Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

194results about How to "In line with the concept of energy saving and environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

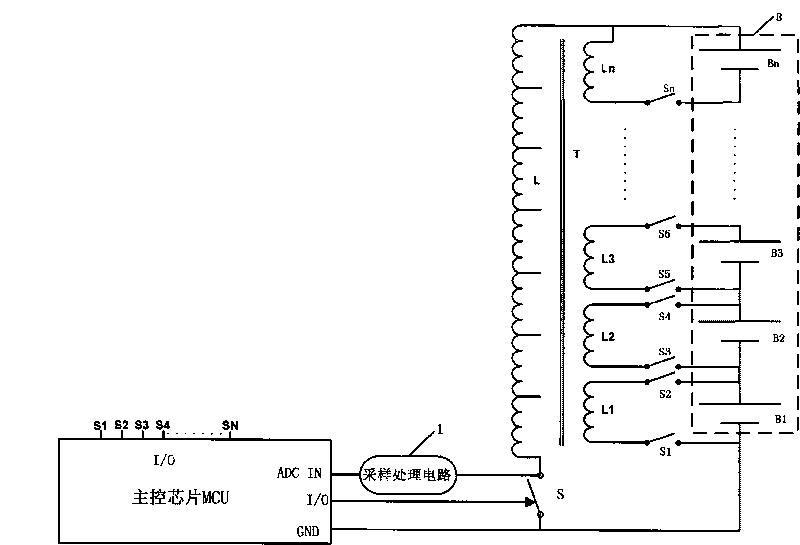

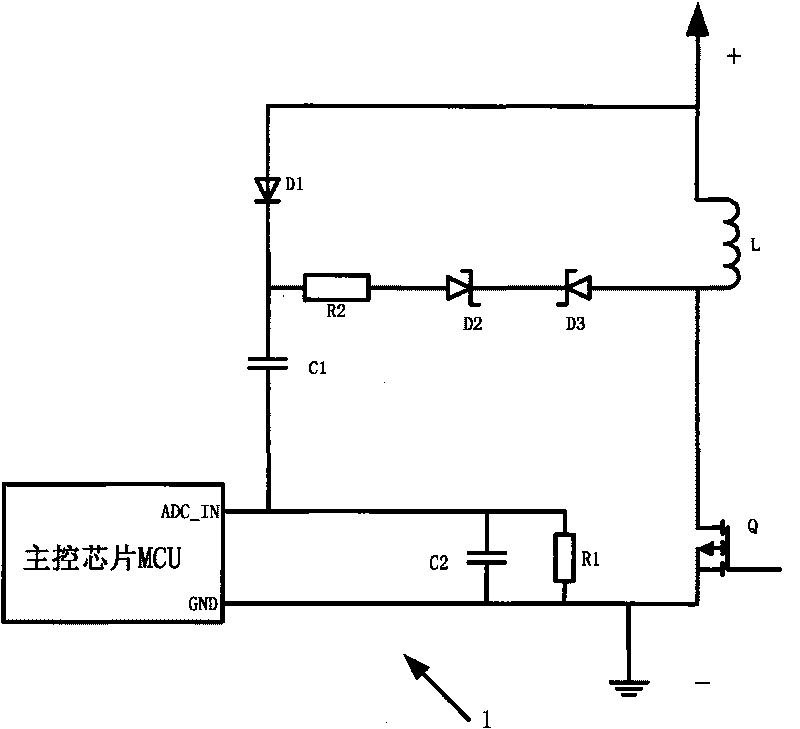

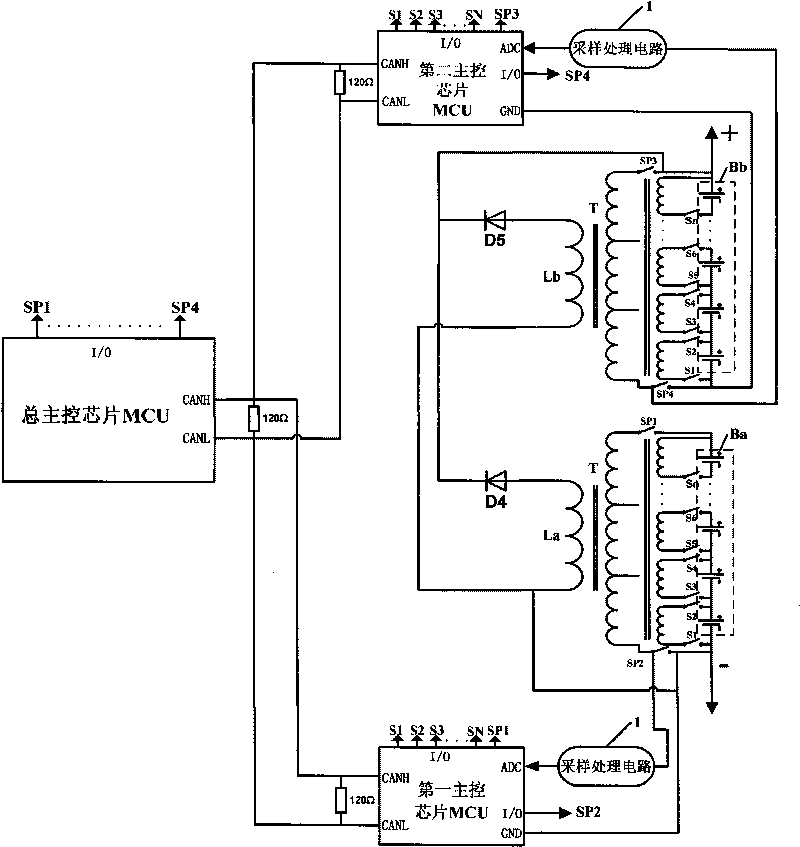

Active equalization system of lithium-ion power battery and equalization method thereof

ActiveCN101740827AExtend your lifeSimple structureSecondary cells charging/dischargingLithiumPower battery

The invention relates to an active equalization system of a lithium-ion power battery. The active equalization system comprises a battery module B formed by connecting a plurality of single batteries in series, a primary coil L of a transformer T is connected with the anode and cathode of the battery module B via a master switch S, each secondary coil of the transformer T is respectively connected to the anode and cathode of each single battery via each sub switch, the master switch S is bridged between the signal input terminal of the main control chip MCU and the earth terminal, a sampling processing circuit is connected between the signal input terminal of the main control chip MCU and the master switch S. The invention also discloses an equalization method for the active equalization system of the lithium-ion power battery. In the invention, the process of mutually charging and discharging by converting electric energy to magnetic energy and then to electric energy is completed by using inductive effect, thus realizing the function of equalizing the upper limit or lower limit of the electric quantity of the single batteries, prolonging the service life of the storage batteries, needing no cooling system and having simple structure.

Owner:CHERY AUTOMOBILE CO LTD +1

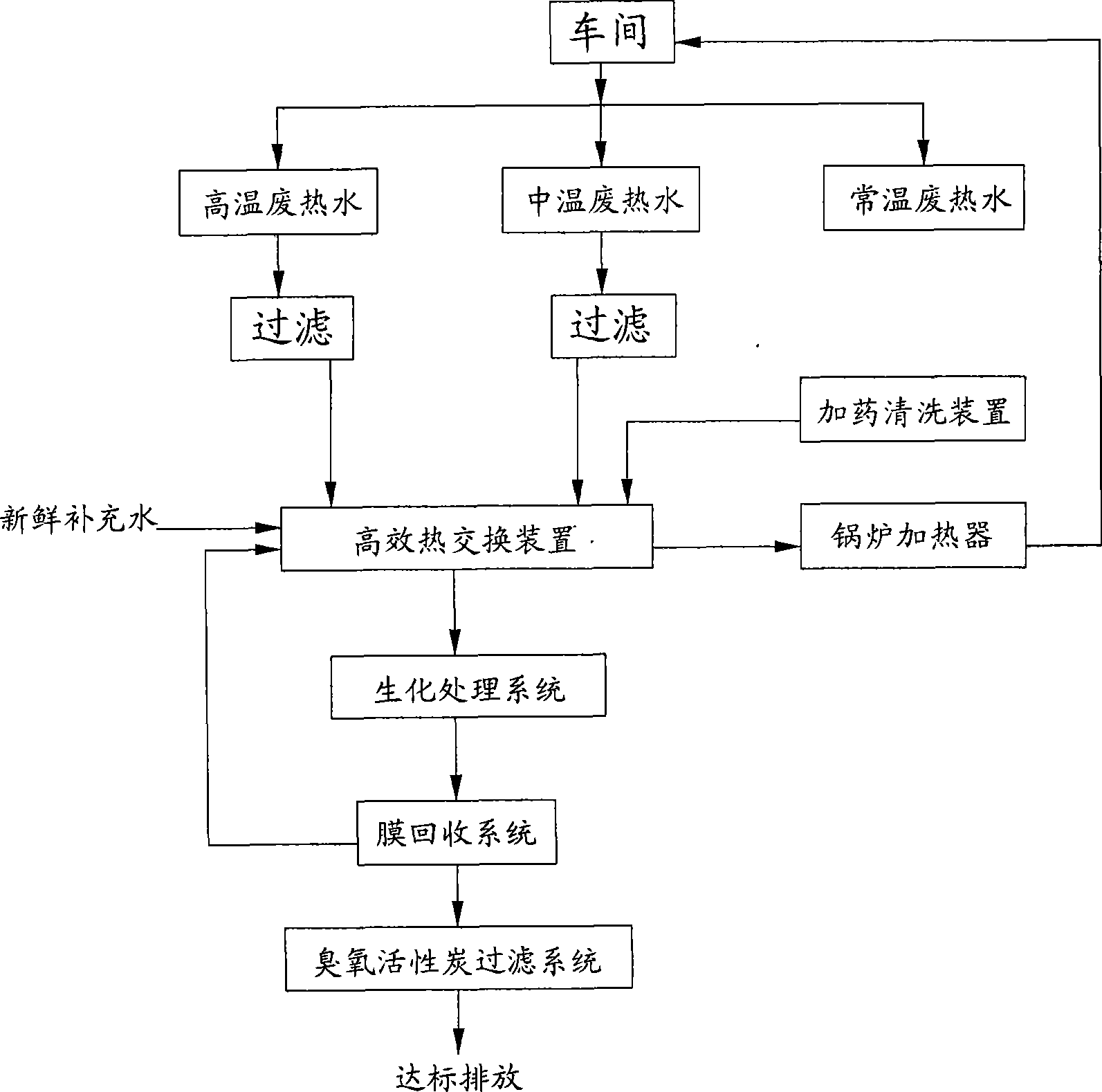

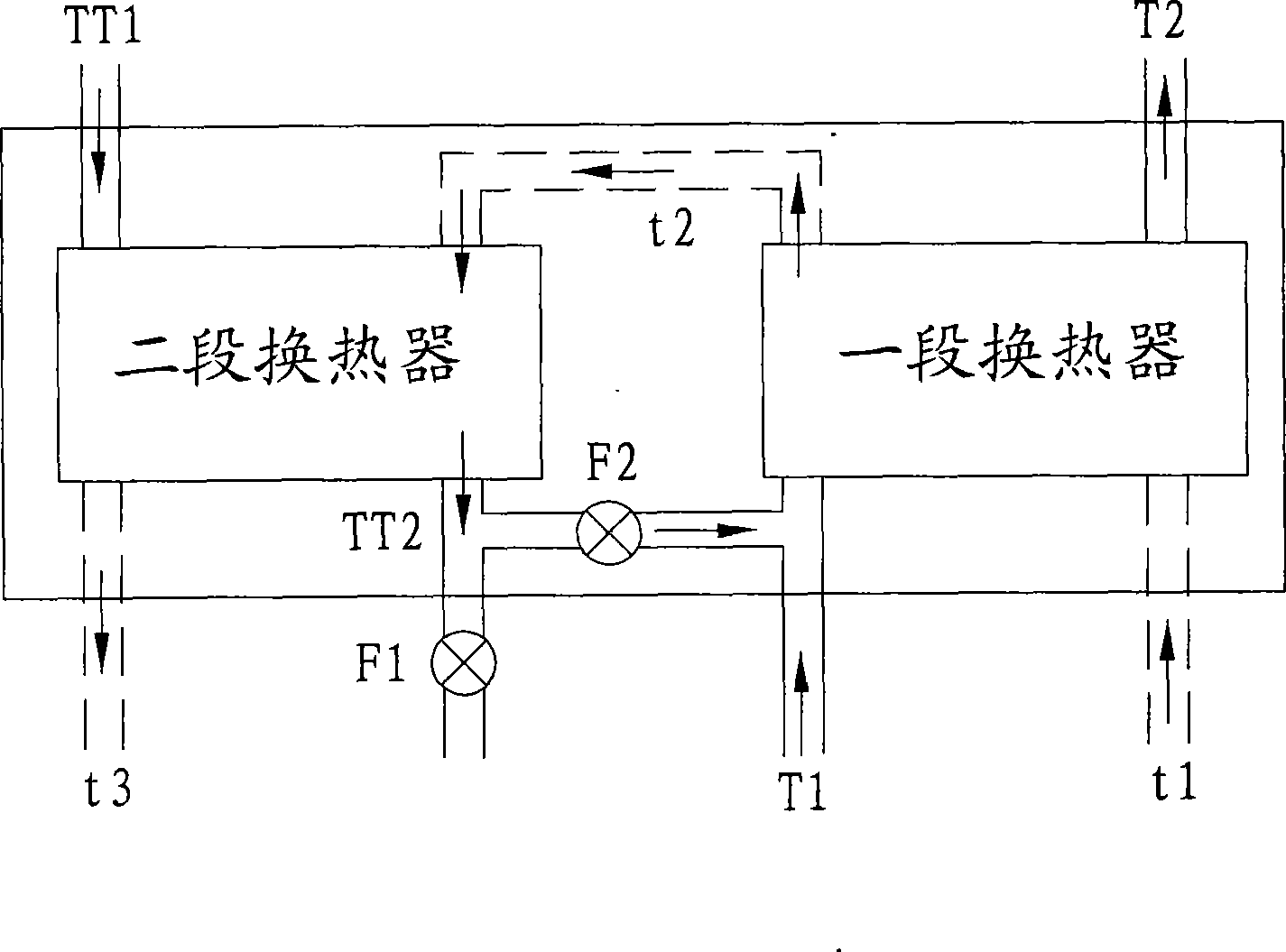

Comprehensive recovery method for heat energy and water from printing and dyeing industry wastewater and heat-exchanging system

InactiveCN101462809AReduce consumptionReduce the temperatureWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentRecovery methodThermal energy

The invention discloses an integrated recovery method and a heat exchanger for the heat energy and water in the wastewater of the printing and dyeing industry. The invention belongs to the technical field of the wastewater treatment in the printing and dyeing industry. The integrated recovery method for the heat energy and water in the wastewater of the printing and dyeing industry comprises the following steps: dividing the printing and dyeing wastewater emitted by a workshop into three types, namely normal temperature water, moderate temperature water and high temperature water, and treating the three types of water separately; after respectively removing impurities through filtration treatment, leading the moderate temperature wastewater and the high temperature wastewater into a high efficiency heat exchange device to carry out the heat exchange with a cold water source and increase the temperature of the cold water source in advance before the cold water source enters a boiler heating room, simultaneously reducing the temperature of the hot wastewater, mixing the high temperature wastewater and moderate temperature wastewater undergoing the heat exchange with the normal temperature wastewater, and then leading the water into a subsequent membrane treatment system for treatment; and taking the membrane system penetrating water and fresh compensation water together as the cold water source which is sent to the high efficiency heat exchange device, and realizing the emission up to the standards after the treatment of the enriched water. The invention can not only reclaim heat energy, but also have the advantages of energy conservation and emission reduction, improvement of equipment service life, convenient equipment maintenance, and the like.

