Chlorination section byproduct hydrogen chloride gas absorption and purification acid-forming system and process

A technology for purifying hydrogen chloride gas and tail gas, which is applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of high energy consumption, large equipment investment, low economic benefits, etc., and achieves large amount of hydrochloric acid and high dechlorination efficiency. , the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further understand the content of the present invention, the present invention is described in detail in conjunction with examples, and the following examples are used to illustrate the present invention, but are not used to limit the scope of the present invention.

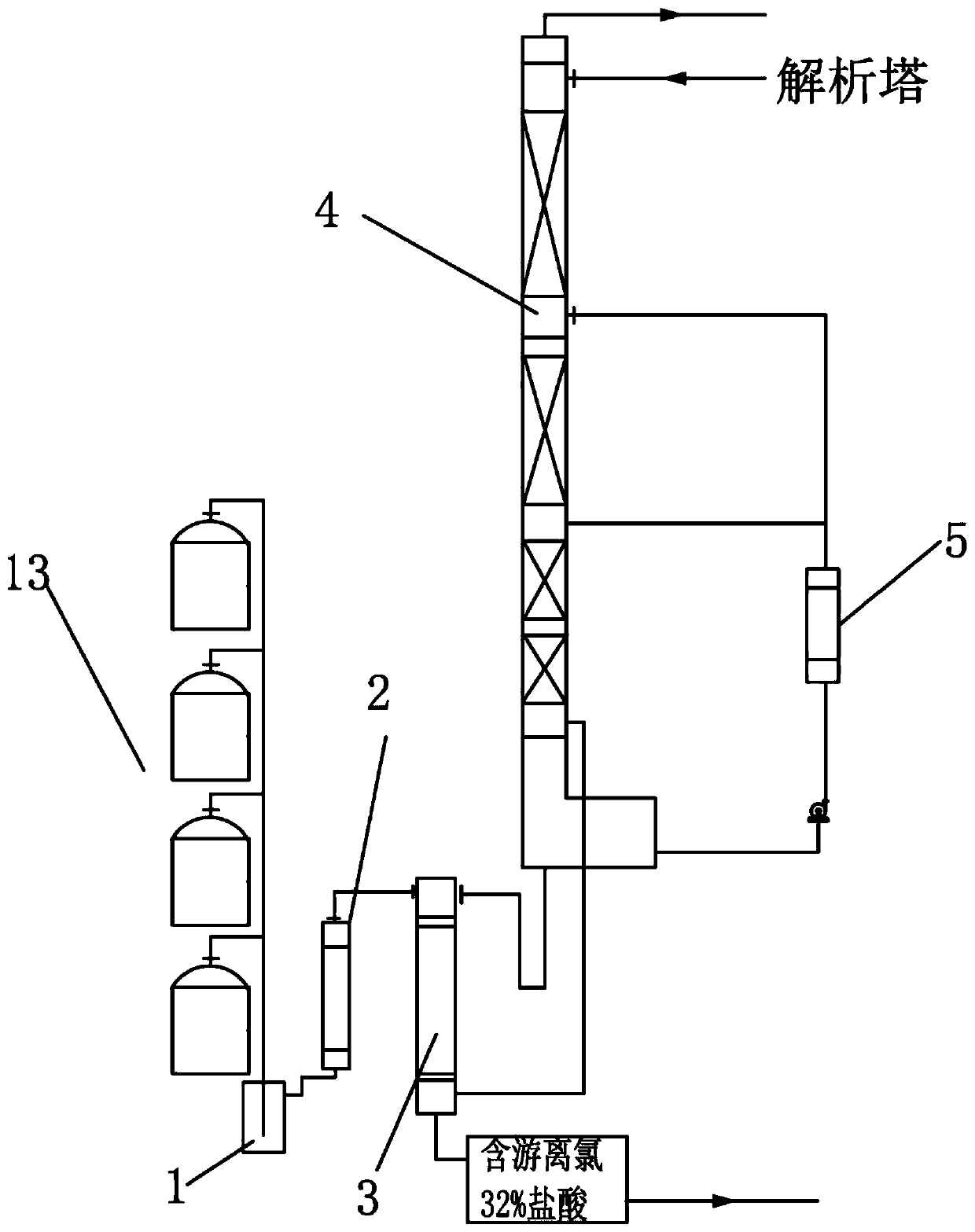

[0036] like figure 1 and figure 2 As shown, the present embodiment relates to a system for absorbing and purifying by-product hydrogen chloride gas in the chlorine generation section into an acid system, which is used to process the hydrogen chloride gas generated in the chlorination reactor 13, which includes interconnected tail gas purification into acid system, dechlorination The washing device and the analysis and concentration device, the tail gas purification into acid system includes a washing tank 1, a cooler 2, a falling film absorber 3 and a first absorption tower 4 connected in sequence, and the dechlorination washing device includes a sequential connection steam heater 6, dechlori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com