Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

85results about How to "Control liquid level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

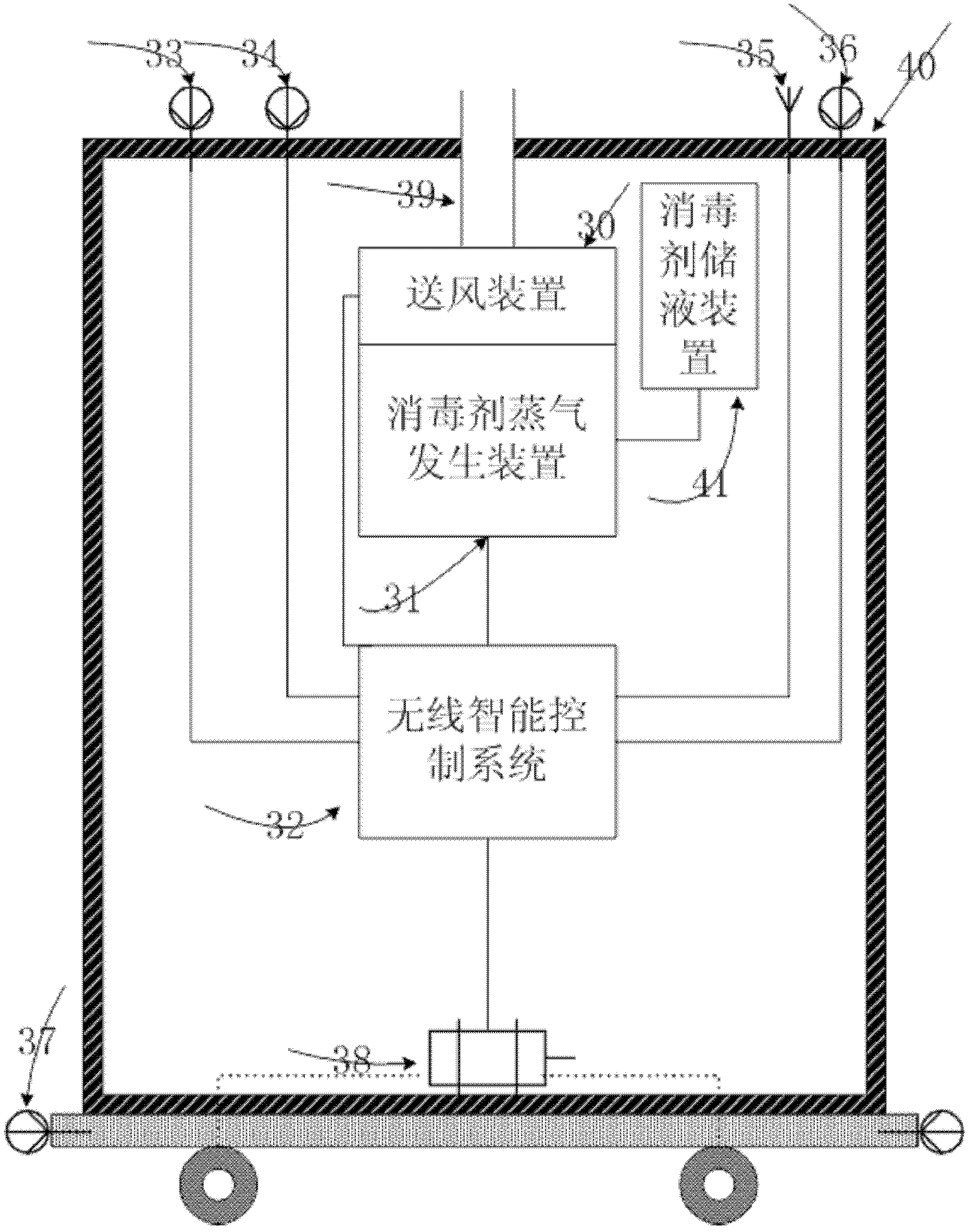

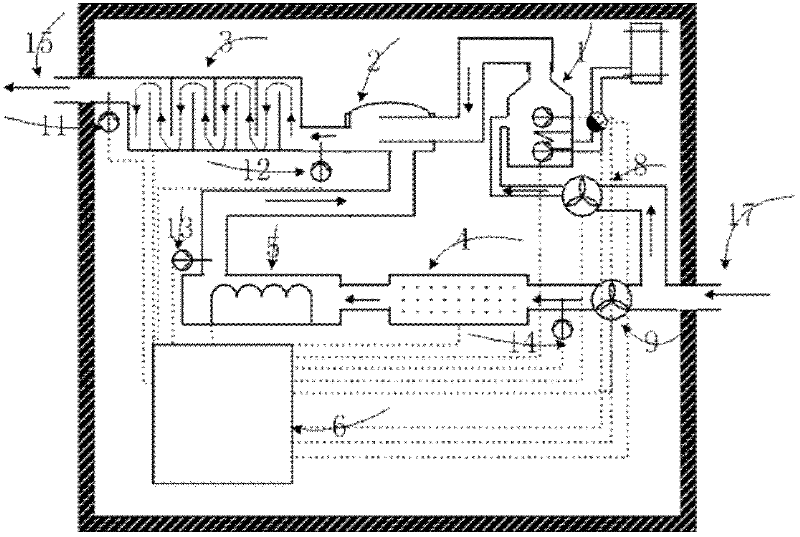

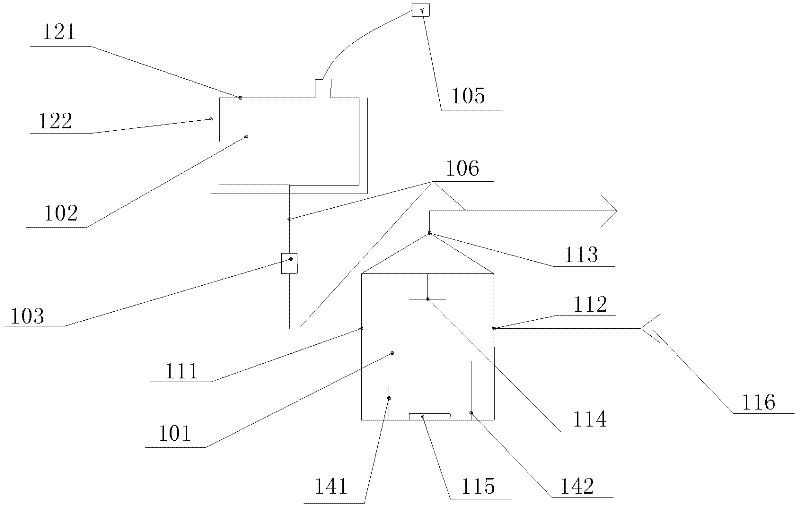

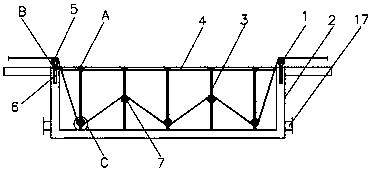

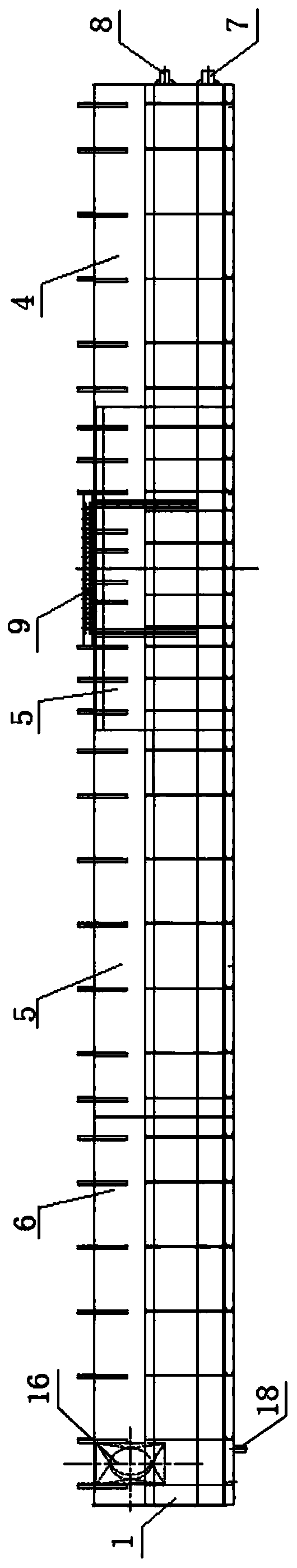

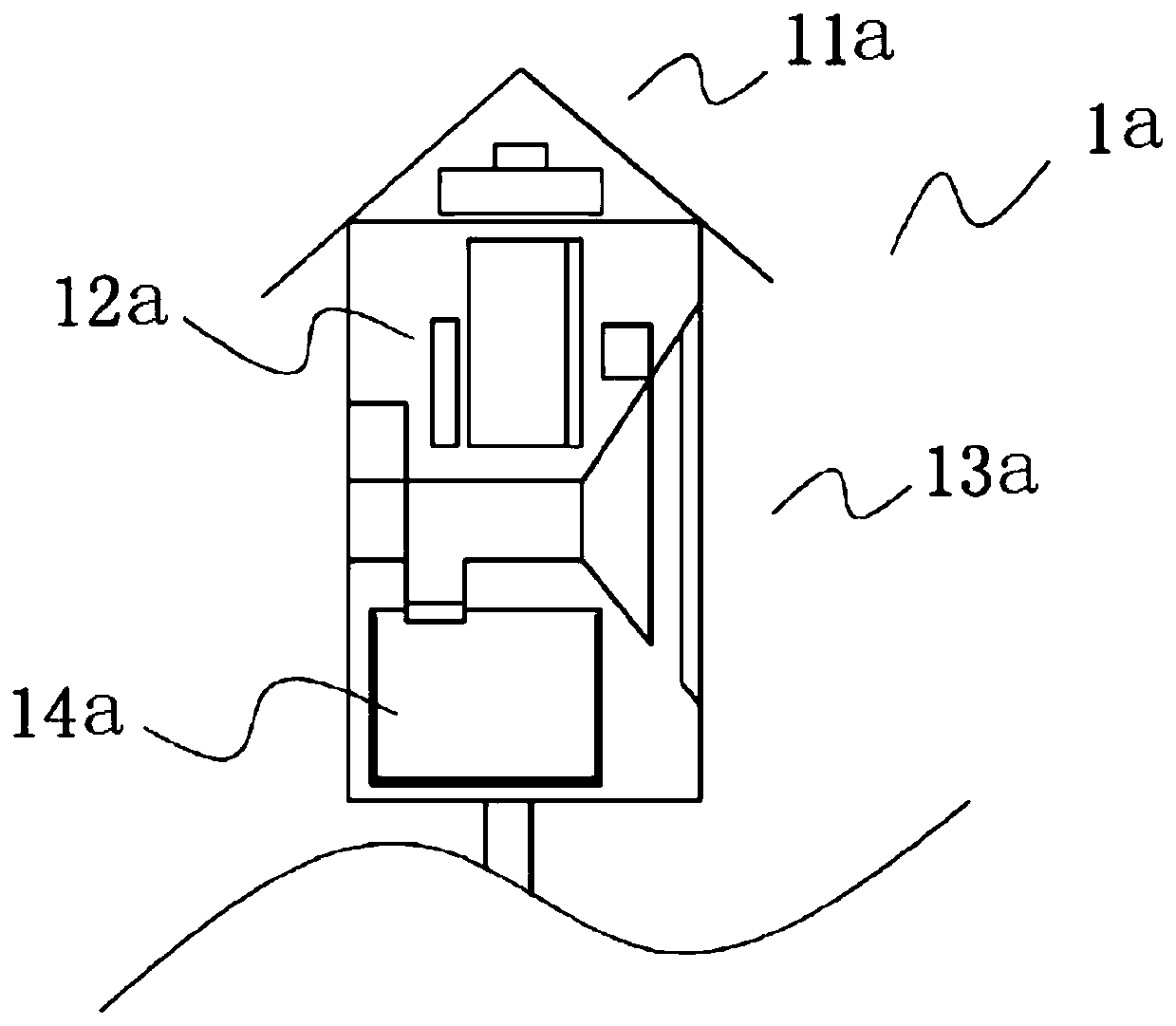

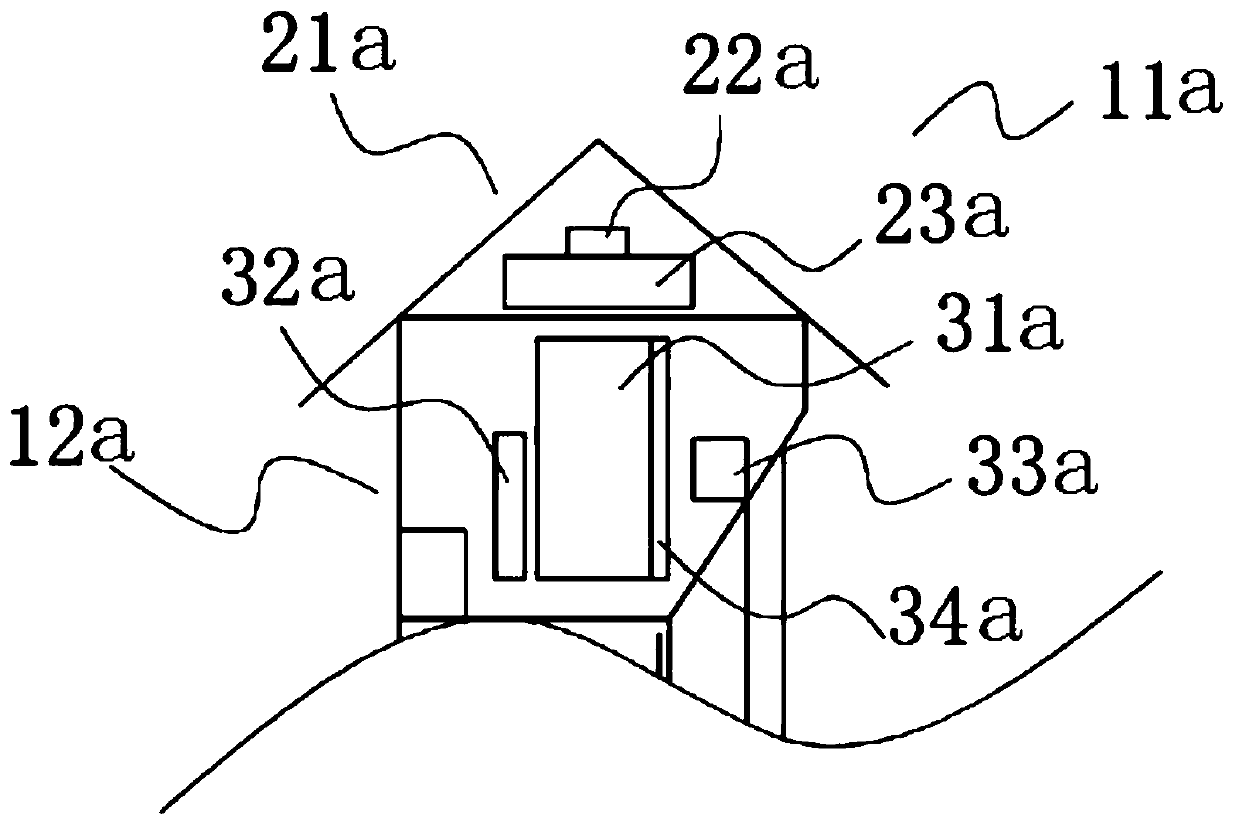

Mobile type indoor disinfectant vapor disinfection system

InactiveCN102423496AImprove disinfection efficiencyEasy to controlLavatory sanitoryDeodrantsThree levelEngineering

The invention relates to a mobile type indoor disinfectant vapor disinfection system, which comprises a disinfectant vapor generation device, a wireless intelligent control system, a power-driven device, an environmental monitoring device, an air supply device, a mobile device and a disinfectant storage device. The disinfectant vapor generation device comprises a disinfectant vapor three-level refinement system, a filtering and catalyzing integrated system and a vapor generation control device; the air supply device supplies secondary power for scattering vapor in a space; and the wireless intelligent control system is communicated with the environmental monitoring device, the air supply device and the power-driven device so as to finish the operations of controlling the disinfectant vapor generation device, acquiring environmental parameters, and switching on / off the air supply device and the power-driven device in a disinfection target. The mobile type indoor disinfectant vapor disinfection system can intelligently, comprehensively and efficiently finish the disinfection operation of a closed space of large-sized equipment and is particularly suitable for the disinfection operation of a closed space with long and narrow passages, so that the mobile type indoor disinfectant vapor disinfection system has the advantages of strong maneuverability, high disinfection efficiency, no secondary pollution, and the like.