Owner:VISBE XIAMEN ENVIRONMENT TECH CO LTD

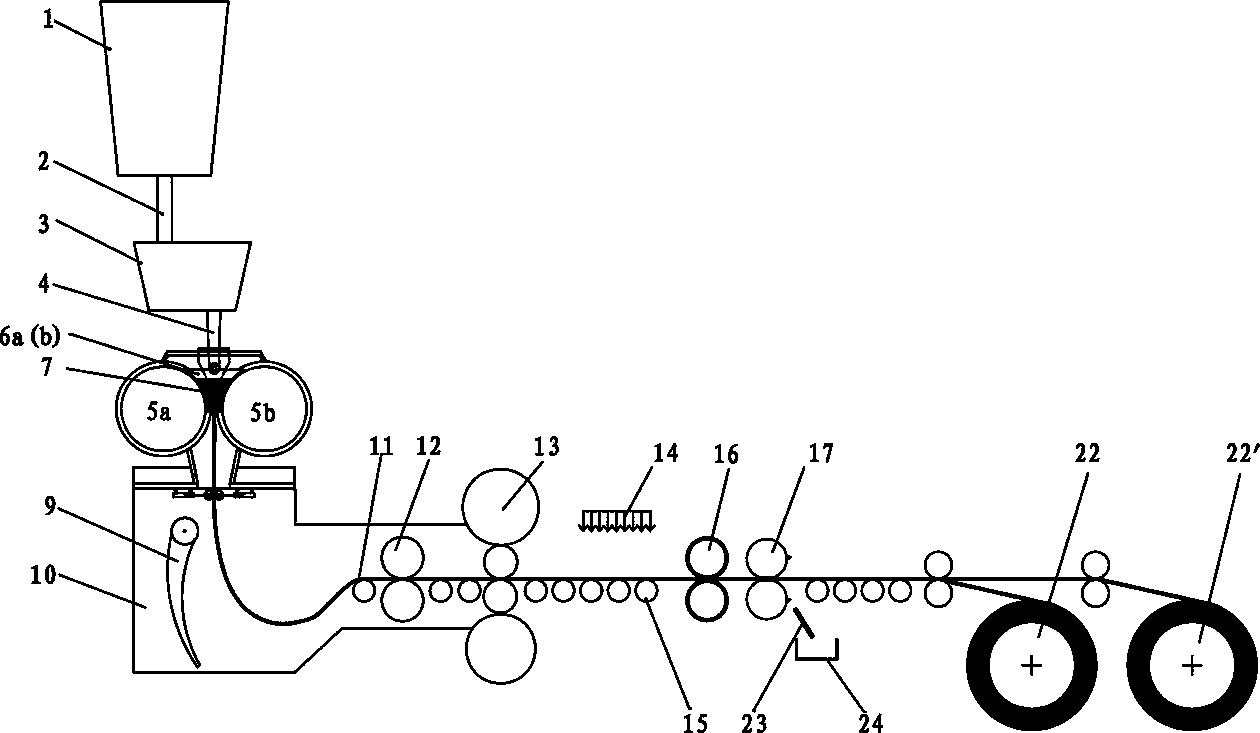

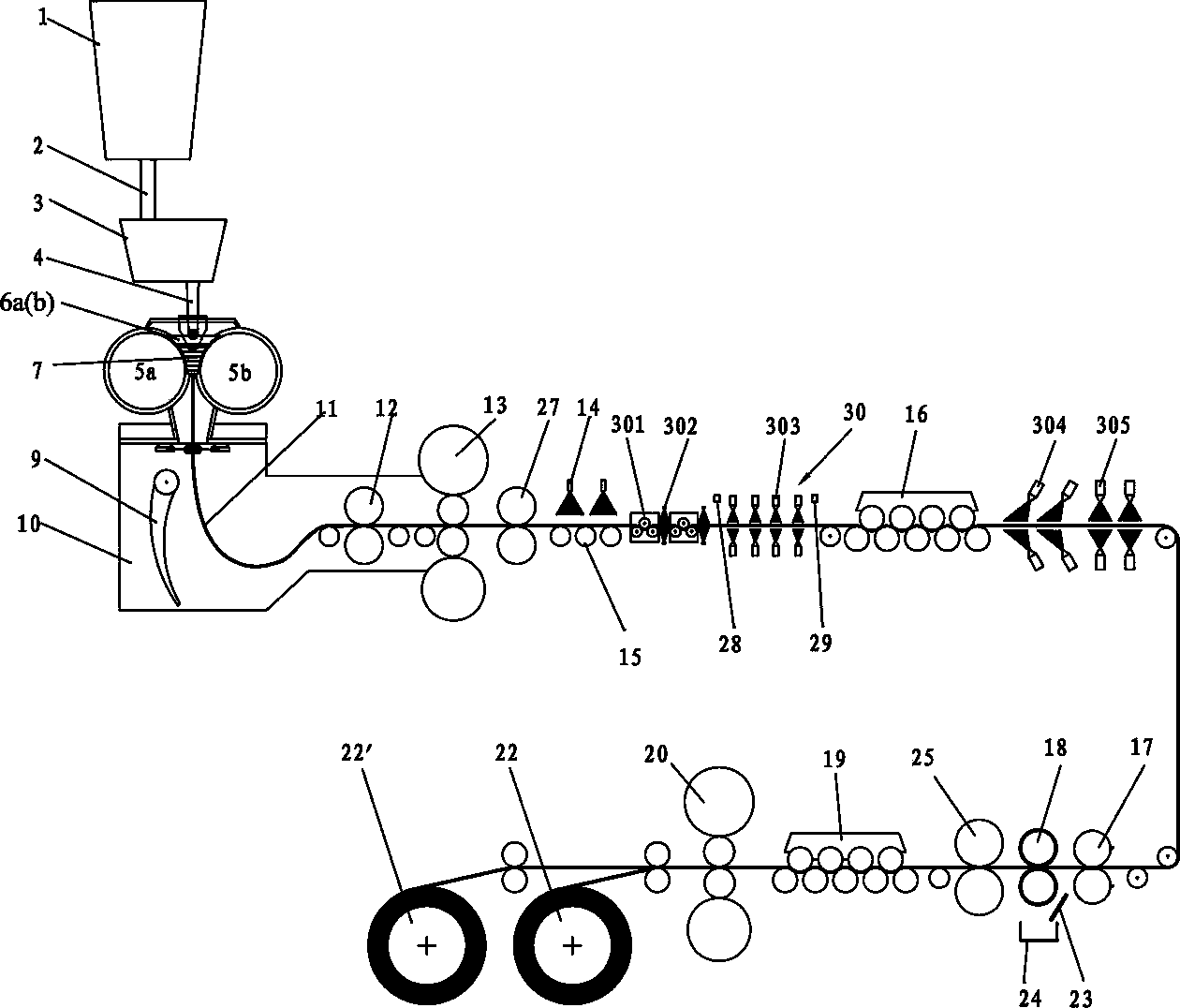

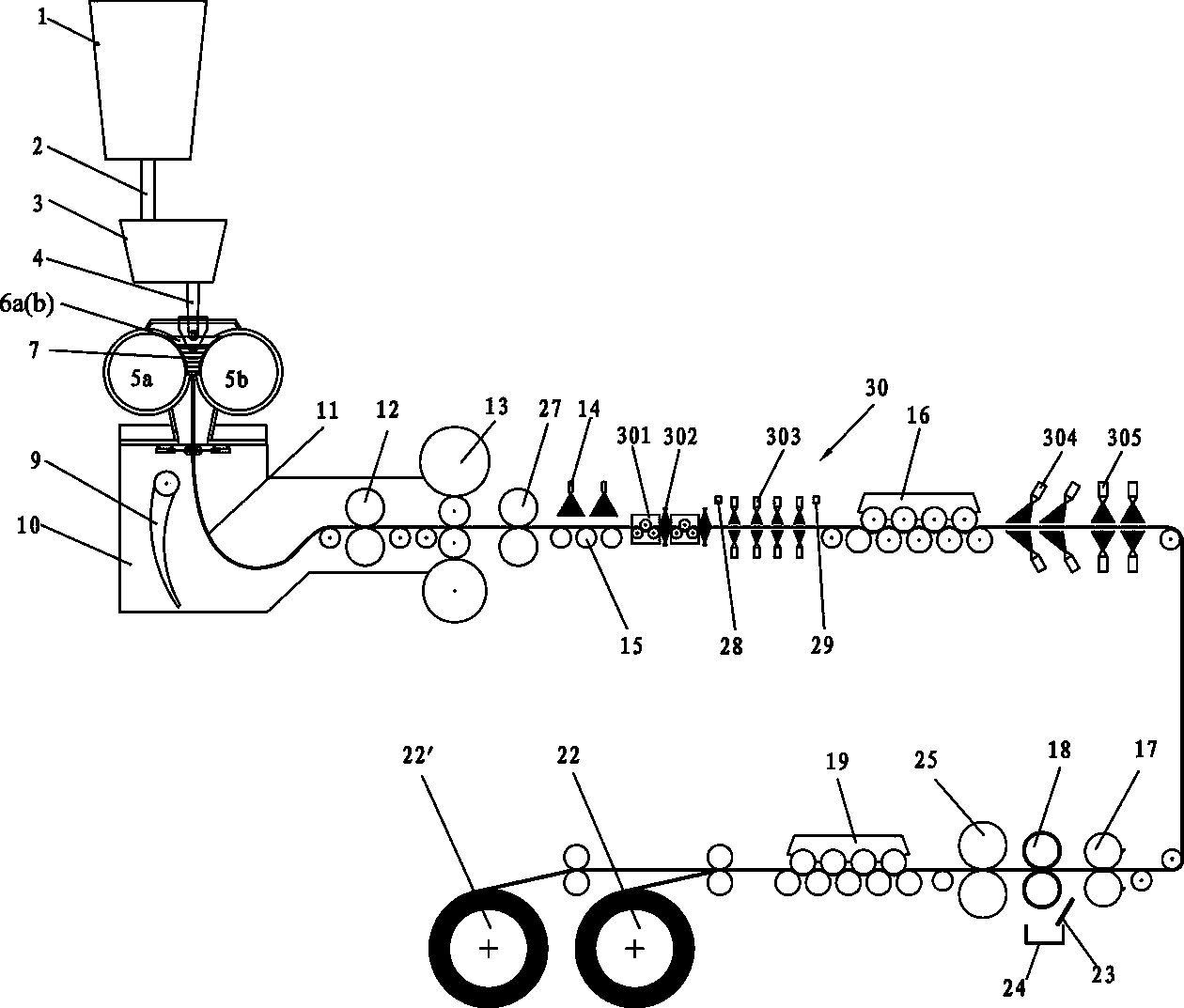

Method for producing high-strength thin strip steel in short process

ActiveCN103658177AFast jetImprove cooling uniformityWork treatment devicesMetal rolling arrangementsProduction rateProduction line

A method for producing high-strength thin strip steel in a short process comprises the first step of carrying out smelting and casting, wherein a twin roll strip casting technology is adopted, the second step of carrying out online hot rolling, the third step of carrying out cooling, wherein atomization cooling is adopted, the atomized cooled water mist is directly sprayed on the surface of the strip steel, the fourth step of carrying out scale breaking and blowing for sweeping, the fifth step of carrying out anti-oxidation intensive cooling and scale removing, wherein gas along with dry ice is directly sprayed on the surface of the strip steel for scale removing and intensive cooling, the sixth step of carrying out jet flow for scale removing, wherein solid-liquid mixed media are sprayed to the surface of the strip steel at a high speed, and the seventh step of carrying out straightening and reeling up. According to the method, the twin roll strip casting technology is utilized for producing the thin high-strength strip steel containing copper, hot rolling is performed on the casting belt, and then staged intensive cooling, oxide skin controlling and acid-free scale removing are combined and performed on the casting belt, so that the length of a production line is further shortened, and productivity is enhanced; meanwhile, the strength of the strip steel is increased through intensive cooling, the malleability of the strip steel is improved through grain refinement, and pollution to the environment is reduced by the adoption of the acid-free scale removing method.

Owner:BAOSHAN IRON & STEEL CO LTD

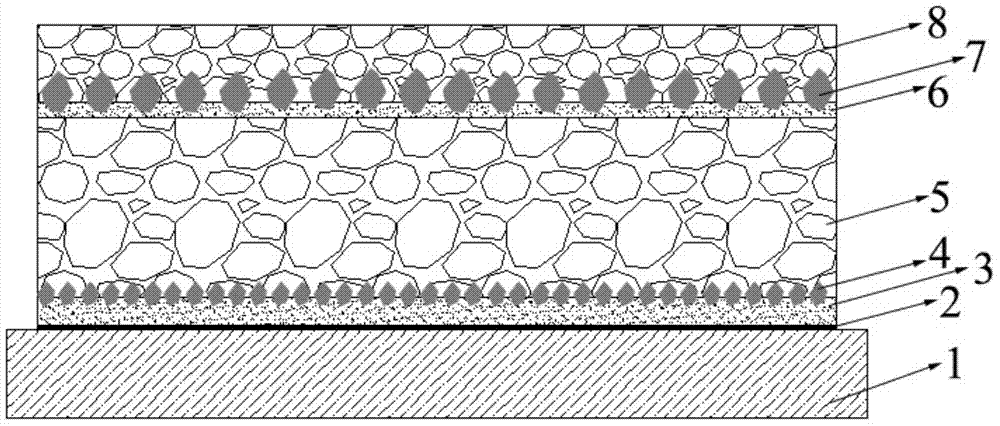

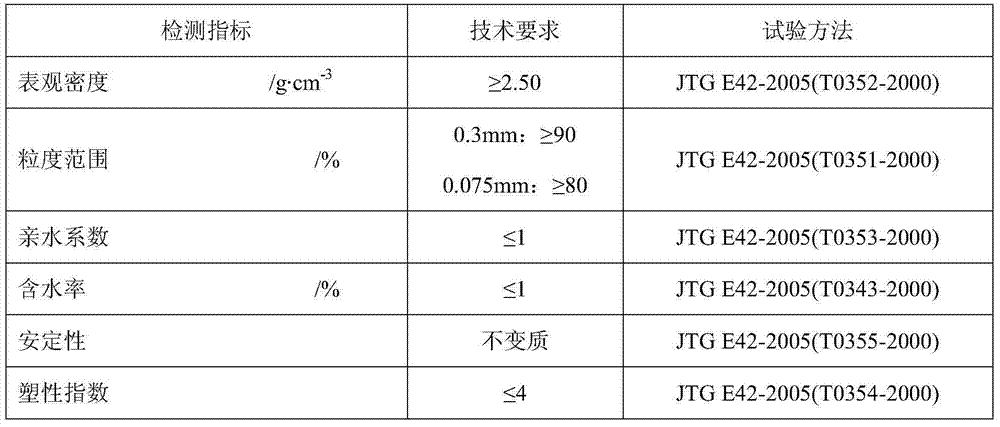

Long-life pavement structure for steel bridge deck and pavement method of pavement structure

ActiveCN104499431AAvoid performance requirementsAdd depthIn situ pavingsBridge structural detailsSteel platesWear resistant

The invention discloses a long-life pavement structure for a steel bridge deck and a pavement method of the pavement structure. The long-life pavement structure comprises an anti-corrosion layer, a lower adhesive layer, a lower gravel layer, a structural layer, an upper adhesive layer, an upper gravel layer and a wearing layer which are sequentially arranged on the steel bridge deck from bottom to top. The pavement structure has excellent antiskid and waterproof performances, low-temperature cracking resistance, high-temperature rutting resistance, fatigue resistance and water stability, is fine in deformation compatibility with a steel plate and wear-resistant, surface aggregates do not easily fall off, the pavement method of the pavement structure is high in mechanization degree and strong in feasibility, the paved steel bridge deck can be put into operation in a short time, only the wearing layer of the pavement structure is damaged, only regular surface milling and top facing repair are needed, the pavement structure does not need to be structurally reconstructed in a long service life period, maintenance is facilitated, maintenance cost is saved, and the pavement method conforms to the design concept of a long-life pavement and also conforms to the energy conservation and environmental protection concept of modern society.

Owner:SOUTHEAST UNIV

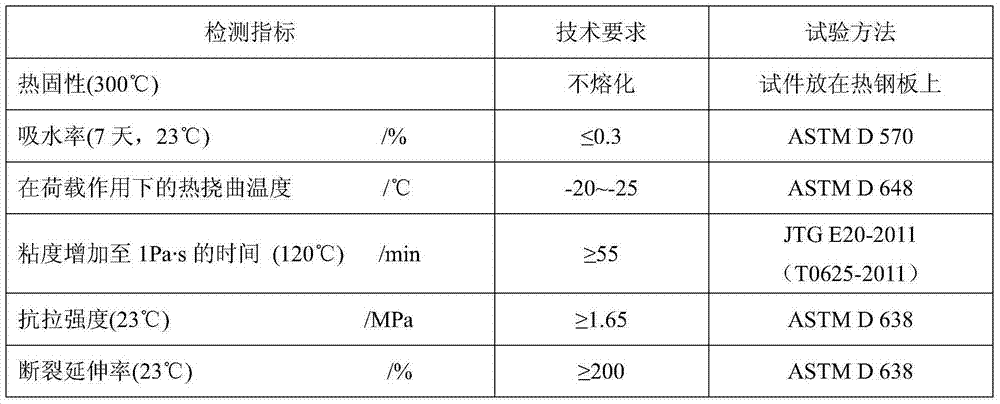

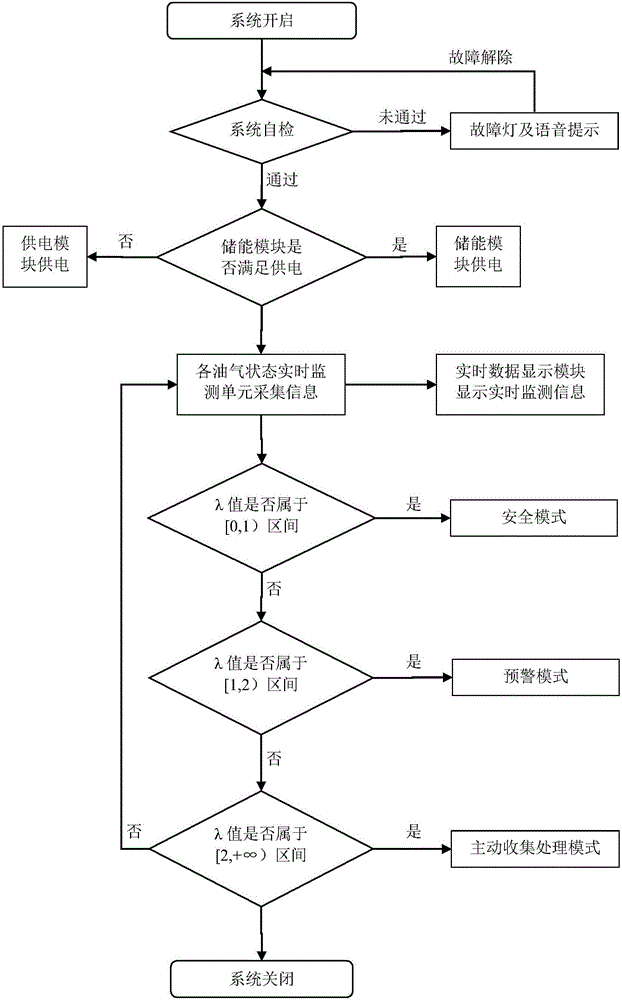

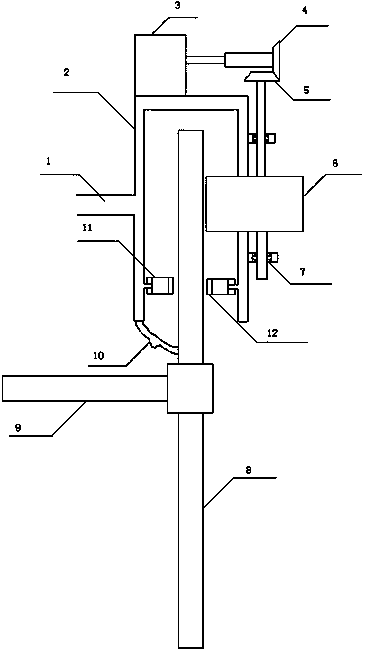

Oil station oil and gas monitoring and collecting-processing system and method

ActiveCN106430070AReduce security risksIn line with the concept of energy saving and environmental protectionLiquid transferring devicesControl systemCritical position

The invention relates to an oil station oil and gas monitoring and collecting-processing system and method. Compared with the prior art, aiming at the conditions that a large number of inflammable and explosive oil products are stored in an oil station, large potential safety hazards exist, and fire and explosion accidents are liable to occur, on the basis that the design layout of the oil station and actual demands are considered comprehensively, a plurality of oil and gas state real-time monitoring units are arranged in necessary key positions, a plurality of oil and gas collecting openings are distributed within the corresponding monitoring range where accidents are liable to occur and potential safety hazards exist, integrated control over monitoring and collecting processing is achieved, a collecting-processing device of the oil station oil and gas monitoring and collecting-processing system is controlled according to the magnitude of the oil and gas state actual risk, multi-point monitoring is achieved, and collecting and processing are controlled in a multi-mode mode. In addition, and through the advantage of the large daylighting area of the oil station, a solar power generation and charging module is arranged. According to the oil station oil and gas monitoring and collecting-processing system and method, the safety risk of the oil station is lowered, the accidents are prevented from occurring, and the ideas of energy conservation and environment protection are also met.

Owner:SHANXI PROVINCIAL RES INST OF COMM

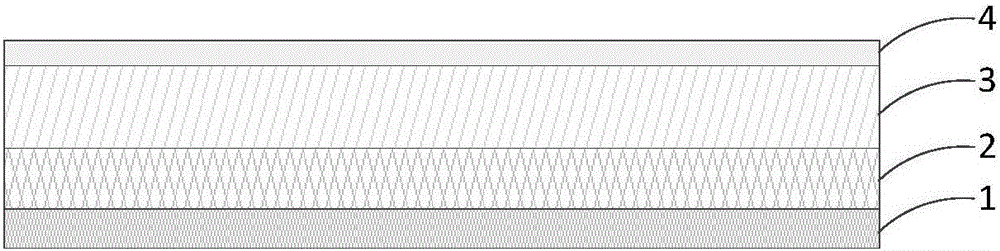

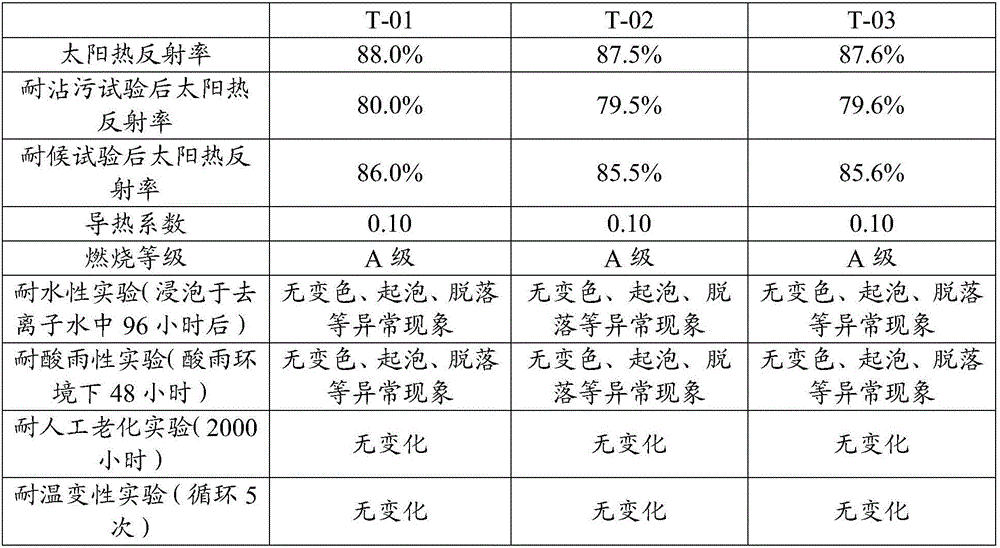

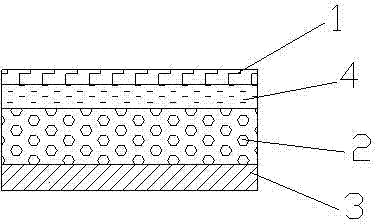

Solar heat reflection type heat insulation coating structure and preparation method thereof

ActiveCN106830994ALow costTightly boundFilling pastesReflecting/signal paintsCombustionMaterials science

The invention discloses a solar heat reflection type heat insulation coating structure. The solar heat reflection type heat insulation coating structure comprises an inorganic heat insulation mortar layer, a flexible heat insulation putty layer, an elastic heat insulation coating and a solar heat reflection coating layer which are sequentially arranged at the outer surface of a wall body from interior to exterior. The solar heat reflection type heat insulation coating structure has the advantages that the cost is low, the bonding with the wall body is tight, the construction is simple and controllable, the excellent heat reflection cooling and heat insulation effects are realized, the combustion property class requirement is met, and the energy-saving and environment-protection concept is met.

Owner:CHINA NAT OFFSHORE OIL CORP +3

Novel automobile braking energy recycling device

InactiveCN103552552AReduce lossReduce the temperatureBraking element arrangementsElectricityMaster cylinder

Disclosed is a novel automobile braking energy recycling device. A brake caliper body straddled over a brake disc is fixed onto an axle, two pistons and two friction blocks arranged inside the brake caliper body are arranged on two sides of the brake disc, and during braking, brake oil enters two communicated hydraulic cavities inside the brake caliper body from a brake master cylinder via an oil inlet to press the friction blocks on the two sides of the brake disc towards the brake disc to generate braking. An electric generator is arranged on the outside surface of the brake caliper body, an electric generator shaft is connected with a first bevel gear, the first bevel gear and a second bevel gear are engaged, and during braking, the first bevel gear can drive the input shaft of the electric generator to rotate due to the function of a friction wheel to enable the electric generator to generate electricity. The automobile braking energy recycling device can convert heat energy generated due to kinetic energy during automobile braking into electric energy and recycle the electric energy into a vehicle-mounted storage battery for supplying power to vehicle-mounted electric equipment; meanwhile, can also reduce the temperature of the brake disc and prolong the service life of the brake disc.

Owner:SHENYANG JIANZHU UNIVERSITY

Meat and poultry breeding apparent temperature detection device and method

ActiveCN110160669AFast heat conductionAccurate detection of wind speedBody temperature measurementAvicultureSomatosensory systemApparent temperature

The invention discloses a meat and poultry breeding apparent temperature detection device and method. In the meat and poultry breeding apparent temperature detection device, a constant temperature wind measuring element is made of a copper or aluminum material, and the material has good thermal conductivity; an intelligent controller detects the temperature of the constant temperature wind measuring element in real time through a temperature detecting element on a constant temperature heating element; when the measured temperature of the constant temperature wind measuring element does not reach a target range, the heating current is increased; when the temperature detecting element reaches a temperature which is higher than a target temperature range, the heating current is reduced; the heating law is adjusted by a PID law; the temperature of the constant temperature wind measuring element is kept to be constantly higher than an ambient temperature, and at the time, through detectingthe heating current, the wind speed can be calibrated. The base and the intelligent controller in the invention are integrated, the circuit part is mainly concentrated in the base, the base is provided with a temperature and humidity sensor for measuring the physical temperature and humidity of the environment, the temperature and humidity sensor is combined with a wind speed to calculate the apparent temperature, and the controller is provided with a communication power supply interface for device power supply and data remote transmission.

