than −10° C.

Owner:SUMITOMO METAL MINING CO LTD

Method for producing metal oxide film, metal oxide film, element using the metal oxide film, substrate with metal oxide film, and device using the substrate with metal oxide film

InactiveCN102933496AImprove compactnessHigh strengthConductive layers on insulating-supportsTantalum compoundsPhysical chemistryThermal treatment

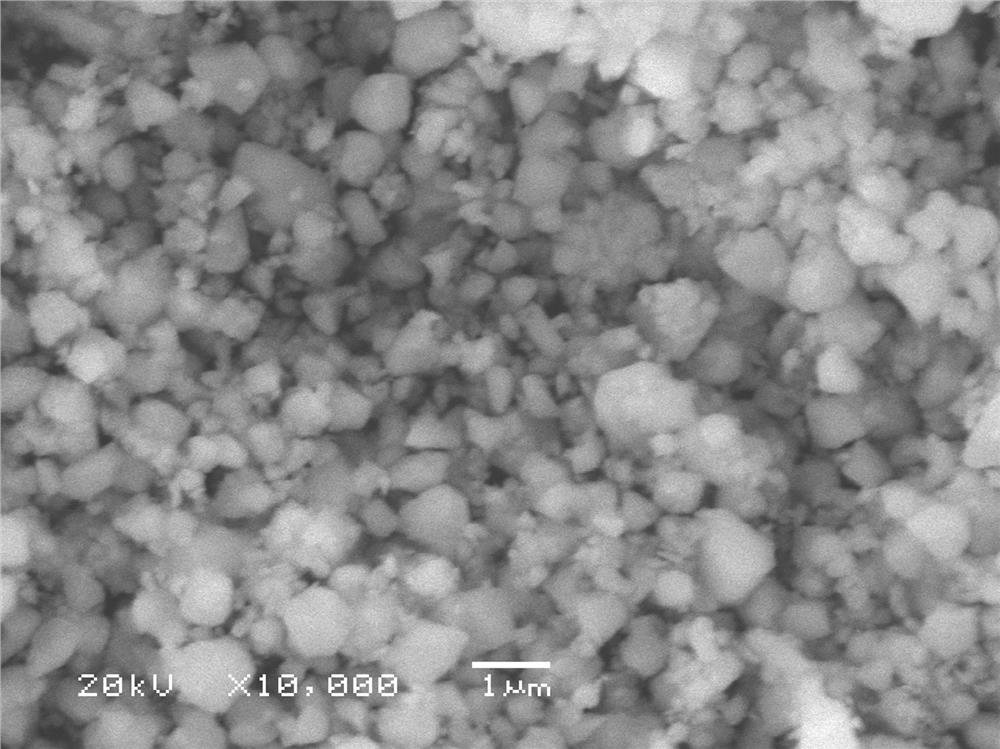

Disclosed are: a metal oxide film, which is formed by a coating method that is one of the methods for producing a metal oxide film, and which has a good balance between excellent transparency and high electrical conductivity, while having excellent film strength; and a method for producing the metal oxide film. Specifically disclosed is a method for producing a metal oxide film, which comprises: a coating step wherein a coating film is formed on a substrate using a metal oxide film-forming coating liquid that contains various organic metal compounds; a drying step wherein the coating film is changed into a dry coating film; and a heating step wherein an inorganic film is formed from the dry coating film. The method for producing a metal oxide film is characterized in that in the heating step, the dry coating film, which is mainly composed of the various organic metal compounds, is heated to a temperature at which at least mineralization of organic metal compound components occurs or higher in an oxygen-containing atmosphere at a temperature not higher than the temperature that is lower by 10 DEG C than the dew point, so that the organic components in the dry coating film are removed by thermal decomposition or combustion, or by thermal decomposition and combustion, thereby forming a metal oxide fine particle layer which is densely filled with metal oxide fine particles that are mainly composed of various metal oxides.

Owner:SUMITOMO METAL MINING CO LTD

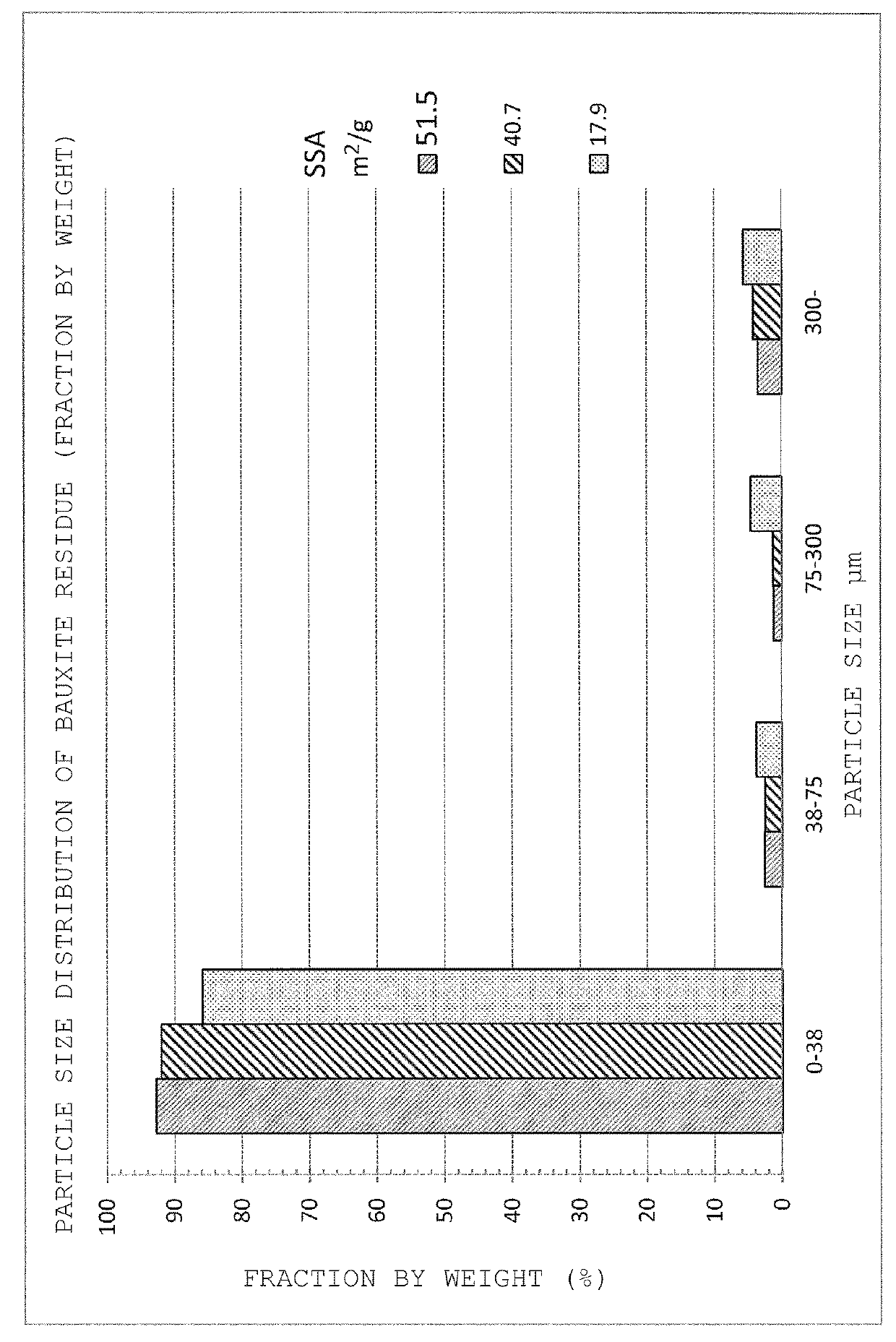

Method of recovering rare-earth elements

ActiveUS20150086449A1Reduce profitabilityImprove leaching efficiencyLanthanide oxides/hydroxidesSolid waste disposalRare-earth elementSlurry

Provided is a method of recovering rare-earth elements by which rare-earth elements can be recovered efficiently from a bauxite residue serving as a raw material and containing the rare-earth elements. Specifically provided is a method of recovering rare-earth elements from a raw material, the raw material being a bauxite residue produced as a by-product in a Bayer process, the method including: using a bauxite residue having a specific surface area of 35 m2 / g or more; adding, to the raw material bauxite residue, a liquid leaching agent formed of an aqueous solution of at least one kind of mineral acid selected from sulfuric acid, hydrochloric acid, nitric acid, and sulfurous acid, thereby preparing a slurry having a liquid-solid ratio of 2 to 30 and a pH of 0.5 to 2.2; subjecting the slurry to leaching treatment of the rare-earth elements under a temperature condition of room temperature to 160° C.; subjecting the slurry after the leaching treatment to solid-liquid separation, yielding a leachate; and separating and recovering the rare-earth elements from the leachate.