Owner:中国人民解放军防化学院 +1

Method for improving rapid continuous casting tundish change success rate

The invention discloses a method for improving the rapid continuous casting tundish change success rate. The method comprises the following steps that firstly, the waiting time for which a steel ladlefully contains molten steel is 5-10 min, and the temperature that the steel ladle reaches a continuous casting platform is 1,590-1,600 DEG C; secondly, the work tundish molten steel pull rate is reduced by one gear at the interval of 20 s, and the pull rate of a continuous casting machine is reduced to 0.3 m / min within 8 min; thirdly, the work tundish liquid level is measured, and when work tundish pouring is stopped, a standby tundish car and a work tundish car conducting pouring are started towards the other side at the same time; fourthly, after the standby tundish car is driven to the pouring station, an infrared immersing type water gap is rapidly installed; fifthly, after preparation of the standby tundish car is finished and 10 tons of molten steel is poured, 150-200 kg of a covering agent is added into a standby tundish; sixthly, when the steel ladle pours 20 tons of molten steel into the standby tundish, the molten steel is injected into a crystallizer; and after the standbytundish starts pouring, the continuous casting pull rate starting operation is conducted. By means of the method, the rapid continuous casting tundish change time is shortened, the rapid continuous casting tundish change success rate is increased, the continuous casting machine operation rate is increased, the production cost is reduced, and the labor intensity of workers is relieved.