Owner:JIANGSU DEEPAGRI INTELLIGENT TECH CO LTD

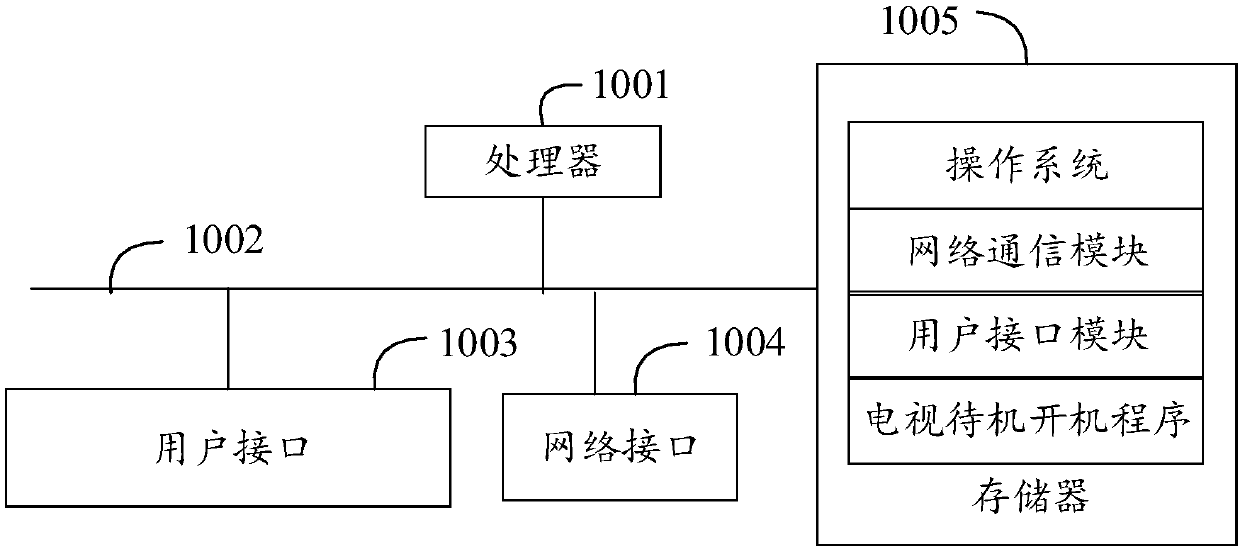

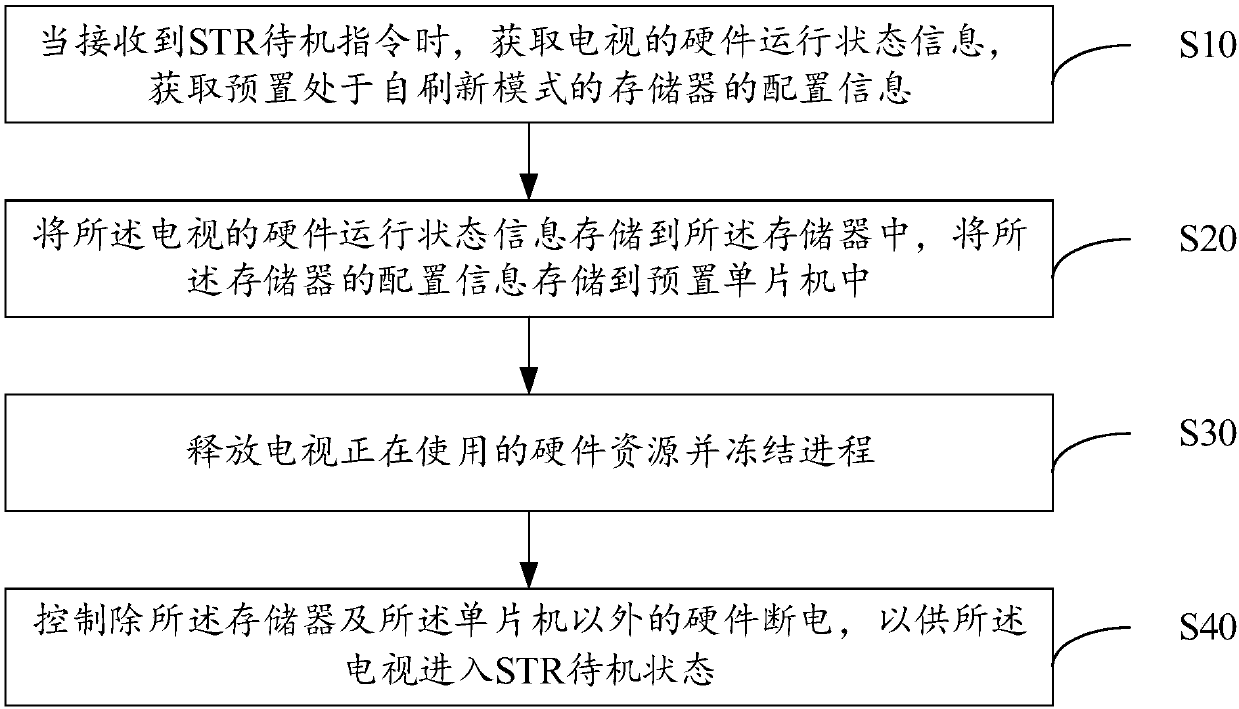

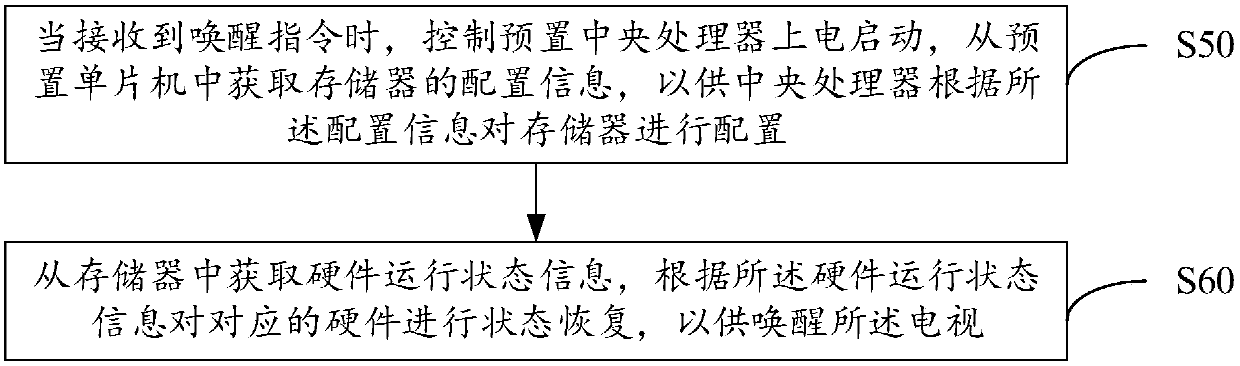

Television standby starting method, television and computer readable storage medium

ActiveCN108040292AReduce the power consumption of the whole machineIn line with the concept of energy saving and environmental protectionTelevision system detailsColor television detailsMicrocomputerMicrocontroller

The invention discloses a television standby starting method, a television and a computer readable storage medium. The television standby starting method comprises the following steps: when an STR standby instruction is received, obtaining hardware running status information of the television, and obtaining configuration information of a memory in a self-refresh mode; storing the hardware runningstatus information of the television in the memory, and storing the configuration information of the memory in a preset single chip microcomputer; releasing hardware resources being used by the television and freezing the process; and controlling hardware excluding the memory and the single chip microcomputer to turn off, so that the television enters an STR standby state. By adoption of the television standby starting method disclosed by the invention, only the power supply of the memory and the single chip microcomputer are needed, thereby reducing the overall power consumption of the television in the STR standby state, and the television is more in line with the concept of energy saving and environmental protection.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