Owner:NIPPON LIGHT METAL CO LTD

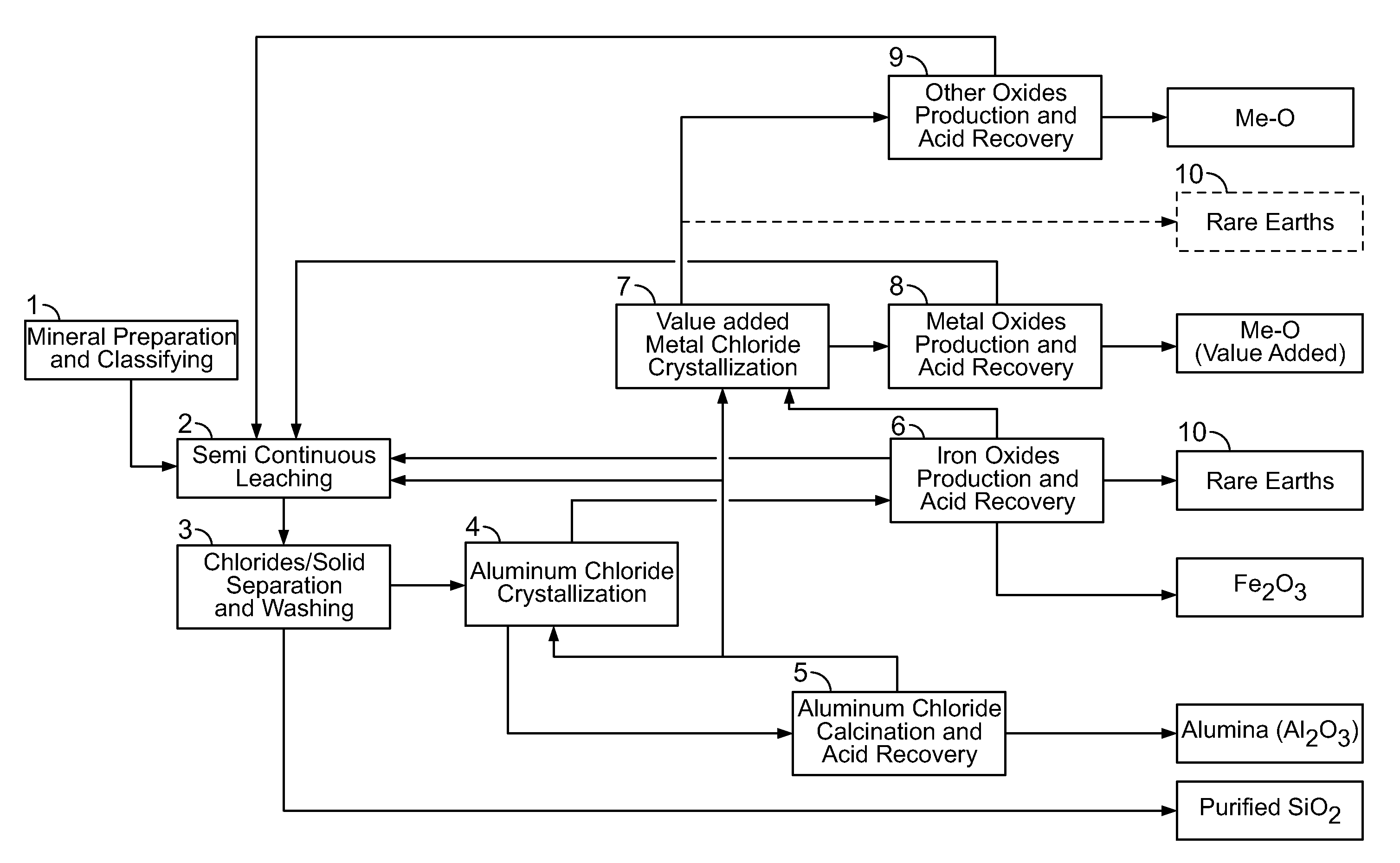

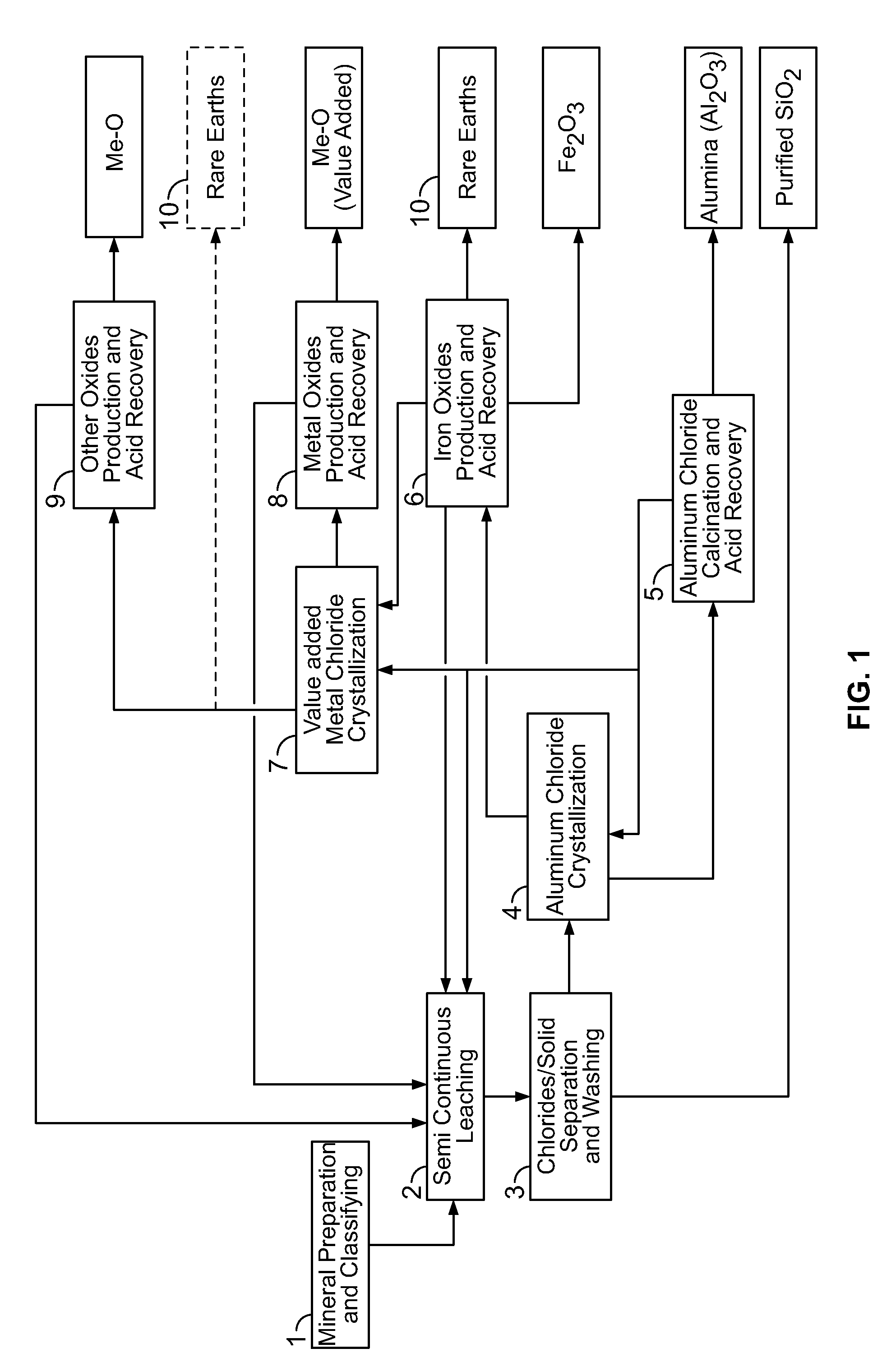

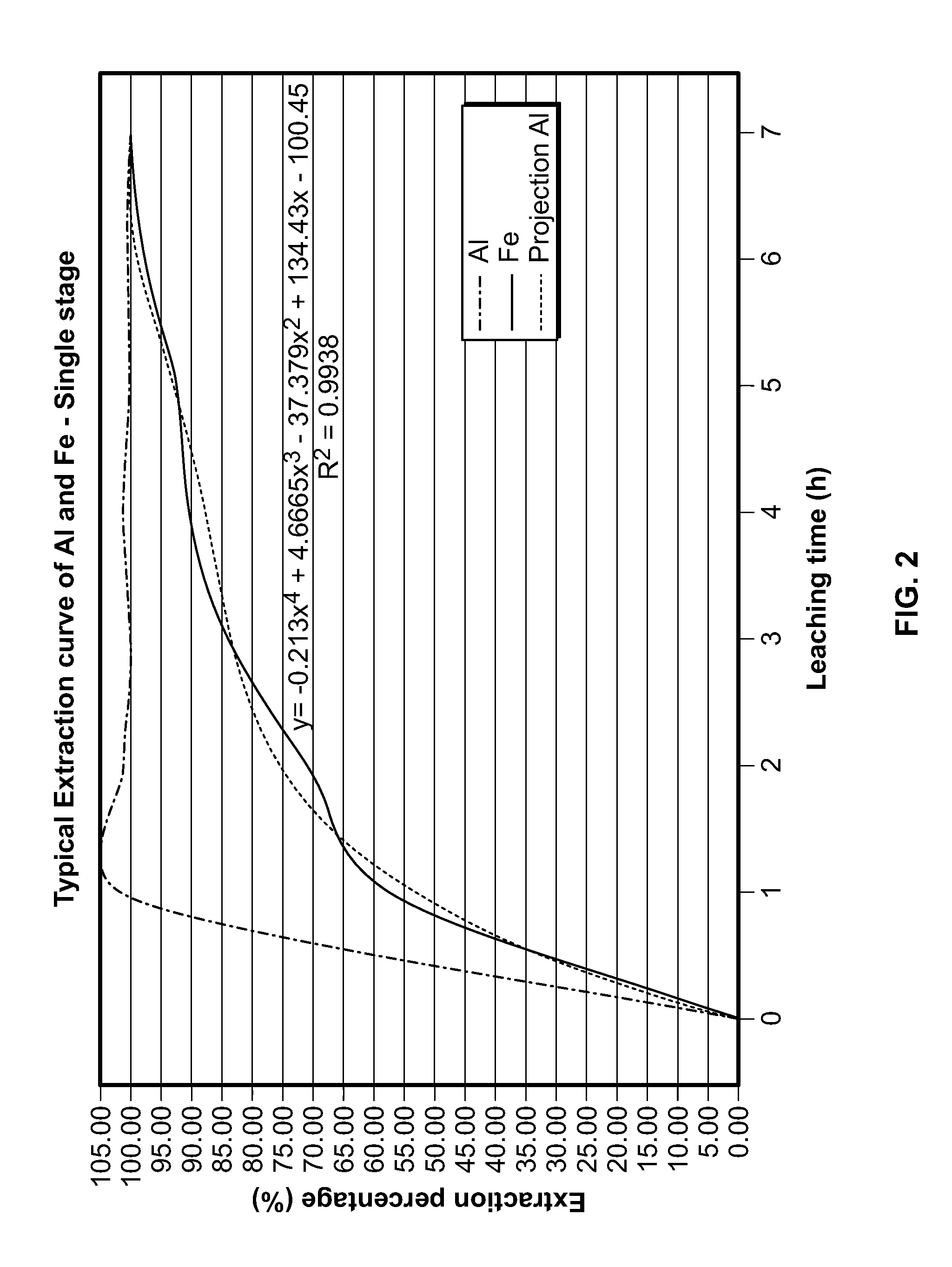

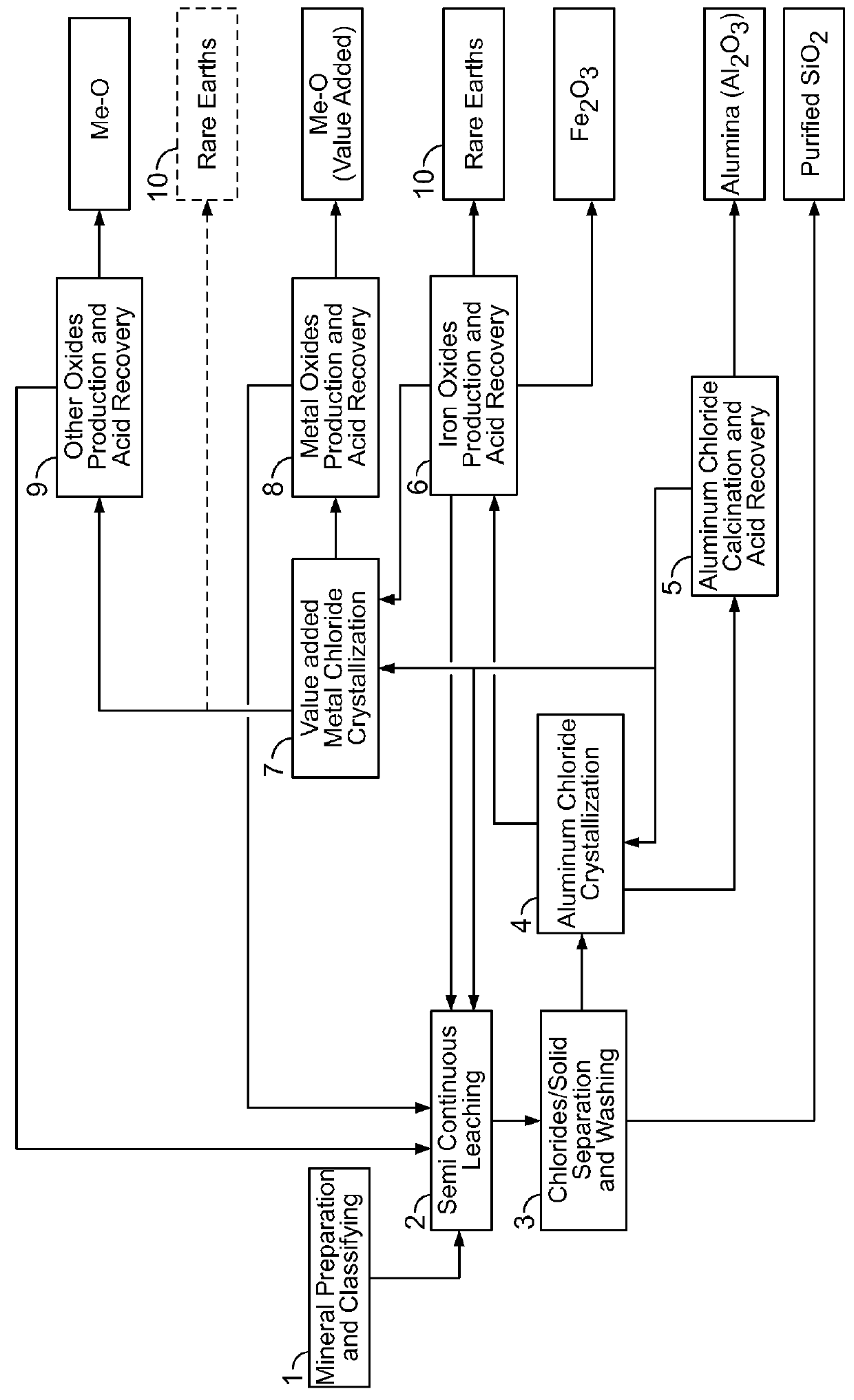

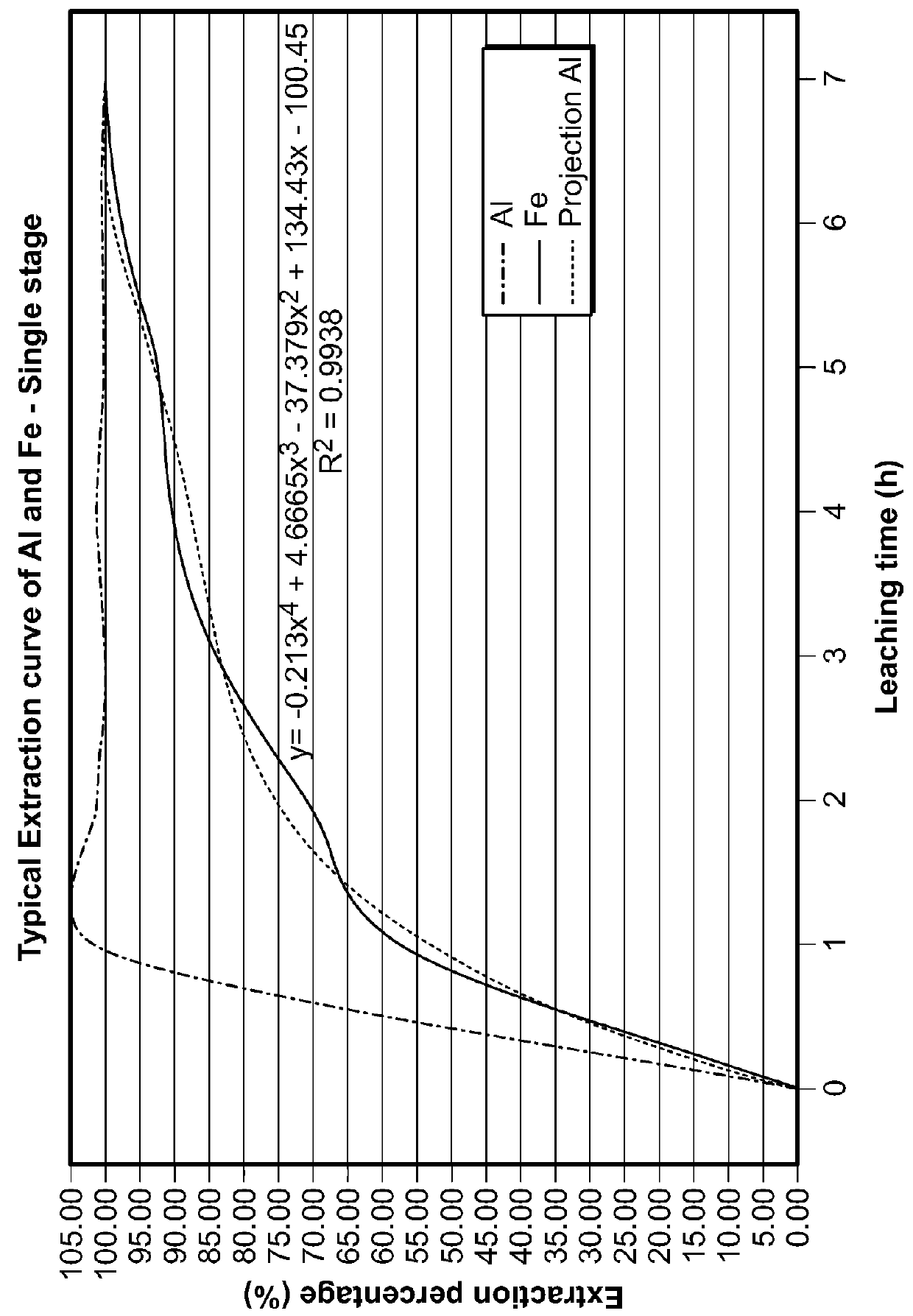

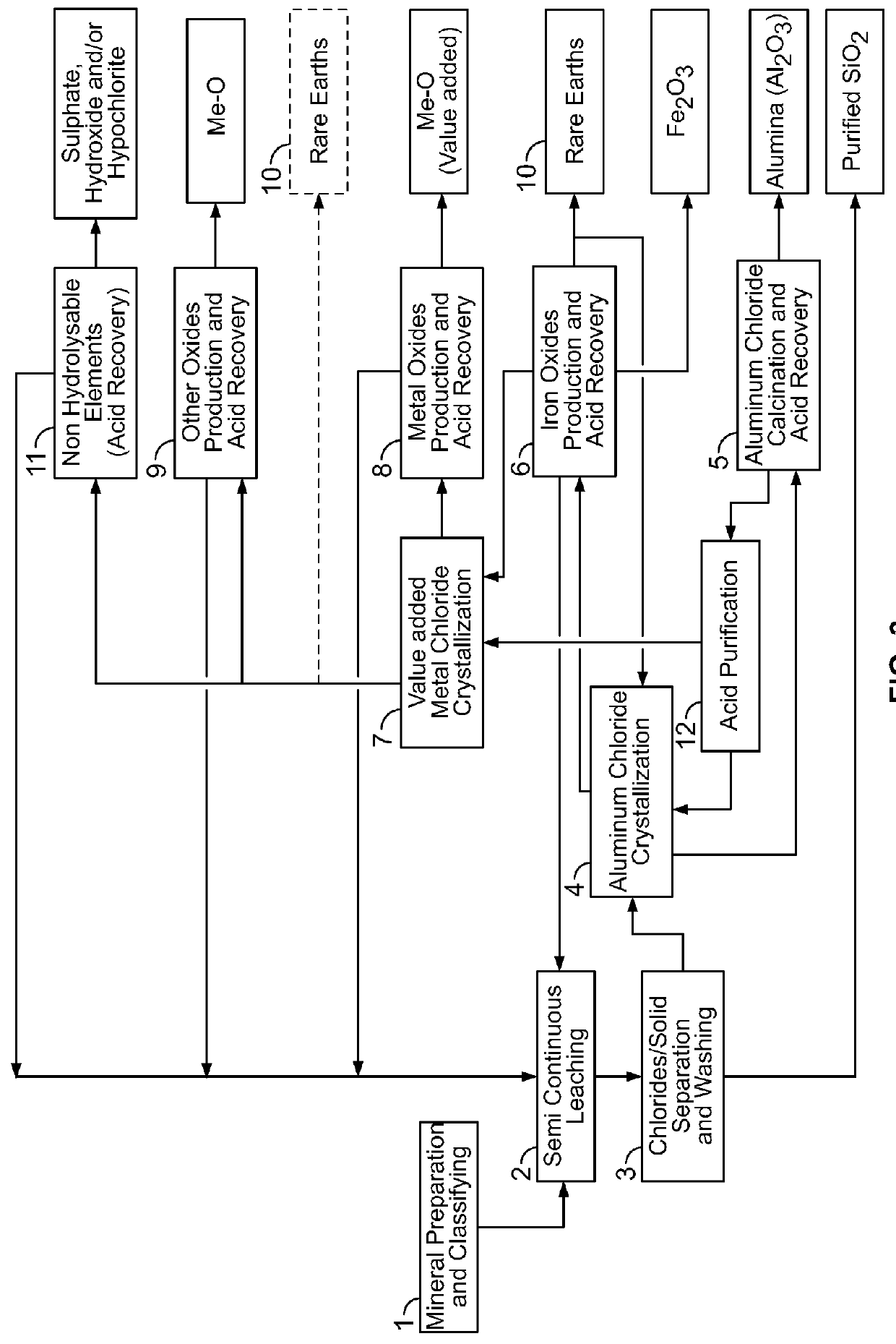

Processes for preparing alumina and various other products

There are provided processes for preparing alumina. These processes can comprise leaching an aluminum-containing material with HCl so as to obtain a leachate comprising aluminum ions and a solid, and separating said solid from said leachate; reacting said leachate with HCl so as to obtain a liquid and a precipitate comprising said aluminum ions in the form of AlCl3, and separating said precipitate from said liquid; and heating said precipitate under conditions effective for converting AlCl3 into Al2O3 and optionally recovering gaseous HCl so-produced. These processes can also be used for preparing various other products such as hematite, MgO, silica and oxides of various metals, sulphates and chlorides of various metals, as well as rare earth elements, rare metals and aluminum.