Owner:XINJIANG BAYI IRON & STEEL

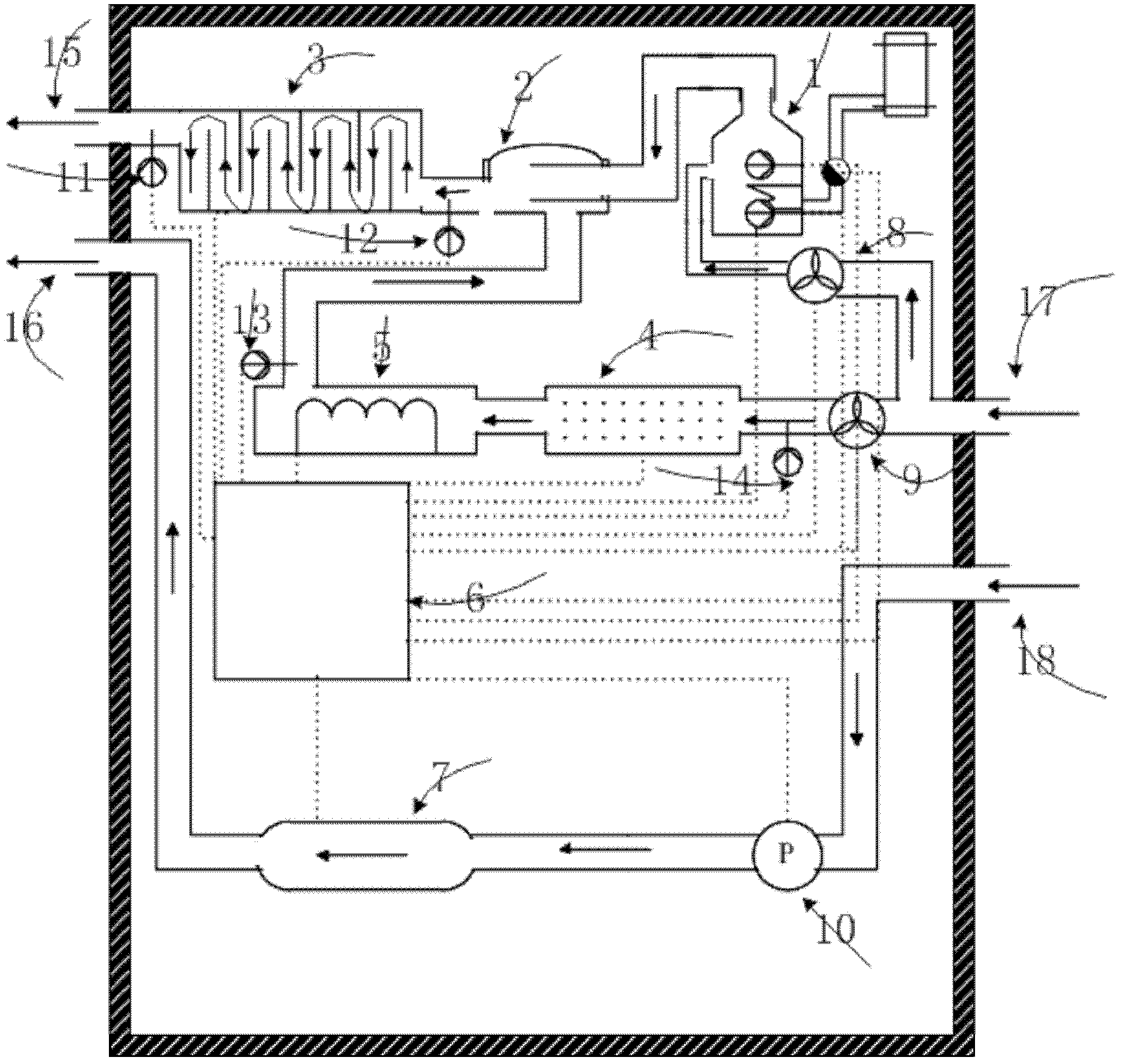

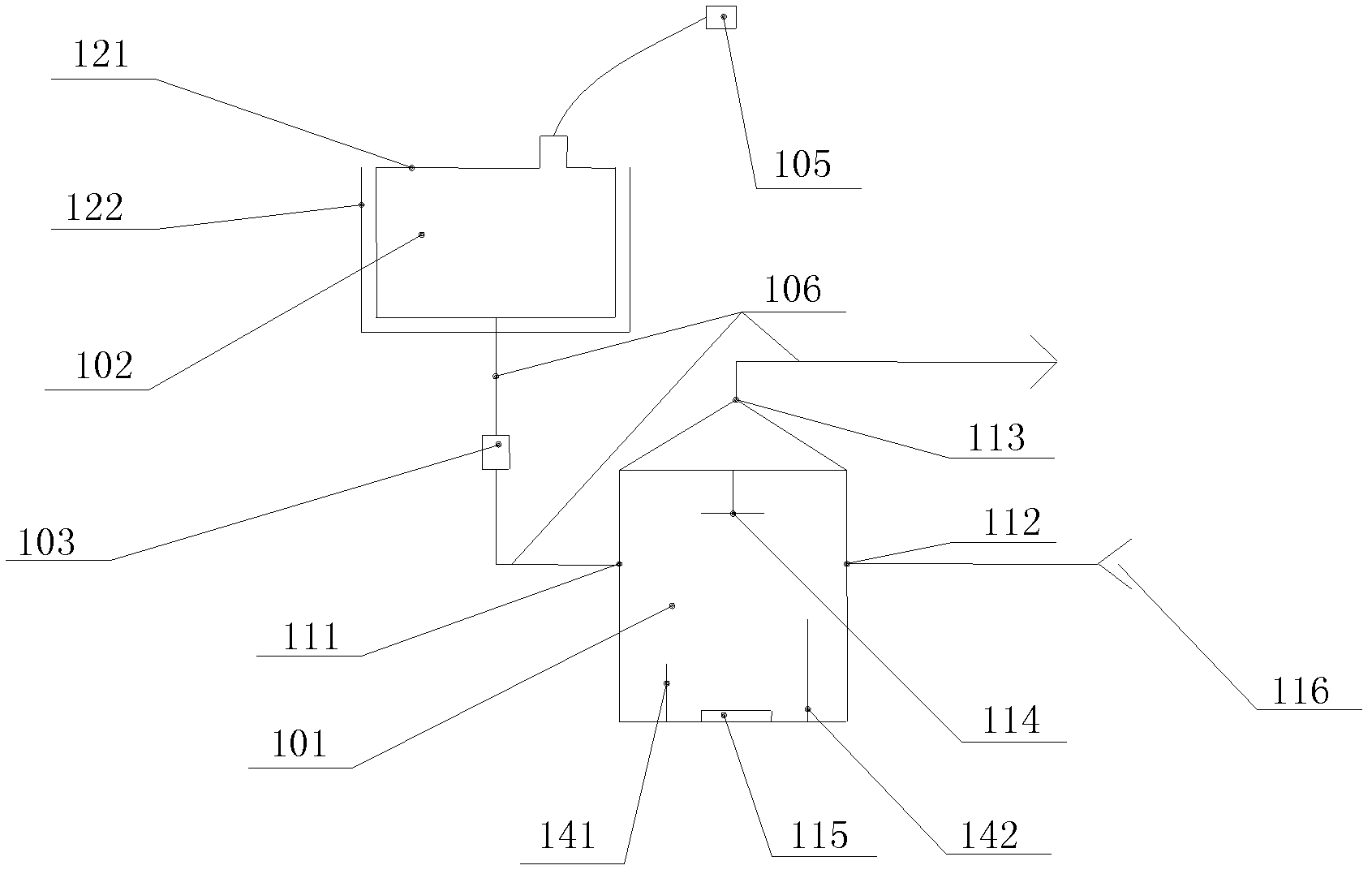

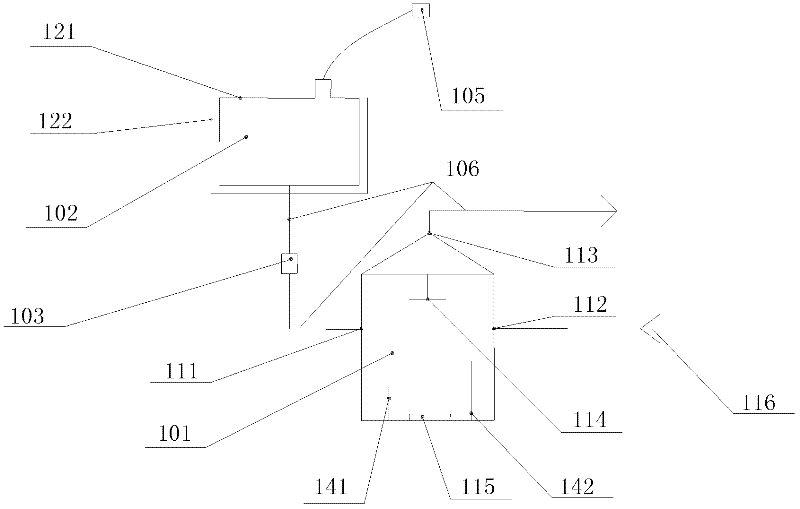

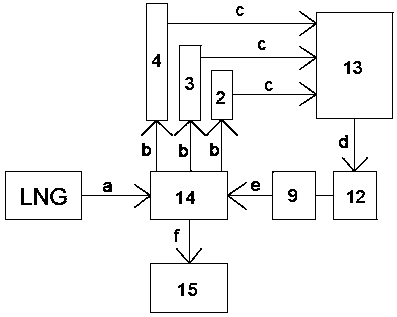

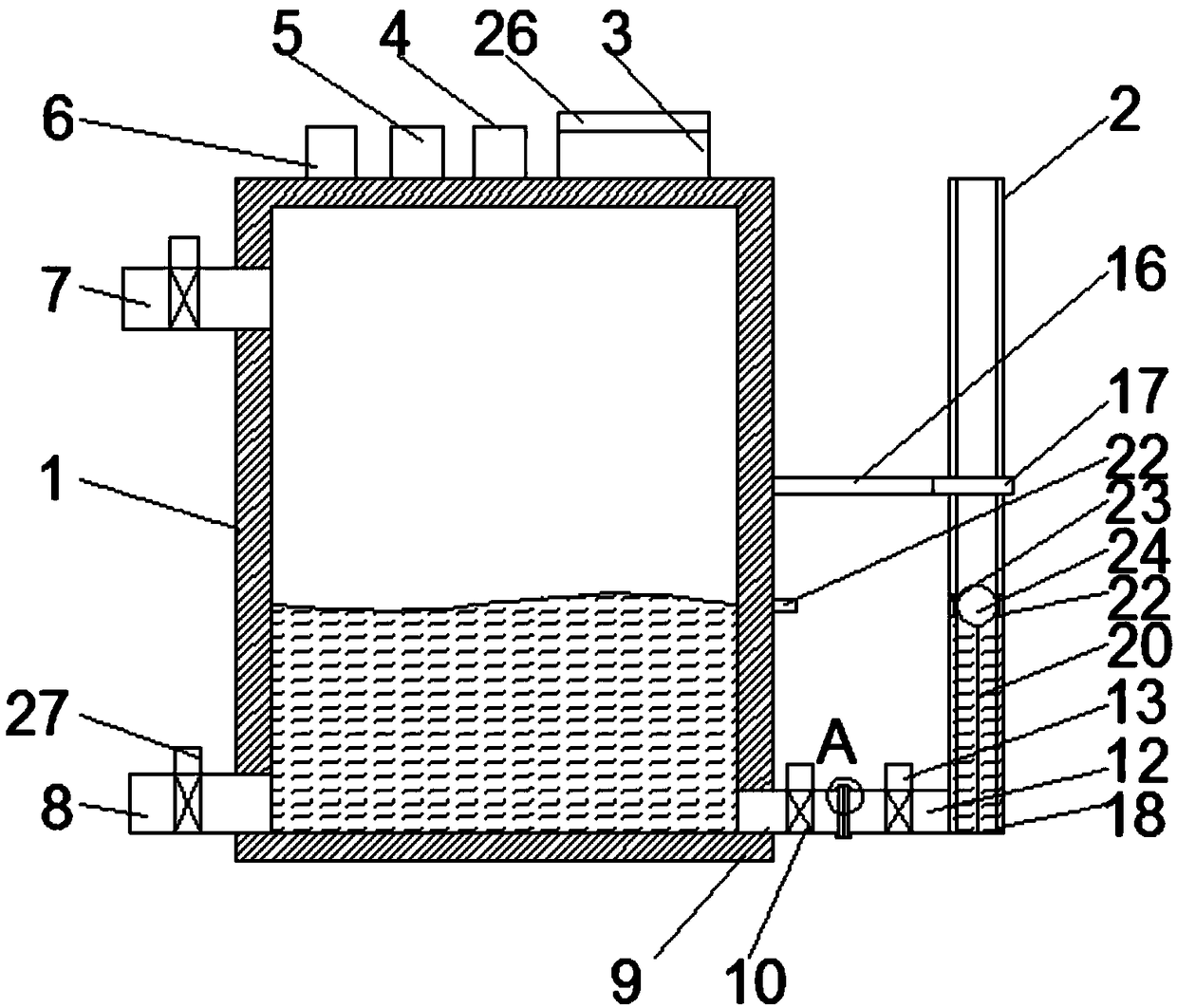

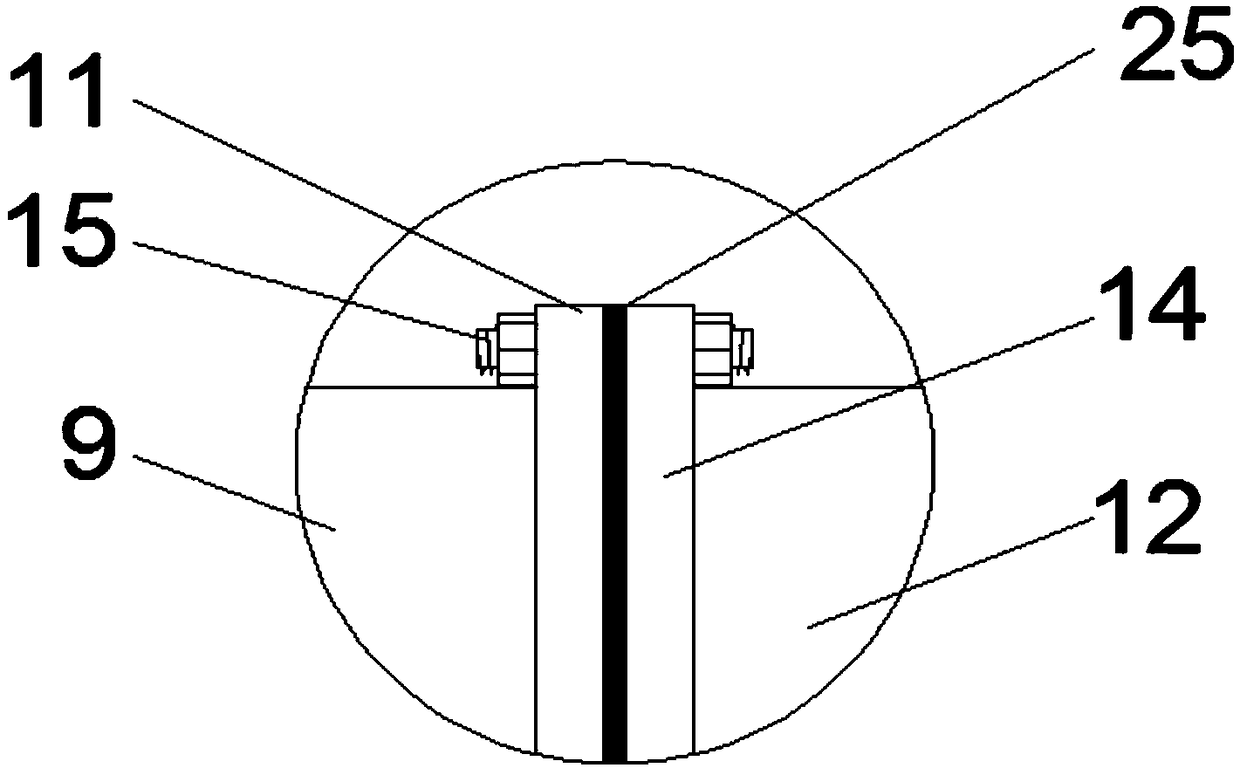

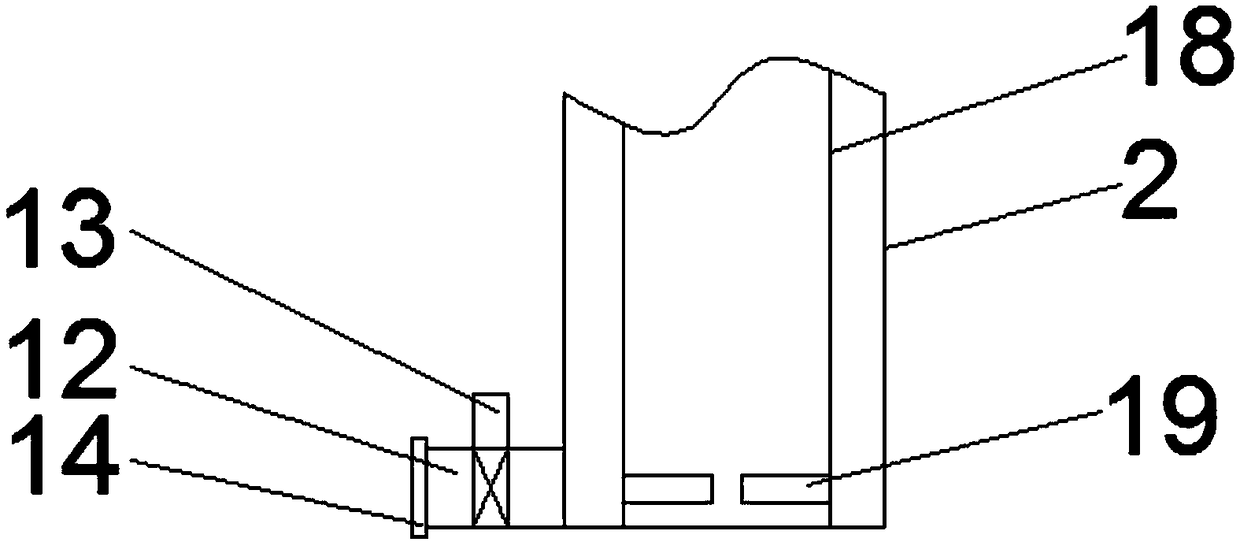

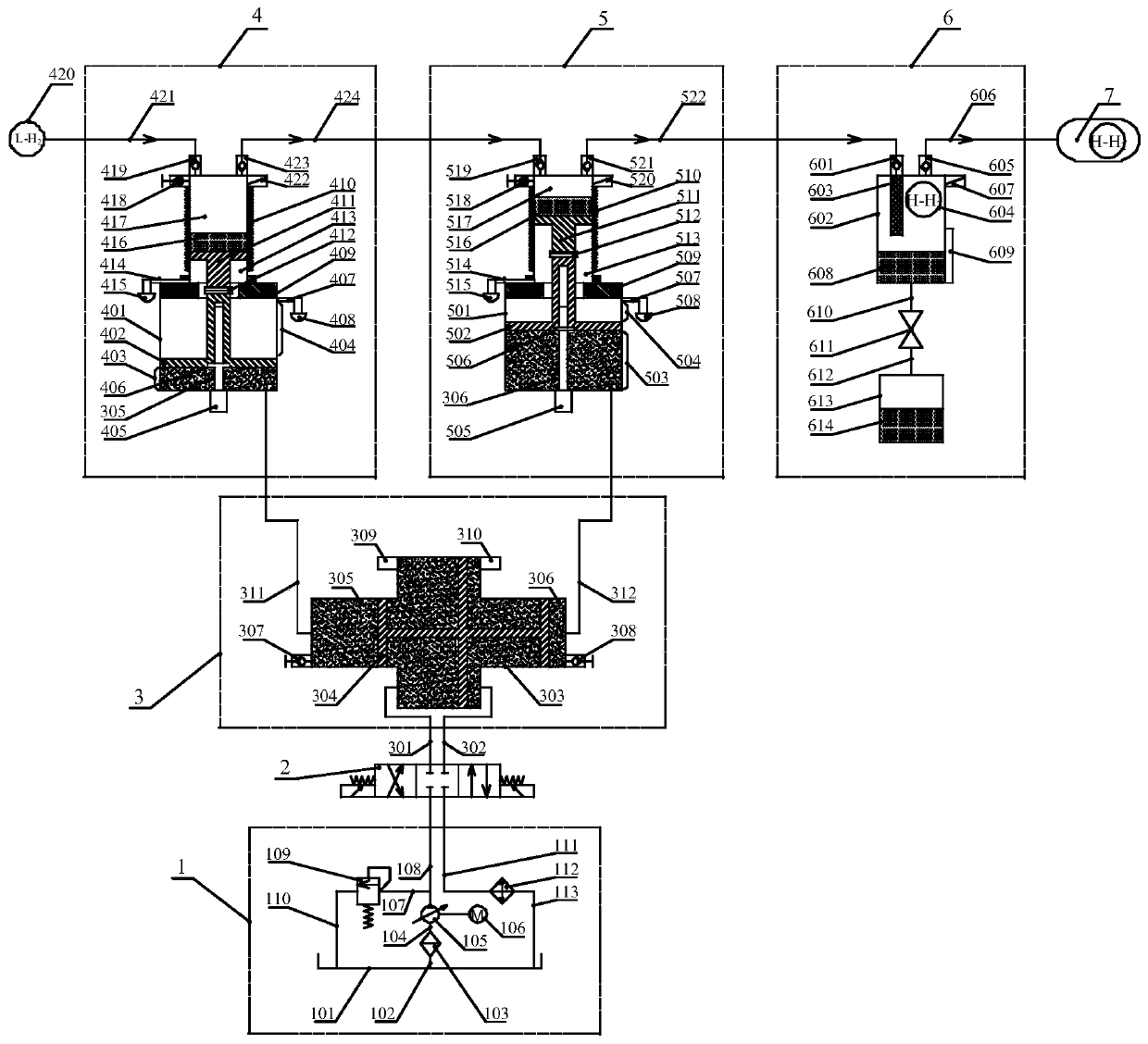

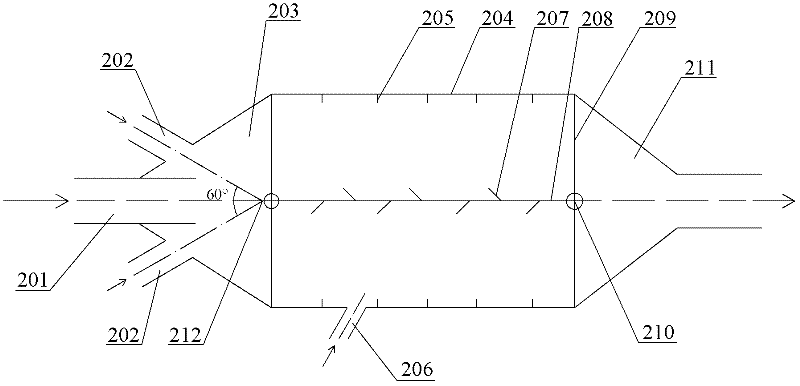

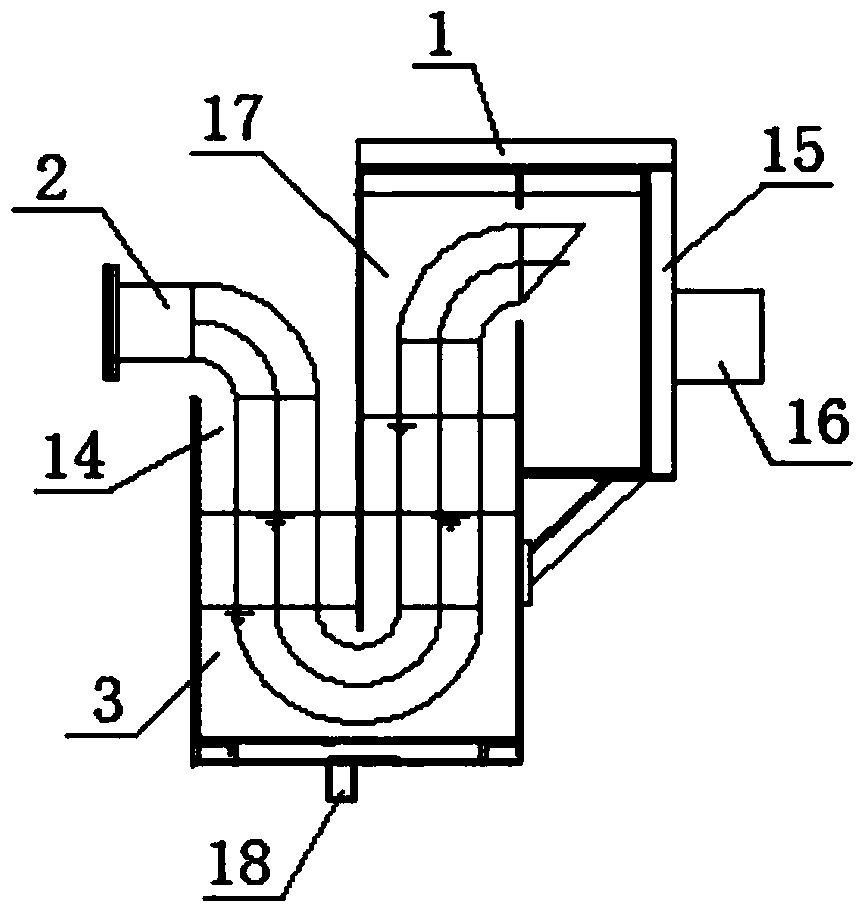

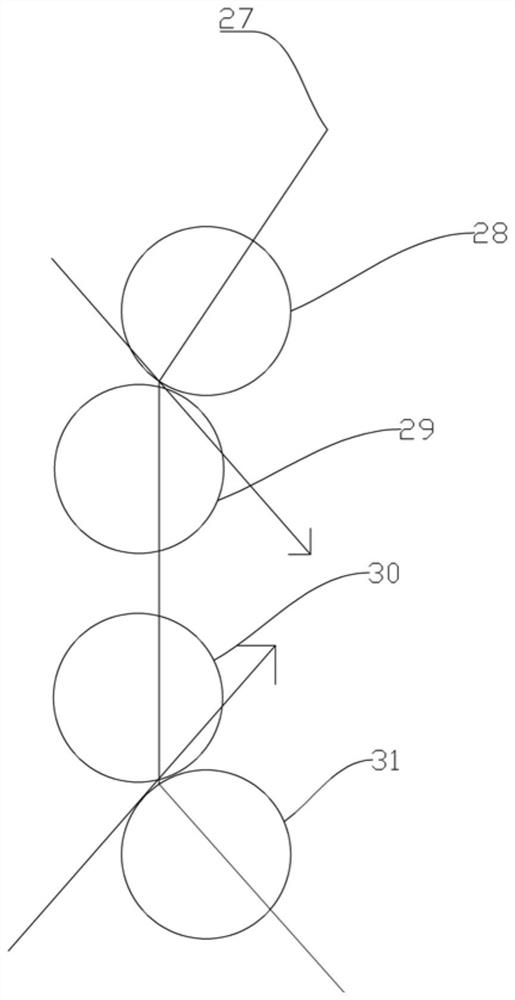

Disinfectant steam disinfection equipment

InactiveCN102552957AImprove disinfection effectImprove efficiencyDeodrantsAtomized substancesParticulatesControl system

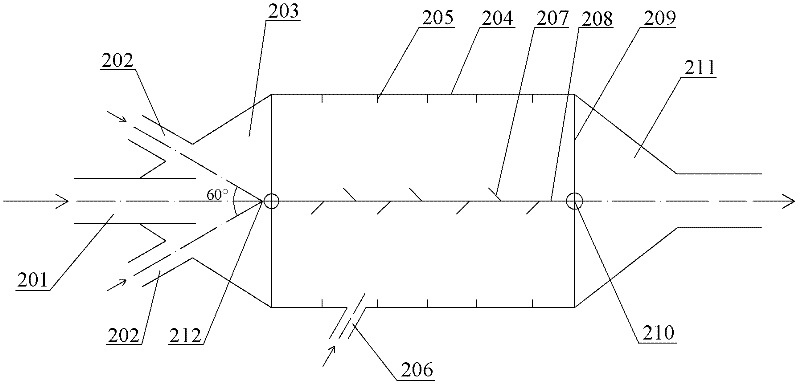

The invention discloses disinfectant steam disinfection equipment, which comprises a disinfectant steam three-stage refining system, a filtering-catalyzing integrated system and a control system, wherein the disinfectant steam three-stage refining system is used for initially atomizing a disinfectant liquid with an ultrasonic atomizing device; a hybrid refining device is used for effectively crushing disinfectant atomized gas molecular groups under the colliding, cutting and crushing actions of air current in an atomized gas hybrid refining device to perform secondary refining on disinfectant atomized gas; an evaporator is used for fully contacting a mixed gas of a disinfectant and the air with the inner wall of the evaporator, heating and evaporating to perform third refining on the atomized gas, so that the aim of outputting ultrafine particulate disinfect steam is fulfilled; the filtering-catalyzing integrated system is used for catalytically decomposing disinfectant gas particles formed by the three-stage refining system to complete filtering and catalyzing work; and the control system is used for controlling the entire process of the three-stage refining system and the filtering-catalyzing system. Due to the adoption of the disinfectant steam disinfection equipment, disinfectant gas is further refined, micro-sized disinfectant gas particles are formed finally, and the decontamination effect and efficiency of disinfectant steam are improved greatly.