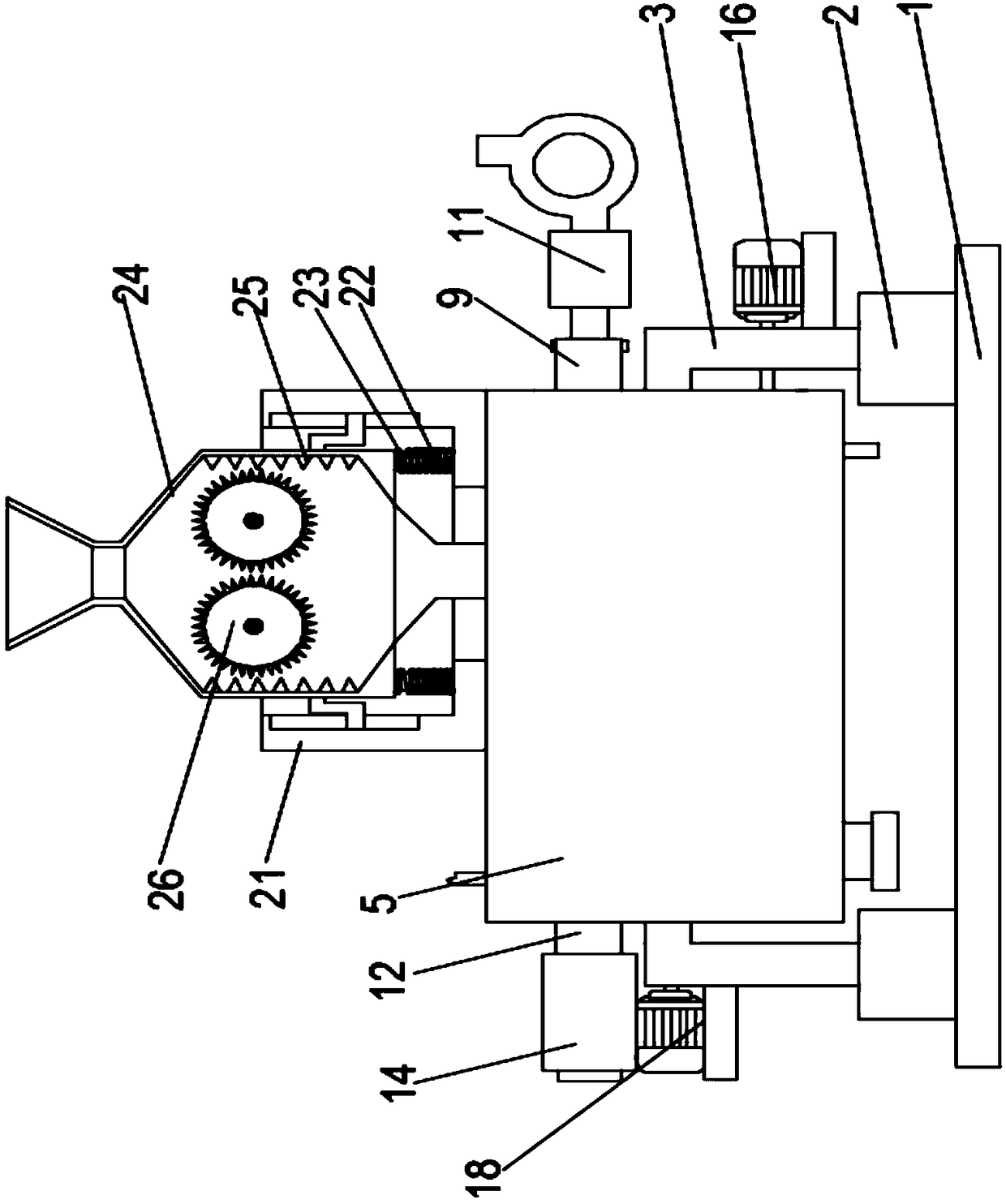

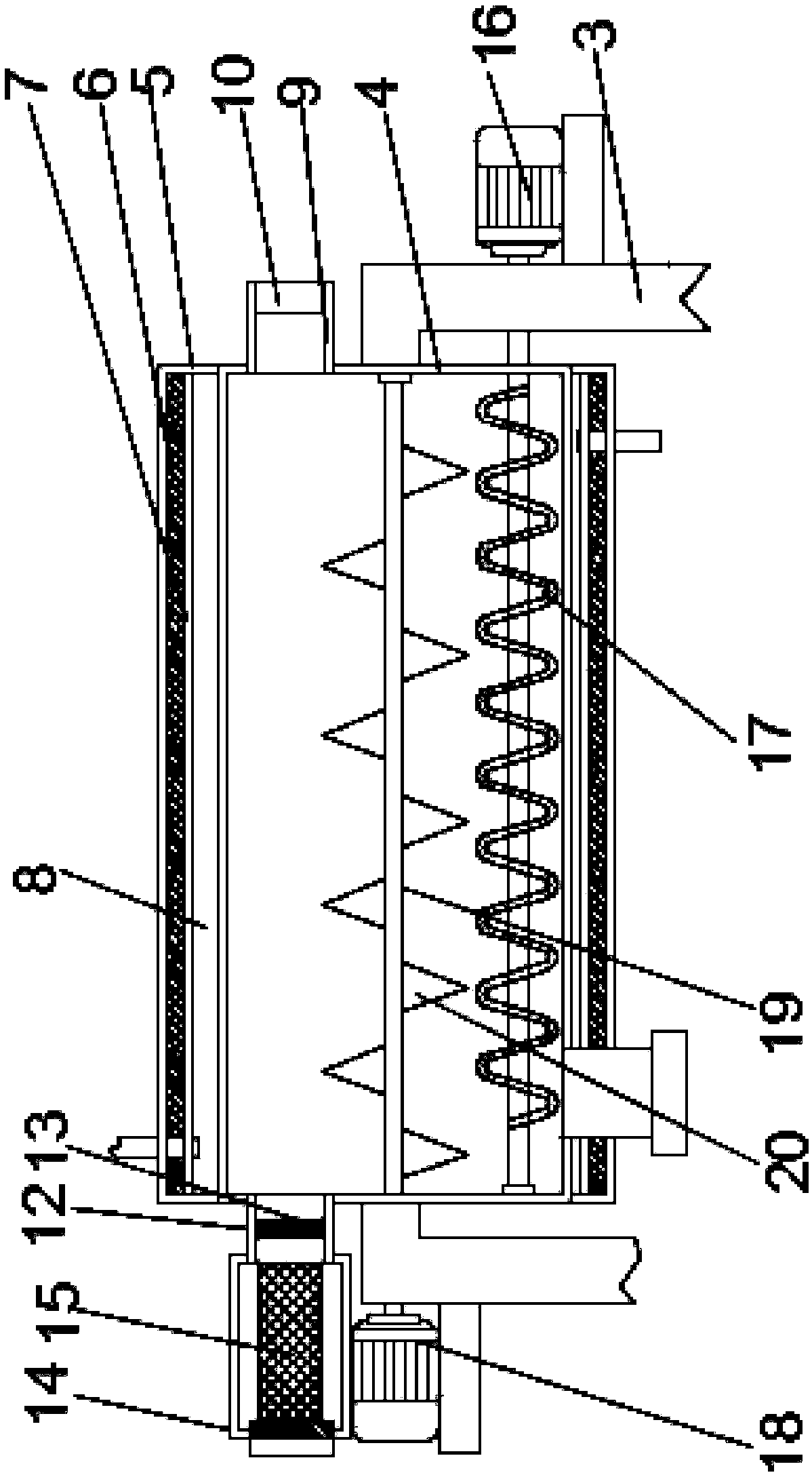

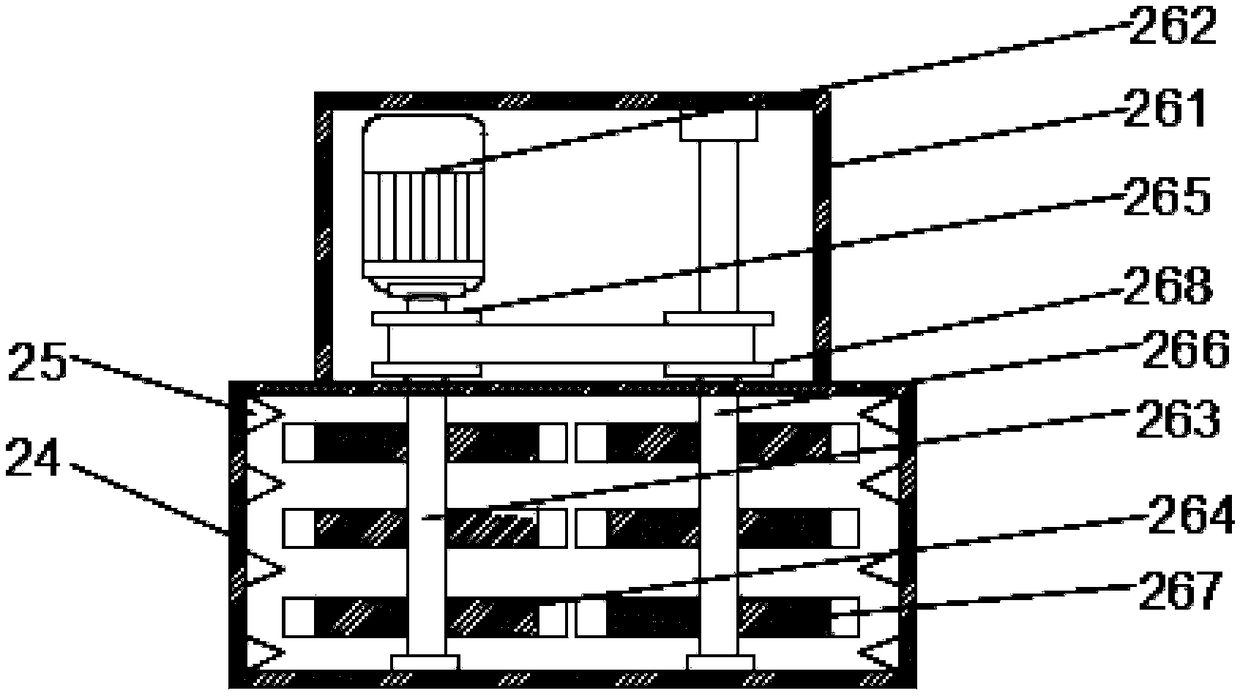

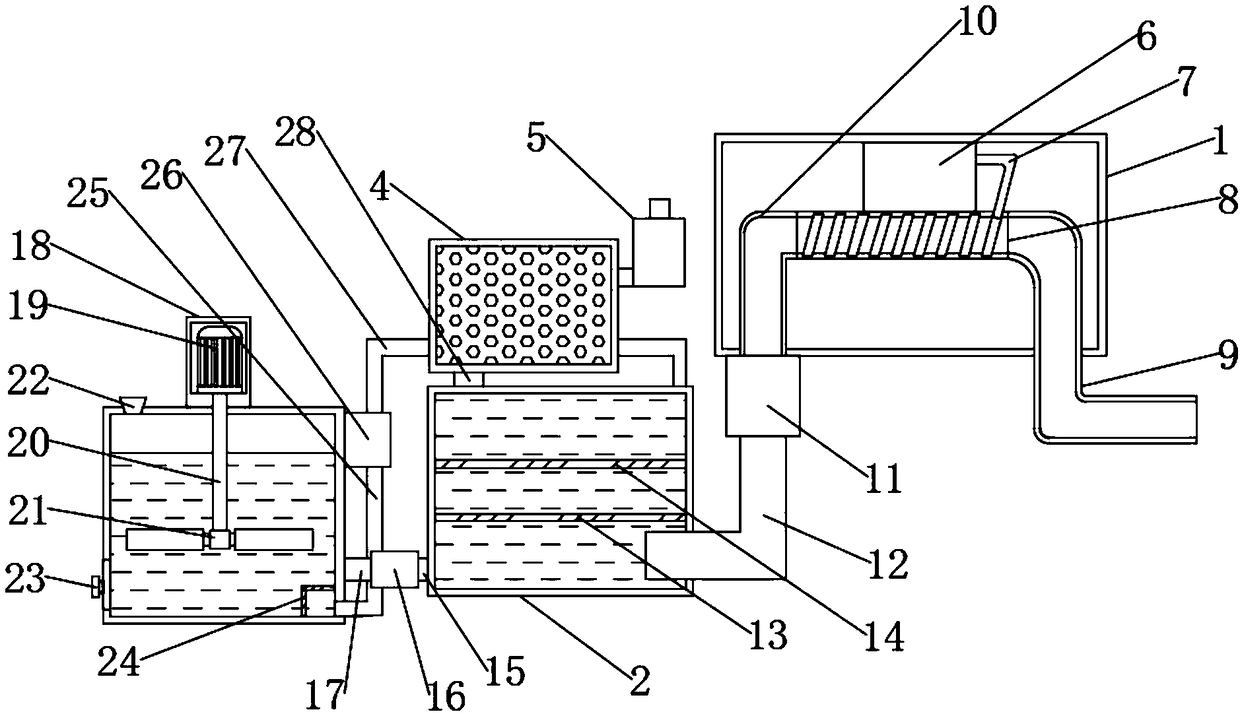

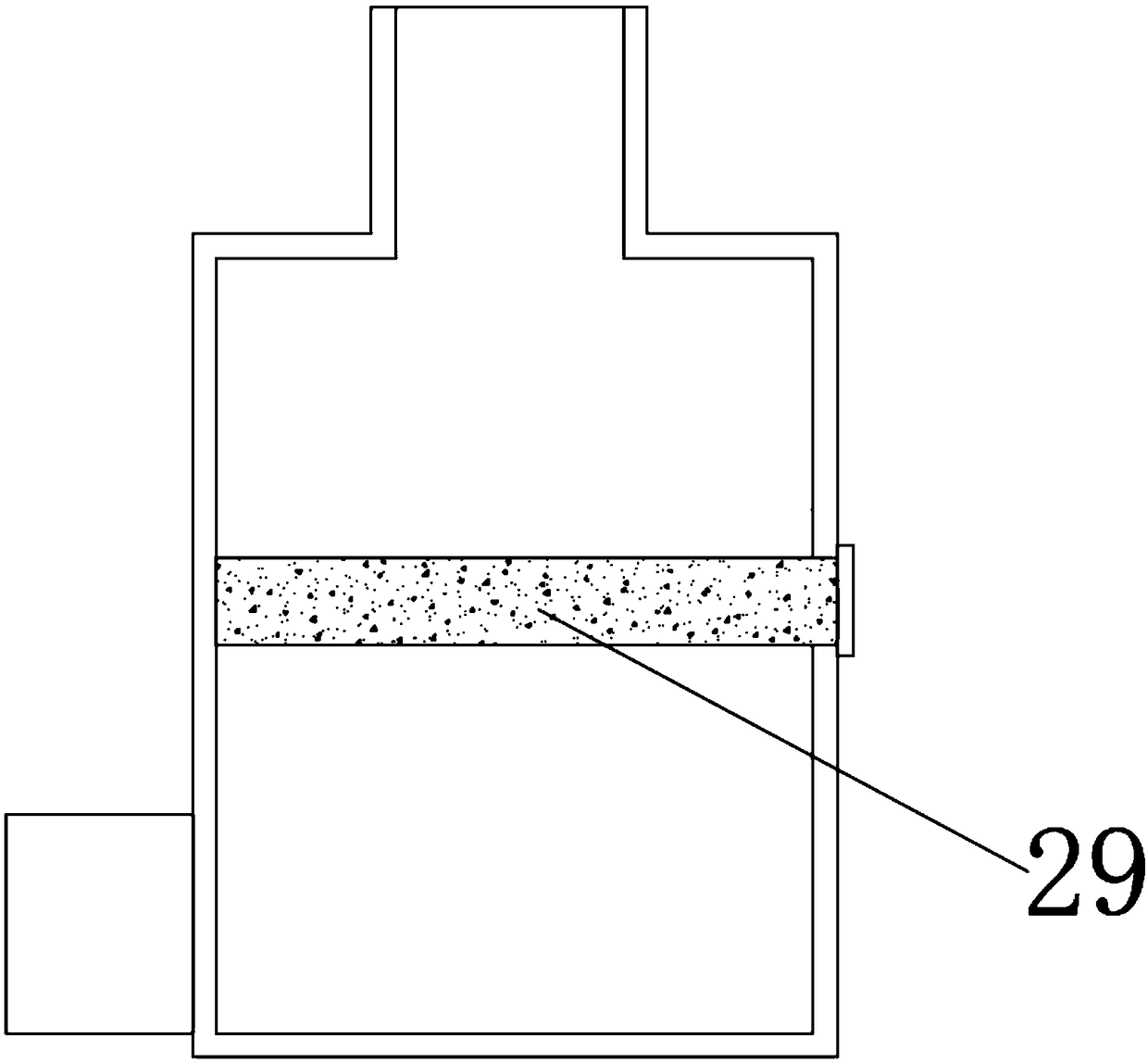

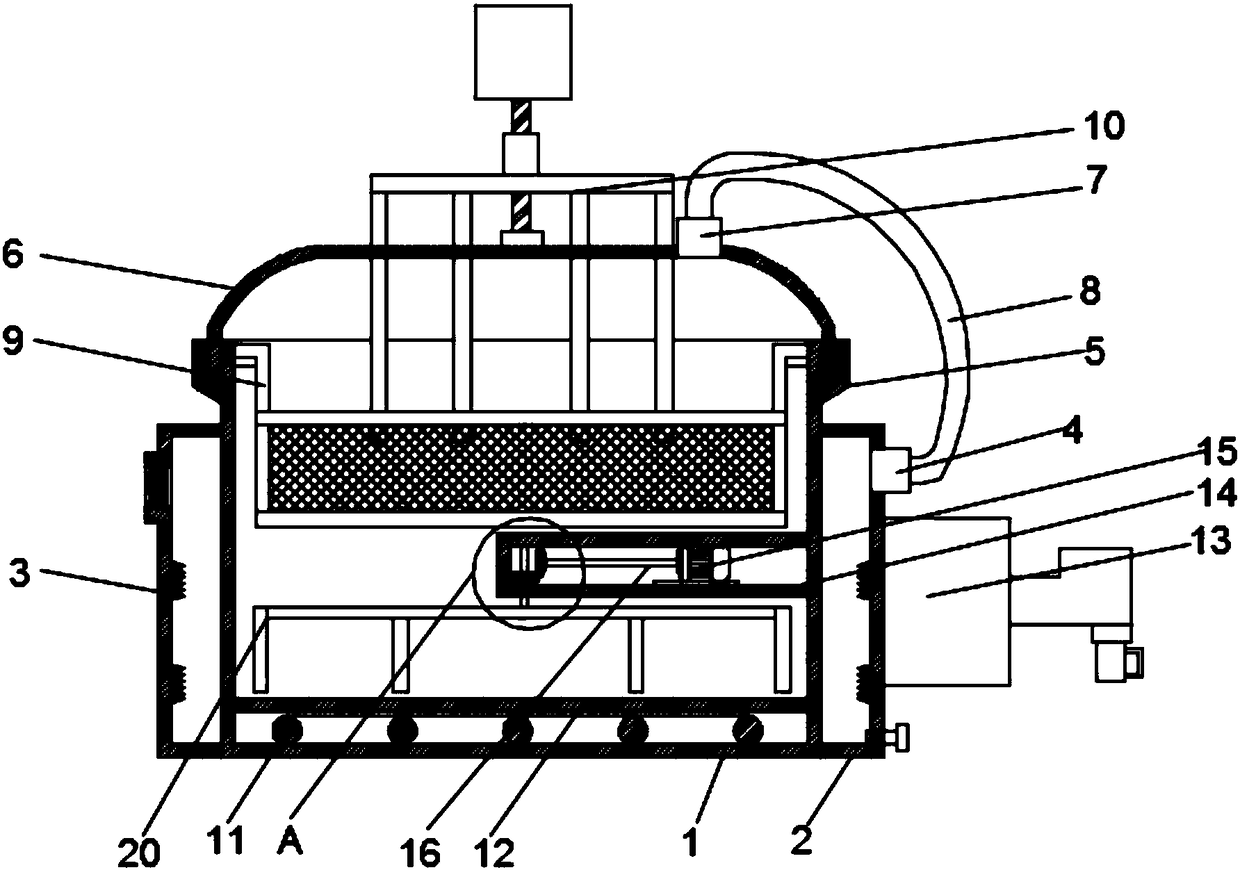

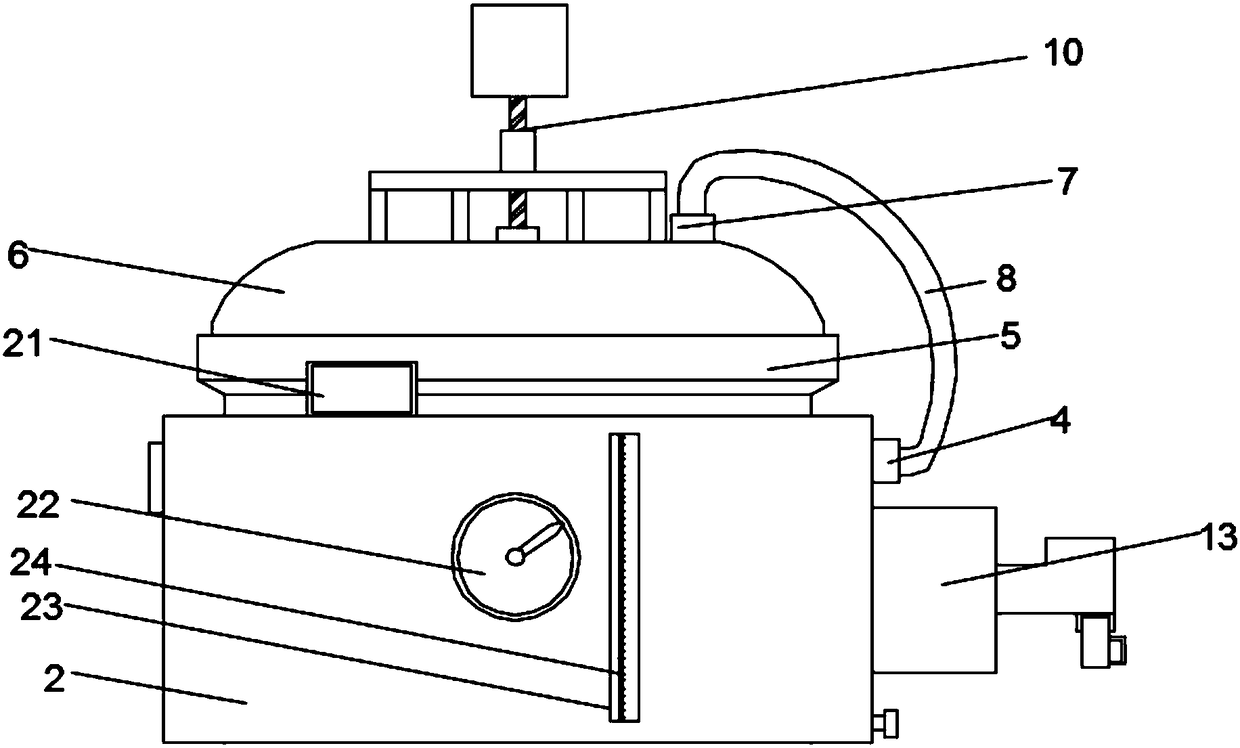

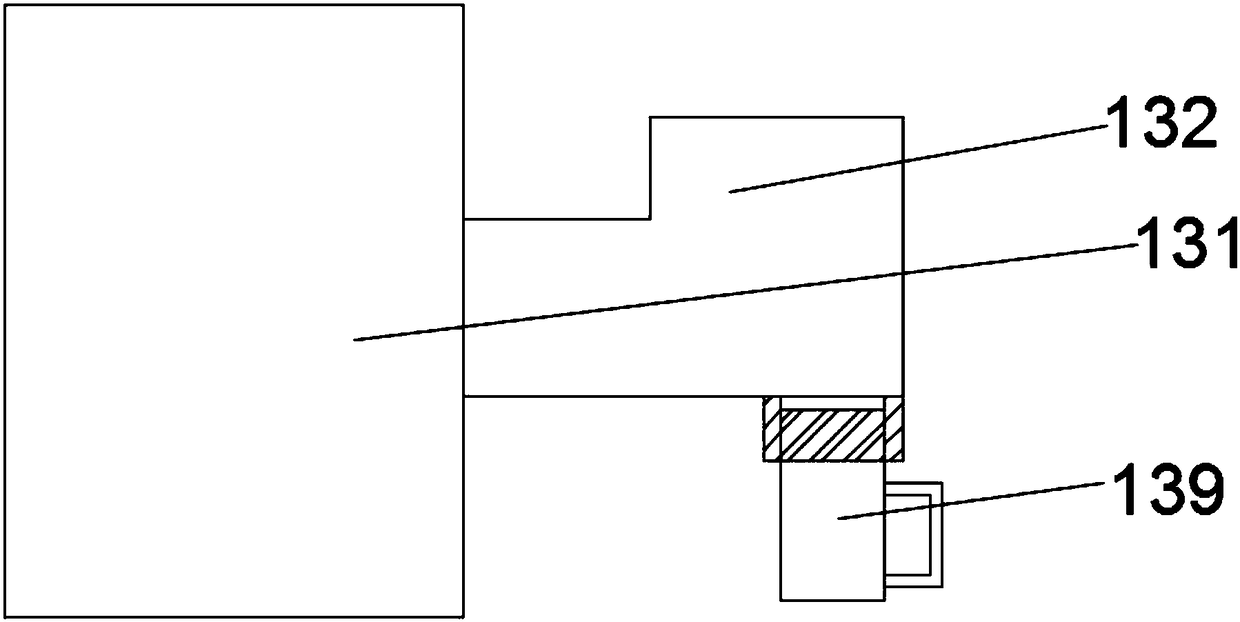

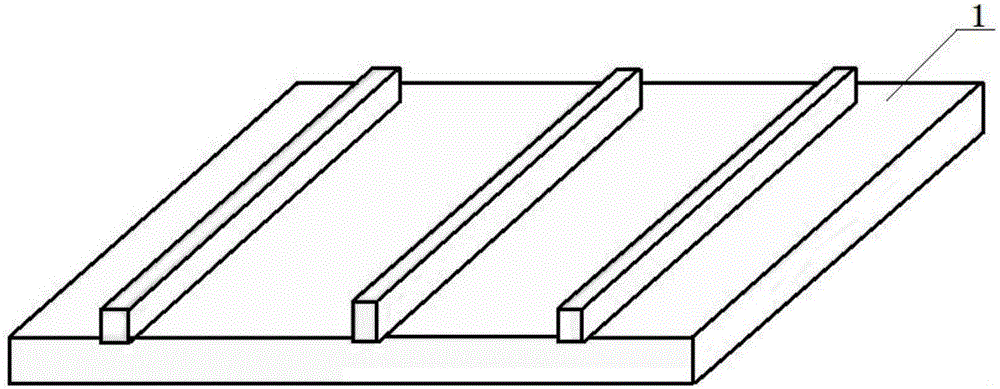

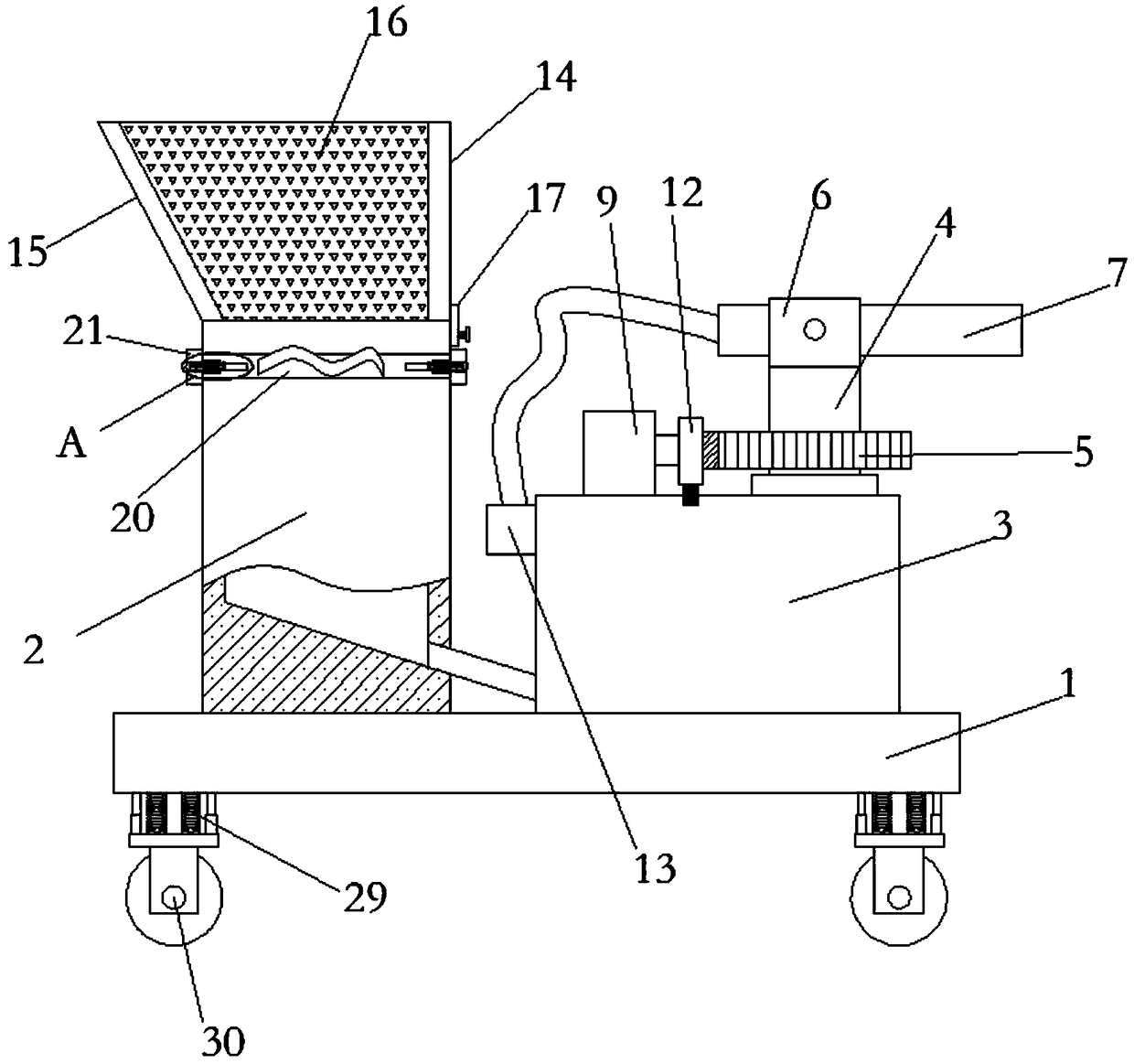

Organic fertilizer fermentation device

InactiveCN108947609AReduce areaImprove filtration efficiencyOrganic fertiliser apparatusAir filterAgricultural engineering

The invention discloses an organic fertilizer fermentation device. The organic fertilizer fermentation device comprises a base, wherein buffering devices are fixedly connected with two sides of the top of the base; supporting frames are arranged at the upper sides of the buffering devices; a fermentation tank is fixedly connected with the upper ends of one sides of outer walls of the supporting frames; a heat insulation shell is fixedly connected with the outer wall of the fermentation tank; the organic fertilizer fermentation device relates to the technical field of biological fermentation. By adopting the organic fertilizer fermentation device, the aims of conveniently crushing a bottom material and improving the stability are realized, and the aims of saving energy source and preventingair pollution are realized; the bottom material is subjected to crushing treatment and the area of the bottom material is saved; the fermentation efficiency of the bottom material is improved, the vibration generated in an operation process of the device is weakened, the stability of the device is improved and the service life of the device is prolonged; the fermentation tank keeps proper temperature to the greatest extent, the loss of heat is reduced and heat energy is saved; the device accords with an energy-saving and environment-protection concept; and after undesirable odor in the air isfiltered through an air filter element, the air is discharged, so that the undesirable odor is reduced and the environment is prevented from being polluted by the air with the undesirable odor.

Owner:连云港通威饲料有限公司

Down coat with fluorescence function

InactiveCN102342595AImprove washabilityExtended service lifeSynthetic resin layered productsOvergarmentsSurface layerLight energy

The invention discloses a down coat with a fluorescence function. The down coat comprises a surface layer, a middle layer and an inner layer, wherein the surface layer is made of a transparent waterproof coating fabric; the middle layer is a down layer; the inner layer is a textile fabric layer; a photosensitive layer is additionally arranged between the surface layer and the middle layer; and the photosensitive layer can emit fluorescent lights at night. The down coat with the fluorescence function disclosed by the invention has the advantages that the photosensitive layer is arranged in the fabric layer, thereby causing the down coat to have a fluorescence effect at night; the required light energy is from the solar energy absorbed by the fabric by day; the design meets the energy-saving environmentally-friendly conception; simultaneously the photosensitive layer is protected by the surface fabric during a washing process; the washing fastness of the fabric is high; the service life is long; and the effect of the fluorescence function is obvious.

Owner:JIANGSU YUELONG DRESS

Construction method of shield and continuous cutting pile foundation for penetrating through residential building group

ActiveCN104847364AFew constraintsImprove applicabilityTunnelsArchitectural engineeringConstruction management

The invention relates to a construction method of a shield and continuous cutting pile foundation for penetrating through a residential building group. The construction method comprises the following steps that the first step, house investigation and investigation of pipelines around houses are conducted; the second step, pile cutting construction numerical simulation is conducted; the third step, an automatic monitoring instrument is installed; the fourth step, pre-grouting reinforcement is conducted, wherein the reinforcement range includes buildings, the pipelines and planning tool changing points, and the reinforcement mode is a retrograde grouting mode; the fifth step, shutdown and inspection of a shield machine are conducted before pile cutting is conducted; the sixth step, pile cutting tunneling and pipe sheet splicing are conducted; the seventh step, grout supplement and emergent reinforcement are conducted. According to the construction method, pile cutting and penetration can be directly conducted without the operation that the existing buildings are demolished, the idea of energy conservation and environmental protection is met, the investment cost can be substantially reduced, the negative influence caused by demolition is reduced, and the number of the constraint factors of metro line selection is reduced; in addition, shield construction parameters and grouting parameters can be guided according to data which are fed back in real time through automatic monitoring, a comprehensive dynamic construction management system is implemented, the engineering risk is controllable, and the construction cost can be substantially reduced.

Owner:CHINA CONSTR COMM ENG GRP UNITED

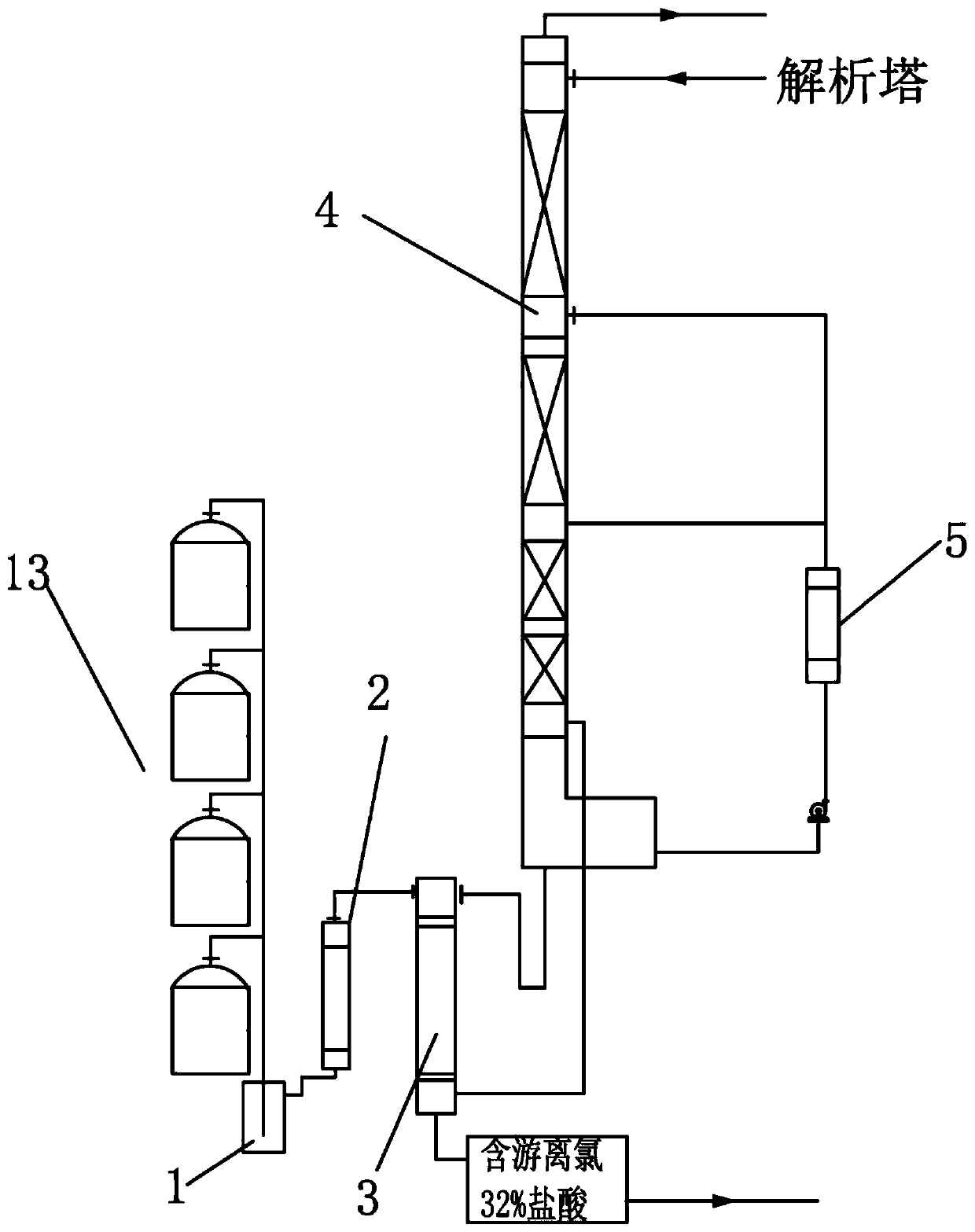

Chlorination section byproduct hydrogen chloride gas absorption and purification acid-forming system and process

ActiveCN111330412AAchieve recyclingIn line with the concept of energy saving and environmental protectionGas treatmentDispersed particle separationWater chlorinationExhaust fumes

The invention relates to a chlorination section byproduct hydrogen chloride gas absorption and purification acid-forming system and process. The system comprises: a tail gas purification acid-formingdevice, which is used for absorbing byproduct hydrogen chloride gas into 31-33wt% hydrochloric acid containing free chlorine; a dechlorination washing device, which is used for dechlorinating the hydrochloric acid containing free chlorine to obtain 30-31wt% dechlorinated hydrochloric acid; and a desorption concentration device, which is used for desorbing one part of dechlorinated hydrochloric acid into hydrogen chloride gas, and performing absorption with the other part of dechlorinated hydrochloric acid to obtain 31-32wt% industrial-grade hydrochloric acid; wherein the tail gas purificationacid-forming device, the dechlorination washing device and the desorption concentration device are sequentially communicated. According to the invention, hydrogen chloride-containing waste gas generated by reaction in a chlorination reaction kettle can be absorbed and purified into industrial hydrochloric acid, so that the waste gas can be recycled, and the concept of energy conservation and environmental protection is met.