Owner:ORBITE ALUMINAE INC

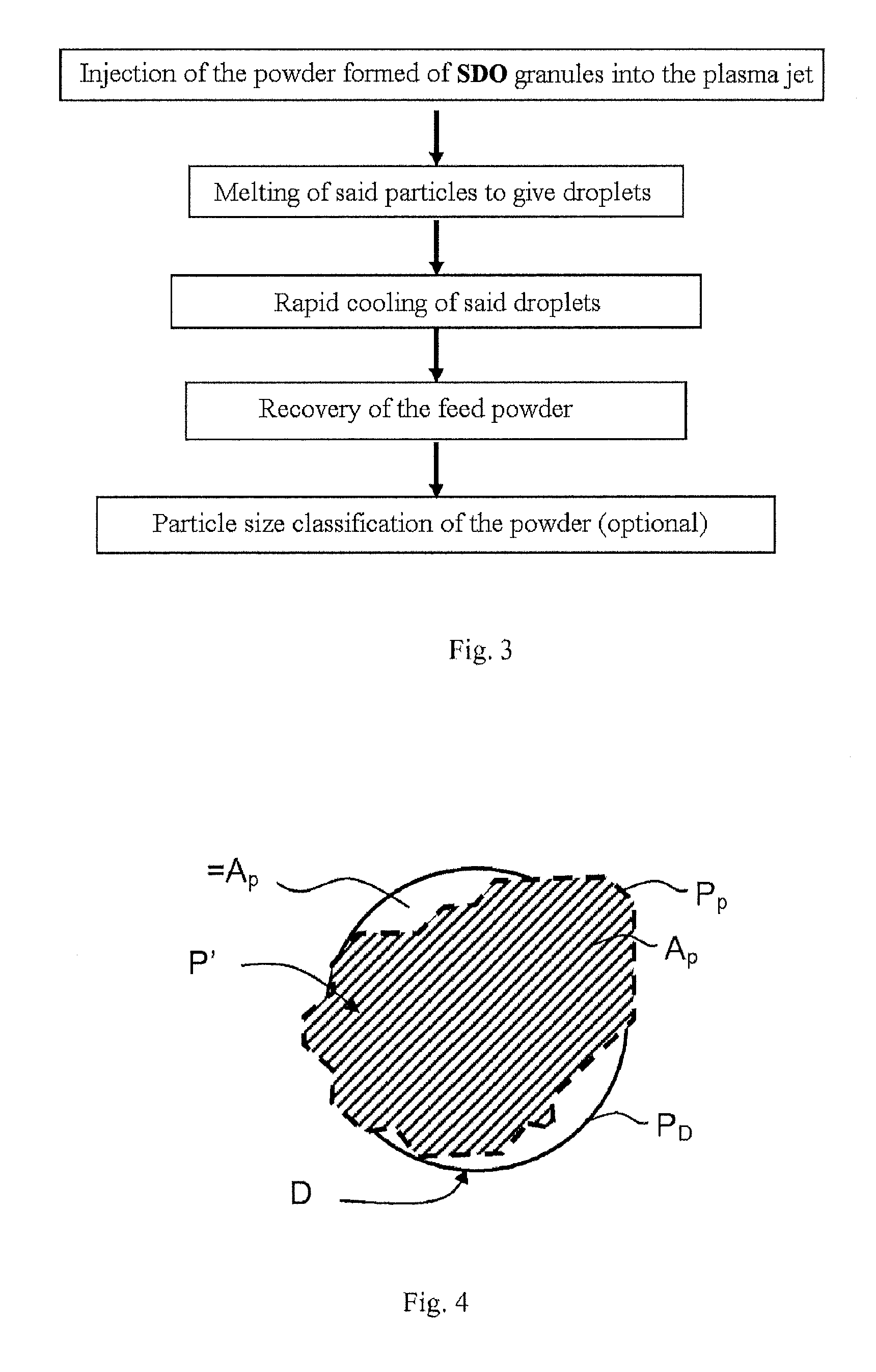

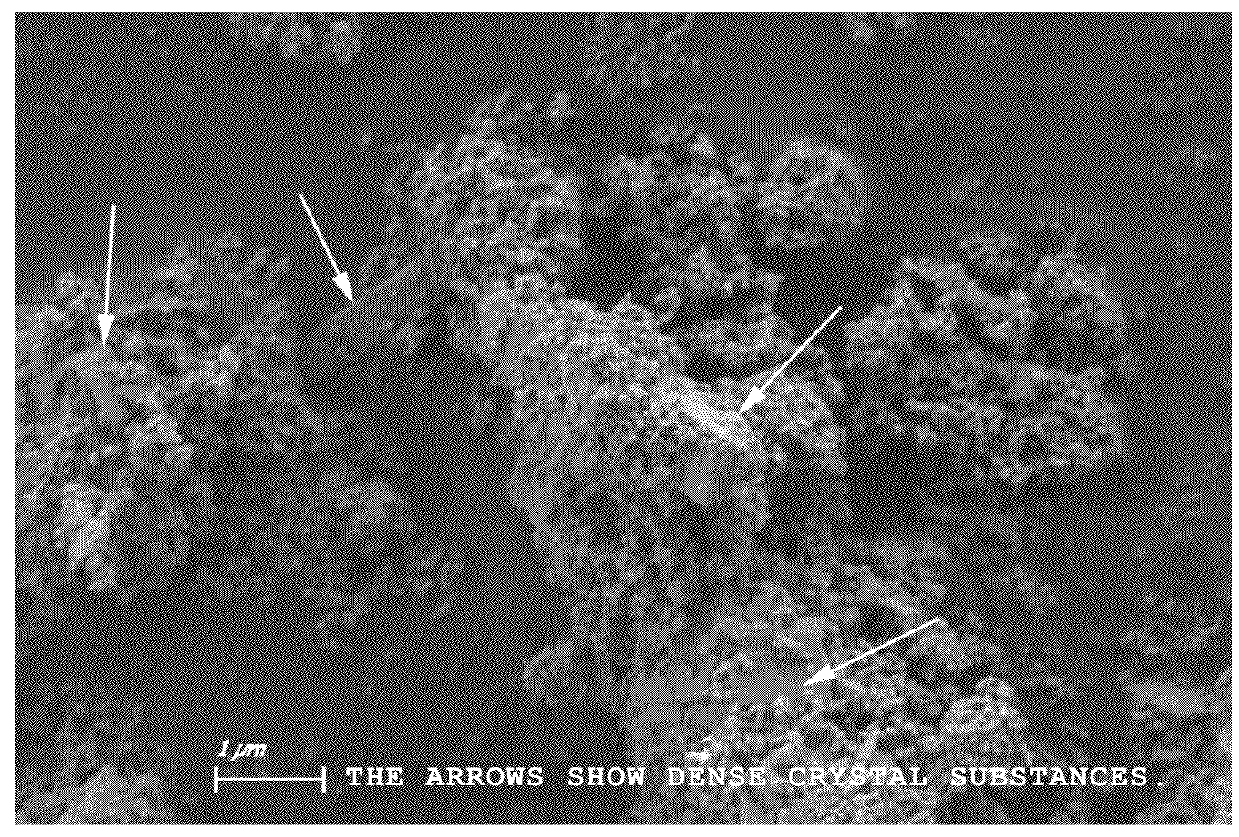

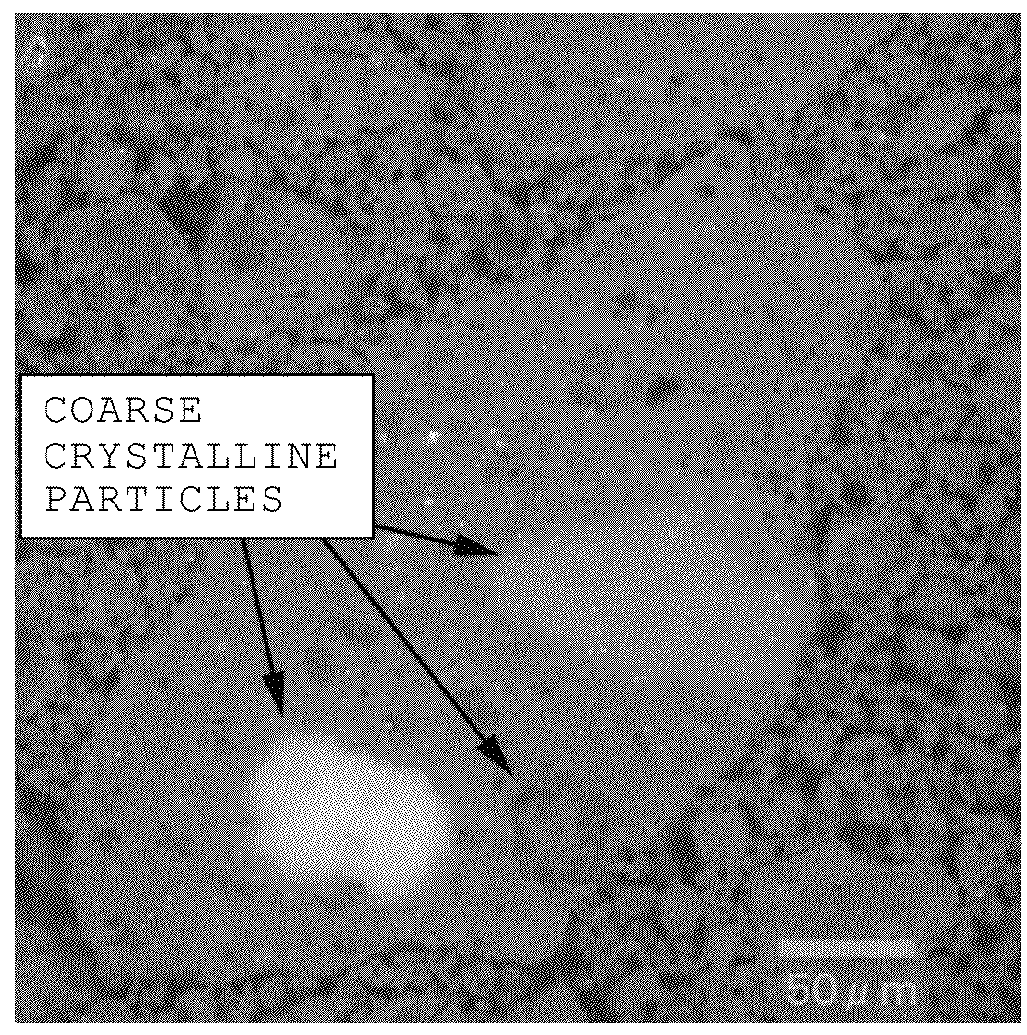

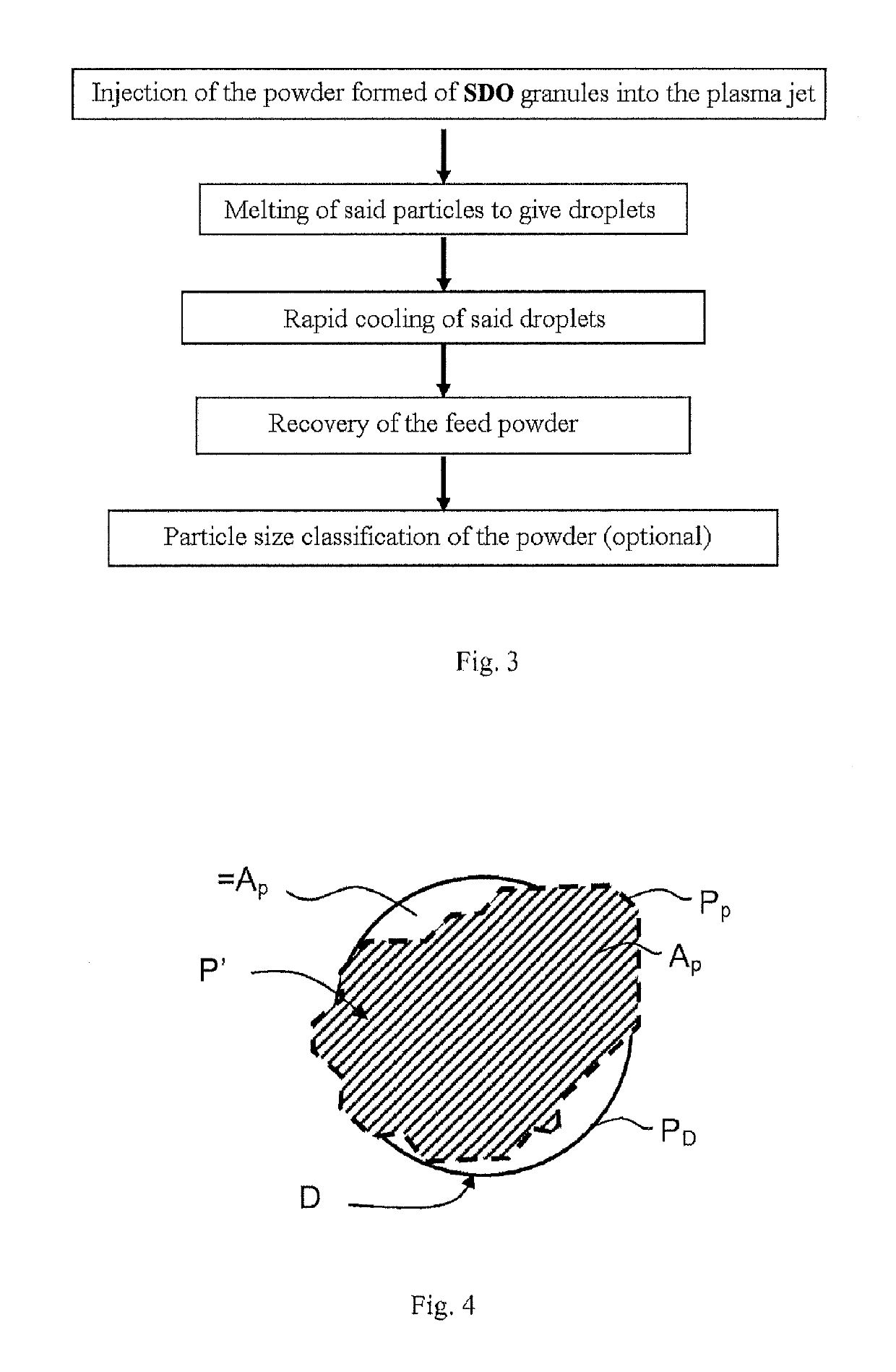

Highly pure powder intended for thermal spraying

ActiveUS20150298986A1High purityMolten spray coatingGlass/slag layered productsApparent densityThermal spraying

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

Method of recovering rare-earth elements

ActiveUS9228248B2Improve leaching rateRaise the ratioMetal recyclingLanthanide oxides/hydroxidesRare-earth elementSlurry

Provided is a method of recovering rare-earth elements by which rare-earth elements can be recovered efficiently from a bauxite residue serving as a raw material and containing the rare-earth elements. Specifically provided is a method of recovering rare-earth elements from a raw material, the raw material being a bauxite residue produced as a by-product in a Bayer process, the method including: using a bauxite residue having a specific surface area of 35 m2 / g or more; adding, to the raw material bauxite residue, a liquid leaching agent formed of an aqueous solution of at least one kind of mineral acid selected from sulfuric acid, hydrochloric acid, nitric acid, and sulfurous acid, thereby preparing a slurry having a liquid-solid ratio of 2 to 30 and a pH of 0.5 to 2.2; subjecting the slurry to leaching treatment of the rare-earth elements under a temperature condition of room temperature to 160° C.; subjecting the slurry after the leaching treatment to solid-liquid separation, yielding a leachate; and separating and recovering the rare-earth elements from the leachate.

Owner:NIPPON LIGHT METAL CO LTD

A Process, Method and Plant for Recovering Scandium

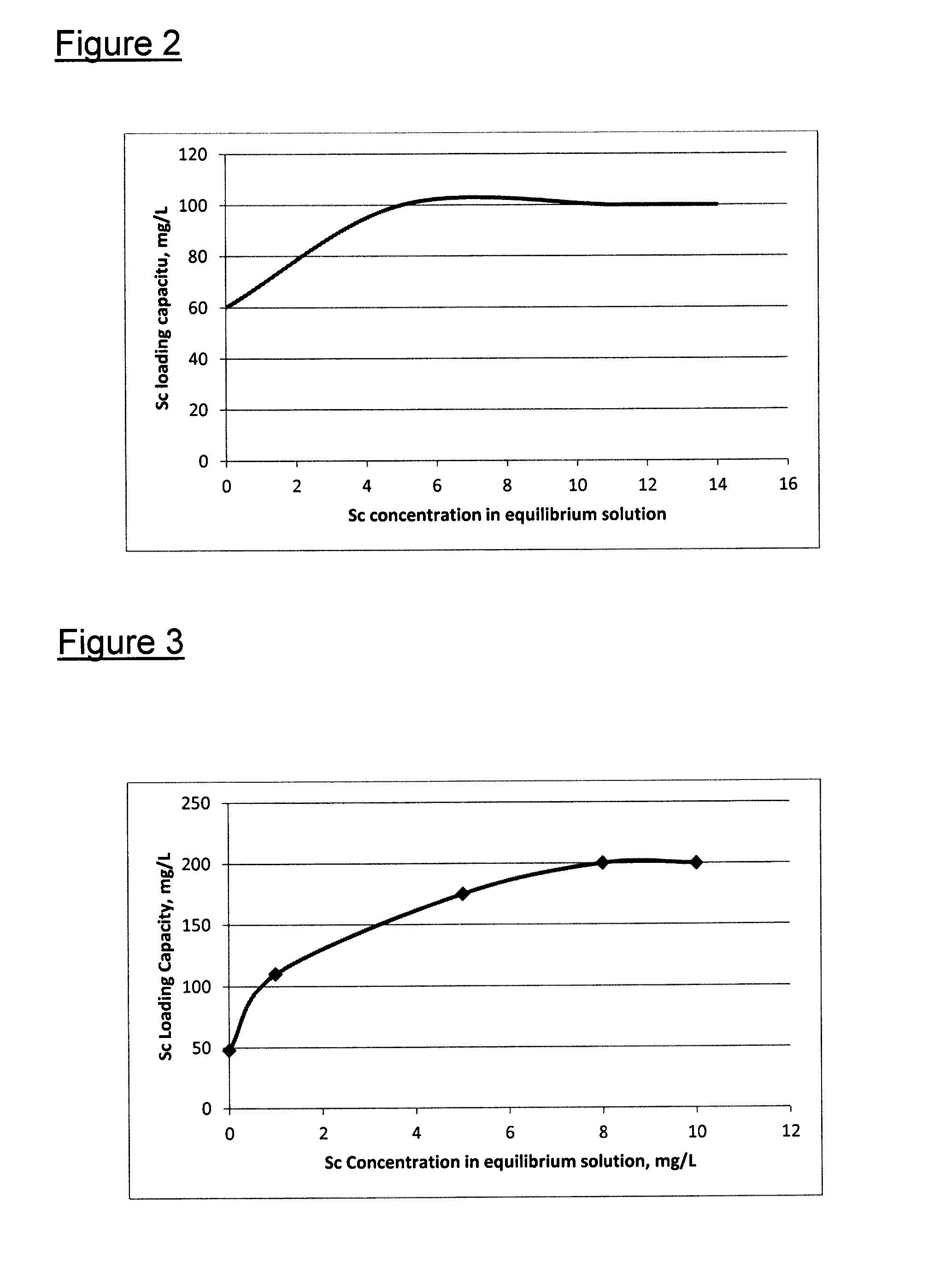

ActiveUS20150307966A1Improve adsorption capacityPossible to recoverIon-exchange process apparatusIon-exchanger regenerationIon exchangeIon-exchange resin

Owner:CLEAN TEQ PTY LTD

Method of manufacturing metal oxide film

InactiveUS8753987B2High densityHigh film strengthTantalum compoundsSemiconductor/solid-state device manufacturingOxygenMetal

Provided is a method of manufacturing a metal oxide film to be formed through the following processes: a coating process of forming a coating film on a substrate by using a coating liquid for forming metal oxide film containing any of various organometallic compounds; a drying process of making the coating film into a dried coating film; and a heating process of forming an inorganic film from the dried coating film under an oxygen-containing atmosphere having a dew-point temperature equal to or lower than −10° C.

Owner:SUMITOMO METAL MINING CO LTD

Processes for preparing alumina and various other products

There are provided processes for preparing alumina. These processes can comprise leaching an aluminum-containing material with HCl so as to obtain a leachate comprising aluminum ions and a solid, and separating said solid from said leachate; reacting said leachate with HCl so as to obtain a liquid and a precipitate comprising said aluminum ions in the form of AlCl3, and separating said precipitate from said liquid; and heating said precipitate under conditions effective for converting AlCl3 into Al2O3 and optionally recovering gaseous HCl so-produced. These processes can also be used for preparing various other products such as hematite, MgO, silica and oxides of various metals, sulphates and chlorides of various metals, as well as rare earth elements, rare metals and aluminum.