Owner:中国人民解放军防化学院 +1

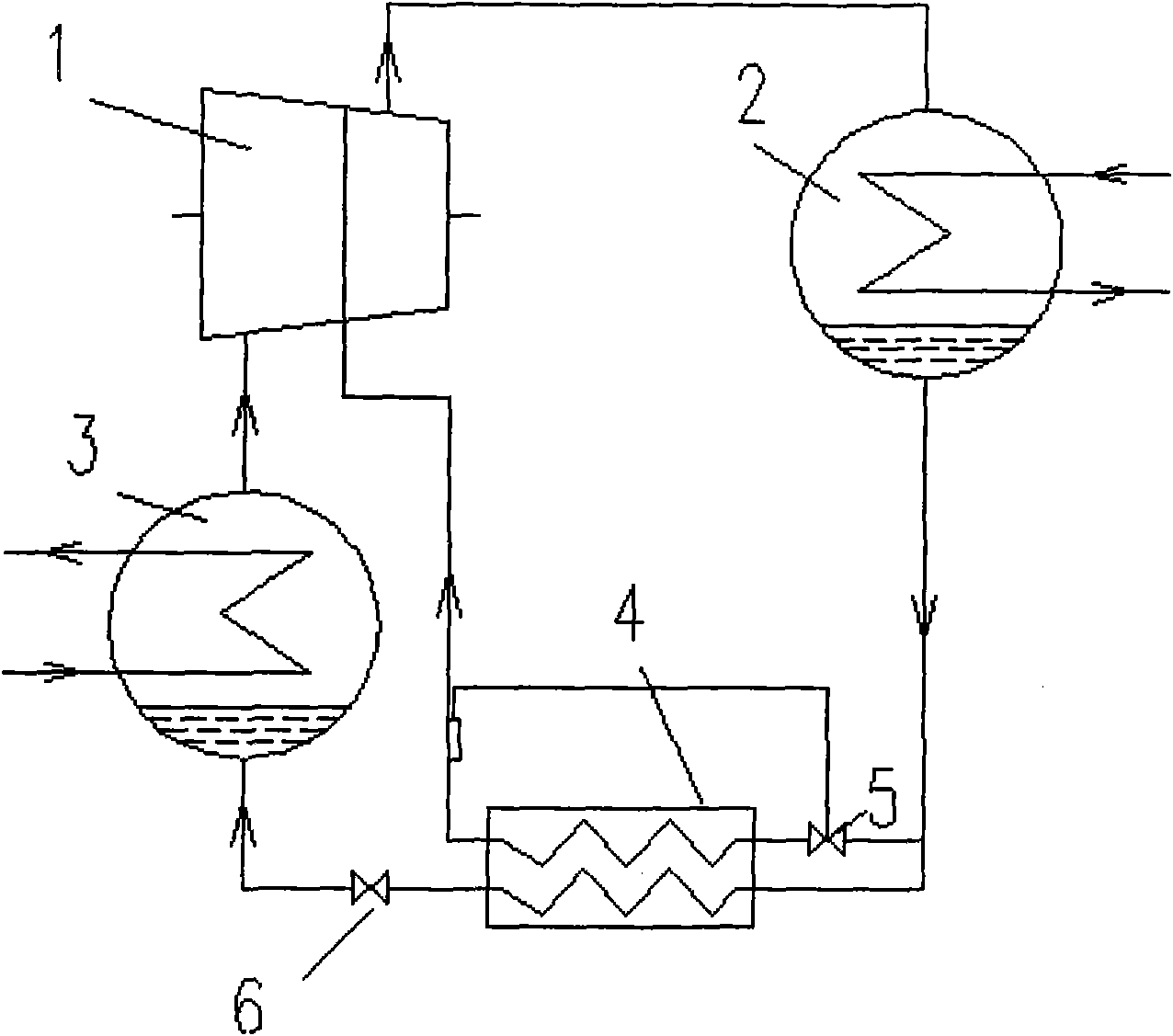

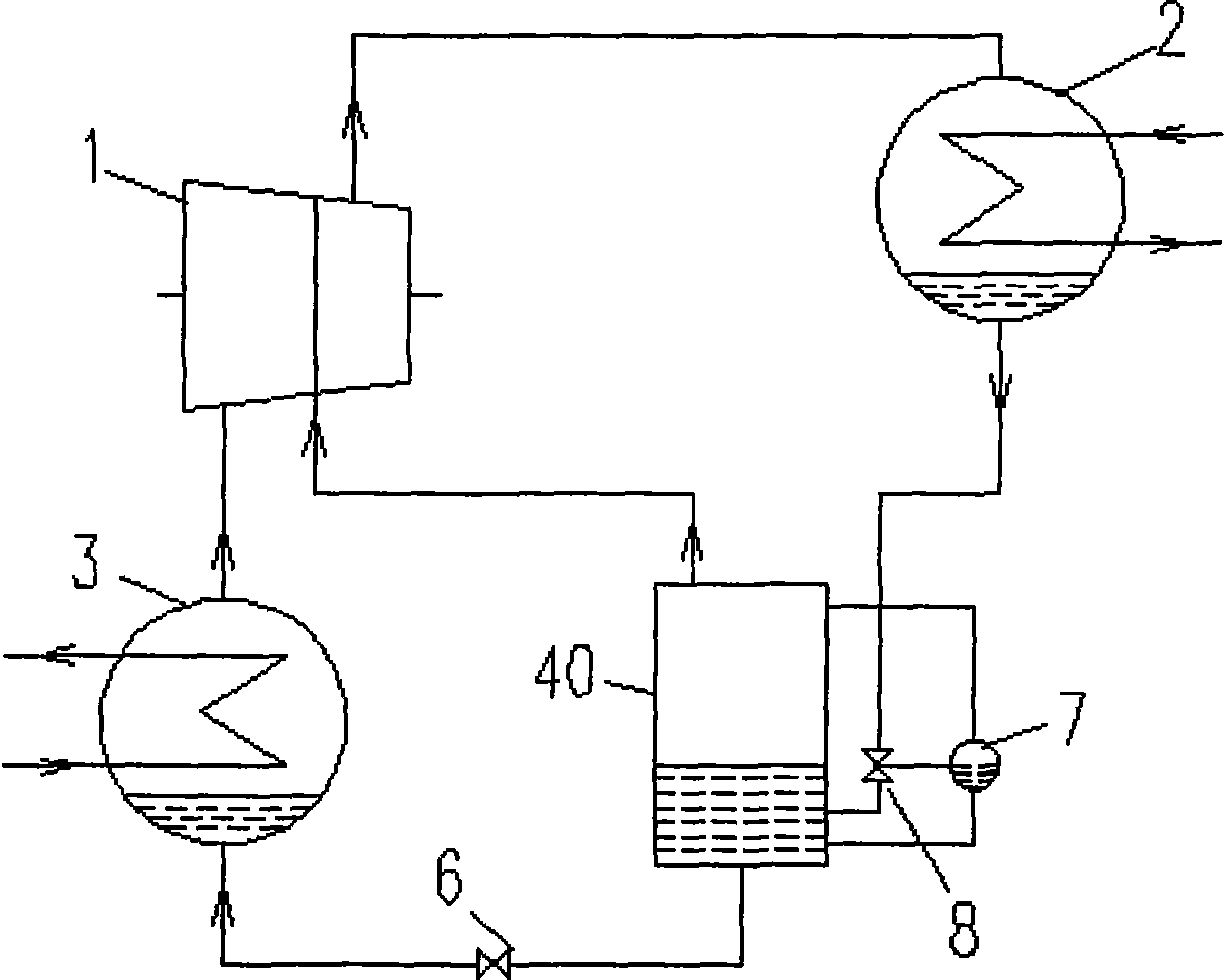

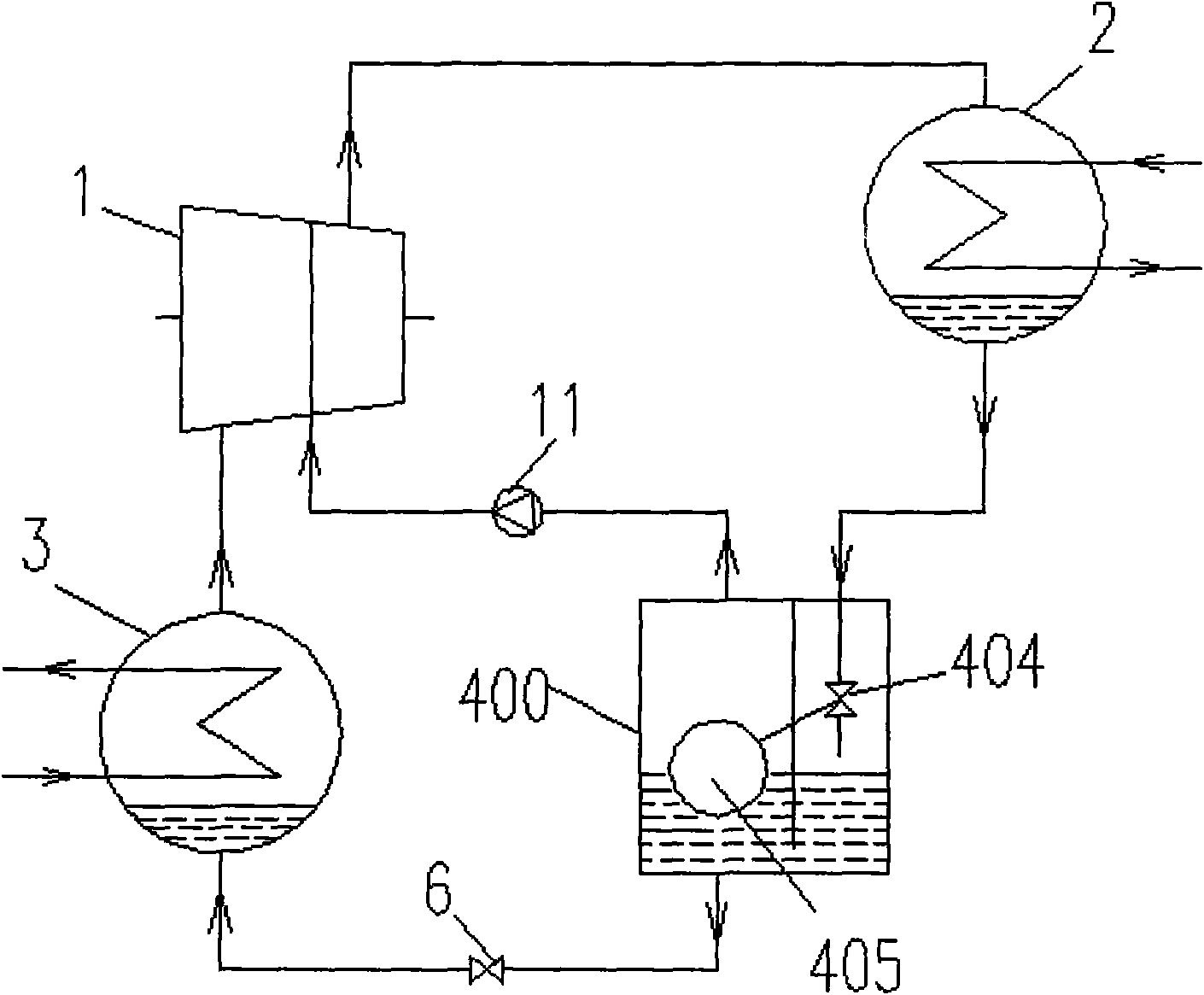