Owner:杭州东日节能技术有限公司

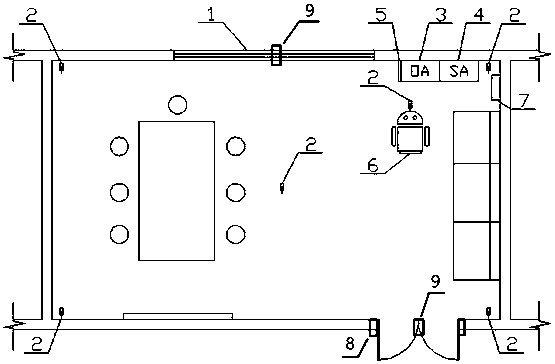

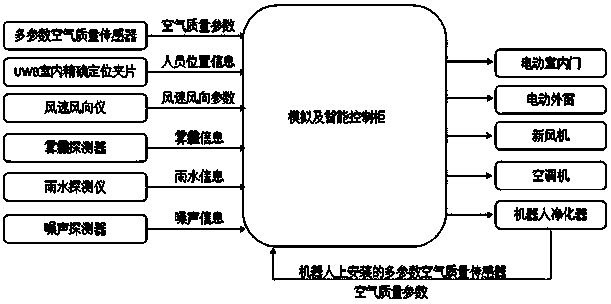

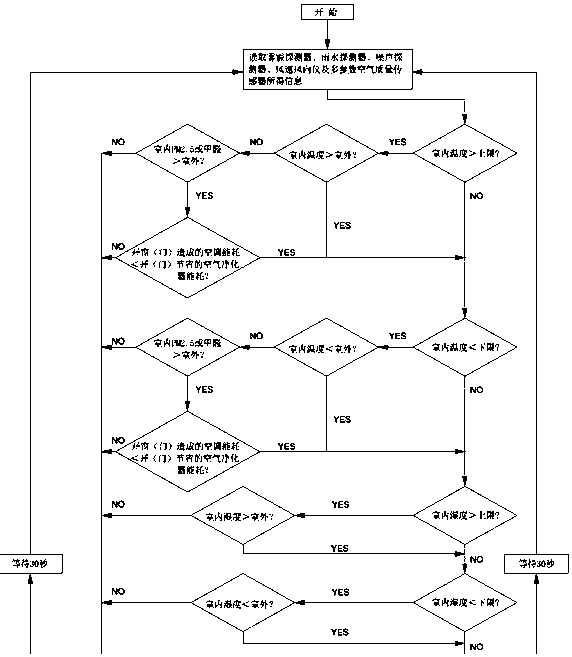

Intelligent environment control system based on indoor precise positioning and automatic simulation

ActiveCN109869866AReduce noise transferEliminate heating and cooling loadsMechanical apparatusSpace heating and ventilation safety systemsIntelligent environmentControl system

The invention discloses an intelligent environment control system based on indoor precise positioning and automatic simulation. The system comprises an electric outer window, a multi-parameter air quality sensor, an air refresher, an air conditioner, an intelligent UWB indoor precise positioning clamping piece, a robot air purifier, a simulation and intelligent control cabinet, an electric indoordoor and an air speed and air direction instrument; the electric outer window is provided with a haze detector, a rainwater detector and a noise detector; the air refresher and the air conditioner areconnected with the robot air purifier; the haze detector, the rainwater detector, the noise detector, the multi-parameter air quality sensor, the intelligent UWB indoor precise positioning clamping piece and the air speed and air direction instrument are connected with the simulation and intelligent control cabinet; and the simulation and intelligent control cabinet is connected with the electricouter window, the air refresher, the air conditioner, the robot air purifier and the electric indoor door. The system is high in intelligence degree and excellent in energy saving effect, can precisely control indoor environments, prominently improves the human body heat comfort of indoor persons, and achieves more uniform indoor heat comfort and air environment.

Owner:CHINA RAILWAY CONSTR GROUP +1

Energy-saving greening watering device for municipal administration and application thereof

InactiveCN107155818AWater savingSave electricityGeneral water supply conservationWatering devicesElectricityAgricultural engineering

The invention discloses an energy-saving greening watering device for municipal administration and application thereof. The energy-saving greening watering device includes a bottom plate; a water collection tank is arranged on the top of the bottom plate; a tank cover is arranged on the top of the water collection tank; a filtering net is arranged between a left side wall and a right side wall of an inner cavity of the tank cover; a door roller is arranged on the top of the tank cover; a liquid level sensor is arranged on the bottom of a left wall of the inner cavity of the water collection tank; a solar energy converter is arranged on the left side of the water collection tank; a solar cell panel is arranged on the left side of the solar energy converter; a water conveying pipe is connected to a right side wall of the water collection tank; the right side of the water collection tank is connected to a water supply pump through the water conveying pipe; the right side of the water supply pump is connected to a spraying box through the water conveying pipe; and a spraying disc is arranged on the top of the spraying box. The energy-saving greening watering device can save water and electricity, can achieve an environment-friendly and energy-saving effect, can save human resources, can reasonably utilize resources, and meets the current energy-saving and environment protection idea.

Owner:夏胜军

Environmentally-friendly smoke dust denitrification and desulfurization equipment

InactiveCN108744908AAdequate responseGood flocculation effectGas treatmentDispersed particle filtrationOzone generatorSulfur

The invention provides environmentally-friendly smoke dust denitrification and desulfurization equipment and relates to the technical field of environmentally-friendly equipment. The environmentally-friendly smoke dust denitrification and desulfurization equipment comprises an oxidation box; an ozone generator is fixedly arranged in the oxidation box; the right side of the ozone generator is communicated with a connecting pipe; a gas mixing pipeline is fixedly arranged at the bottom of the ozone generator; the ozone generator is communicated with the gas mixing pipe through the connecting pipe; the right side of the gas mixing pipeline is communicated with a gas inlet pipeline; and the left side of the gas mixing pipeline is communicated with a gas outlet pipeline. The environmentally-friendly smoke dust denitrification and desulfurization equipment is provided with a denitrification box and a desulfurization box so as to improve the smoke dust purification efficiency and effect, heatgenerated by reaction is repeatedly used, additional reheat of smoke is not required, and energy consumption is reduced, so as to reduce cost, and calcium oxide particles are added in the desulfurization box without spraying water (the water is sprayed difficulty and non-uniformly) so as to reduce the cost of the desulfurization process.

Owner:WUHU NEW UNIVERSAL ENVIRONMENTAL SCI TECH

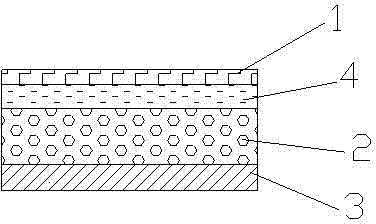

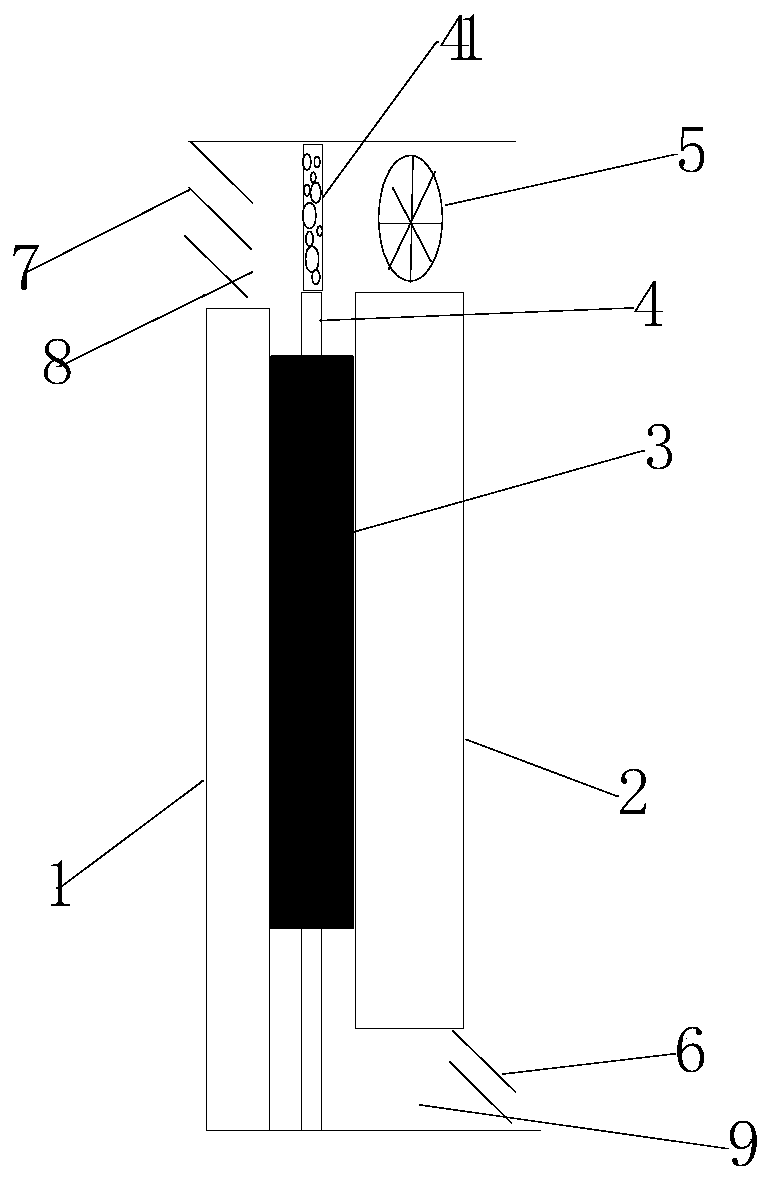

Ventilating insulation moisture-absorbing wall

InactiveCN105507448AVentilatedHygroscopicLighting and heating apparatusWallsSuspended particlesEngineering

The invention provides a ventilating insulation moisture-absorbing wall, comprising an outer wall, a moisture-absorbing structure layer and an inner wall, wherein the outer wall is provided with a vent hole by extending its upper portion along its thickness direction, a controllable louver device is arranged beside the vent hole, giving ventilation and also ensuring that outside suspending particles are avoided entering a room, upper and lower portions of the inner wall are provided with an axial flow fan and a vent passage, respectively, fresh air can be exchanged with indoor stuffy air by the axial flow fan, and a controllable lover device is arranged inside the vent passage, giving attractiveness and also ensuring air purity.

Owner:XINJINWEI NETWORK TECH

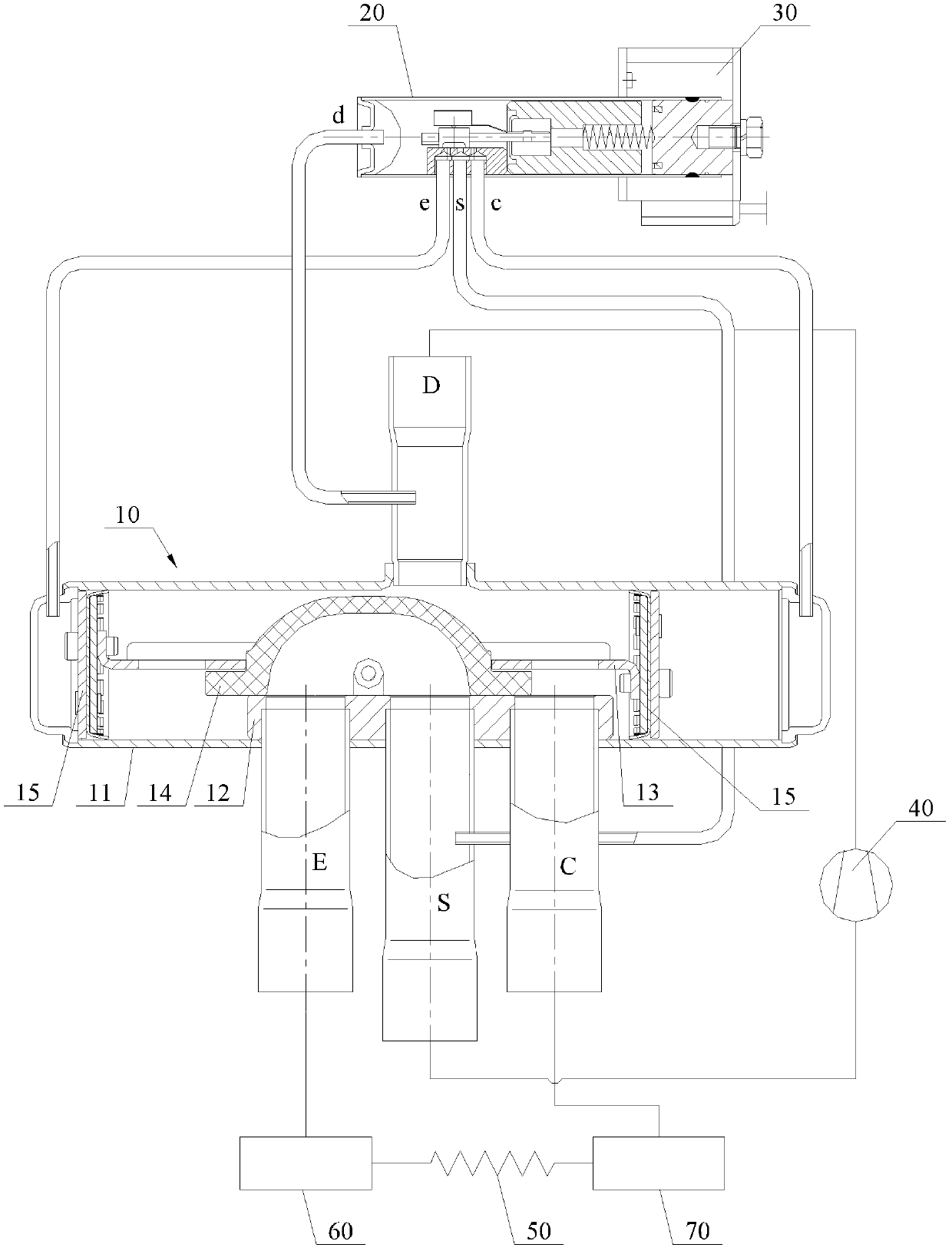

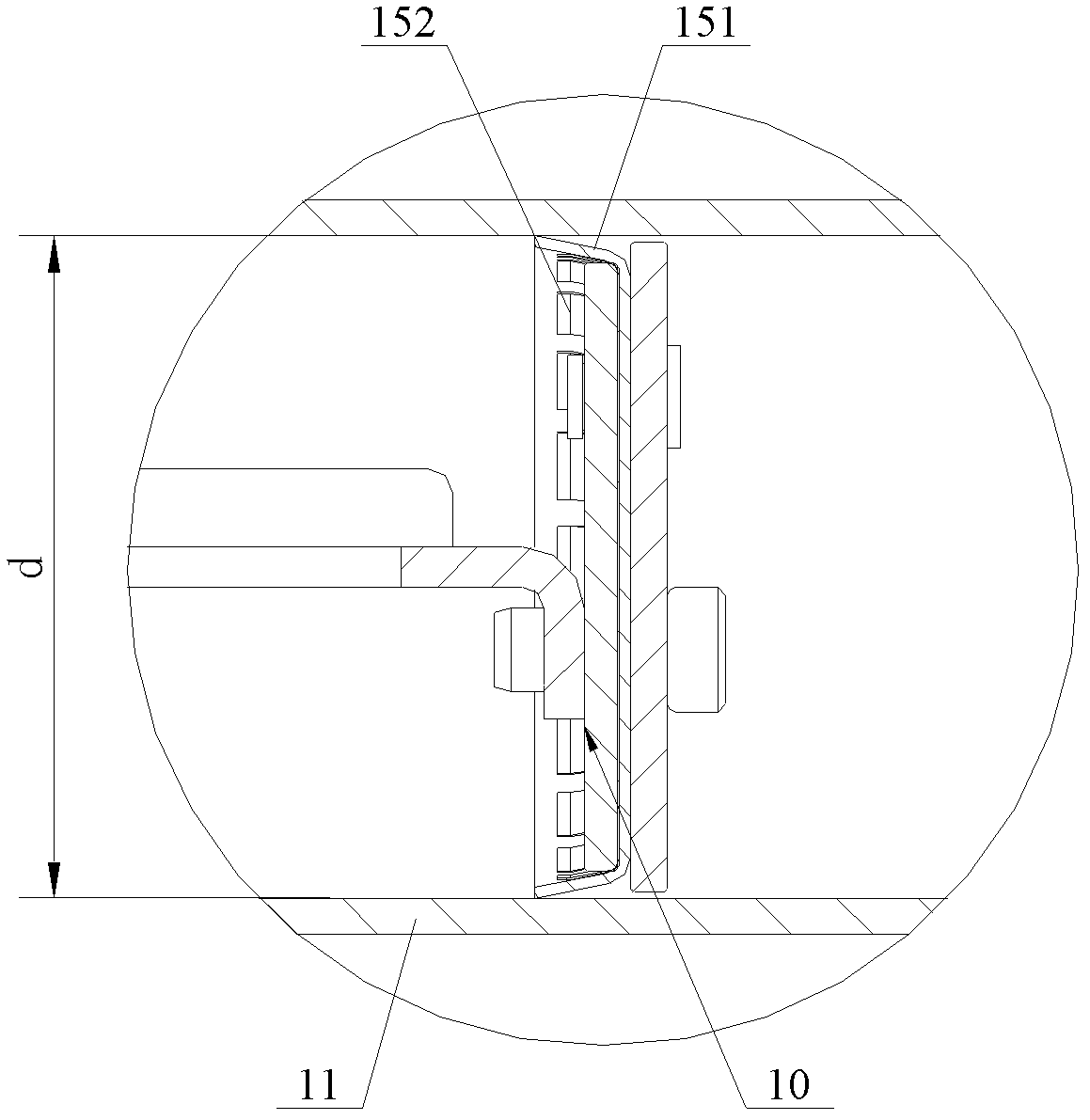

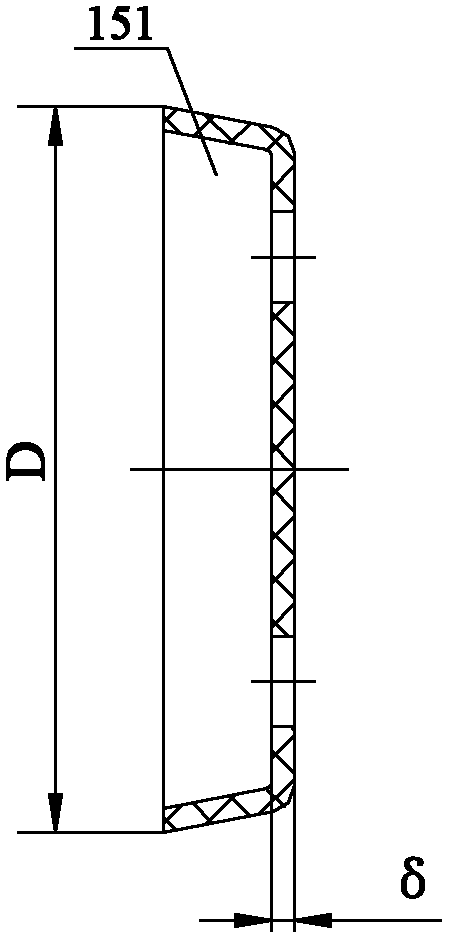

Main valve of four-way reversing valve and four-way reversing valve provided with main valve

InactiveCN103291957AOptimize structure sizeReduce coefficient of frictionOperating means/releasing devices for valvesMultiple way valvesEngineeringAir conditioning

The invention discloses a main valve of a four-way reversing valve. The main valve comprises a valve body, two piston devices and sliding blocks, wherein the piston devices are arranged in the valve body and connected through a connecting rod; the sliding blocks and the piston devices move synchronously; piston cups and piston spring pieces are arranged in the piston devices, the piston cups are glidingly matched with the inner wall of the valve body, and the piston spring pieces are arranged in the piston cups and provide radial action force; the thickness of each piston cup is 0.55-0.65mm, and the thickness of each piston spring piece is 0.11-0.15mm; and the piston cups are made of materials by weight of 85%-95% of a polytetrafluoroethylene base material and 5%-15% of an additive capable of reducing friction coefficients. By means of optimization and improvement in two aspects of structure dimension and material selection, the adaptability of the four-way reversing valve is effectively improved, and configuration requirements of different air conditioning systems can be met. On the basis, the invention further provides a four-way reversing valve provided with the main valve.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

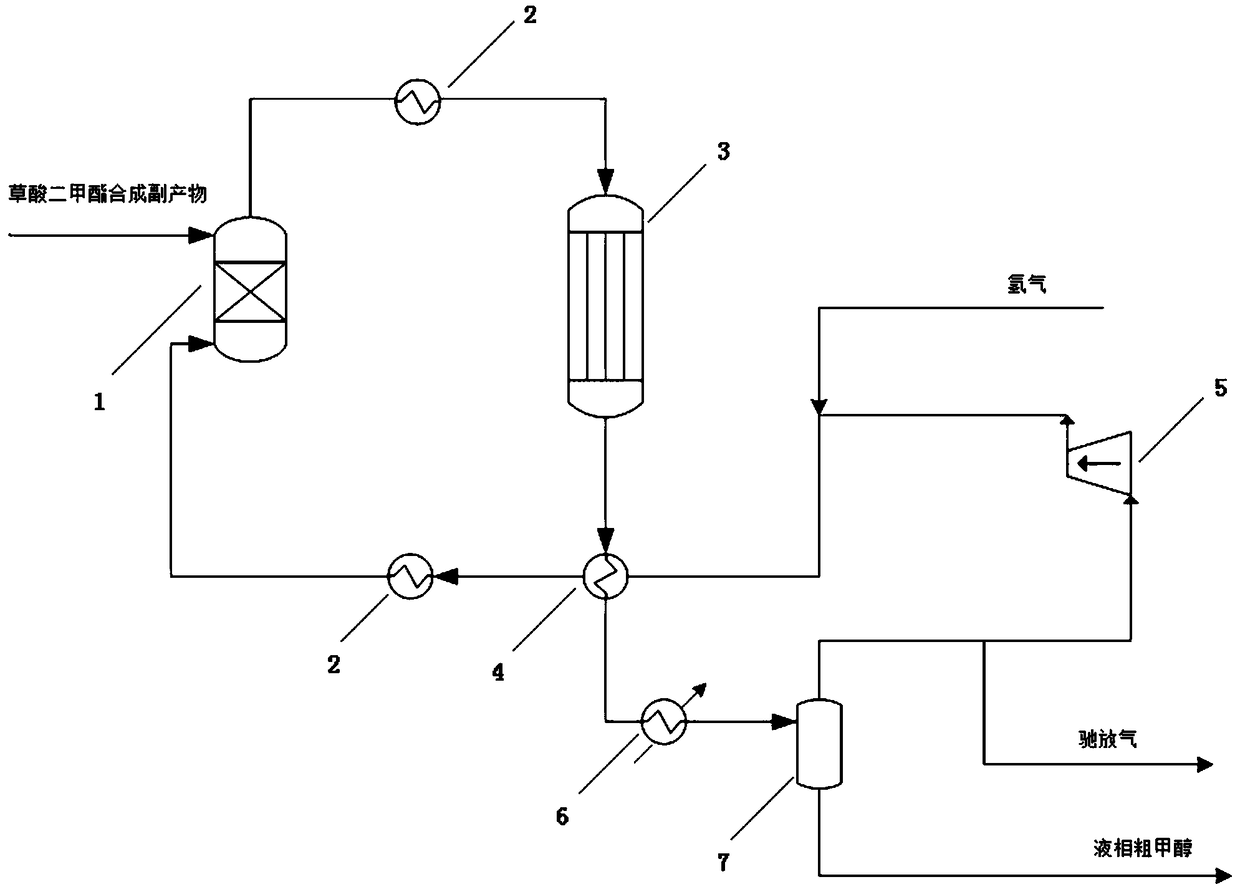

Method and system for recovering by-products in synthesis process of dimethyl oxalate

ActiveCN108997085AEliminate the distillation and refining stepsReduce investmentOrganic compound preparationChemical industryRecovery methodHydrogenation reaction

The invention discloses a method for recovering by-products in a synthesis process of dimethyl oxalate. The method comprises the following steps: taking a copper-based catalyst as a reaction catalyst,carrying out an ester hydrogenation reaction on dimethyl carbonate and methyl formate in synthetic by-products of the dimethyl oxalate to convert all the by-products into methanol; and carrying out heat exchange cooling on the methanol to recycle the methanol in the synthesis step of the dimethyl oxalate. The method has the advantages that the rectifying and refining steps of the by-products in the synthesis process of the dimethyl oxalate are omitted; the process flow is simplified; the equipment investment and the raw material input are reduced; and the method is an efficient and clean recovery process. In addition, the invention also discloses a system for recovering the by-products in the synthesis process of the dimethyl oxalate. The system has the advantages that the equipment is simple; the conversion and the recovery of the methanol can be realized; the heat recovery rate of the system is high at the same time. Therefore, the system conforms to the concepts of energy conservation and environmental protection.