Owner:ORBITE ALUMINAE INC

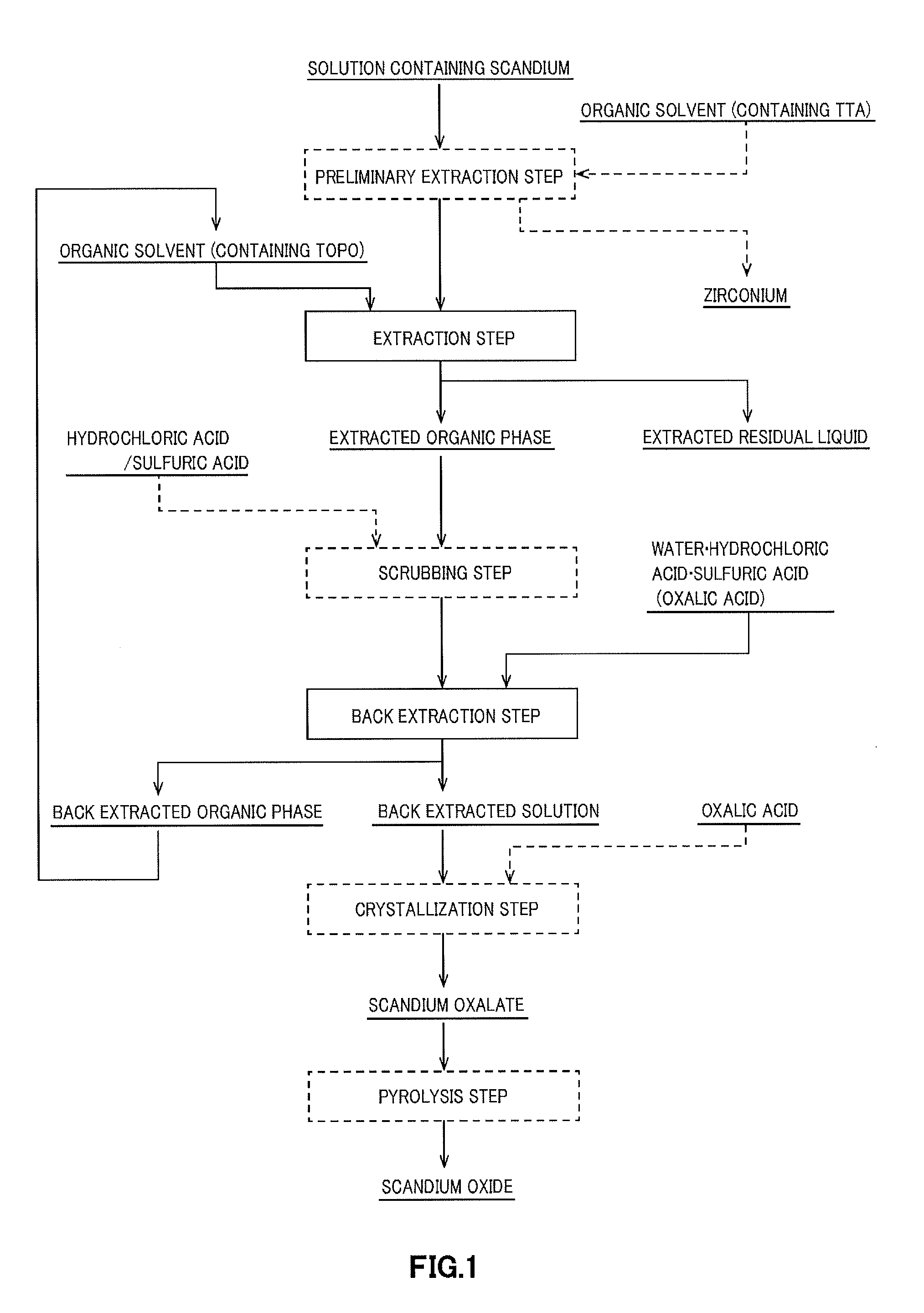

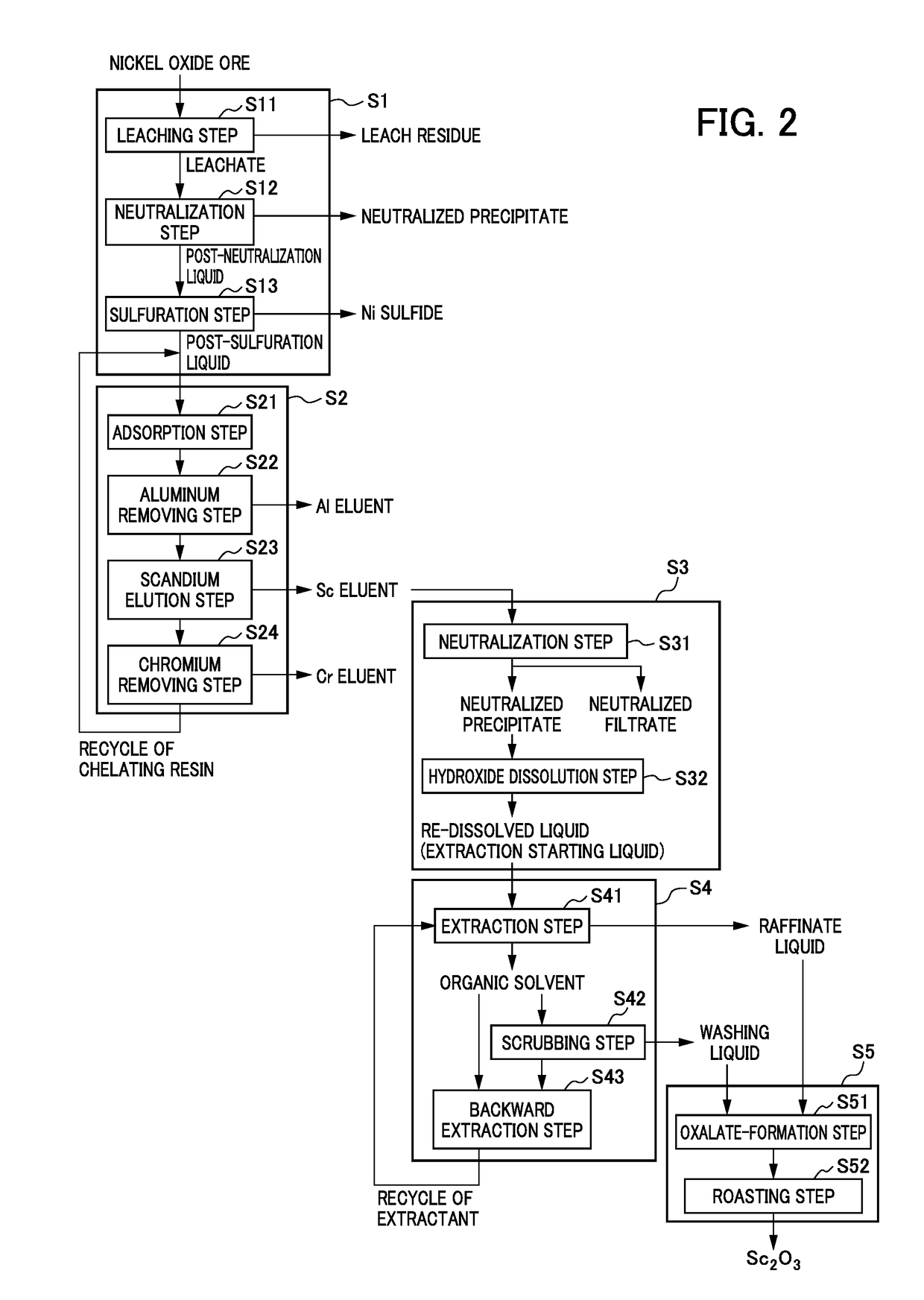

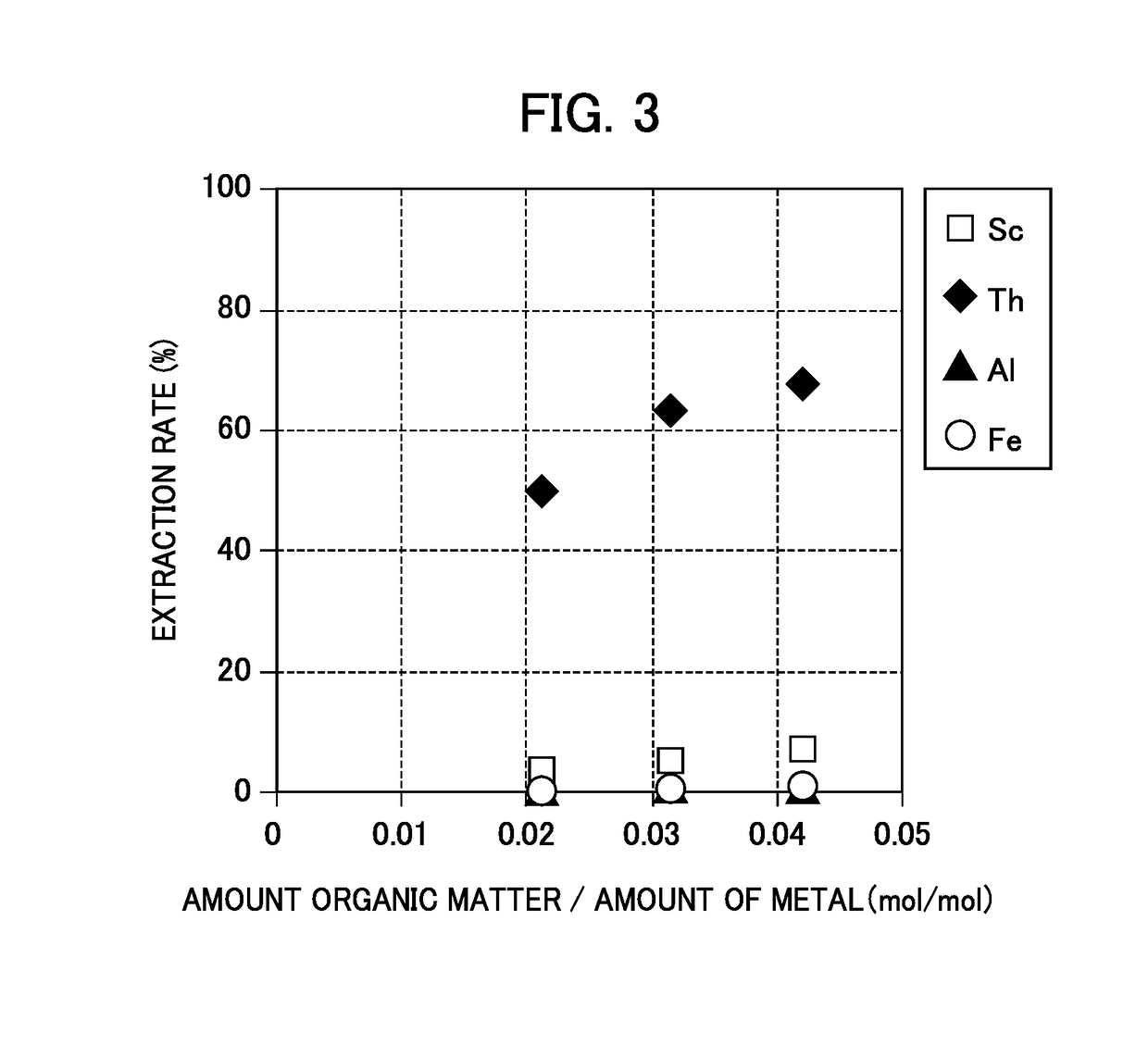

Method for separating and refining scandium

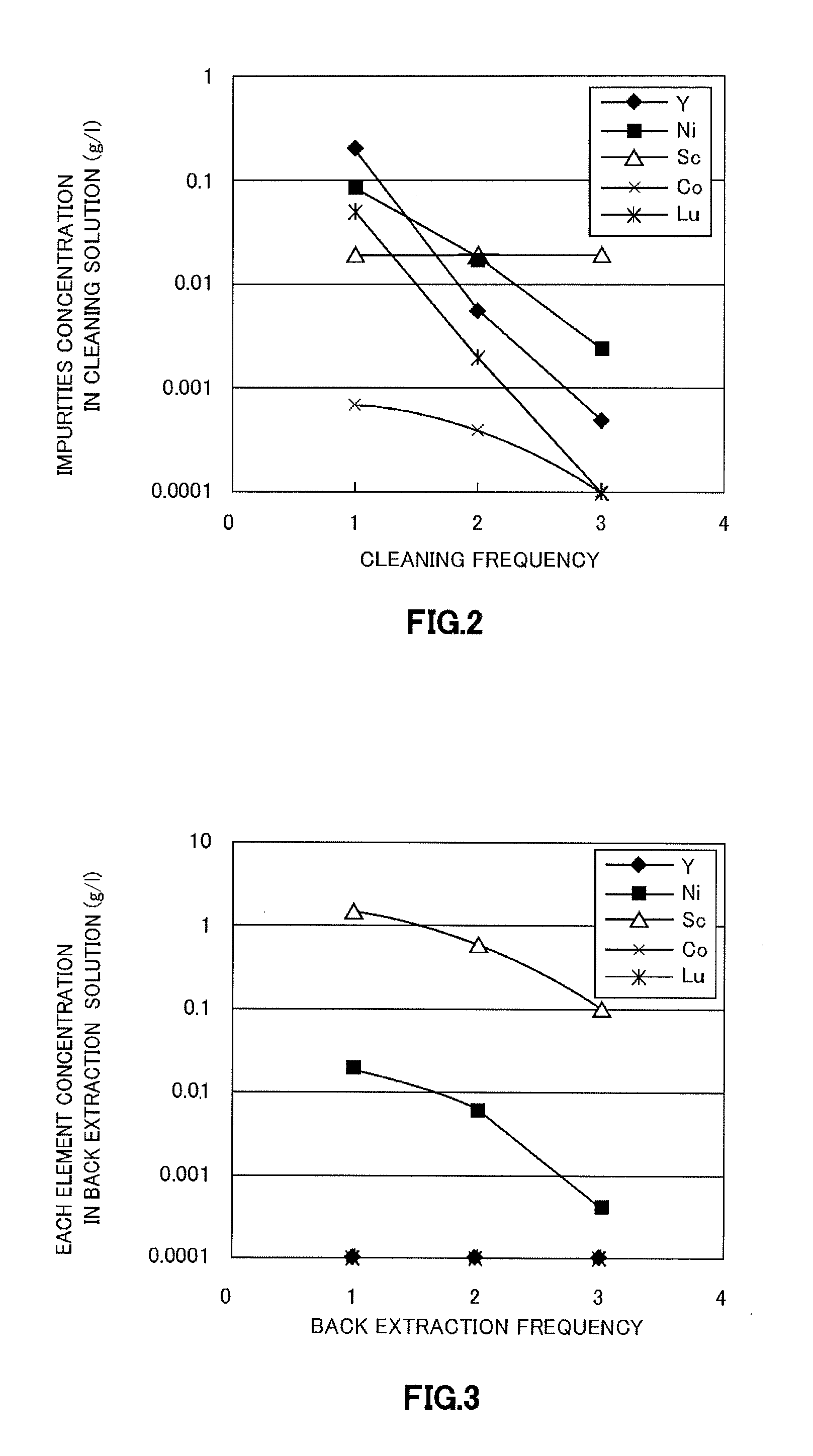

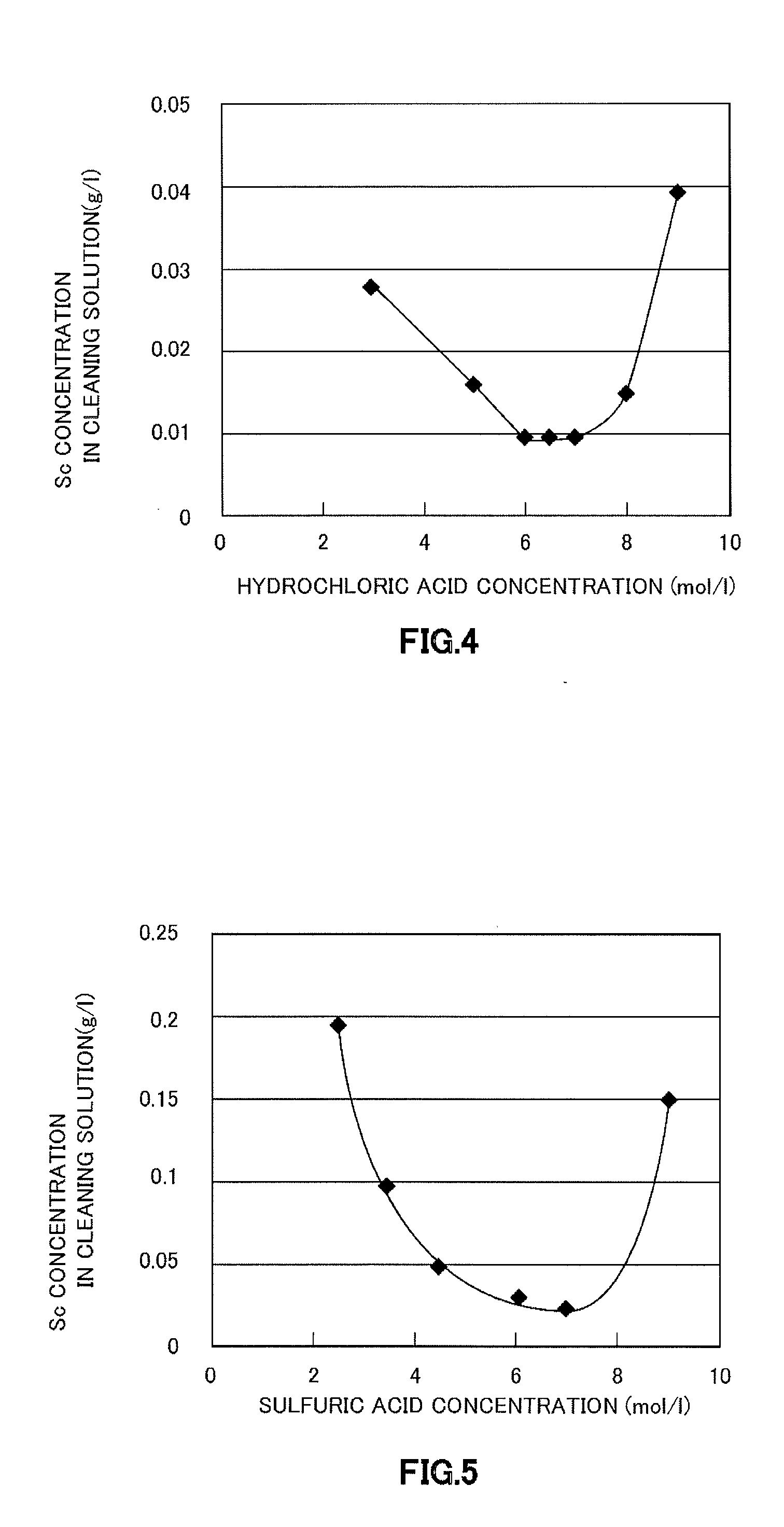

ActiveUS20150184268A1Facilitate strippingHigh stripping rateScandium oxides/hydroxidesRare earth metal compounds preparation/treatmentOxalateOrganic solvent

An object of the present invention is to provide a method for separating and refining scandium capable of efficiently separating and refining the scandium from a solution containing the scandium, with improved stripping, while securing separability (selectivity) of the scandium from impurity elements. The method of the present invention involves mixing a solution containing the scandium with an organic solvent containing a trioctylphosphine oxide to extract the scandium into the organic solvent; and mixing the organic solvent with a stripping starting solution containing any one or more of water, hydrochloric acid, sulfuric acid, and oxalic acid to strip the scandium from the organic solvent.

Owner:SUMITOMO METAL MINING CO LTD

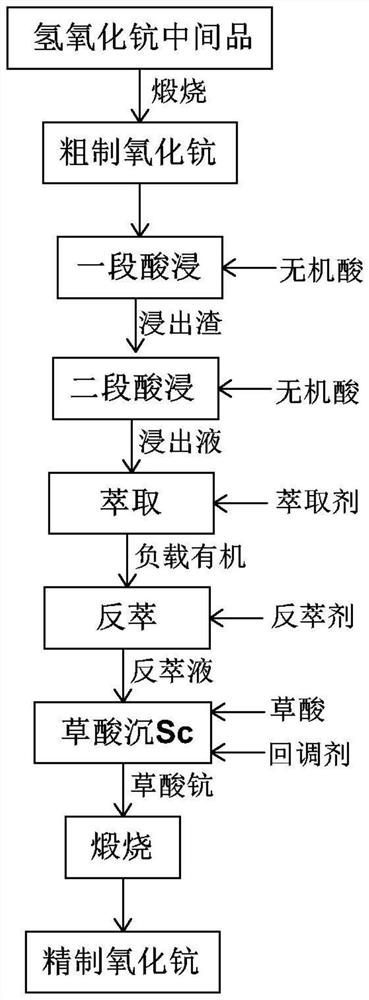

Method for purifying and refining high-purity scandium oxide from scandium hydroxide intermediate product

PendingCN112320832AShort processEasy to operateScandium oxides/hydroxidesRare earth metal compounds preparation/treatmentOXALIC ACID DIHYDRATEProcess engineering

The invention discloses a method for purifying and refining high-purity scandium oxide from a scandium hydroxide intermediate product, which comprises the following steps: calcining the scandium hydroxide intermediate product to obtain crude scandium oxide; adding water into the crude scandium oxide for slurrying, adding inorganic acid to adjust the pH value to 1.0-3.0, and conducting filtering and washing to obtain first-stage leaching residues; putting the first-stage leaching residues into an inorganic acid solution, and conducting filtering to obtain a second-stage leaching solution; performing extraction and phase splitting on the second-stage leaching solution by using an extraction agent P350, and then performing reverse extraction and phase splitting to obtain a scandium-containingreverse extraction solution; adding an oxalic acid solution into the scandium-containing reverse extraction solution, adding a back-regulating agent to regulate the pH value to 0.5-2.0, and conducting filtering and washing to obtain scandium oxalate precipitate; and calcining the scandium oxalate precipitate to obtain refined high-purity scandium oxide. Aiming at the characteristic difference ofscandium oxide and impurity elements, the high-purity scandium oxide is prepared by combining the segmented leaching and extraction processes, so that the process flow can be greatly shortened.

Owner:JINGMEN GEM NEW MATERIAL

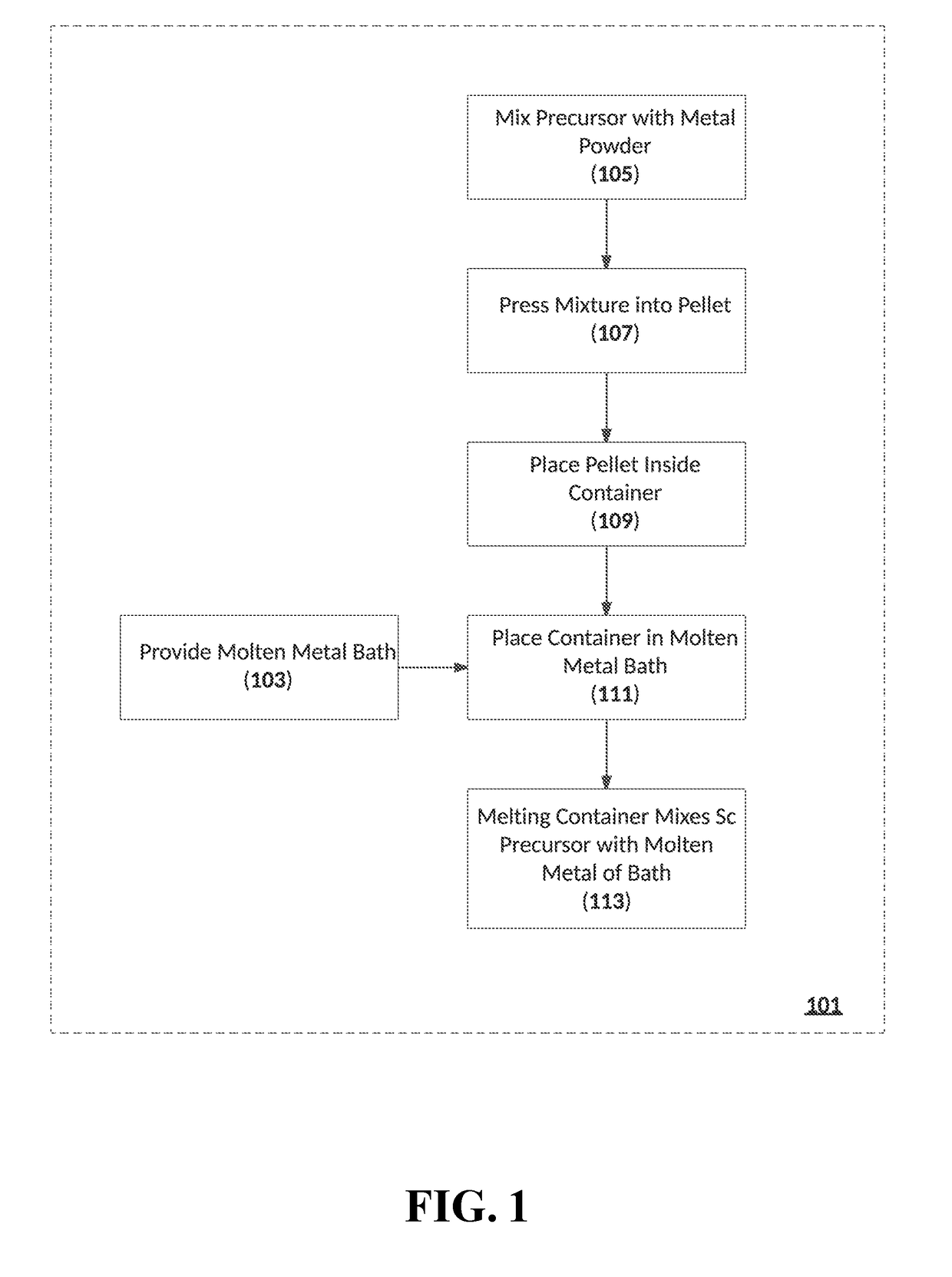

Scandium-containing master alloys and method for making the same

A method (101) is provided for making a scandium-containing alloy. The method includes providing a molten metal (103), and mixing the molten metal with a scandium-containing precursor (113) which undergoes thermal decomposition at the temperature of the molten metal to produce scandium oxide, thereby producing a scandium-containing alloy.

Owner:SCANDIUM INT MINING

Method of recovering metal compounds from solid oxide fuel cell scrap

A method of recovering metal compounds from solid oxide fuel cell scrap includes processing the solid oxide fuel cell scrap to form a powder, digesting the processed scrap, extracting lanthanum oxide and cerium oxide from a solution containing the digested processed scrap, extracting a zirconium compound from the solution after extracting the lanthanum oxide and cerium oxide, and extracting scandium compound from the solution extracting the zirconium compound from the solution.