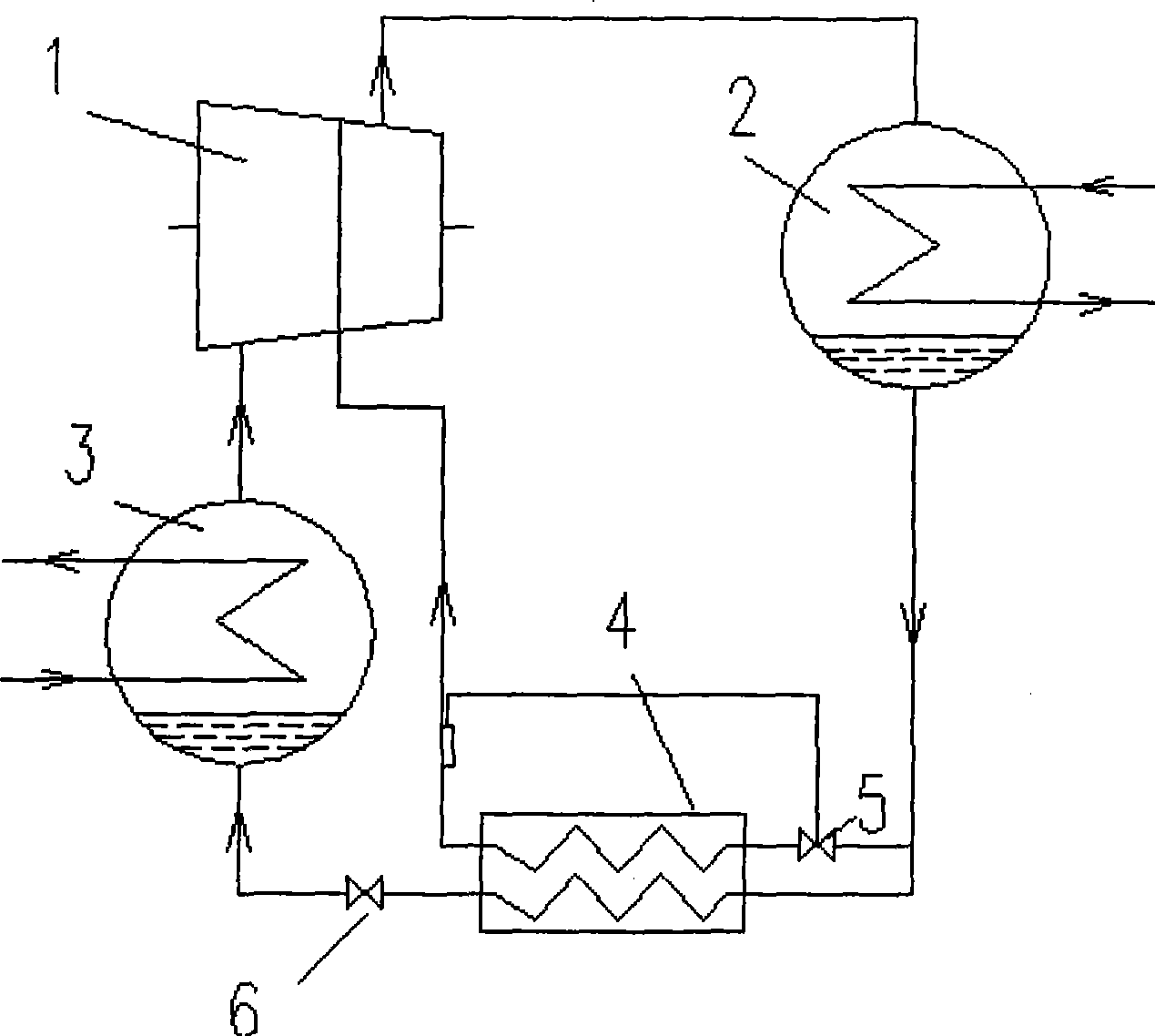

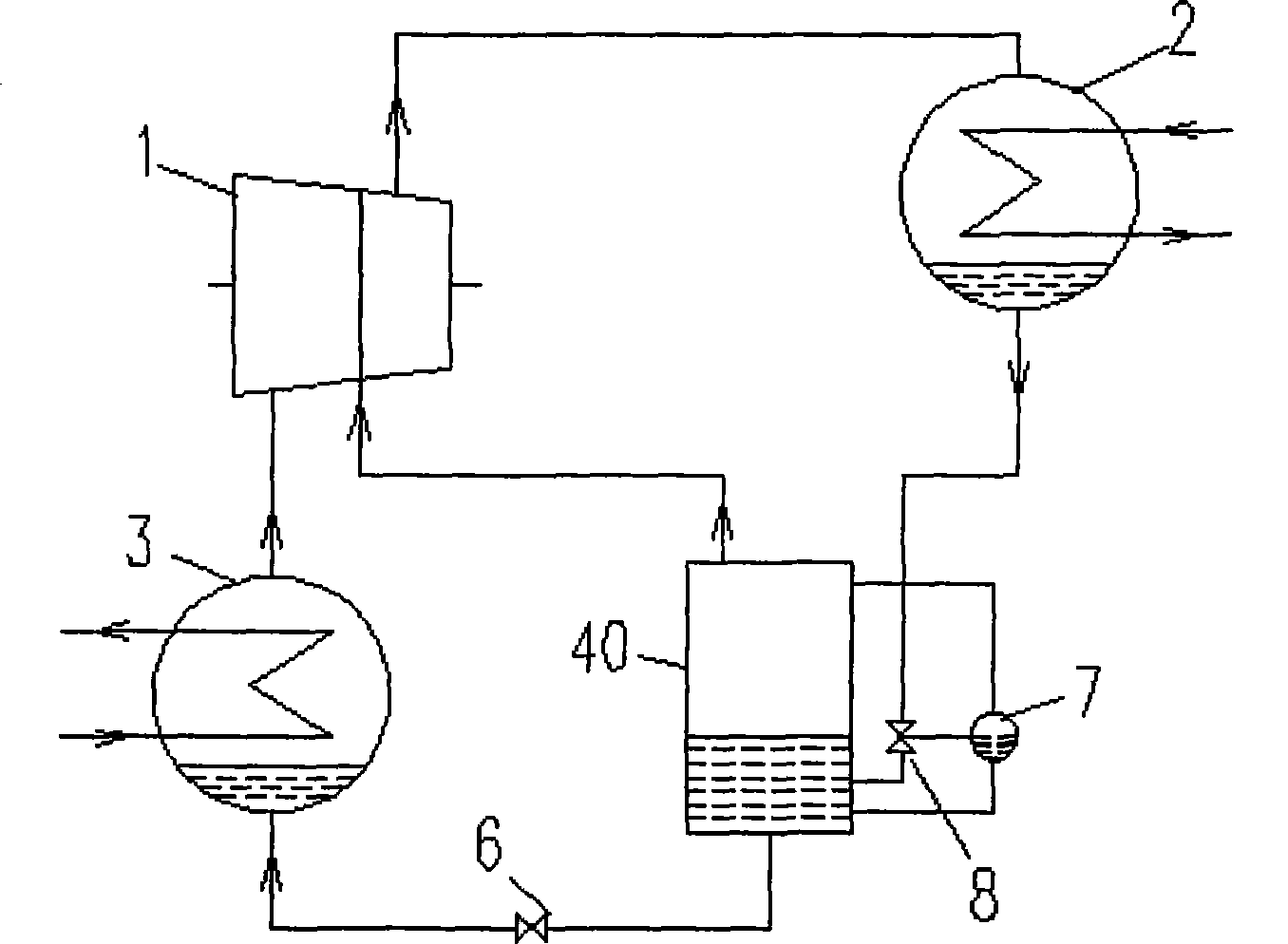

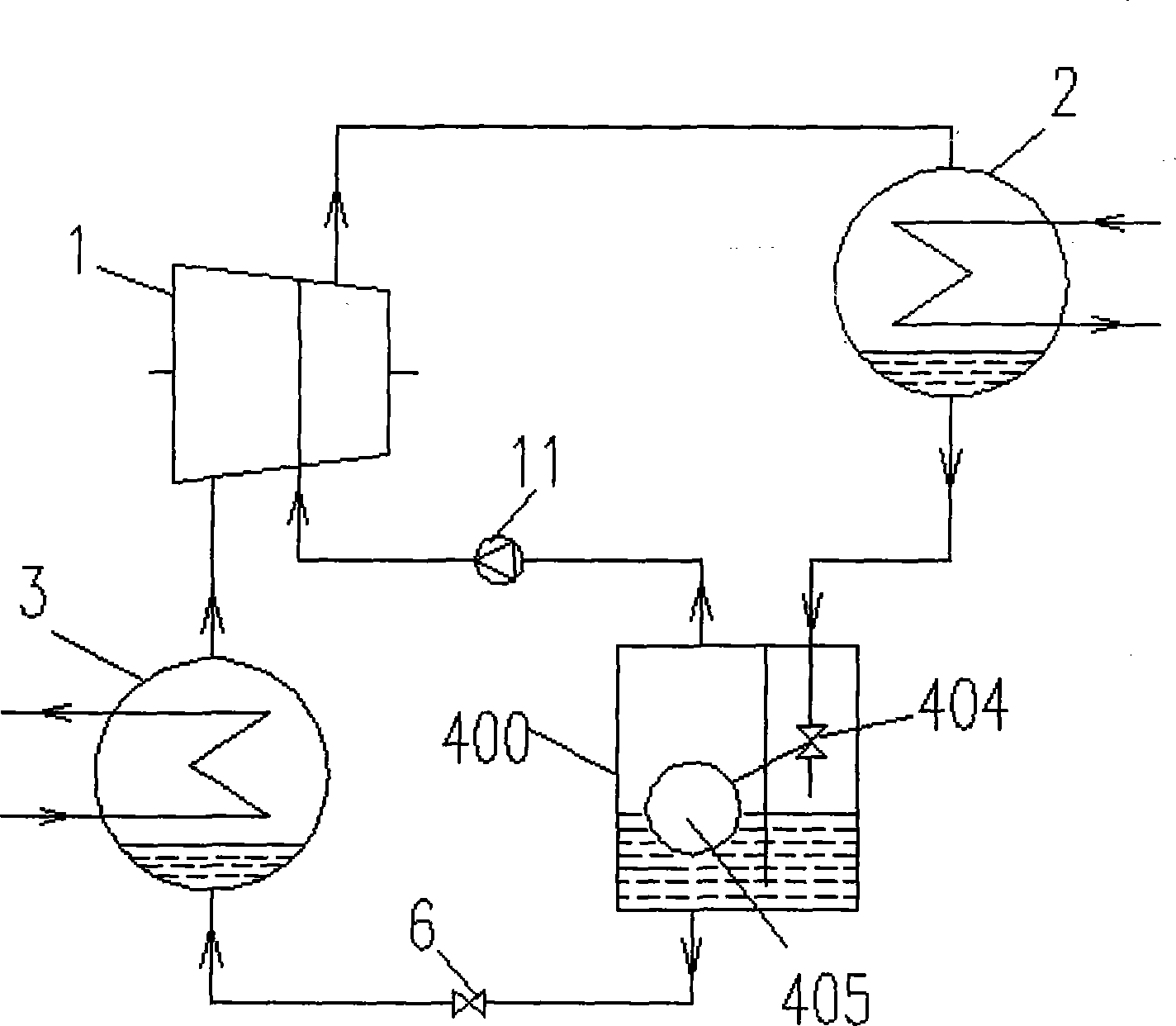