Owner:高化学(江苏)化工新材料有限责任公司

Energy-saving and environment-friendly fabricated wall and assembly method thereof

InactiveCN111236470AReduce areaReduce weightWallsHeat proofingStructural engineeringMechanical engineering

The invention discloses an energy-saving and environment-friendly fabricated wall and an assembly method thereof, and belongs to the field of fabricated buildings. The energy-saving and environment-friendly fabricated wall comprises two supporting columns, a plurality of groups of first wall bodies, second wall bodies and third wall bodies are arranged between the two supporting columns, and the first wall bodies, the second wall bodies and the third wall bodies are connected in a spliced mode, a partition plate is arranged between the two supporting columns and located between every two adjacent sets of the first wall bodies, the second wall bodies and the third wall bodies, inserting grooves are formed in one sides of the first wall bodies and one sides of the second wall bodies, and first inserting blocks matched with the inserting grooves are fixedly connected to one sides of the second wall bodies. Rapid installation of fabricated wall can be achieved, the area and the weight of asingle wall body are reduced, hoisting equipment is not needed, the installation cost is saved, positioning connection between the wall bodies is achieved through inserting connection of the inserting blocks and the inserting grooves, direct inserting can be achieved during installation, dislocation movement of the wall bodies is prevented, and in-place installation is ensured.

Owner:杜广锋

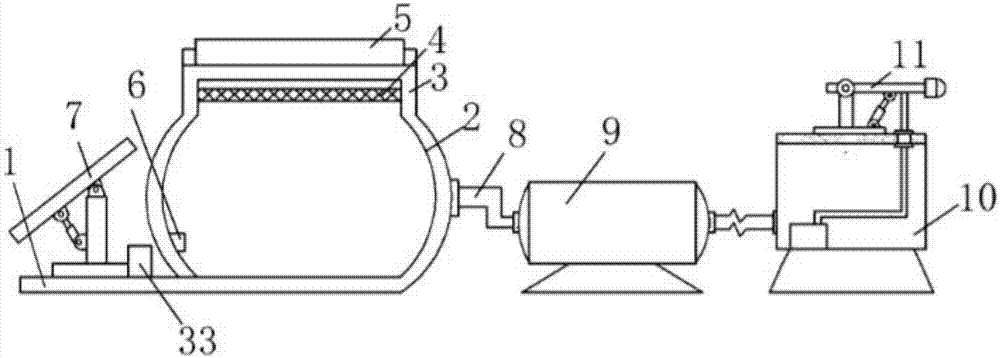

Domestic rice wine brewing device

InactiveCN108587837ATemperature rises fastImprove permeabilityAlcoholic beverage preparationYeastThreaded pipe

The invention discloses a domestic rice wine brewing device, which comprises a barrel body, wherein the upper end and the lower end of two sides of the outer wall of the barrel body are fixedly connected with a heat preservation cavity; one side of the inner wall of the heat preservation cavity is fixedly connected with a heating wire; the upper end of one side of the outer wall of the heat preservation cavity is fixedly communicated with a first threaded pipe; the upper end of the two sides of the outer wall of the barrel body is fixedly connected with a positioning groove, the surface of theinner wall of the positioning groove is movably connected with a barrel cover, one side of the top of the barrel cover is fixedly communicated with a second threaded pipe, and the invention relates to the technical field of wine brewing. The domestic rice wine brewing device has the advantages that the cooking efficiency is high, the energy is saved, the hole pricking is facilitated, foreign strains are reduced, the rolling the distiller's yeast is facilitated, the waste of resources is reduced, the energy is saved, the concept of energy conservation and environmental protection is met, the cooking efficiency of the sticky rice can be improved, which ensures that the sticky rice can be fully steamed, the sanitary condition when the rice wine is fermented is guaranteed, the success rate ofthe rice wine fermentation is improved, the rolling the distiller's yeast is facilitated, the labor is saved and the device is convenient for people to use.

Owner:江苏龙河酒业有限公司

Thick copper plate manufacturing method

InactiveCN105072827AImprove press-fit white edgesImprove lamination lack of glueMultilayer circuit manufactureEngineeringCopper

The invention belongs to the circuit board processing field, and more specifically relates to a thick copper plate manufacturing method. Through changing a resin glue filling flow, the method can well improve the problems of stitching white edges, stitching starvation and pcb unevenness in a stitching process, effectively improve a thick copper pcb, allow the internal layer copper thickness to be greater than 30 Z, and increase a qualified rate of stitching manufacture; accordingly, the method reduces resource waste, accords with the idea of energy conversation and environmental protection, reduces costs, and has a great prospect of use and large economic value.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

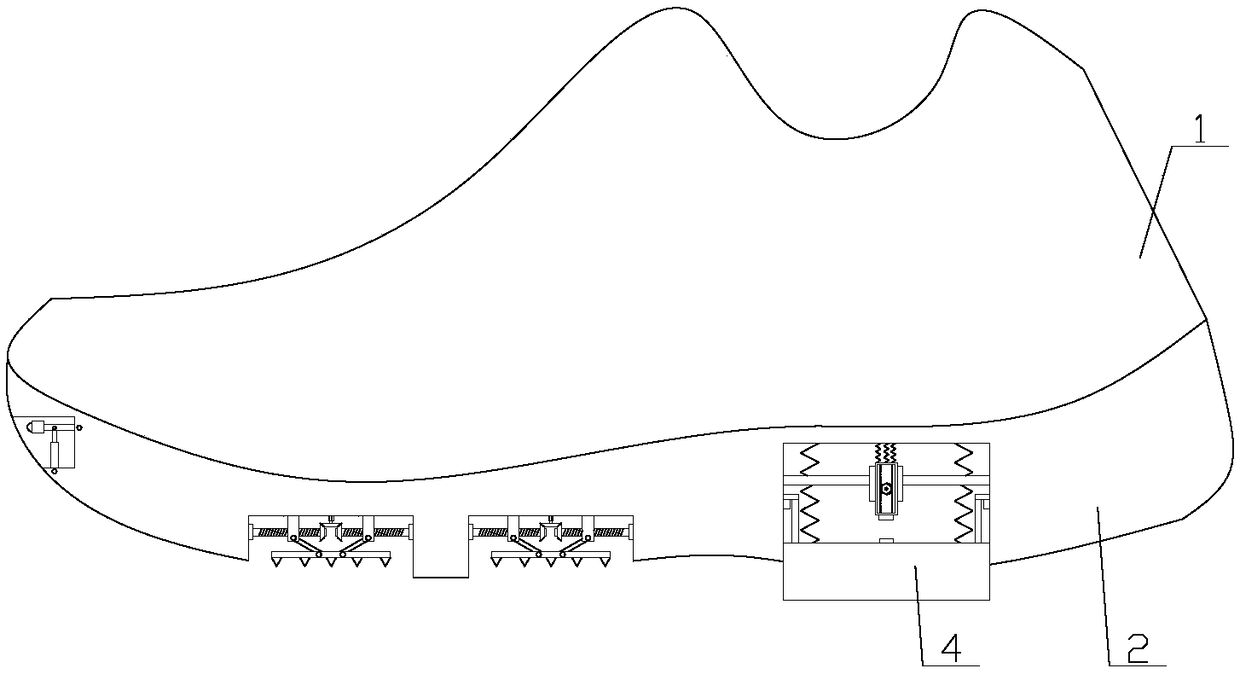

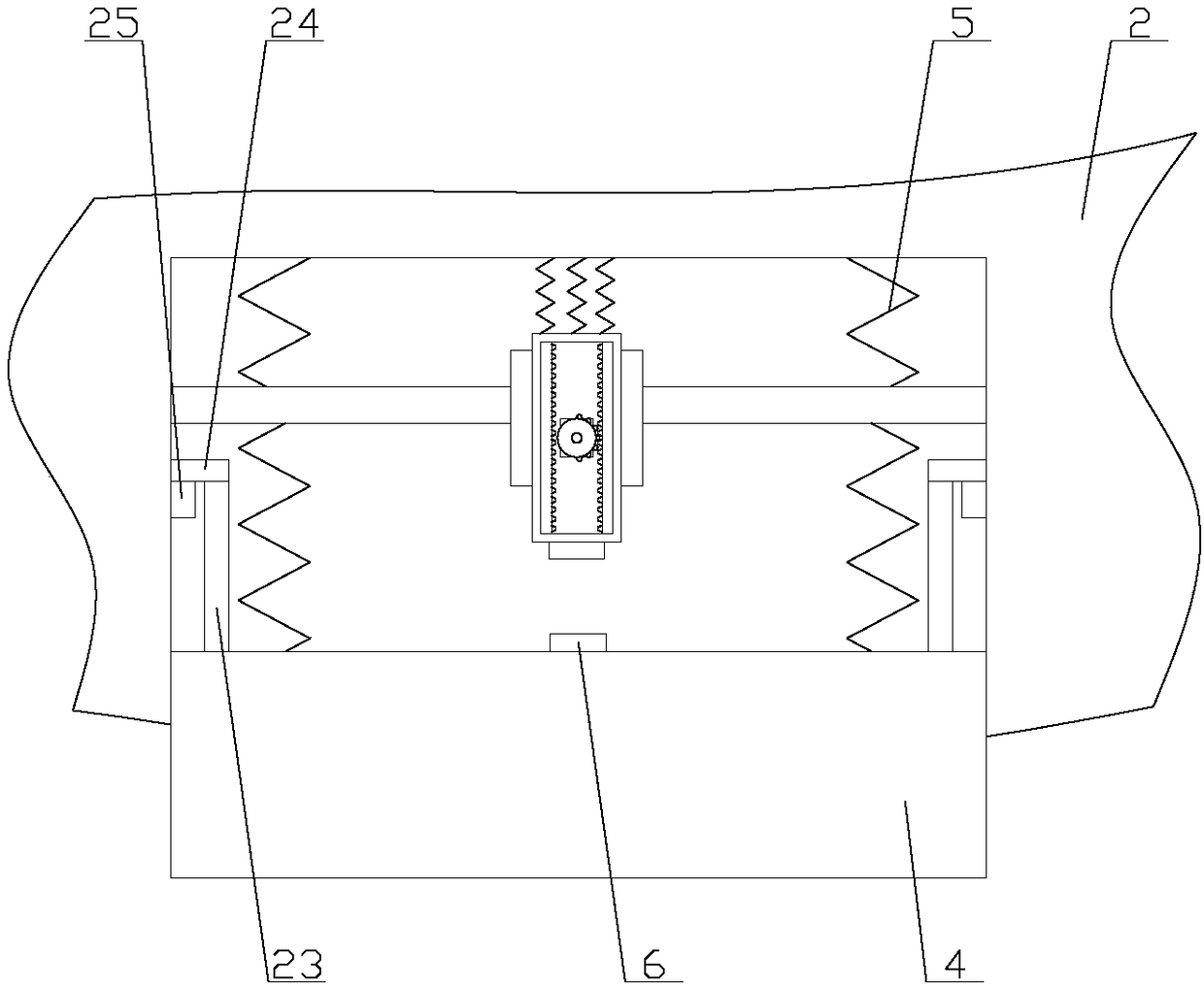

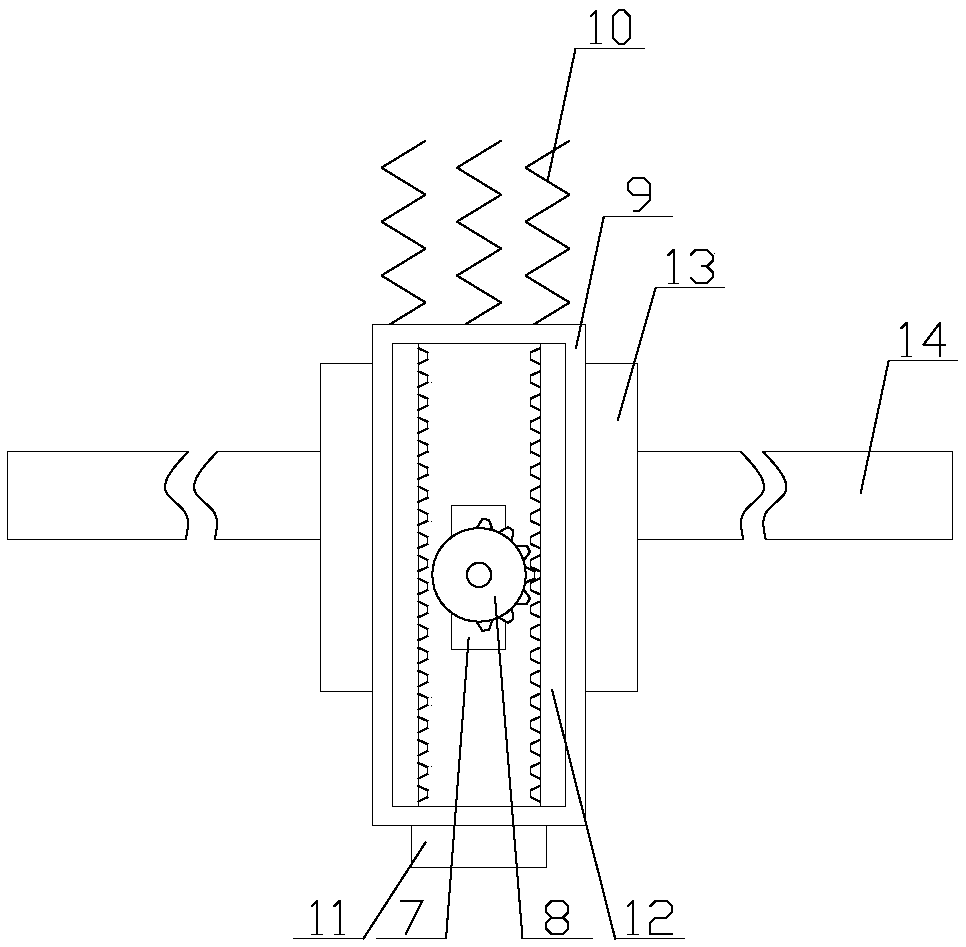

Energy-saving intelligent shoe with antiskid function on basis of internet of things

InactiveCN108391891AImprove practicalityImprove convenienceSolesLighting elementsThe InternetEngineering

The invention relates to an energy-saving intelligent shoe with an antiskid function on the basis of an internet of things. The energy-saving intelligent shoe comprises a shoe, a shoe sole, an illuminating lamp, a power generation mechanism and a plurality of antiskid mechanisms. The power generation mechanism comprises a driving assembly and a power generation assembly, and each antiskid mechanism comprises a driving motor, a first bevel gear, a lifting plate and two lifting units. The energy-saving intelligent shoe with the antiskid function on the basis of the internet of things has the advantages that kinetic energy generated when people walk can be sufficiently utilized, and accordingly power can be continuously generated by the power generation mechanism; electric energy can be stored, accordingly, the illuminating lamp can continuously work, batteries can be omitted and do not need to be changed, the practicality and the convenience of the energy-saving intelligent shoe can be improved, energy consumption can be reduced, and the energy-saving intelligent shoe conforms to energy-saving and environment-friendly concepts; the antiskid mechanisms can be started when a wearer needs to wear the energy-saving intelligent shoe to ascend or walk on icy road surfaces, accordingly, the shoe sole can be prevented from skidding, and the practicality and the safety of the energy-saving intelligent shoe can be improved.

Owner:SHENZHEN XIAOKONG COMM TECH CO LTD

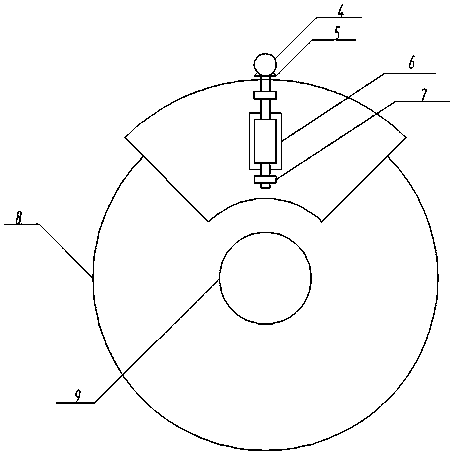

Ratchet wheel control mechanism of pipe washing impoundment door

InactiveCN104775512AEasy to solveAs it rises, the storage door also rises, and the storage door falls to preventSewer systemsRatchetWater storage

The invention discloses a ratchet wheel control mechanism of a pipe washing impoundment door. The ratchet wheel control mechanism comprises the impoundment door, a floating barrel, a water level adjusting mechanism and an impoundment door control mechanism. The impoundment door is connected with the impoundment door control mechanism through two parallel first support connecting rods, and the floating barrel is connected with the first support connecting rods and second support connecting rods through two parallel suspenders. The water level adjusting mechanism drives the impoundment door control mechanism through floating force of the water level during rising and dropping. According to the ratchet wheel control mechanism of the pipe washing impoundment door, the impoundment door is controlled through the pure mechanical ratchet wheel control mechanism, and the floating force of water serves as driving force to be used in cooperation with the ratchet wheel control mechanism to achieve the no-man control blocking-water storage-pipe washing process on a blow-off line. in addition, compared with electric control, the manufacturing cost of the ratchet wheel control mechanism is low, operation is safe and reliable, manual operation is not needed, and outside input energy resources are not needed.

Owner:NANTONG VOCATIONAL COLLEGE

Omega-3 fatty acid storage microemulsion and preparation method thereof

ActiveCN108077930AHas a transparent appearanceNot easily oxidizedFood ingredient as flavour affecting agentOil phaseProcess efficiency

The invention discloses an Omega-3 fatty acid storage microemulsion and a preparation method thereof. The preparation method comprises the following steps: (1) mixing Omega-3 fatty acid and a mixed solvent uniformly, adding a surfactant, and stirring at a temperature of 20 to 35DEG C for 20-40 min; (2) dropwise adding water under a stirring rate of 200 to 300 rpm to obtain the homogeneous and transparent Omega-3 fatty acid storage microemulsion. The Omega-3 fatty acid storage microemulsion which has a transparent appearance, is soluble in water, and is not easily oxidized can be prepared by the preparation method. Omega-3 fatty acid is easy to take, and can be better absorbed by the body, an oil phase used is isoamyl acetate, and is an aromatic additive for food, and the product has a special flavor. The method needs no high temperature and high pressure treatment, is simple and easy to perform, has high process efficiency, and is in line with the concept of energy saving and environmental protection.