Owner:BLOOM ENERGY CORP

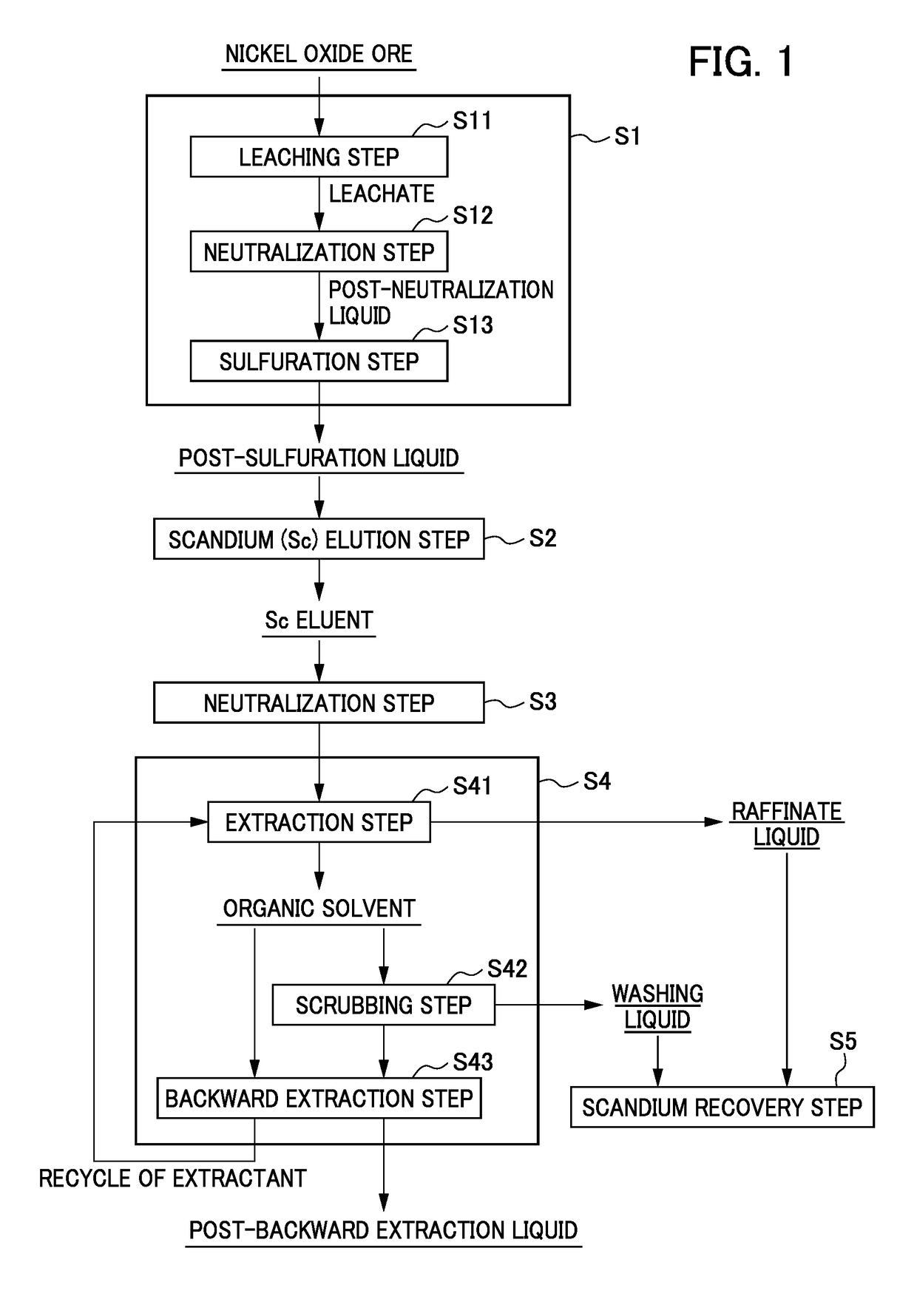

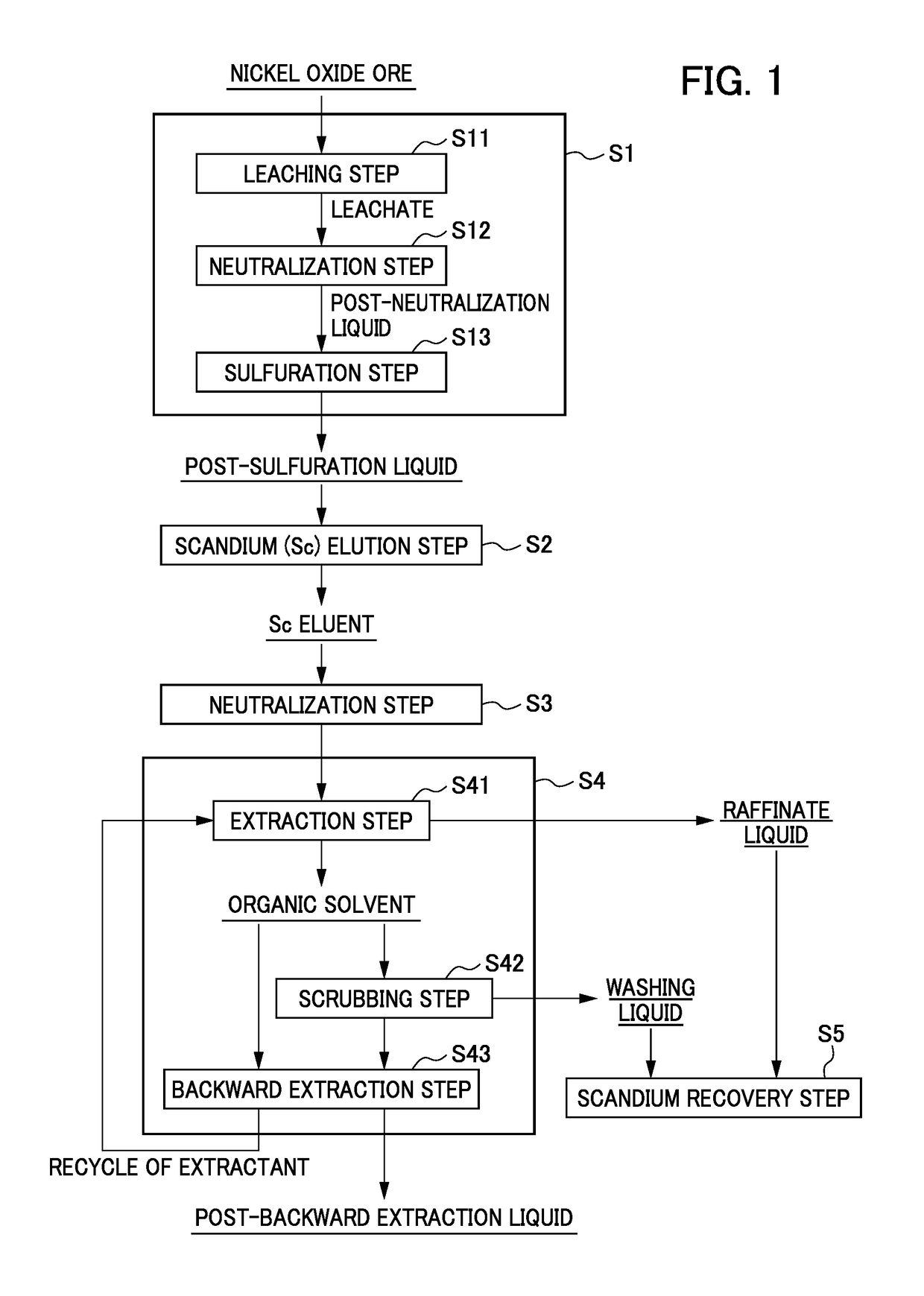

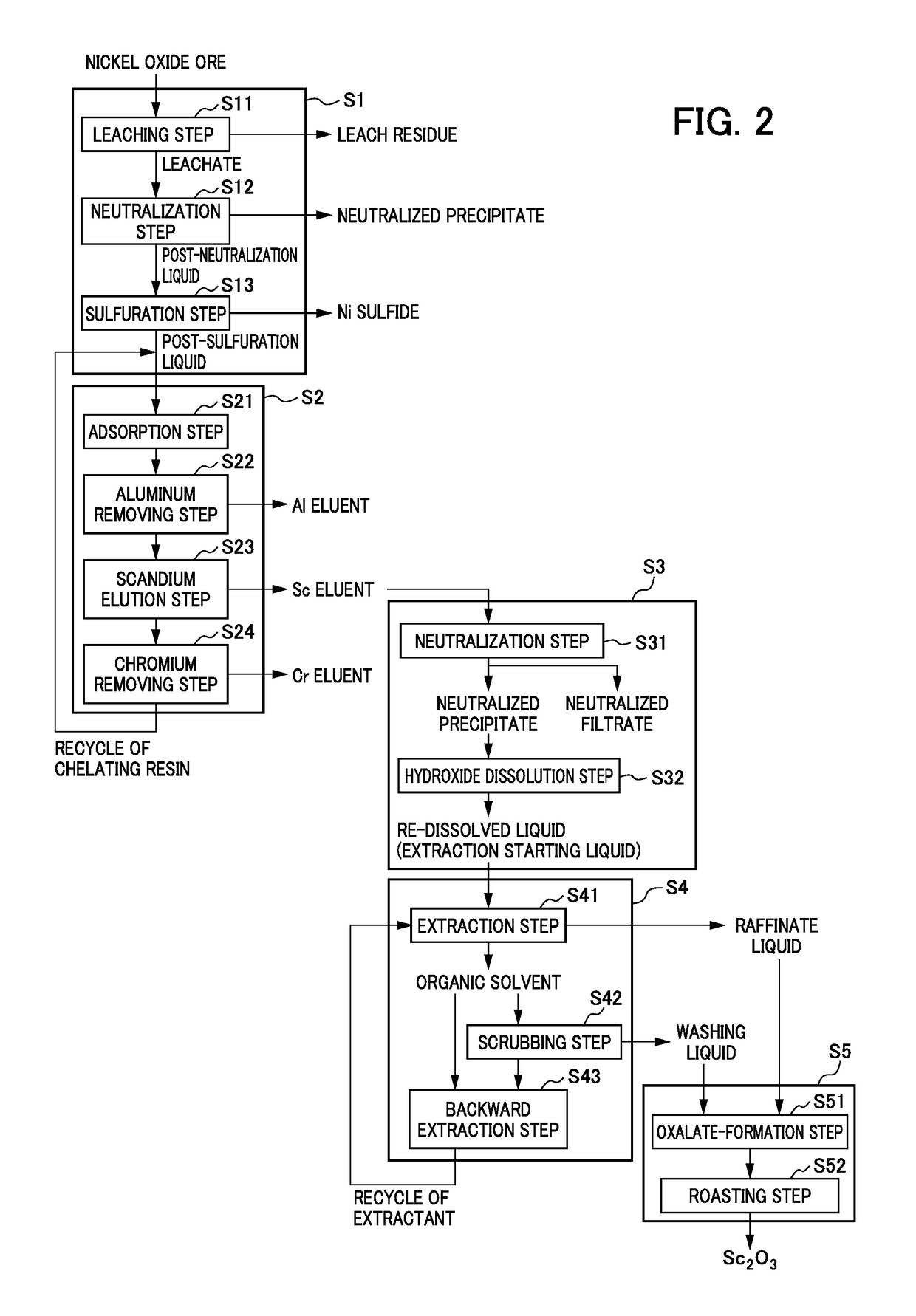

Method for recovering high-purity scandium

InactiveUS20170321301A1Simply and efficiently be recoveredHigh purityOrganic compound preparationScandium oxides/hydroxidesSolventIon-exchange resin

Provided is a method for recovering scandium, with which it is possible to easily and efficiently recover high-purity scandium from nickel oxide ores. This method for recovering scandium involves passing a solution containing scandium through an ion exchange resin, then subjecting the eluant eluted from the ion exchange resin to solvent extraction and separating the extraction residual liquid and the extraction agent after extraction, then performing an oxalation process on the extraction residual liquid to obtain a scandium oxalate precipitate, and roasting the precipitate to obtain scandium oxide, wherein the method is characterized in that an amine-based extraction agent is used as the extraction agent for solvent extraction.

Owner:SUMITOMO METAL MINING CO LTD

Method for producing a solid scandium-containing material of enhanced scandium content

ActiveUS20150368755A1Raise the ratioReduce contentRare earth metal chloridesGroup 3/13 organic compounds without C-metal linkagesHydrogenCarbamate

A method for producing a solid scandium-containing material comprises providing an aqueous solution containing carbonate ions, carbamate ions, hydrogen carbonate (HCO3+) ions, or mixtures thereof, contacting the aqueous solution with a scandium containing material containing one or more impurities to produce a scandium-loaded solution and a depleted scandium containing material, separating the depleted scandium containing material from the scandium loaded solution, treating the scandium loaded solution to cause precipitation of a solid scandium-containing material whilst avoiding or minimising precipitation of impurities present in the aqueous solution, and separating the solid scandium-containing material from the solution. In another embodiment, a high purity scandium containing is produced by contacting a solid material containing scandium with an acid to form a scandium loaded solution, separating the scandium loaded solution from any solids, adding additional acid to the scandium loaded solution to reduce the pH and precipitating a high purity scandium oxalate material by adding oxalic acid to the solution.

