Comprehensive recovery method for heat energy and water from printing and dyeing industry wastewater and heat-exchanging system

A technology for heat exchange devices and industrial wastewater, applied in chemical instruments and methods, textile industry wastewater treatment, adsorption water/sewage treatment, etc., can solve problems such as waste of resources, save consumption, ensure heat exchange effect, and restore heat exchange effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

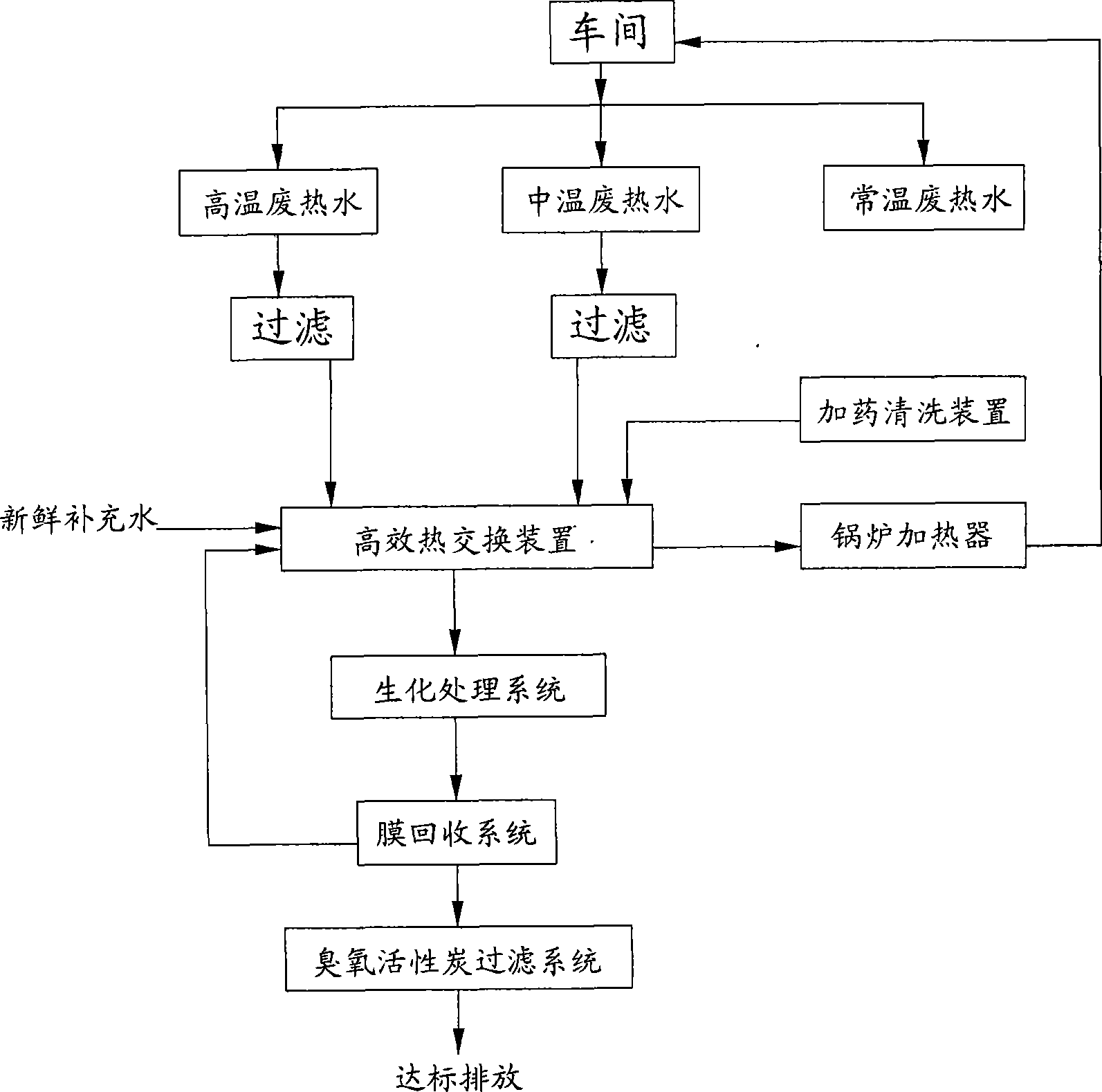

[0033] Example: a structure such as figure 1 Shown, a kind of thermal energy and water comprehensive recovery method in the printing and dyeing industry wastewater, its steps are as follows:

[0034] ①. The printing and dyeing wastewater discharged from the workshop is divided into three types of water according to its different temperatures (that is, the recycling value of heat energy) at normal temperature, medium temperature and high temperature, and the normal temperature, medium temperature and high temperature wastewater are collected and transported to the collection pool for classification and collection. It is normal temperature, 40-70 degrees is medium temperature, and above 70 degrees is high temperature;

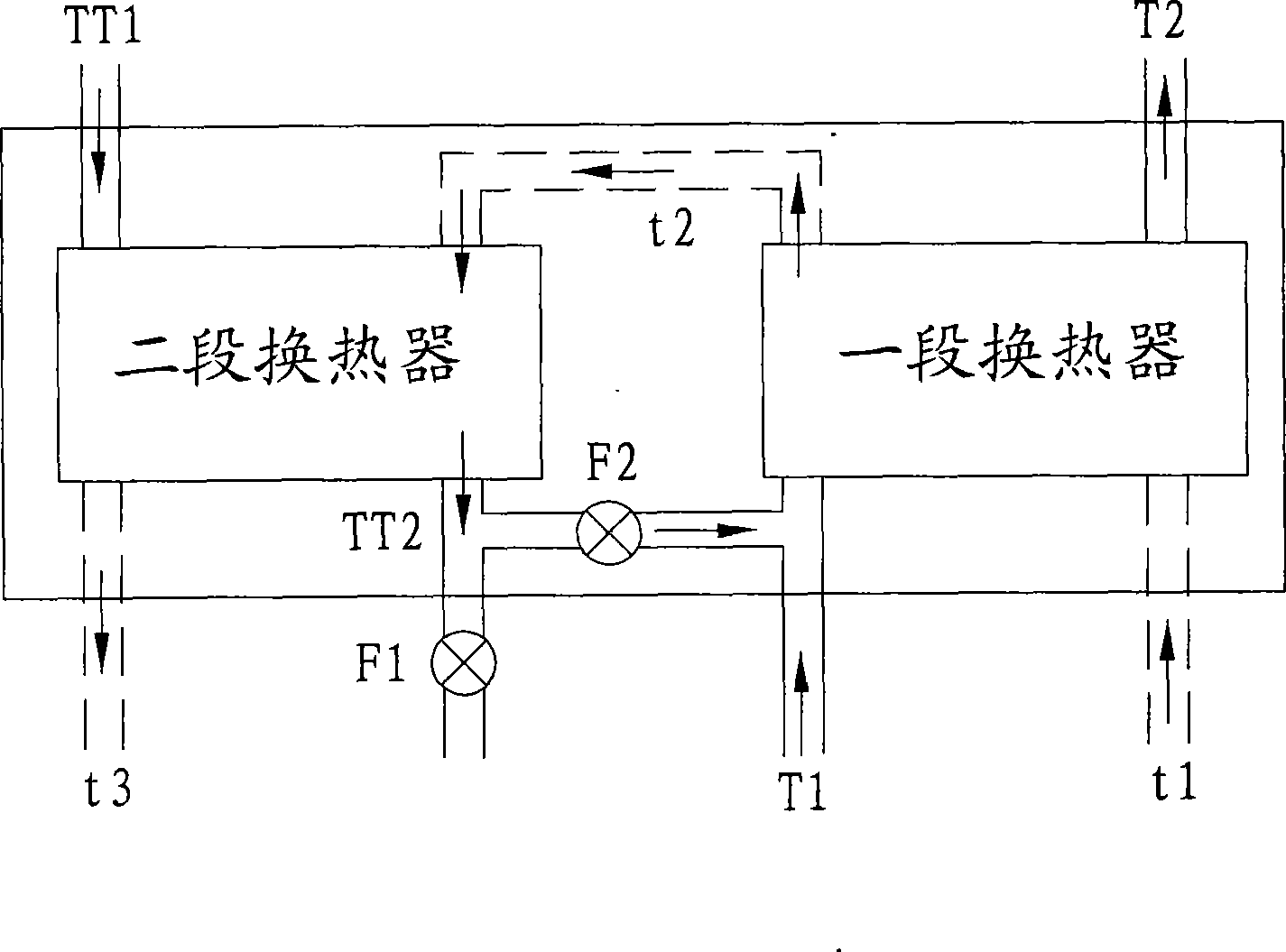

[0035] ②. The medium and high temperature waste water is filtered to remove impurities and then enters the high-efficiency heat exchange device to exchange heat with the cold water source, so that the temperature of the cold water source can be pre-increased befo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com