Owner:TIANJIN UNIV

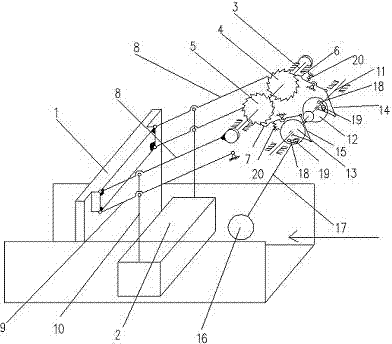

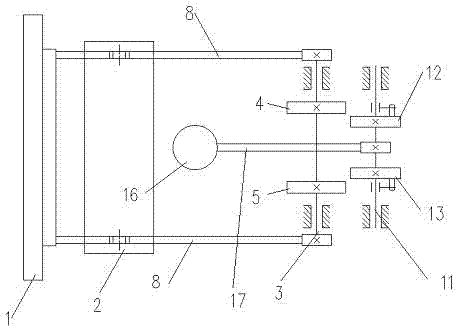

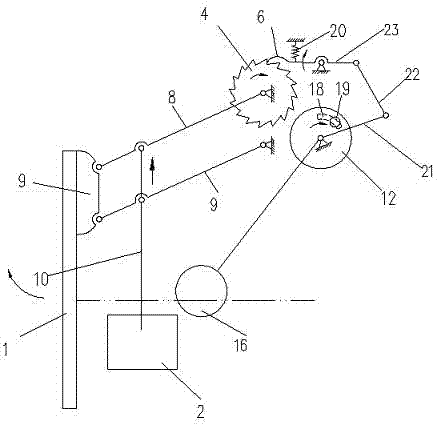

Effective agricultural robot

InactiveCN108887158AImprove water spray efficiencyAutomatic water spray homogenizationGeneral water supply conservationWatering devicesBall bearingSprayer

The invention relates to the technical field of agricultural robot, and discloses an effective agricultural robot. The effective agricultural robot comprises a bottom plate, wherein the upper end of the bottom plate is successively fixedly connected with a rainwater box and a water storage box; the upper end of the water storage box is rotatably connected with a supporting rod through a ball bearing; the rod wall of the supporting rod is fixedly in sleeve connection with a gear; the upper end of the supporting rod is fixedly connected with a U-shaped fixing plate; a water sprayer is rotatablyconnected between two opposite side walls of the U-shaped fixing plate; the upper end of the water storage box is further fixedly connected with a motor and a bearing block which are arranged symmetrically; the output shaft, which is close to the bearing block, of the motor is fixedly connected with a reciprocating threaded rod; the end, which is away from the motor, of the reciprocating threadedrod is rotatably connected with the bearing block through a ball bearing; the rod wall of the reciprocating lead screw is in threaded connection with a moving block; and the side wall of the moving block is fixedly connected with a rack engaged with the gear. The effective agricultural robot has the advantages of uniform water spraying and capability of effectively utilizing rainwater resources.

Owner:ZHEJIANG SHUREN UNIV

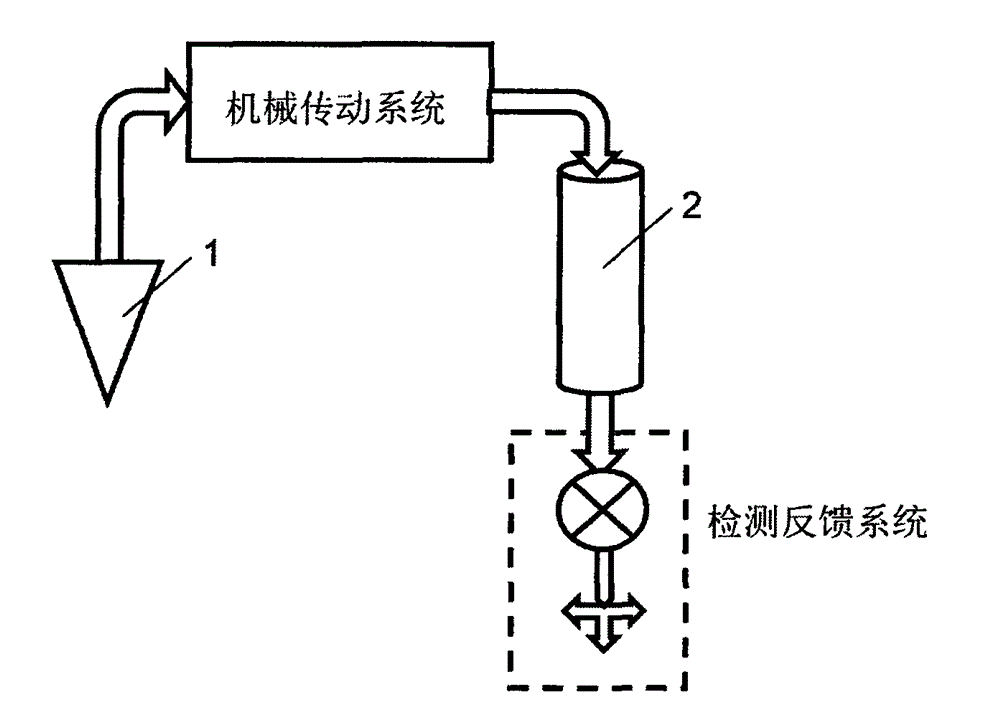

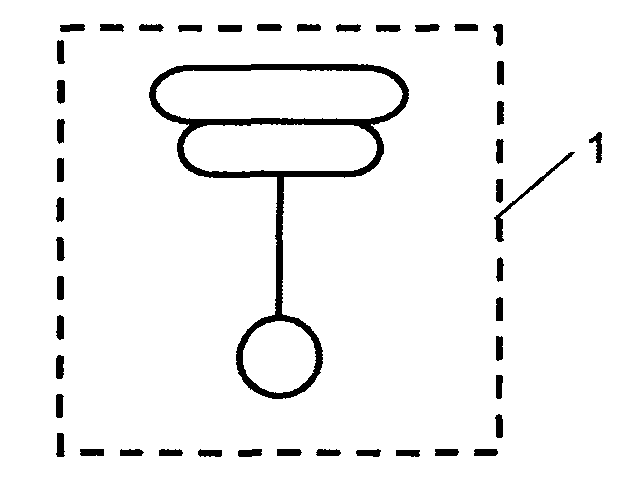

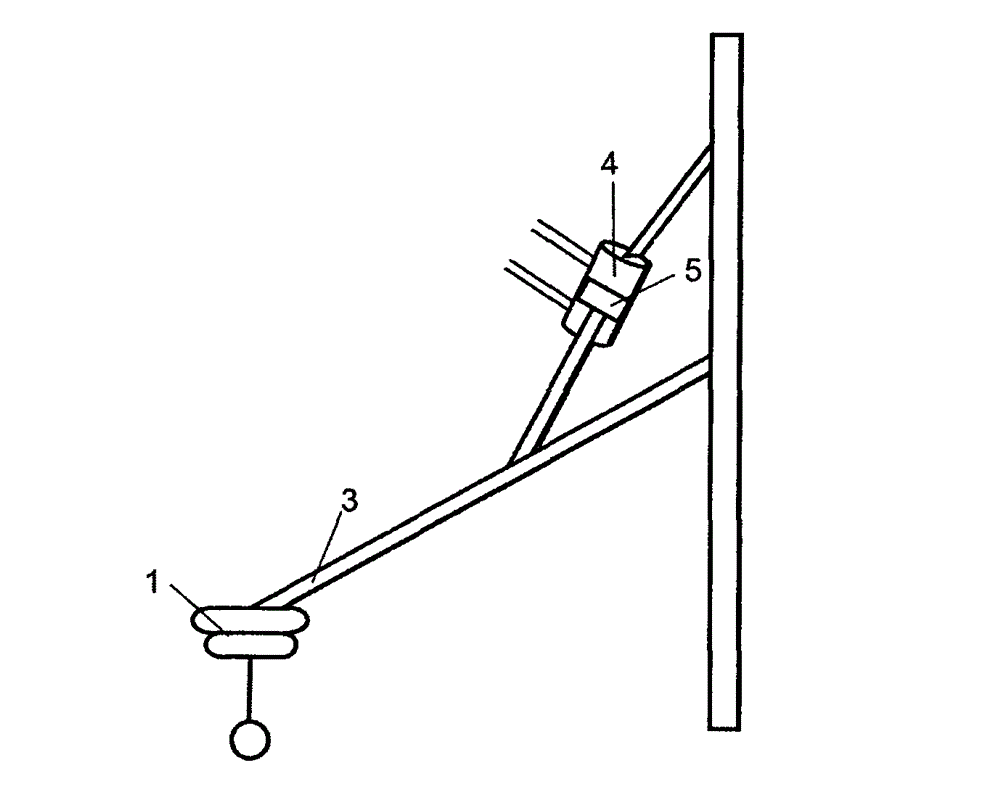

Ship-mounted wave energy seawater desalination apparatus

InactiveCN106277188AImprove energy efficiencyLow energy consumptionGeneral water supply conservationSeawater treatmentSeawaterCargo vessel

The invention relates to a ship-mounted wave energy seawater desalination apparatus, which comprises a wave energy collection module, an integrated membrane reverse osmosis desalination module and a detection feedback module, wherein the bracket of the wave energy collection module is formed by three narrow steel plates and a hinge, the lower end of the bracket is connected to a float, a piston type hydraulic cylinder is fixed on the bracket through the hinge, the inlet position of a water suction pipeline is provided with a filter, the outlet of the water suction pipeline is connected to the water inlet of the piston type hydraulic cylinder, the integrated membrane reverse osmosis desalination module comprises a hydraulic pipeline and three branch membranes, the three branch membranes respectively are an ultra-filtration pretreatment membrane, a Dow SW30-2540 main body membrane and a compensation membrane, the hydraulic pipeline is connected to the hydraulic cylinder and an integrated membrane system and is provided with four check valves, and the detection feedback module comprises a microcontroller development plate, a water flow meter, a salinity meter, an electromagnetic valve, and a connection pipe. According to the present invention, the ship-mounted wave energy seawater desalination apparatus has advantages of miniaturization and portability, can fully utilize the wave energy to desalinate seawater so as to provide fresh water required by the crew, and is suitable for ocean-going cargo ships.

Owner:ZHEJIANG UNIV

Energy-saving vehicle-mounted air purification device for new energy automobile

InactiveCN112389170AIn line with the concept of energy saving and environmental protectionGood purification effectAir-treating devicesNew energyIn vehicle

The invention belongs to the technical field of new energy vehicles, and particularly relates to an energy-saving vehicle-mounted air purification device for a new energy vehicle. The device comprisesa shell, an air inlet cylinder and a purification box are arranged in the shell, the air inlet cylinder is fixedly arranged on the inner bottom surface of the shell, and the purification box is fixedly connected to the inner top surface of the shell; an exhaust hole communicated with the purification box is formed in the top face of the shell, a dust filtering net is installed in the purificationbox, spray points are fixedly installed on the side walls of the two sides of the purification box respectively, the tip ends of the two spray points are right opposite and do not make contact with each other, and the top face and the bottom face of the air inlet cylinder are fixedly connected with an upper friction plate and a lower friction plate respectively. A balancing weight can slide backand forth in the air inlet cylinder under the inertia effect to suck air in a vehicle, dust and impurities in the air are filtered out through a dust filtering net, a good air purification effect is achieved, air discharge is broken down through the spray points, air negative ions are generated, and the purposes of cleaning and purifying the air are further achieved.

Owner:方飞

Dust-removing device for ceramic production line

InactiveCN108421340AAchieve reuseAvoid wastingUsing liquid separation agentTreatment involving filtrationProduction lineWater resources

The invention discloses a dust-removing device for a ceramic production line. The dust-removing device for the ceramic production line comprises a box body; a conveying belt is fixedly connected between a material inlet and a material outlet; a hole is formed in the upper end of the box body; a water spray pipe is fixed in the hole in a sleeving connection mode; the lower end of the water spray pipe is fixedly communicated with a fan-shaped spray head; the inner wall of the upper end of the box body is fixedly connected with a supporting rod; the lower end of the supporting rod is fixedly connected with a hairbrush; the right side wall of the box body is fixedly connected with a flow guide plate; the upper surface of the bottom of the box body is fixedly connected with a partition plate; agroove in the partition plate is rotatably connected with a drainage groove through a rotating shaft; the interior of the drainage groove is fixedly connected with a filtering device; a water outletis formed in the bottom of the right side wall of the box body; the water outlet is fixedly communicated with a circulating water pipe; a water pump is arranged on the circulating water pipe; the circulating water pipe is fixedly communicated with a water tank; the water tank is fixedly communicated with the water spray pipe; an opening is formed in the bottom of the left side wall of the box body; a collecting box is inserted into the opening. The dust-removing device for the ceramic production line saves water resources and facilitates dust treatment.