Owner:ELEMENT 21 PTY LTD

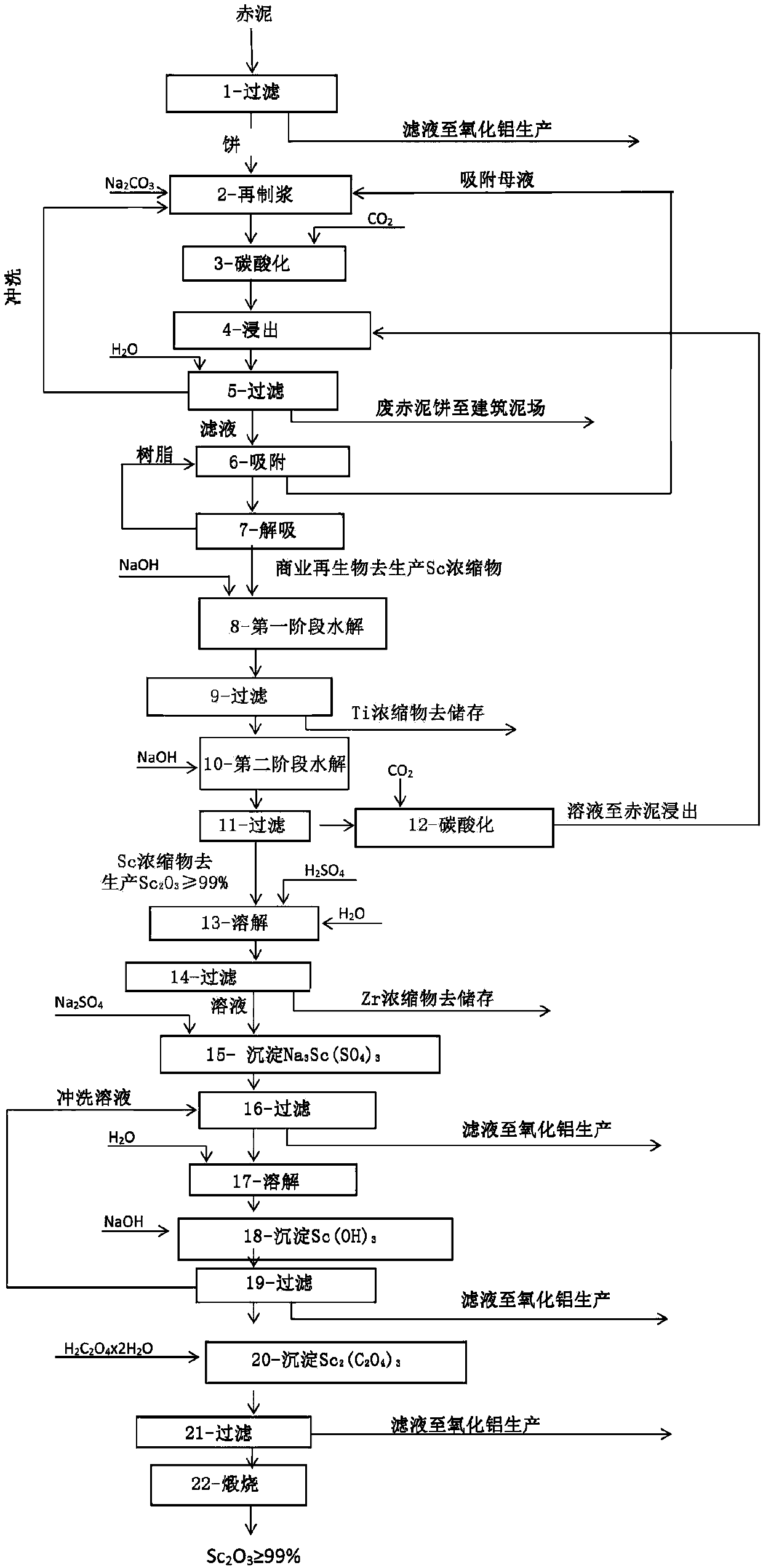

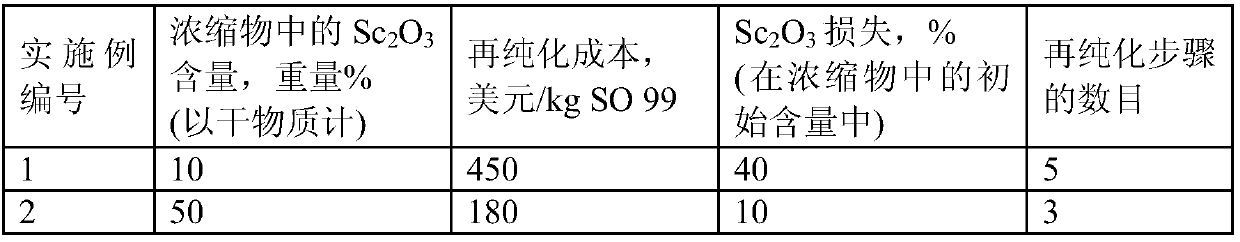

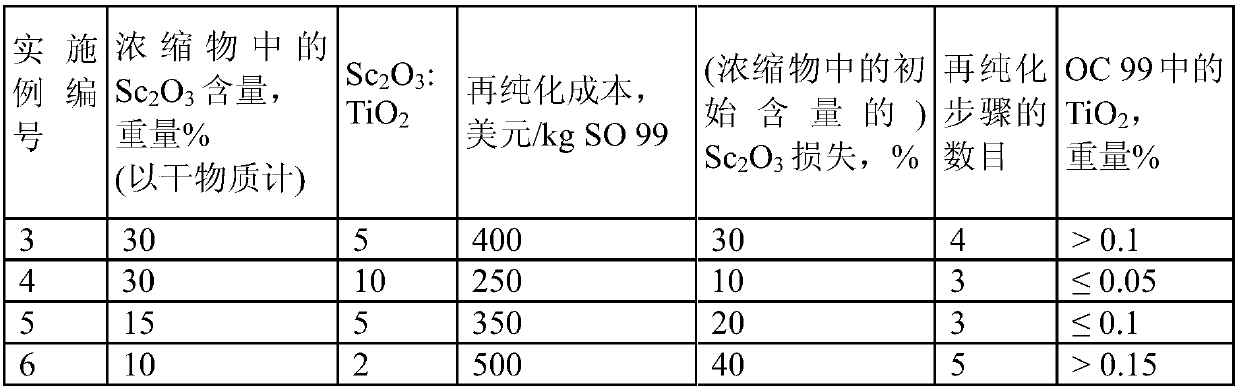

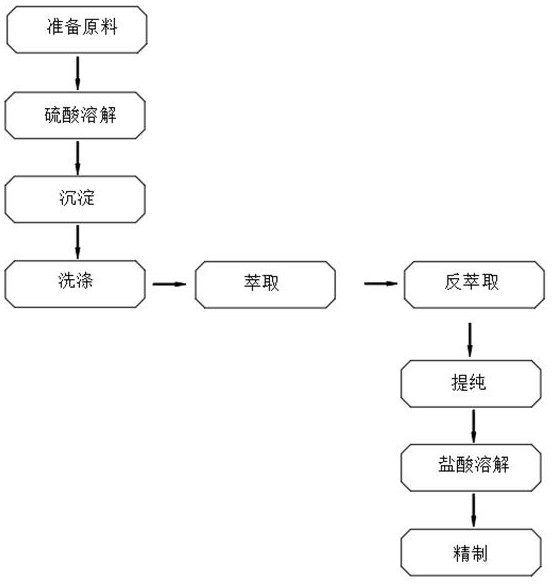

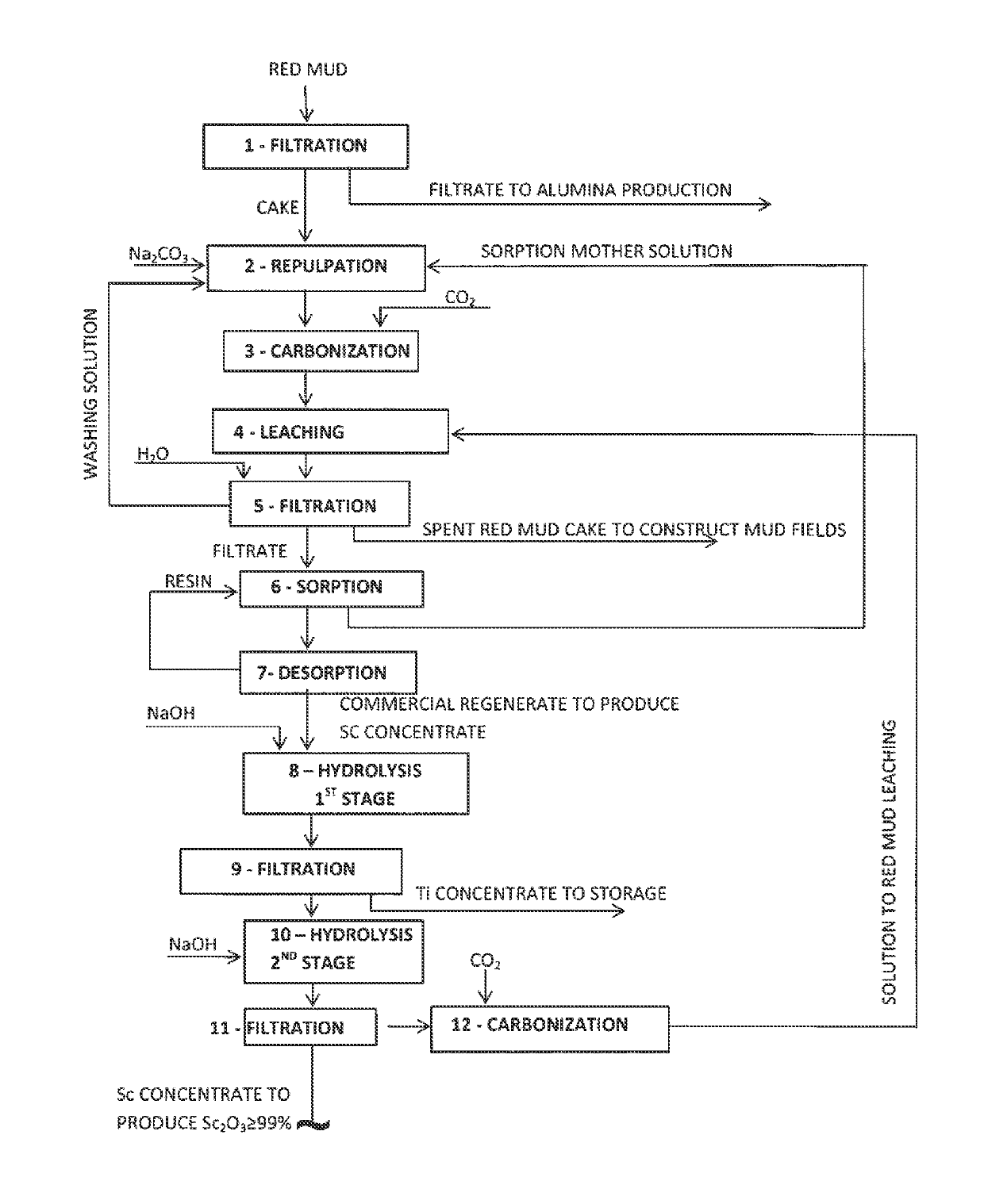

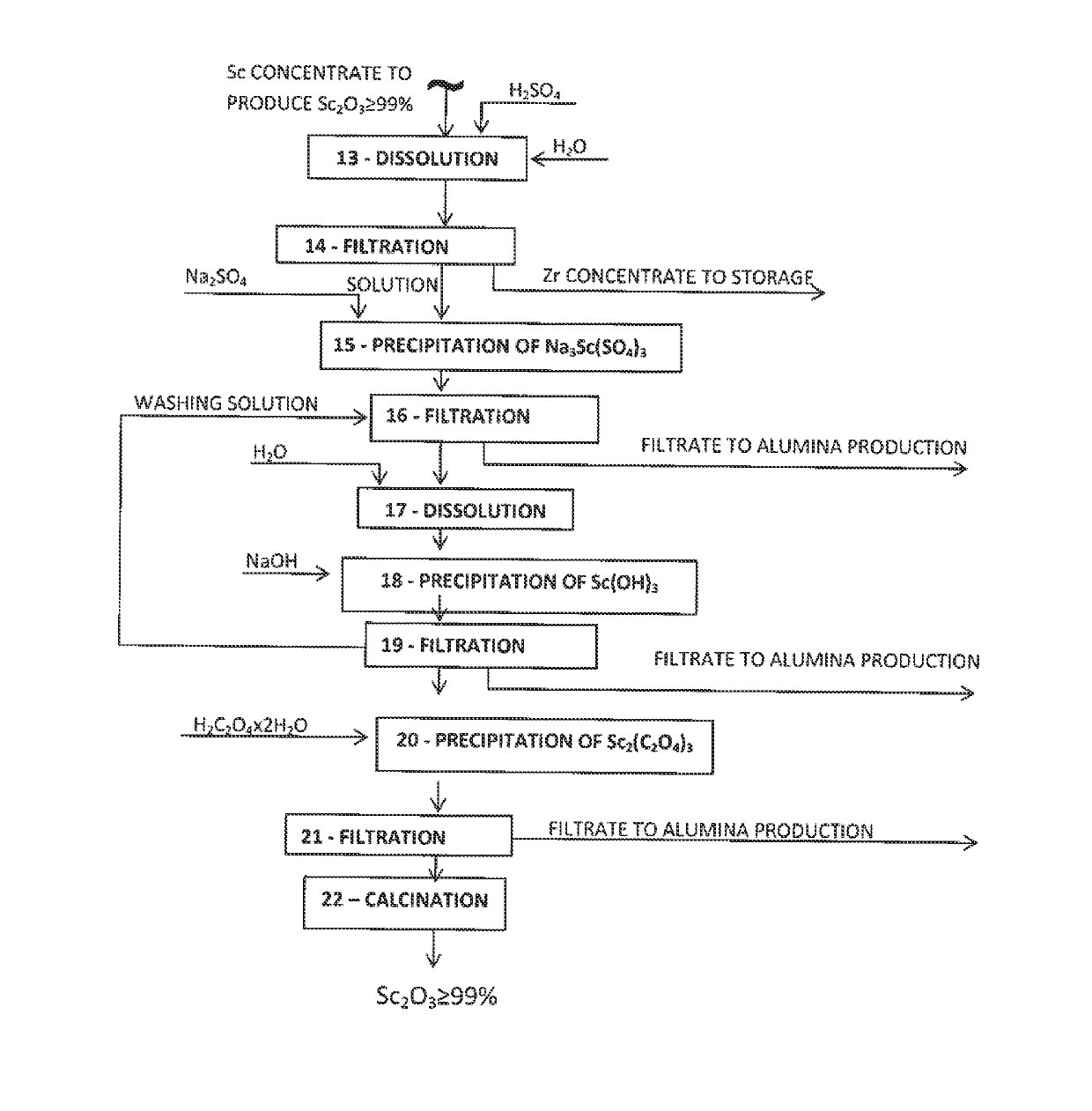

Production of a scandium-containing concentrate and subsequent extraction of high-purity scandium oxide therefrom

ActiveCN108026609ASimple processReduce manufacturing costRare earth metal sulfatesScandium oxides/hydroxidesFiltrationIon exchange

The invention relates to a technology for producing a scandium-containing concentrate from alumina production waste and obtaining a high-purity scandium oxide. The method comprises leaching red mud with a solution containing a mixture of sodium carbonate and sodium bicarbonate, absorbing scandium from the solution on a phosphorus-containing ion exchanger, and desorbing the scandium with a sodium carbonate solution to obtain commercial-grade reclaimed scandium, from which scandium concentrate is precipitated. Said concentrate contains no less than 15 mass% SC2O3, no more than 3 mass% TiO2, andno more than 15 mass% ZrO2, and the scandium in the concentrate is in the form of a mixture of the hydroxide Sc(OH)3 and the basic salt ScOHCO3*4H2O. A method is also proposed that comprises dissolving a scandium-containing concentrate in sulfuric acid, removing the acid-insoluble precipitate, transforming the scandium into a precipitate, filtering, washing, drying, and sintering to obtain a scandium oxide precipitate. After the acid-insoluble scandium precipitate is removed, the scandium is precipitated from the filtrate, removed by filtration, and washed, the binary salt is dissolved in water, and scandium hydroxide is precipitated with caustic soda. The cake is then transformed into scandium oxalate, removed by filtration, and washed with water, and the scandium oxalate is calcined to obtain scandium oxide with a purity approaching 99 mass%.

Owner:OBSHCHESTVO S OGRANICHENNOY OTVETSTVENNOSTYU OBEDINENNAYA KOMPANIYA RUSAL INZHENERNO TEKHNOLOGICHESKIY TSENTR

New method of using novel extracting agent to extract scandium oxide from titanium dioxide waste acid

InactiveCN112095026ANot volatileEasy to separateScandium oxides/hydroxidesRare earth metal compounds preparation/treatmentDioctyl phosphateAcid water

The invention discloses a novel method of using a novel extracting agent to extract scandium oxide from titanium dioxide waste acid. The method comprises the following steps of: S1, preparation of rawmaterials: preparing a titanium dioxide waste acid water raw material and a concentrated sulfuric acid raw material; S2, sulfuric acid dissolution: adding water and a concentrated sulfuric acid solution into titanium dioxide waste acid water, stirring and mixing; S3, precipitation: adding a flocculating agent into the mixed solution, performing precipitation, and filtering the after-precipitationsolution; and S4, washing: adding water, sulfuric acid and hydrogen peroxide into the filtered solution, mixing and stirring, adding hydrogen peroxide, and continuously stirring. According to the method, a new extraction method is carried out by adopting dioctyl phosphate and tributyl phosphate to replace a traditional old extracting agent; during extraction, the separation effect is better, therecovery rate is high, the scandium oxide can be further purified, the extraction rate is increased from about 60% to 85%, and the price of the dioctyl phosphate and the tributyl phosphate is low; andfurthermore, the added flocculating agent is cheap and practical, and the flocculating agent is non-toxic and high in flocculating capacity.

Owner:HUNAN CHUANGDA YUTU CHEM CO LTD

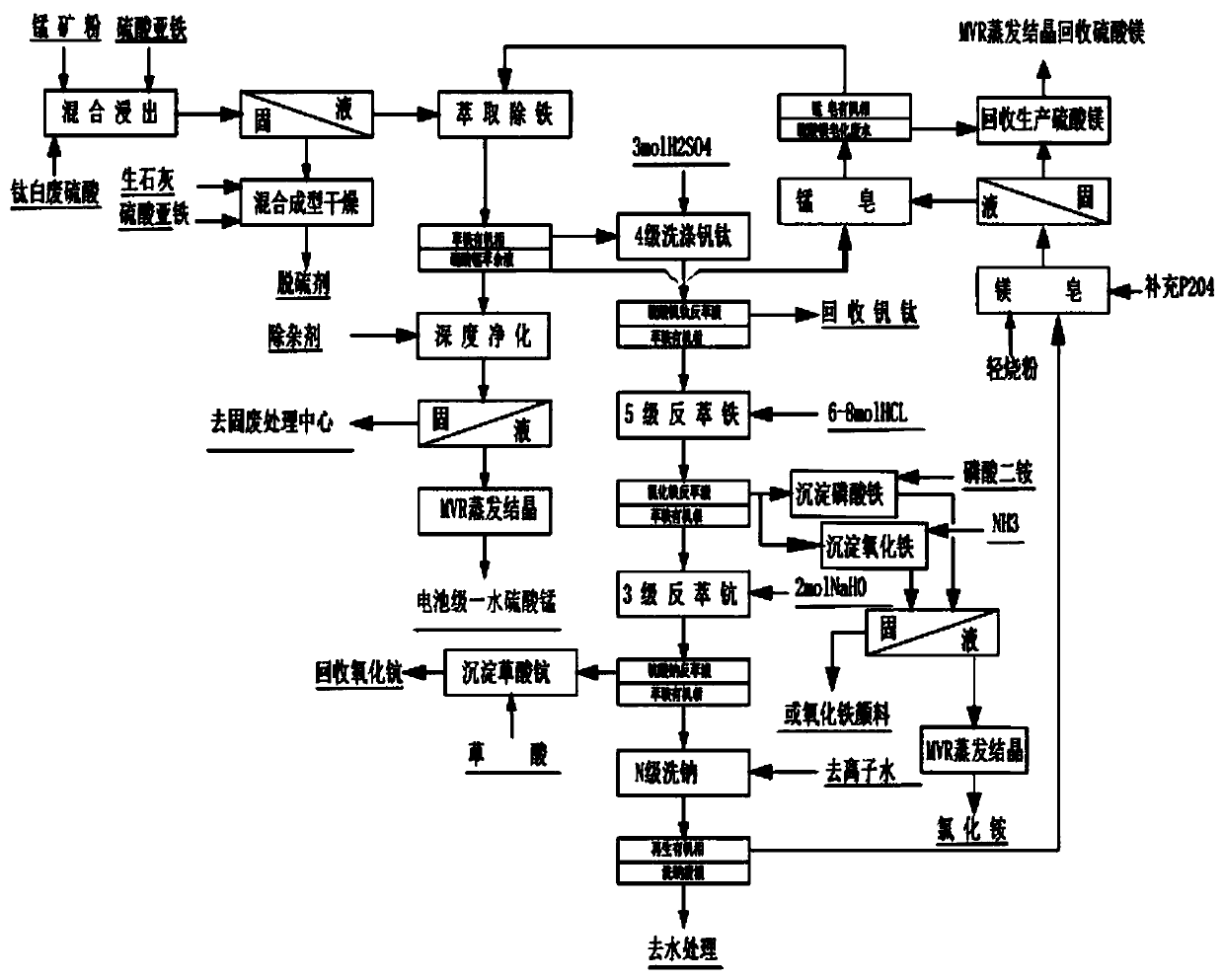

Full resource utilization process of titanium white waste acid

InactiveCN111485102ARealize full resource utilizationIn line with the concept of energy saving and environmental protectionIron oxides/hydroxidesScandium oxides/hydroxidesIron sulfateFerrous sulfate iron

The invention relates to a full resource utilization process of titanium white waste acid. The process specifically comprises the following steps: (1) reducing and leaching manganese oxide ore by using titanium white waste acid and ferrous sulfate to prepare an iron oxide normal-temperature desulfurizer; (2) carrying out magnesium soap extraction on a leached ferric manganese sulfate solution to separate iron and manganese; and (3) treating with an organic phase extractant to respectively recover vanadium, titanium, iron and scandium. The process has the advantages that P204 / 507 is adopted toextract and vanadium, titanium and scandium ions of the enriched titanium white waste acid, full resource utilization of the titanium white waste acid in the real sense is achieved, no new three-wasteproducts are generated, the concepts of energy conservation and environmental protection are met, and the process has a good popularization prospect in the technical field.

Owner:张响

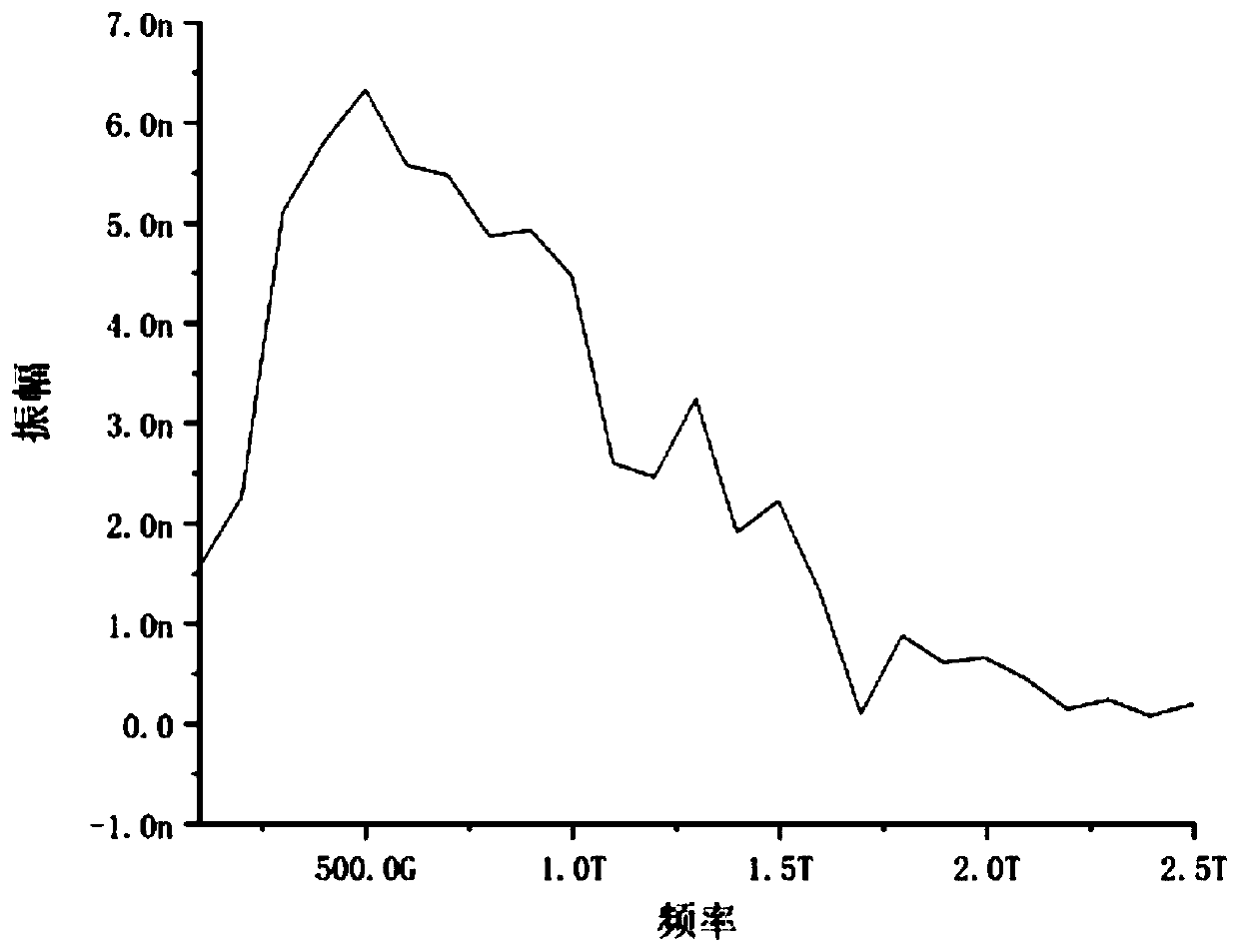

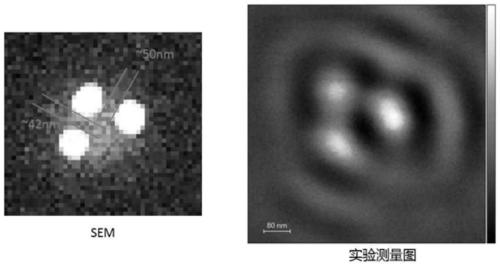

Composite oxide nanoparticle capable of emitting THz frequency and preparation method thereof

ActiveCN111392780AImprove stabilityImprove magnetic propertiesMaterial nanotechnologyLanthanum oxide/hydroxidesFerric hydroxideComposite nanoparticles

The invention belongs to the technical field of terahertz pulse nano materials, and particularly relates to a composite oxide nano particle capable of emitting THz frequency and a preparation method thereof. Rare earth oxide metal and iron oxide react with a concentrated acid respectively to generate corresponding colloidal solutions; by carrying out ultrasonic nonlinear vibration processing through an ammonia water gel system, composite nanoparticles with ferric hydroxide as an inner core and a rare earth metal hydroxide coating the outer layer are generated in a cross-linked grid of the gelsystem, the composite nanoparticles are calcined to obtain composite oxide nanoparticles with ferric oxide as an inner core and rare earth metal oxide coating the outer layer. The composite oxide nanoparticle provided by the invention can release THz frequency at 37 DEG C, has excellent stability and magnetism, can regulate and control THz frequency release power through the intensity of an alternating magnetic field at normal temperature, and is widely applied to the field of biomedicine.

Owner:陈宛莎

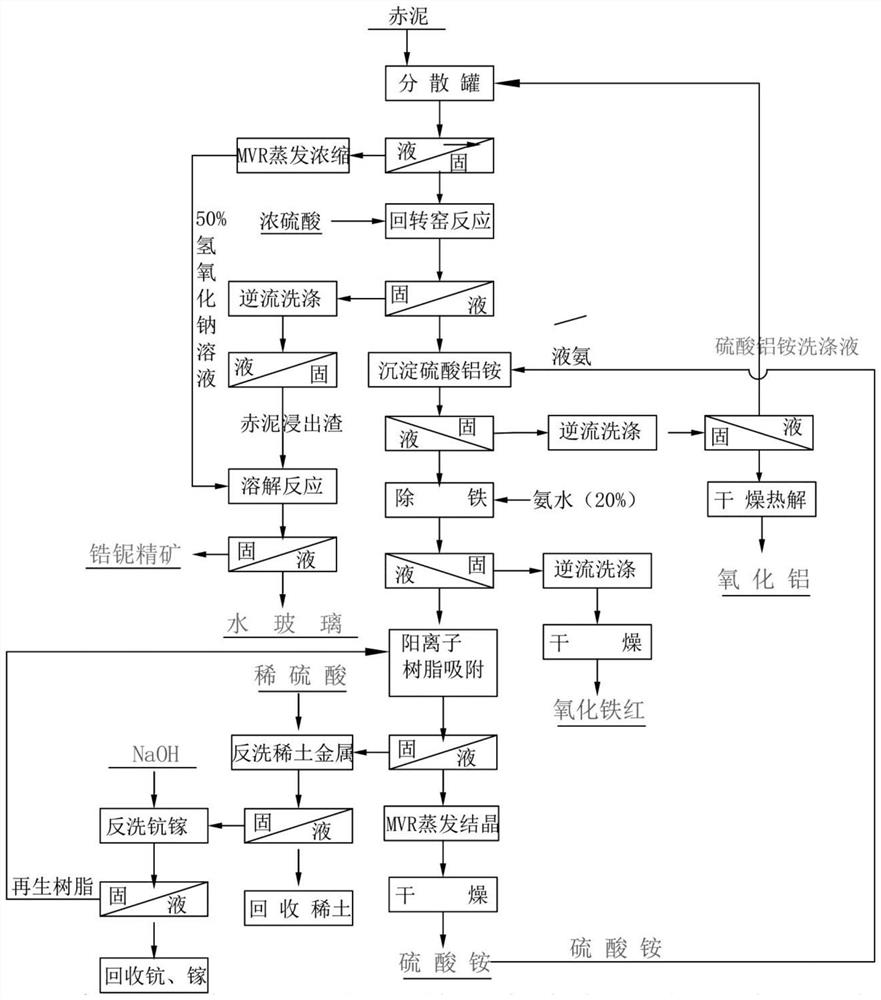

Method for full resource utilization of red mud

ActiveCN111842411ASimple processLow costSolid waste managementTransportation and packagingRheniumRed mud

The invention relates to a method for full resource utilization of red mud. The method for full resource utilization of the red mud specifically comprises the following steps of 1) washing the red mudto recover sodium hydroxide; 2) stirring and leaching out red mud washing residues in a concentrated acid rotary kiln; 3) using the leaching residues obtained in the step 2) for producing sodium silicate and building ceramsite; 4) adjusting the pH value of a leaching solution by using liquid ammonia or ammonia water to precipitate aluminum ammonium sulfate; 5), precipitating an aluminum ammoniumsulfate solution to produce iron oxide red; 6) enriching scandium, vanadium, titanium and gallium through ion exchange; and 7) carrying out MVR evaporative crystallization of ammonium sulfate. The method for full resource utilization of the red mud has the advantages that the pigment-grade iron oxide red with bright color can be obtained without calcining the produced iron oxide red, large-particle smelting-grade aluminum oxide and artificial cryolite can be produced, industrial-grade pure oxides of titanium, scandium, vanadium, gallium, rhenium and rare earth can be produced, full resource recovery of the red mud can be truly realized, the process is simple, the cost is low, and large-scale production is easy.

Owner:张响

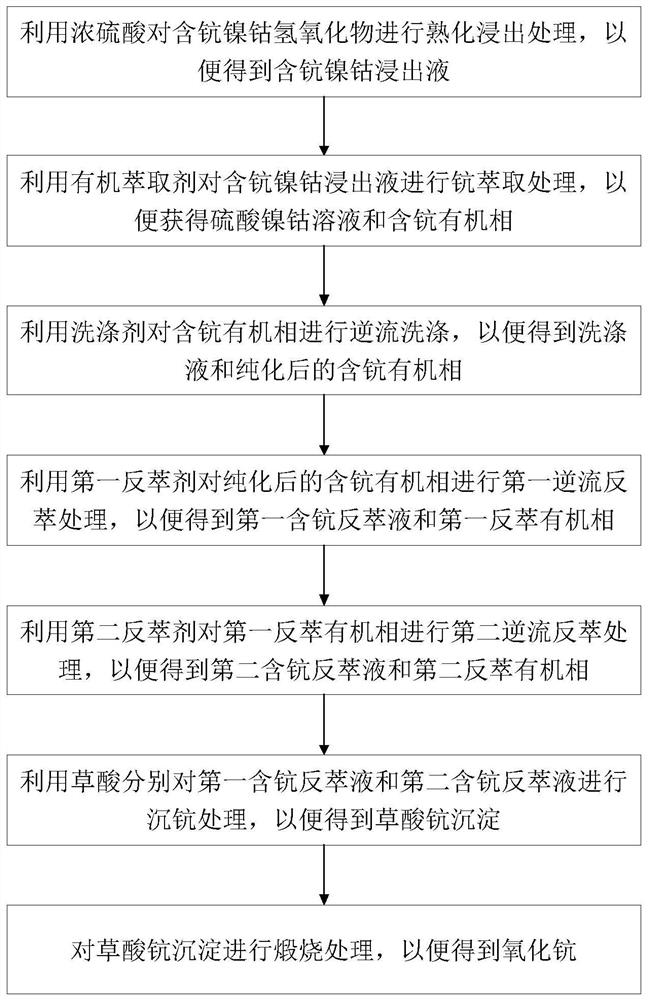

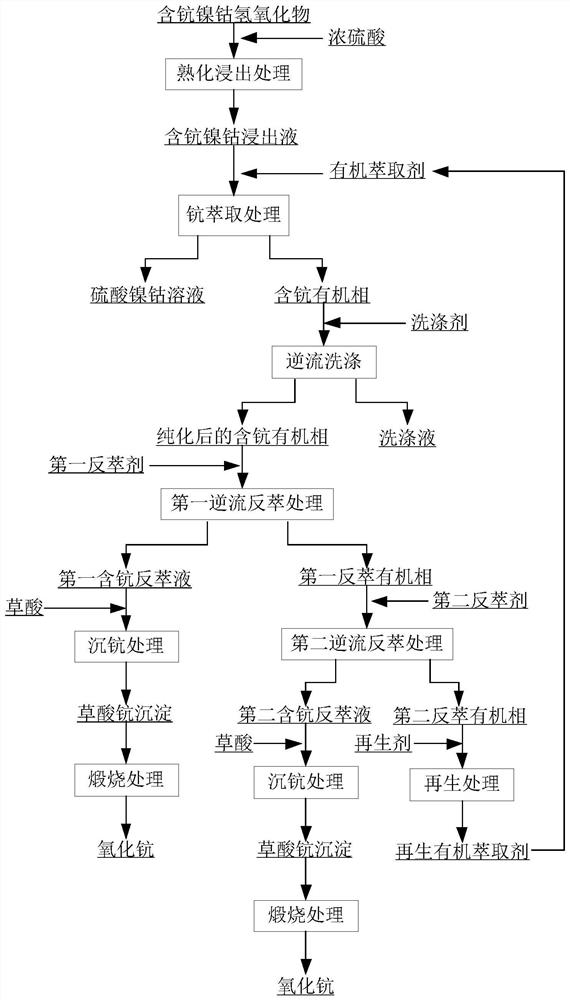

Method for extracting high-purity scandium oxide from scandium-containing nickel-cobalt hydroxide through short process

PendingCN113120941AAvoid it happening againShort operation processScandium oxides/hydroxidesRare earth metal compounds preparation/treatmentOXALIC ACID DIHYDRATEPregnant leach solution

The invention discloses a method for extracting high-purity scandium oxide from scandium-containing nickel-cobalt hydroxide through a short process. The method comprises the following steps: curing and leaching scandium-containing nickel-cobalt hydroxide by using concentrated sulfuric acid to obtain scandium-containing nickel-cobalt leachate; performing scandium extraction treatment on the scandium-containing nickel cobalt leaching solution by using an organic extraction agent to obtain a nickel cobalt sulfate solution and a scandium-containing organic phase; performing countercurrent washing on the scandium-containing organic phase by using a detergent to obtain a washing solution and a purified scandium-containing organic phase; subjecting the purified scandium-containing organic phase to first countercurrent reverse extraction treatment through a first reverse extraction agent, so as to obtain first scandium-containing reverse extraction liquid and a first reverse extraction organic phase; performing second countercurrent reverse extraction treatment on the first reverse extraction organic phase by using a second reverse extraction agent to obtain second scandium-containing reverse extraction liquid and a second reverse extraction organic phase; respectively carrying out scandium precipitation treatment on the first scandium-containing reverse extraction liquid and the second scandium-containing reverse extraction liquid by using oxalic acid to obtain scandium oxalate precipitate; and calcining the scandium oxalate precipitate to obtain scandium oxide. By adopting the method, scandium oxide with the purity of 99.99% can be extracted.

Owner:中冶瑞木新能源科技有限公司

Method for recovering high-purity scandium

InactiveUS10081851B2Simply and efficiently be recoveredHigh purityOrganic compound preparationRecovering materialsSolventIon-exchange resin

Provided is a method for recovering scandium, with which it is possible to easily and efficiently recover high-purity scandium from nickel oxide ores. This method for recovering scandium involves passing a solution containing scandium through an ion exchange resin, then subjecting the eluant eluted from the ion exchange resin to solvent extraction and separating the extraction residual liquid and the extraction agent after extraction, then performing an oxalation process on the extraction residual liquid to obtain a scandium oxalate precipitate, and roasting the precipitate to obtain scandium oxide, wherein the method is characterized in that an amine-based extraction agent is used as the extraction agent for solvent extraction.

Owner:SUMITOMO METAL MINING CO LTD

Method for recovering scandium

ActiveUS20180087128A1Recovered conveniently and efficientlyRare earth metal sulfatesRare earth metal chloridesSulfateDissolution

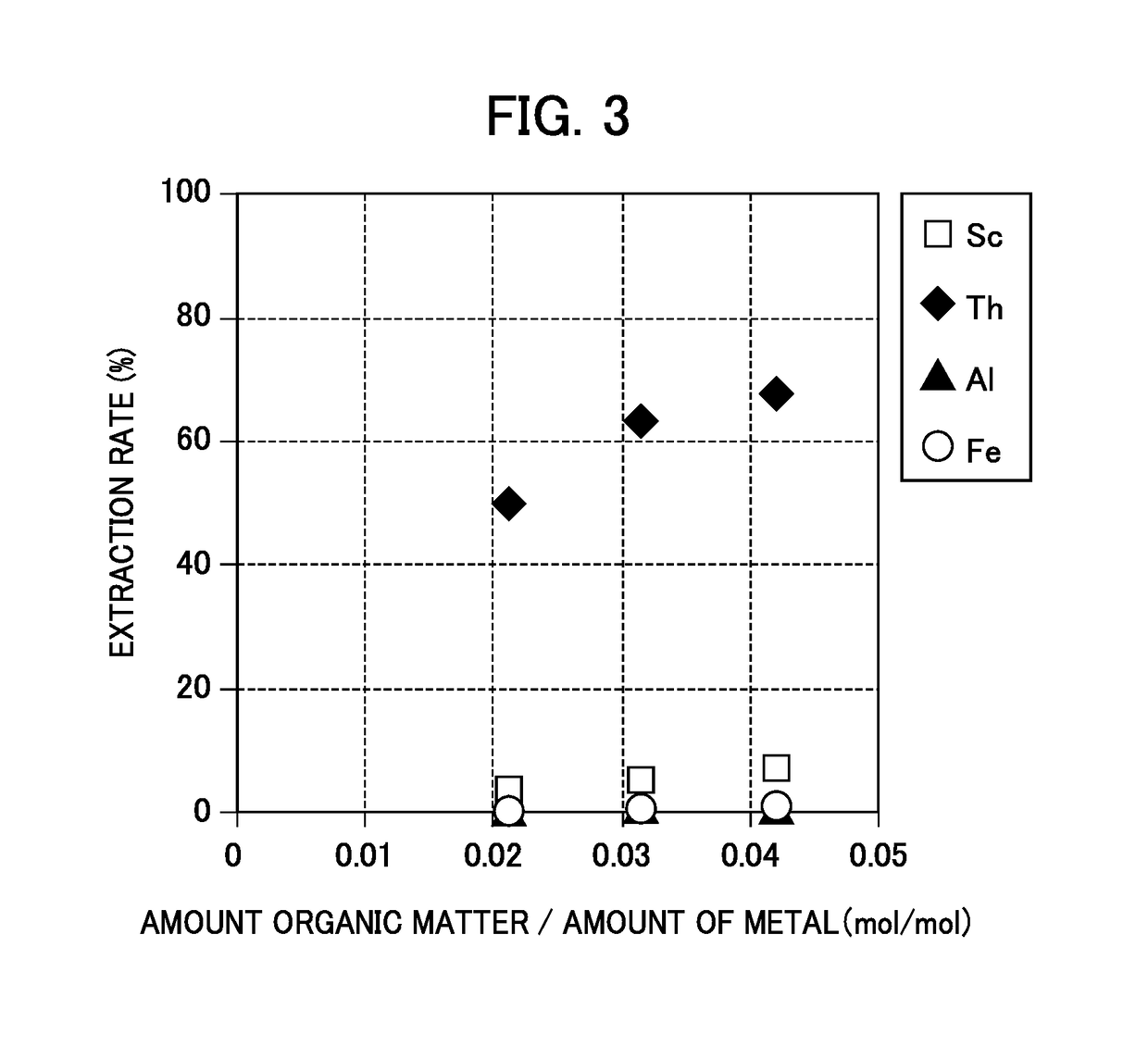

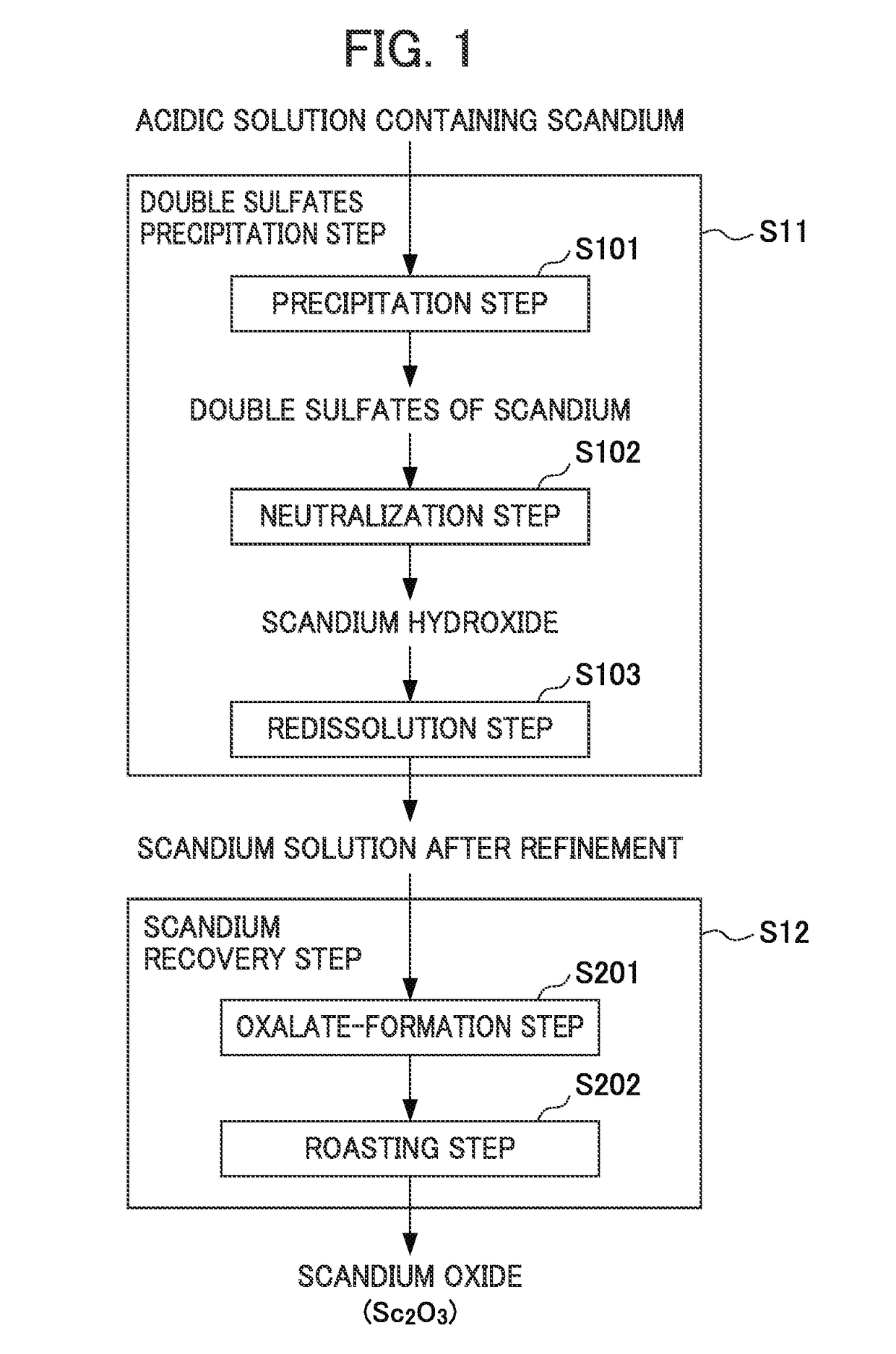

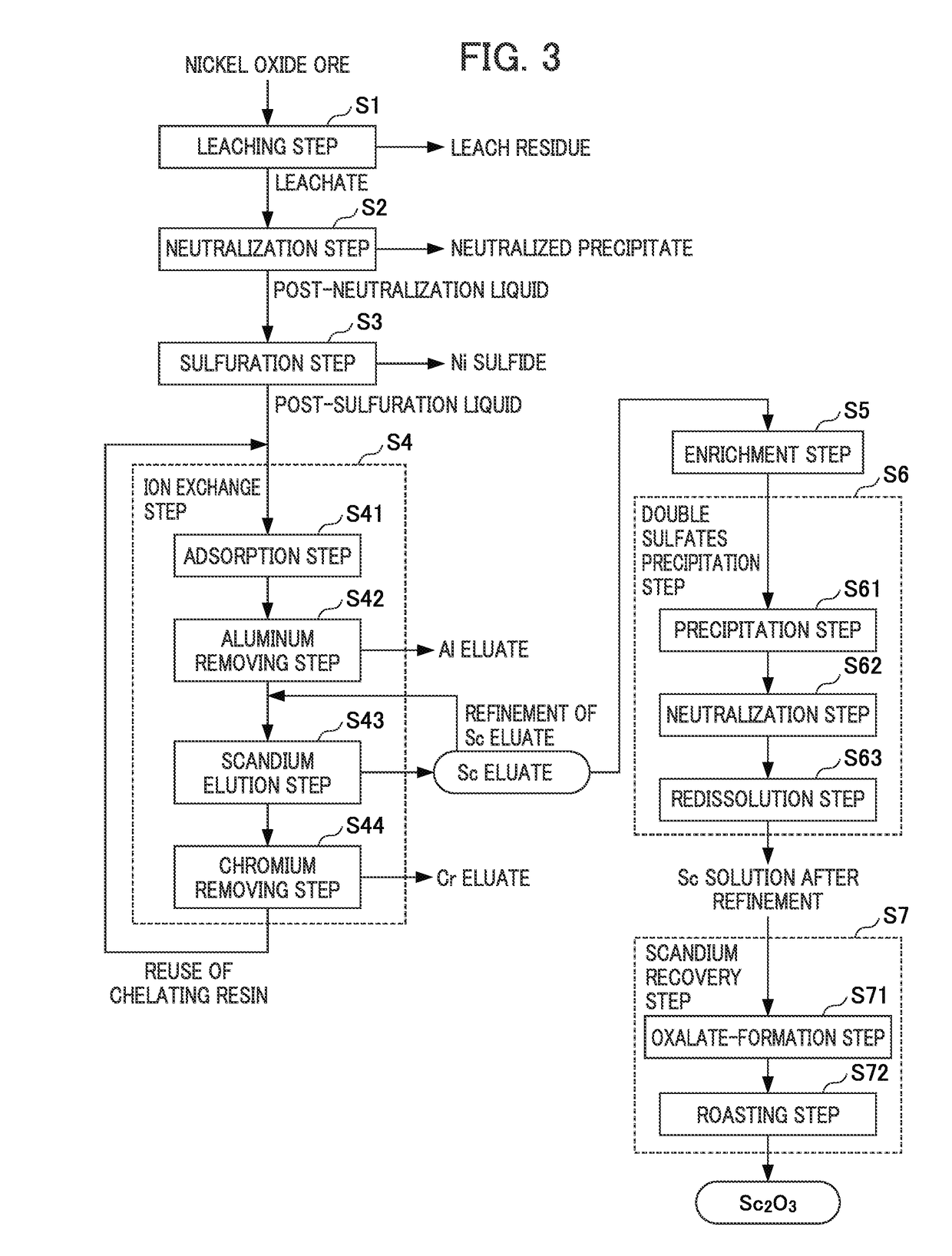

According to this method for recovering scandium, an acidic solution containing scandium is used and a scandium dissolution liquid after purification is obtained by a double sulfate precipitation step, and scandium is recovered from the obtained scandium dissolution liquid, as follows: [A] A precipitation step wherein sodium sulfate is added into the acidic solution containing scandium, so that a precipitate of a scandium double sulfate is obtained; [B] A neutralization step wherein pure water is added to the precipitate of a scandium double sulfate obtained in the precipitation step to dissolve the precipitate of a scandium double sulfate therein, and scandium hydroxide is obtained by adding a neutralizing agent into the obtained dissolution liquid; and [C] A re-dissolution step wherein an acid is added to the scandium hydroxide obtained in the neutralization step, so that a scandium dissolution after purification, in which the scandium hydroxide is dissolved, is obtained.

Owner:SUMITOMO METAL MINING CO LTD

Production of scandium-containing concentrate and further extraction of high-purity scandium oxide from the same

ActiveUS20190161828A1High purityRare earth metal sulfatesScandium oxides/hydroxidesRed mudScandium oxide

The invention relates to a method for producing a scandium-containing concentrate from the wastes of alumina production and extracting high-purity scandium oxide from the same. Provided is a method for producing a scandium-containing concentrate from a red mud, wherein the Sc2O3 content therein is least of 15 wt. % (in terms of dry matter), the TiO2 content not more than 3 wt. % (in terms of dry matter), the ZrO2 content not more than 15 wt. % (in terms of dry matter), and wherein scandium in the concentrate is in form of a mixture of Sc(OH)3 hydroxide with ScOHCO3×4H2O. Also provided is a method for producing high-purity scandium oxide, with a purity of approximately 99 wt. %.