Owner:张耀忠

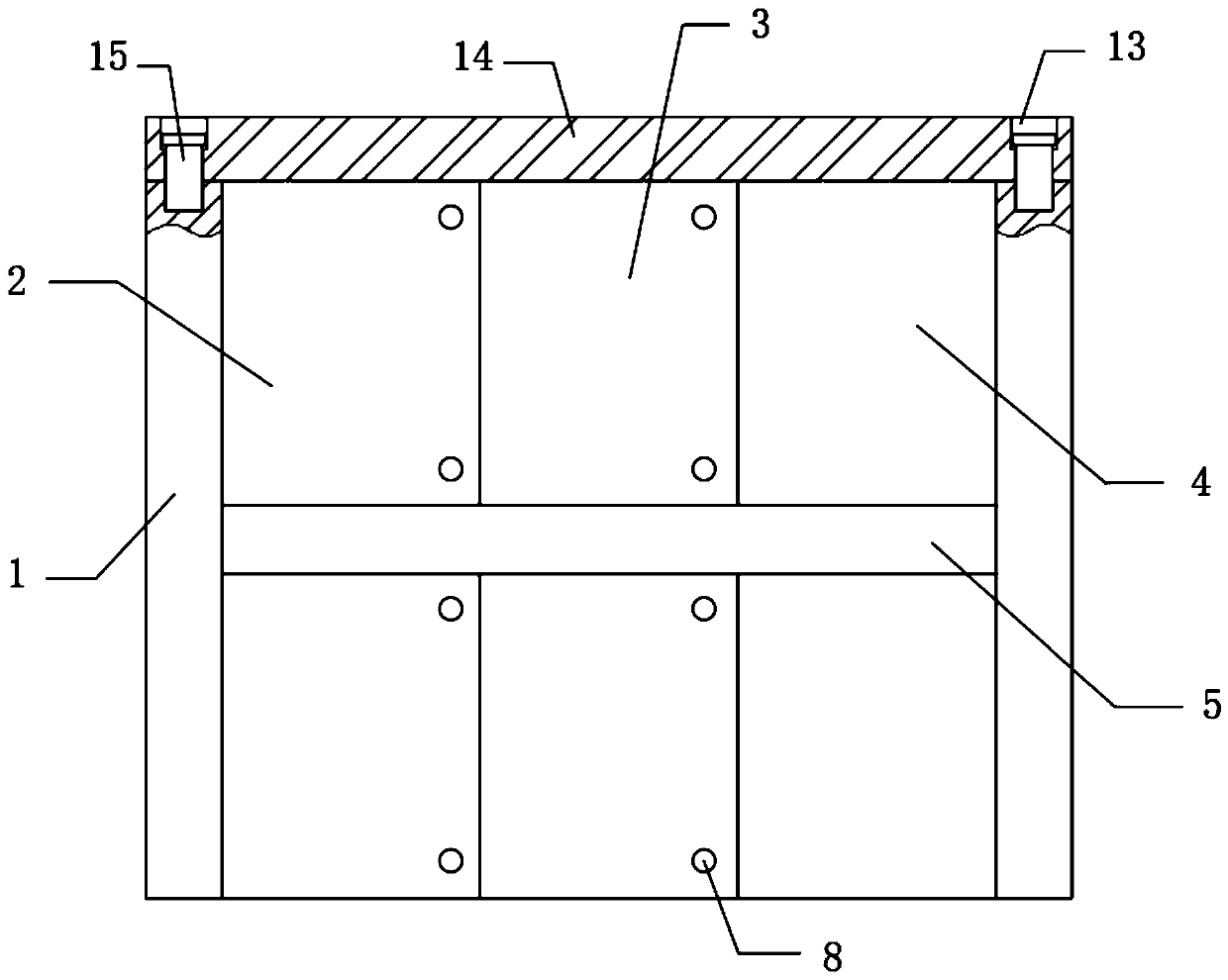

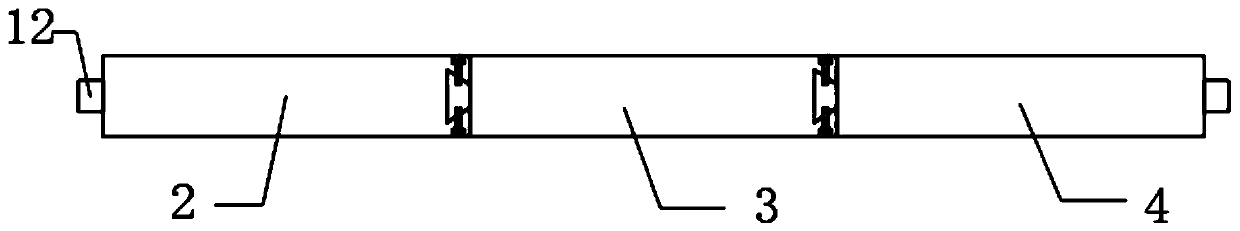

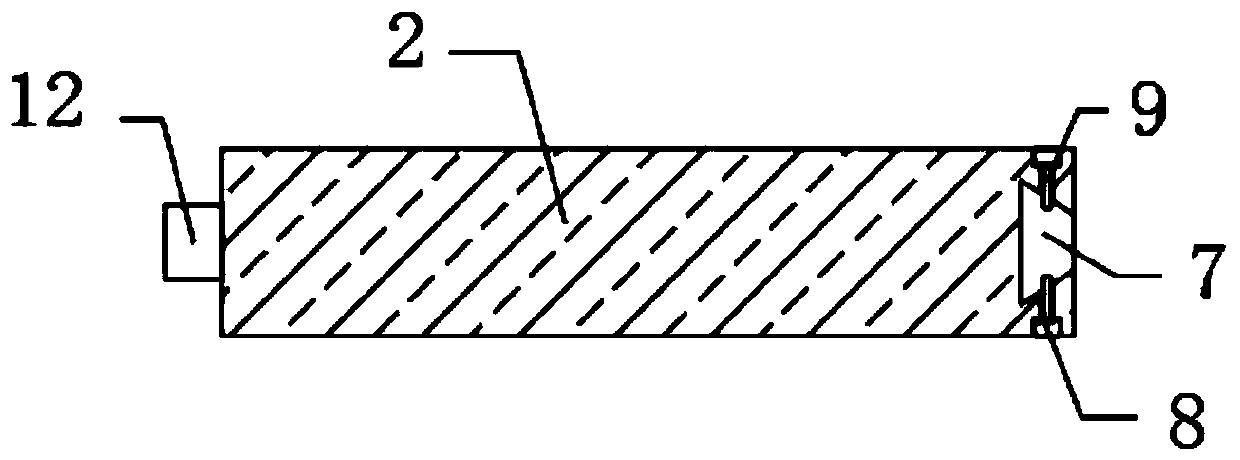

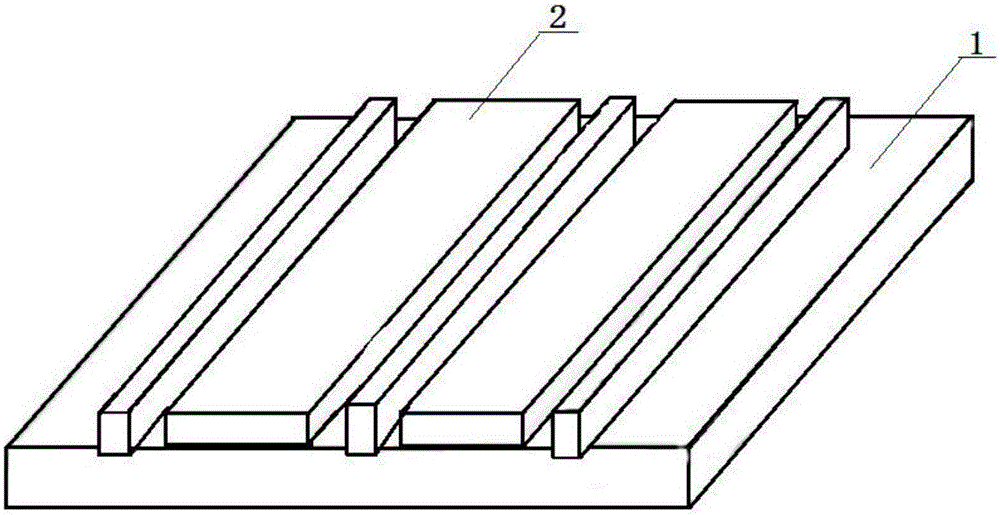

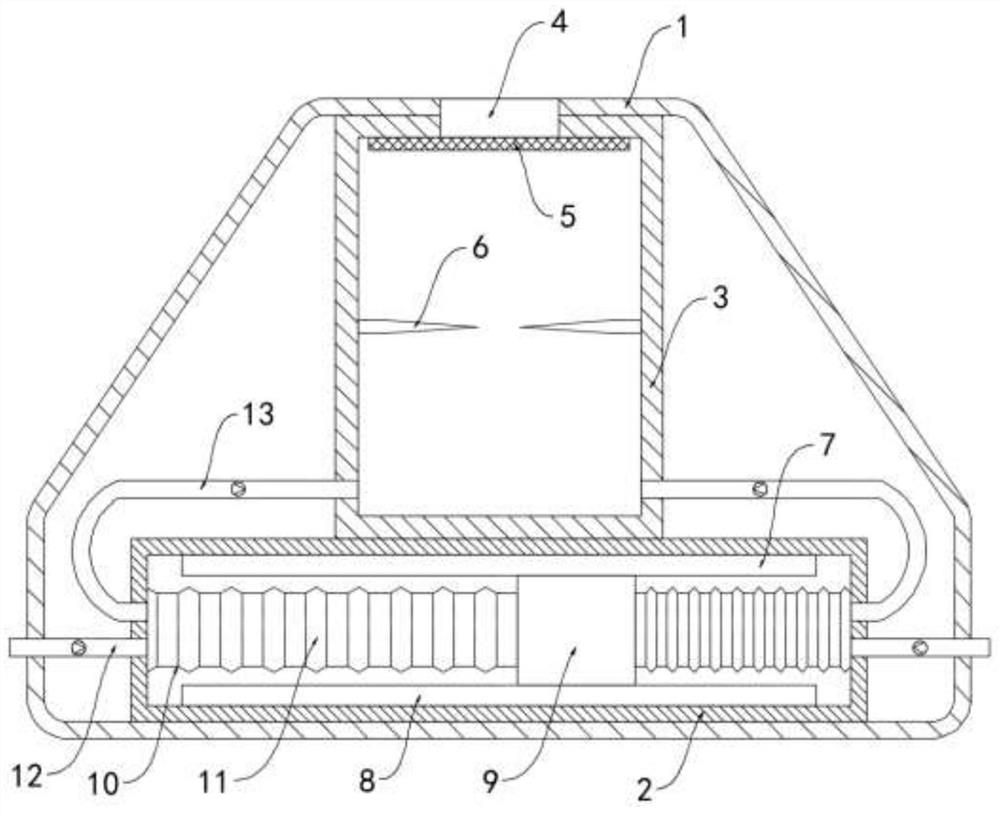

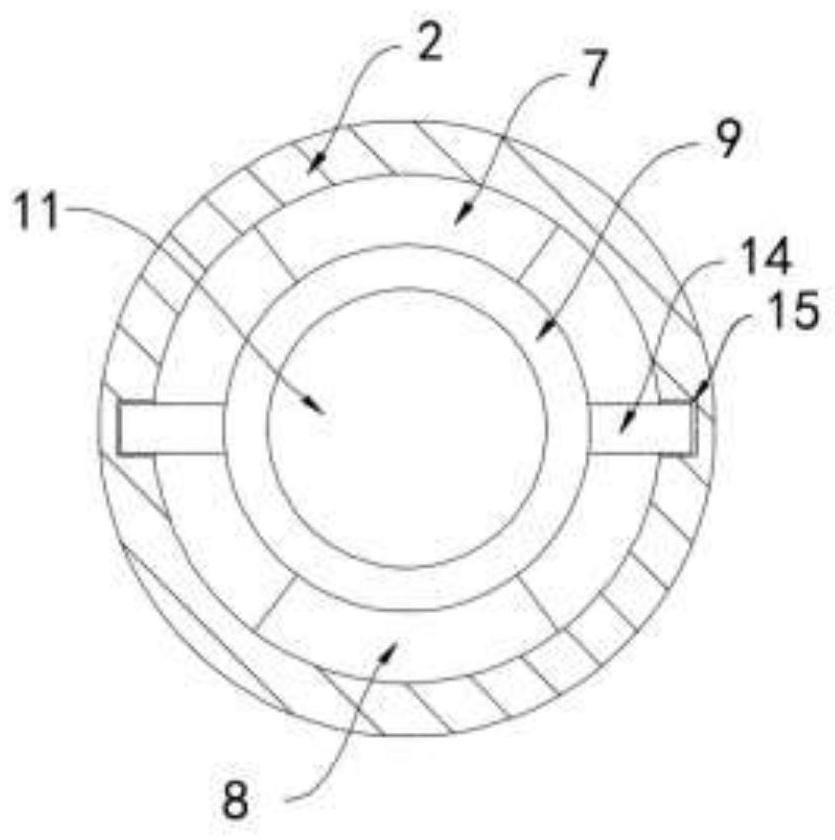

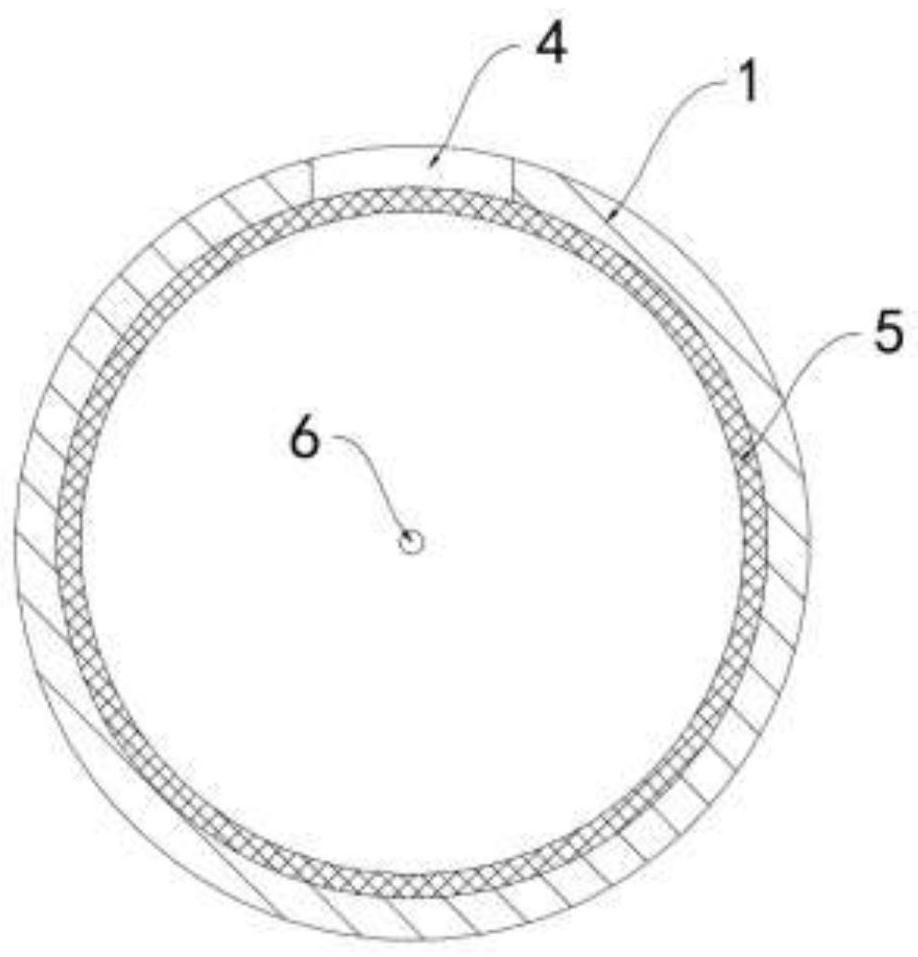

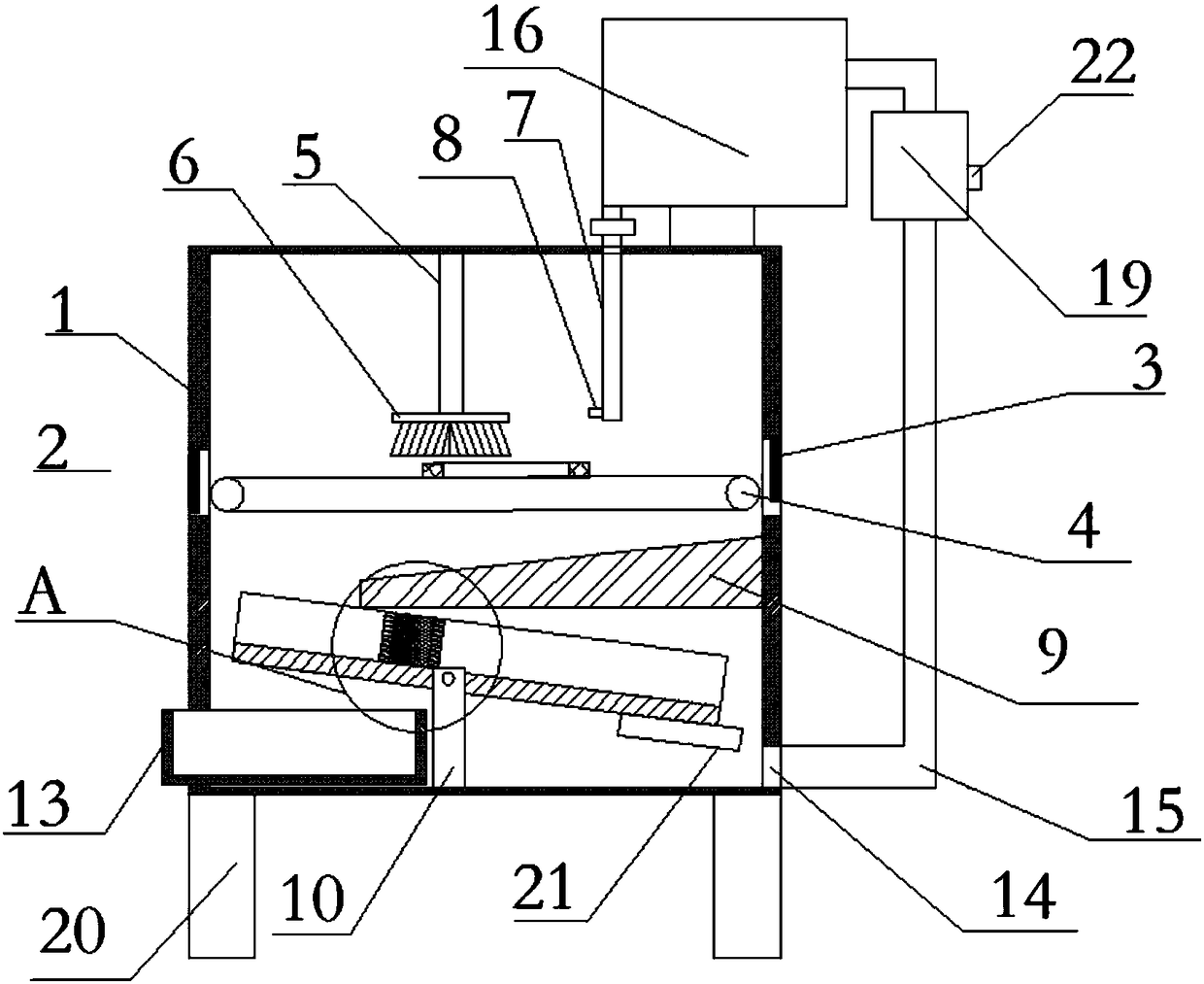

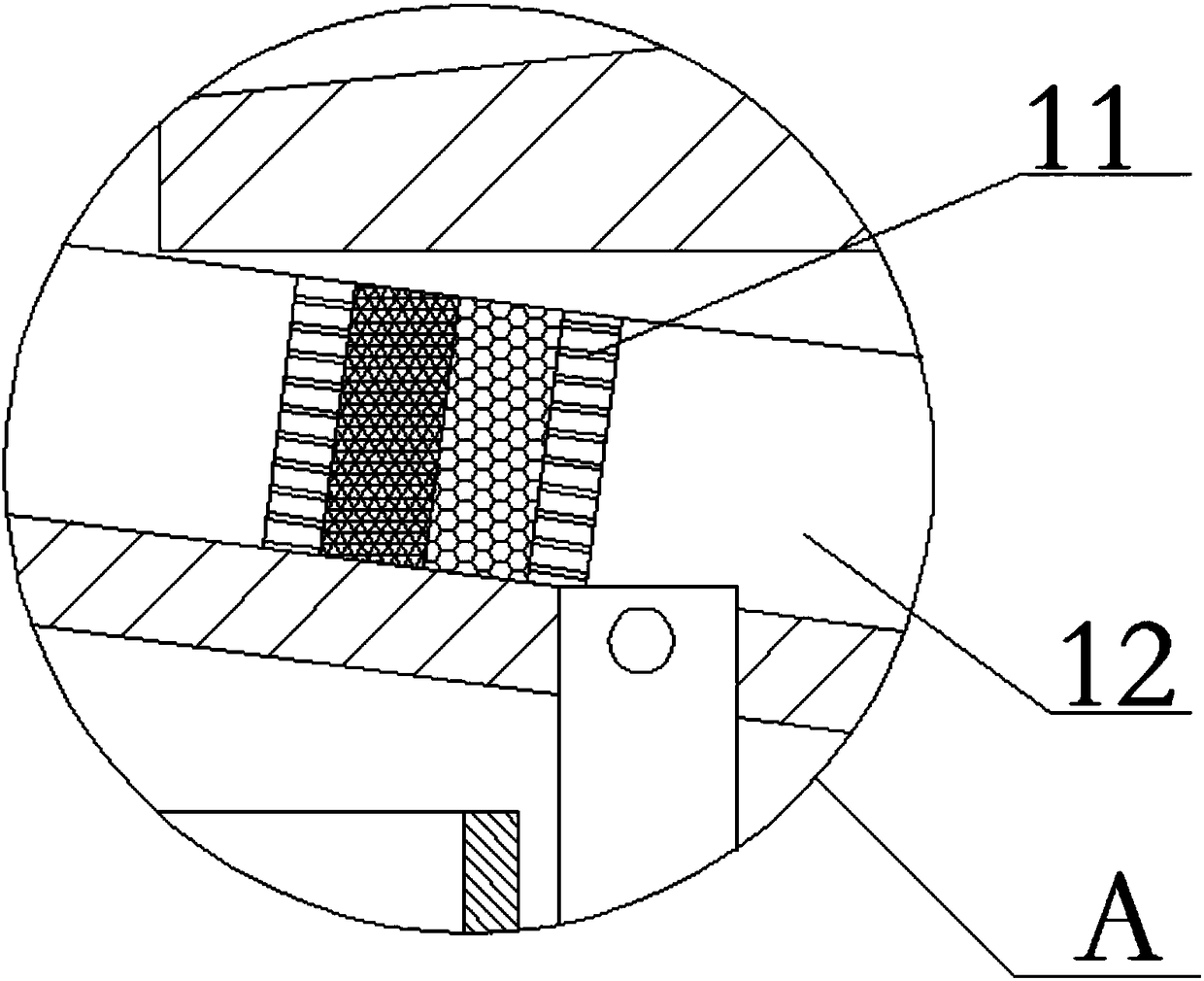

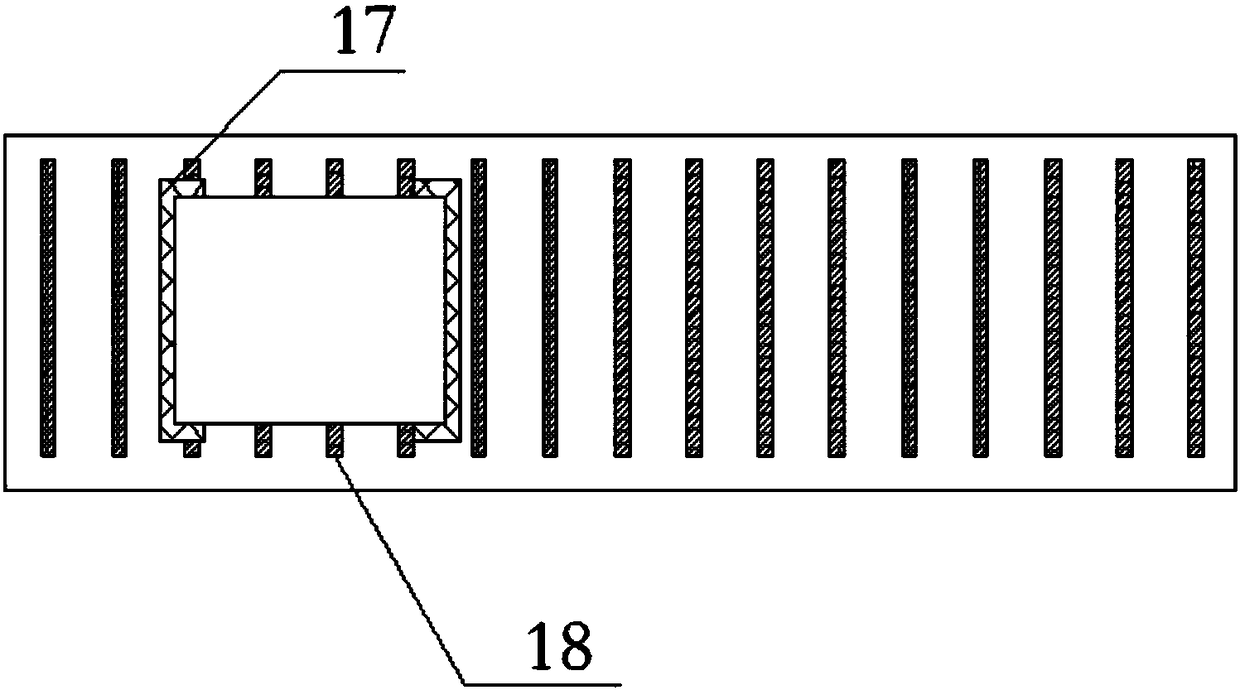

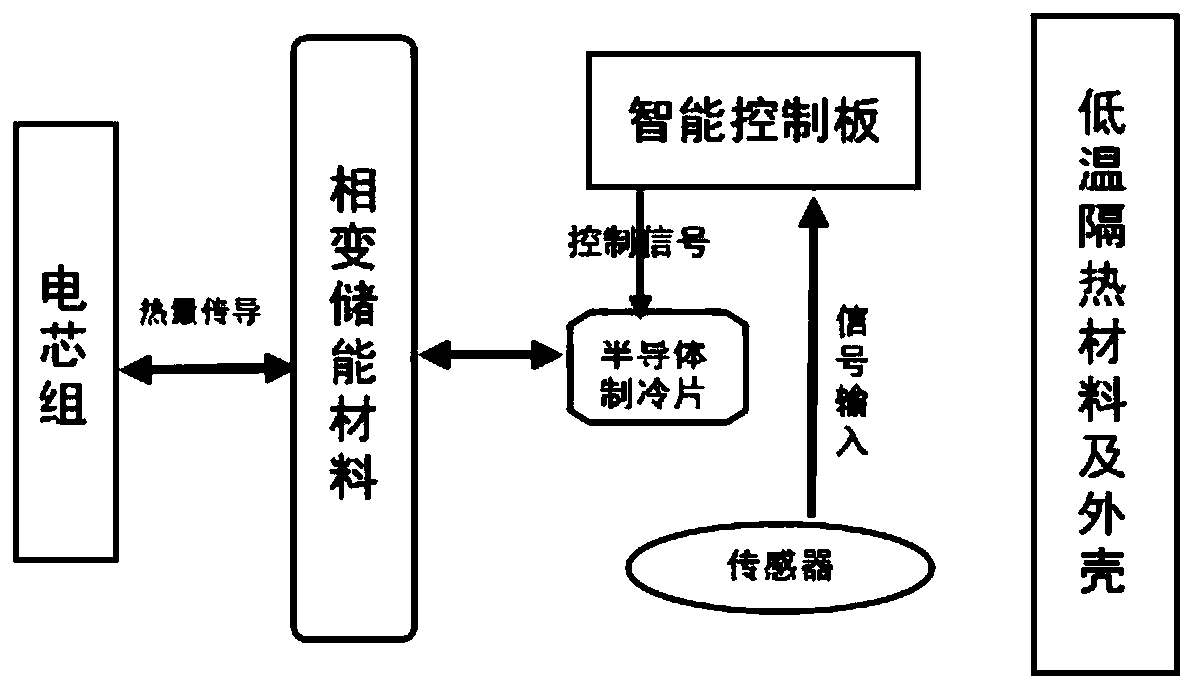

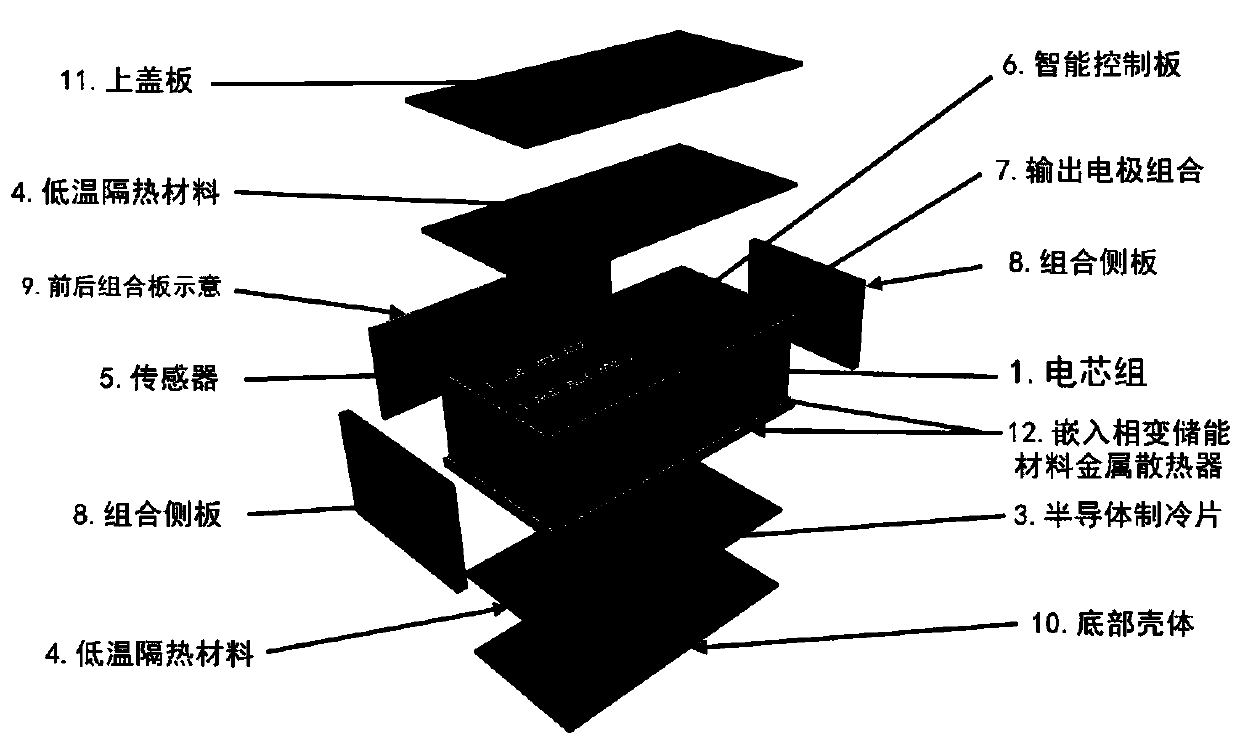

Low-temperature-resistant battery module

InactiveCN110649193AGuaranteed capacityExtend your lifeSecondary cellsCell component detailsThermodynamicsEngineering

The invention discloses a low-temperature-resistant battery module. The low-temperature-resistant battery module is characterized in that irregular gaps and concave-convex surfaces are filled among aplurality of battery cores of a battery core set (1) by adopting a heat conduction joint filling material (2) with electrical insulation and vibration reduction performance; secondly, phase change energy storage material specially-made radiators (12) are tightly arranged and embedded at the periphery and the bottom of the treated battery core set (1); low-temperature heat insulation materials (14)are arranged on the periphery and at the bottom of the phase change energy storage material specially-made radiators (12), semiconductor chilling plates are arranged on the periphery and at the bottom of the phase change energy storage material specially-made radiators (12) in an embedded mode, low-temperature heat insulation materials (4) are arranged on an upper portion of the battery core set(1), and lastly, an outer shell box body composed of reinforcing materials such as metal is arranged outside the low-temperature heat insulation materials. The low-temperature-resistant battery moduleis advantaged in that heat energy in the battery module is fully utilized, active heating is carried out to maintain the temperature environment of the battery core under the condition of low power consumption, the low-temperature-resistant battery module is realized, and the charging frequency, the charging amount and the charging time of the battery core can be saved.

Owner:王建国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com