Owner:UNITED CO RUSAL ENG & TECHNOLOGHY CENT LLC

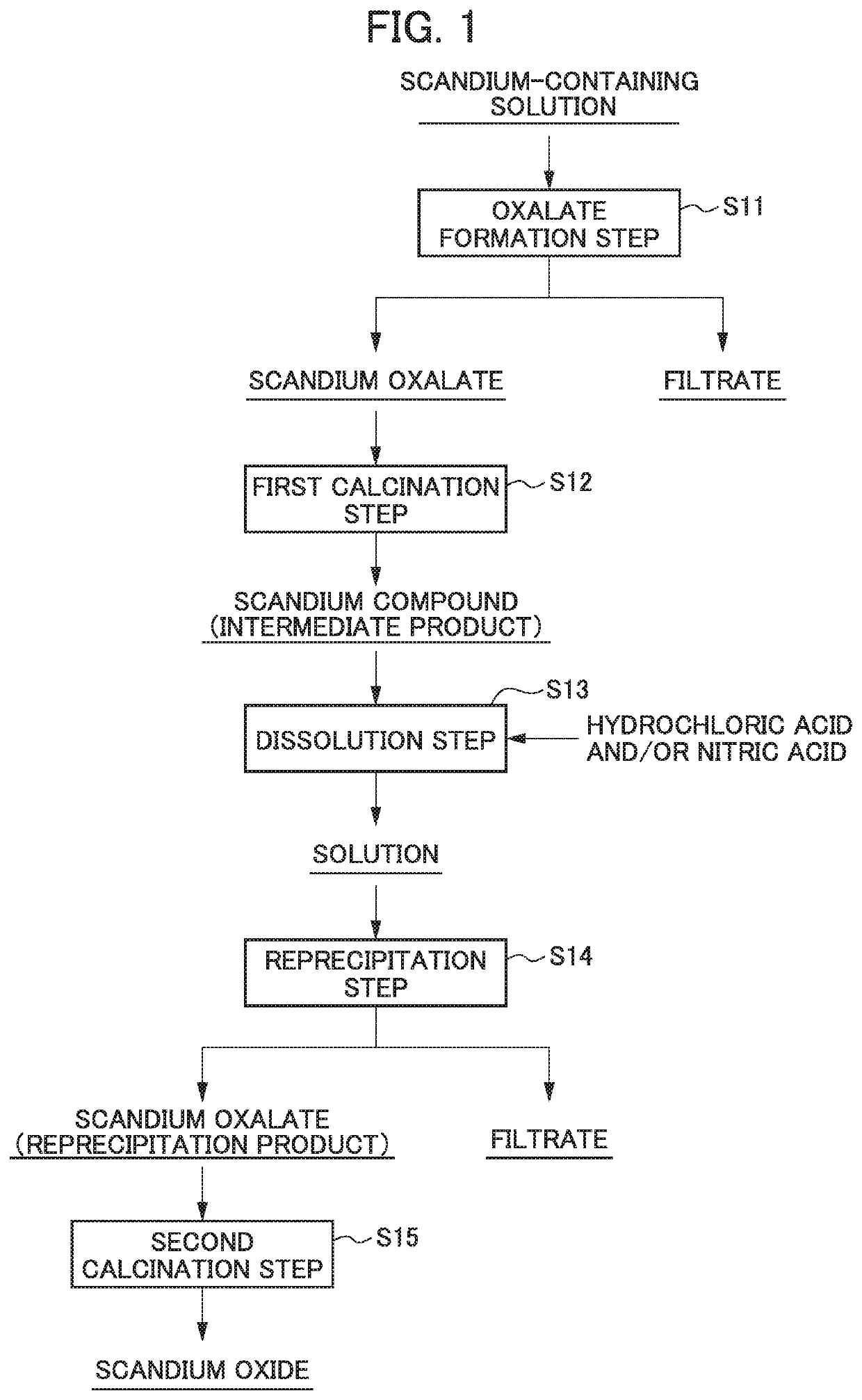

Method for producing high-purity scandium oxide

ActiveUS20210032119A1Efficiently obtainedRare earth metal sulfatesScandium oxides/hydroxidesOXALIC ACID DIHYDRATEOxalate

Provided is a method for obtaining high-purity scandium oxide efficiently from a solution containing scandium. The method for producing high-purity scandium oxide of the present invention has a first firing step S12 for subjecting a solution containing scandium to oxalation treatment using oxalic acid and firing the obtained crystals of scandium oxalate at a temperature of 400 to 600° C., inclusive, a dissolution step S13 for dissolving the scandium compound obtained by firing in one or more solutions selected from hydrochloric acid and nitric acid to obtain a solution, a reprecipitation step S14 for subjecting the solution to oxalation treatment using oxalic acid and generating a reprecipitate of scandium oxalate, and a second firing step S15 for firing the reprecipitate of obtained scandium oxalate to obtain scandium oxide.

Owner:SUMITOMO METAL MINING CO LTD

Purification method of crude scandium oxide

PendingCN112429760AEasy to separateSimplify the purification processScandium oxides/hydroxidesRare earth metal compounds preparation/treatmentOXALIC ACID DIHYDRATEPurification methods

The invention discloses a purification method of crude scandium oxide, which comprises the following steps of (1) first-stage acid leaching: adding water into crude scandium oxide to regulate the slurry, adding inorganic acid to regulate the pH value of the slurry to 1.0-3.0, reacting, and filtering to obtain first-stage leaching residues and a first-stage leaching solution, (2) second-stage acidleaching: putting the obtained first-stage leaching residues into an inorganic acid solution, and reacting to obtain a scandium-rich second-stage leaching solution, (3) oxalic acid scandium precipitation: adding an oxalic acid solution into the second-stage leaching solution, adding a back-regulating agent to regulate the pH value of the reaction material to 0.5-2.0, and filtering after reaction to obtain scandium oxalate precipitate; and (4) calcining: drying the obtained scandium oxalate precipitate, and calcining to obtain purified and refined scandium oxide. According to the method, the difference between the acid solubility of the impurities and the acid solubility of scandium oxide is effectively utilized, the impurities and scandium oxide are leached out separately, the impurity separation effect is good, the existing scandium oxide purification process and operation process are greatly simplified, and the operation cost is saved to a certain extent.

Owner:JINGMEN GEM NEW MATERIAL

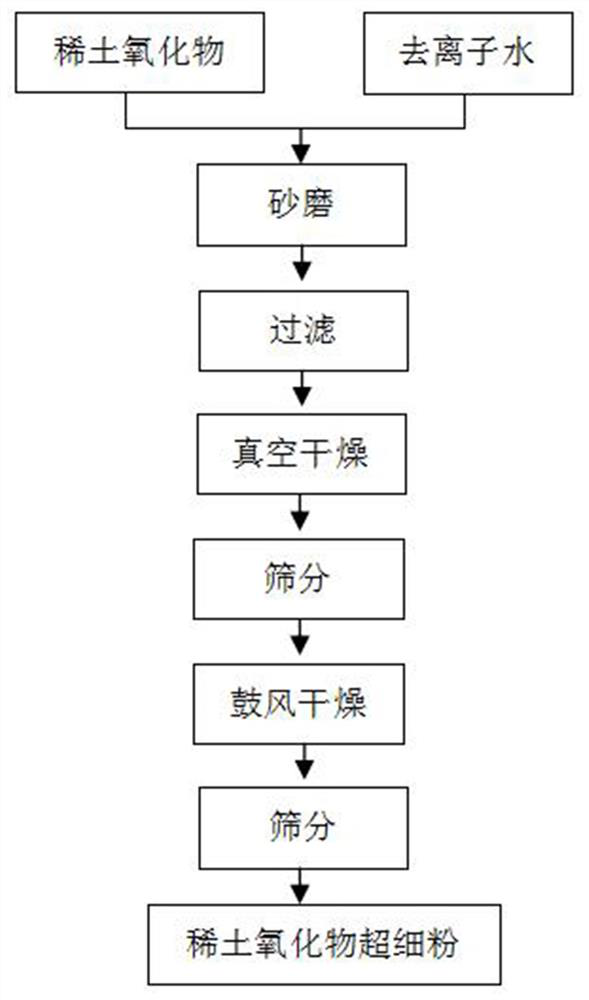

Preparation method of monodisperse rare earth oxide ultrafine powder

InactiveCN112174187AAvoid hard clumpingSimple processLanthanum oxide/hydroxidesCerium oxides/hydroxidesSlurryVacuum drying

The invention relates to a preparation method of monodisperse rare earth oxide ultrafine powder. The preparation method comprises the following steps: (1) adding rare earth oxide serving as a raw material into a mixing container, then adding deionized water into the mixing container, uniformly stirring the slurry, putting the mixed slurry into a sand mill for high-speed ball milling, and then discharging the slurry subjected to high-speed ball milling from the sand mill to obtain rare earth oxide slurry; (2) performing suction filtration on the rare earth oxide slurry prepared in the step (1)to obtain a rare earth oxide filter cake, putting the rare earth oxide filter cake into a vacuum drying oven for primary drying, and sieving the filter cake after drying for a certain time to obtain rare earth oxide powder; and (3) putting the rare earth oxide powder prepared in the step (2) into a blast drying oven for secondary drying. According to the preparation method, a physical method is adopted, hard agglomeration of the powder is avoided in a two-time drying mode, and the preparation method of the monodisperse rare earth oxide ultrafine powder is easy to operate, high in crystallinityand suitable for large-scale production.

Owner:湖南威斯康新材料科技有限公司

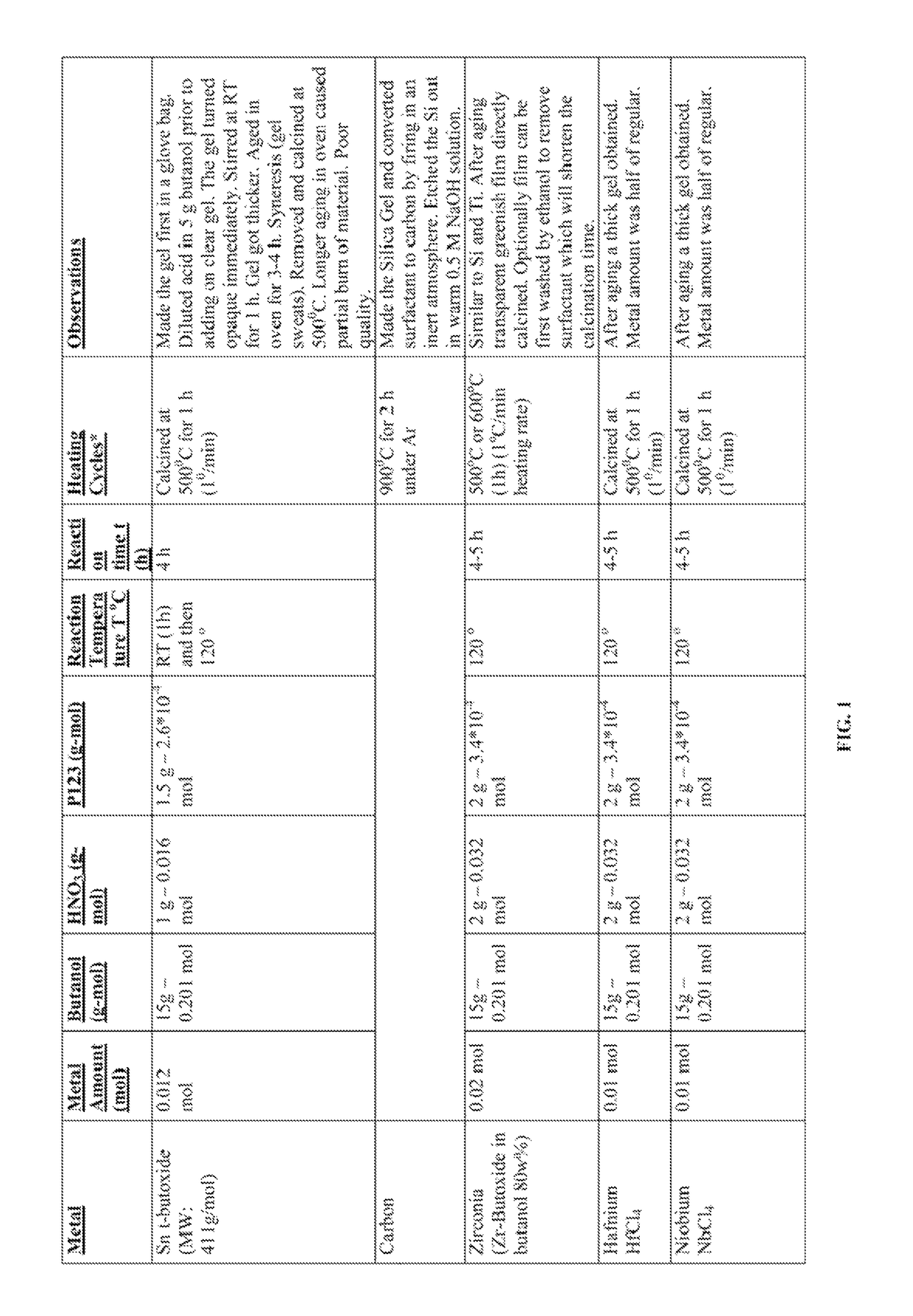

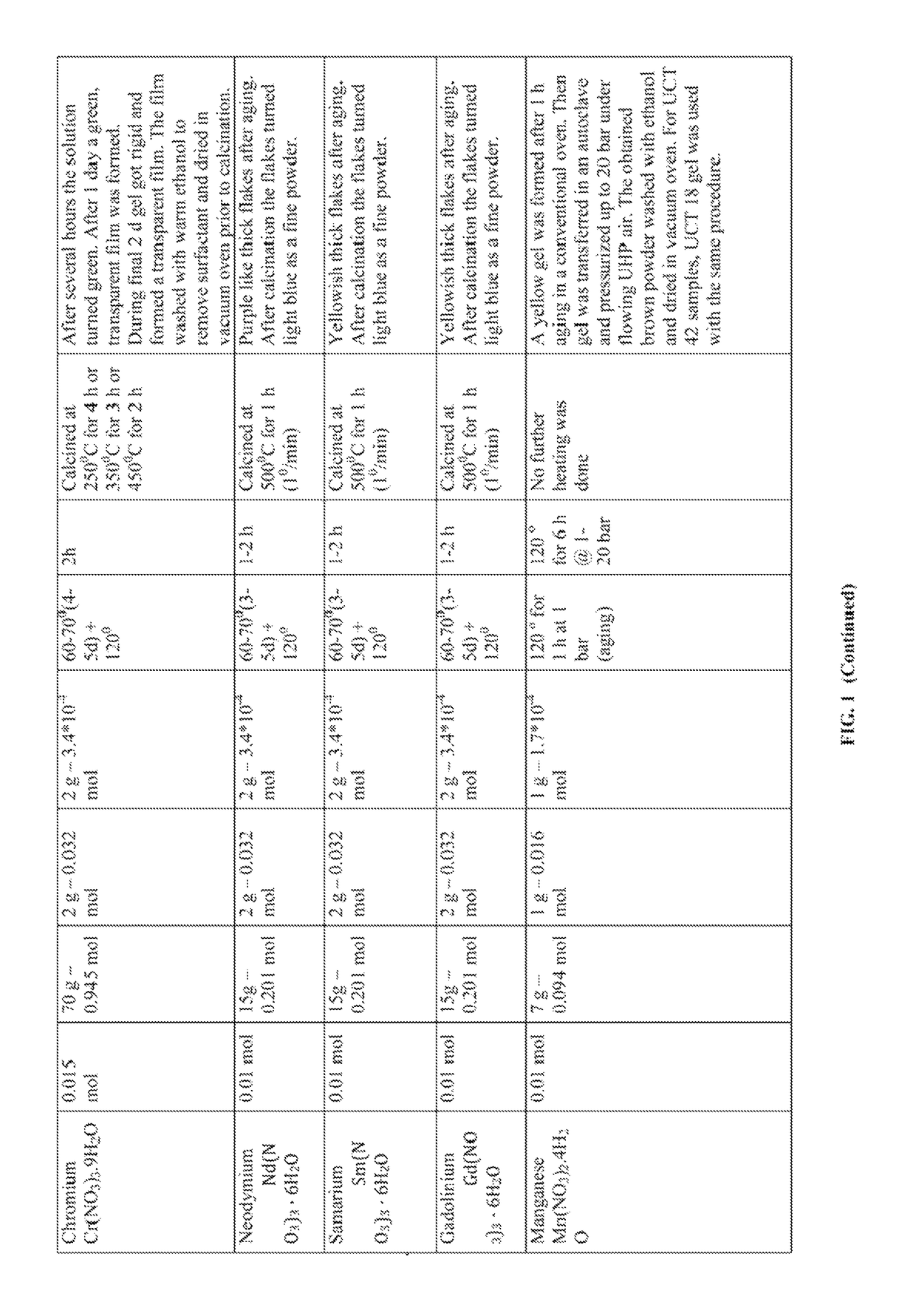

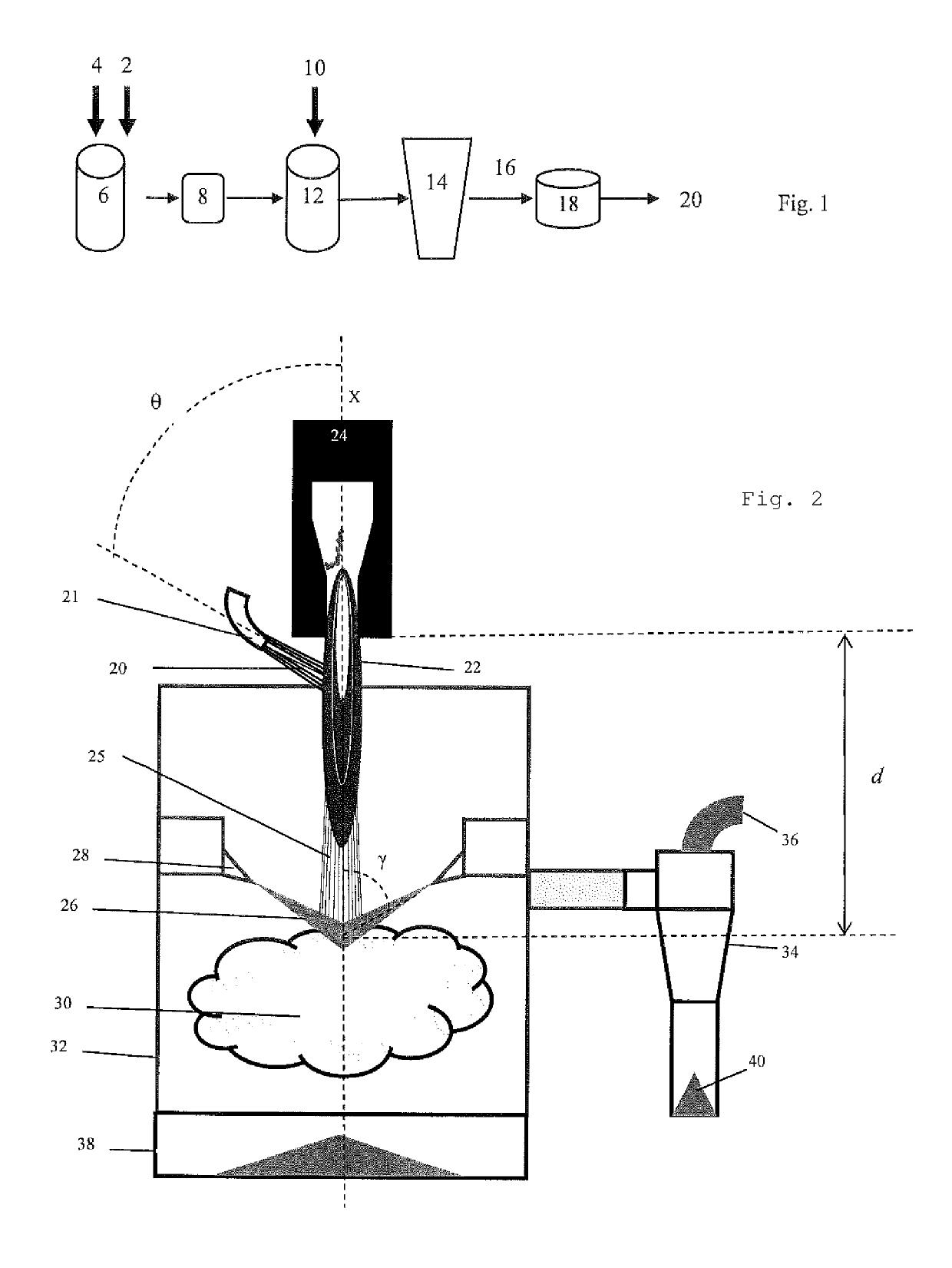

Mesoporous materials and processes for preparation thereof

A process for preparing a mesoporous material, e.g., transition metal oxide, sulfide, selenide or telluride, Lanthanide metal oxide, sulfide, selenide or telluride, a post-transition metal oxide, sulfide, selenide or telluride, and metalloid oxide, sulfide, selenide or telluride. The process comprises providing a micellar solution comprising a metal precursor, an interface modifier, a hydrotropic or lyotropic ion precursor, and a surfactant; and heating the micellar solution at a temperature and for a period of time sufficient to form the mesoporous material. A mesoporous material prepared by the above process. A method of controlling nano-sized wall crystallinity and mesoporosity in mesoporous materials. The method comprises providing a micellar solution comprising a metal precursor, an interface modifier, a hydrotropic or lyotropic ion precursor, and a surfactant; and heating the micellar solution at a temperature and for a period of time sufficient to control nano-sized wall crystallinity and mesoporosity in the mesoporous materials. Mesoporous materials and a method of tuning structural properties of mesoporous materials.

Owner:UNIV OF CONNECTICUT

Highly pure powder intended for thermal spraying

ActiveUS10252919B2High purityLanthanide oxides/hydroxidesMolten spray coatingApparent densityThermal spraying

Powder of particles, more than 95% by number of said particles exhibiting a circularity greater than or equal to 0.85, wherein said powder contains more than 99.8% of a rare earth oxide and / or of hafnium oxide and / or of yttrium aluminum oxide, as percentage by weight relative to the oxides, and has: a median particle size D 50 of between 10 and 40 microns and a size dispersion index (D 90−D 10) / D 50 of less than 3; a percentage by number of particles having a size less than or equal to 5 μm which is less than 5%; an apparent-density dispersion index (P<50−P) / P of less than 0.2, the cumulative specific volume of the pores which have a radius of less than 1 μm being less than 10% of the apparent volume of the powder, in which the percentiles Dn of the powder are the particle sizes corresponding to the percentages, by number, of n %, on the curve of cumulative distribution of the particle size of the powder, the particle sizes being classified in increasing order, the density P<50 being the apparent density of the fraction of particles having a size less than or equal to D50, and the density P being the apparent density of the powder.

Owner:SAINT GOBAIN CENT DE RES & DEVS & DETUD EUROEN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com