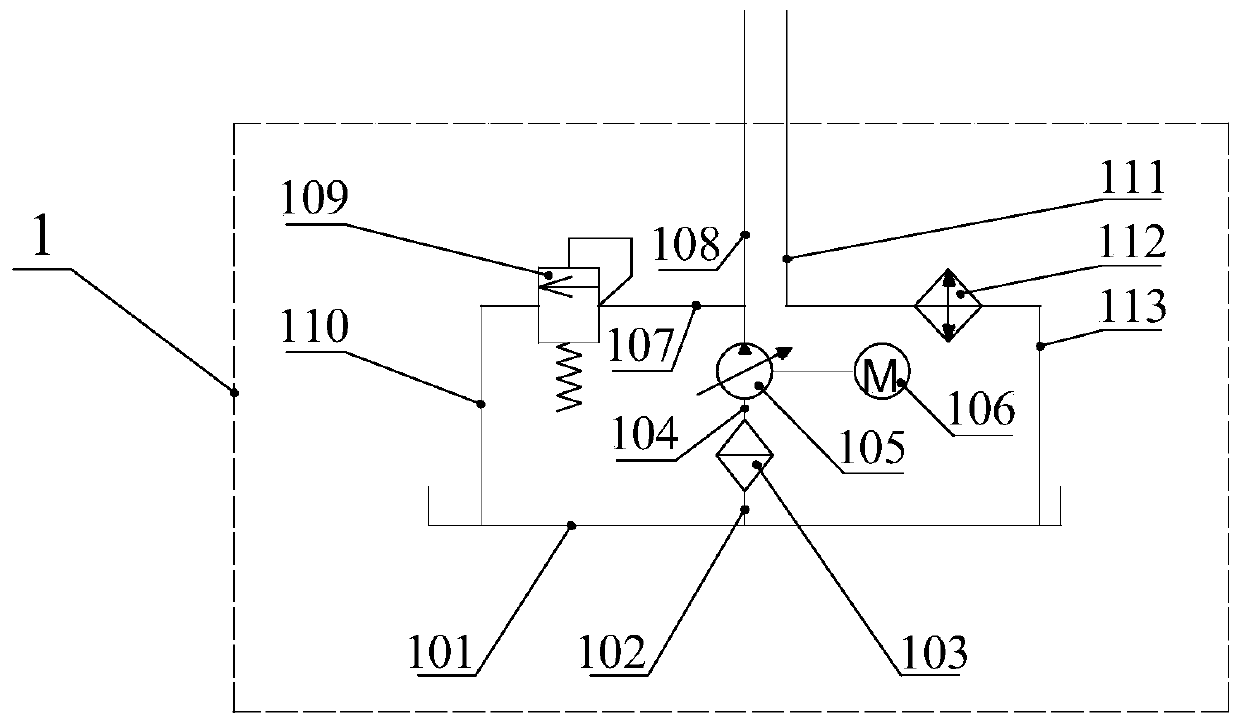

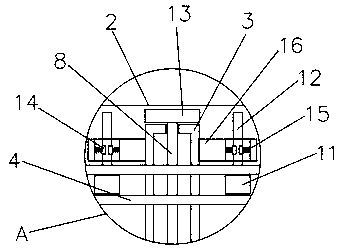

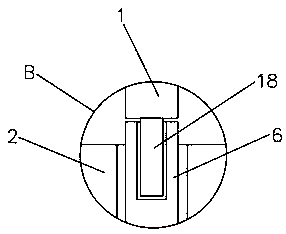

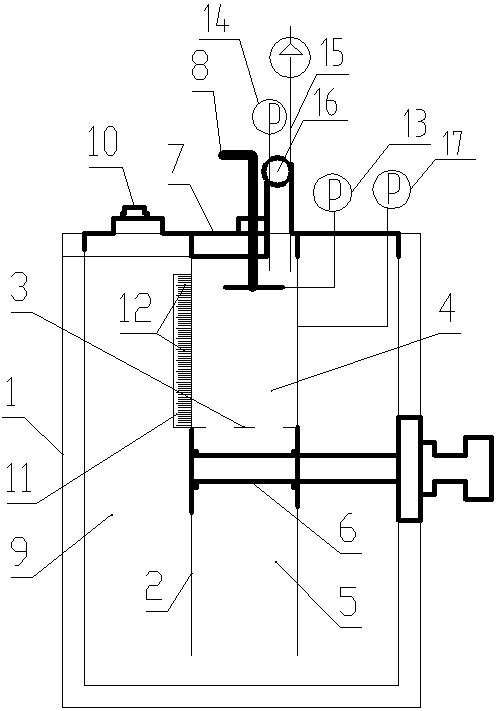

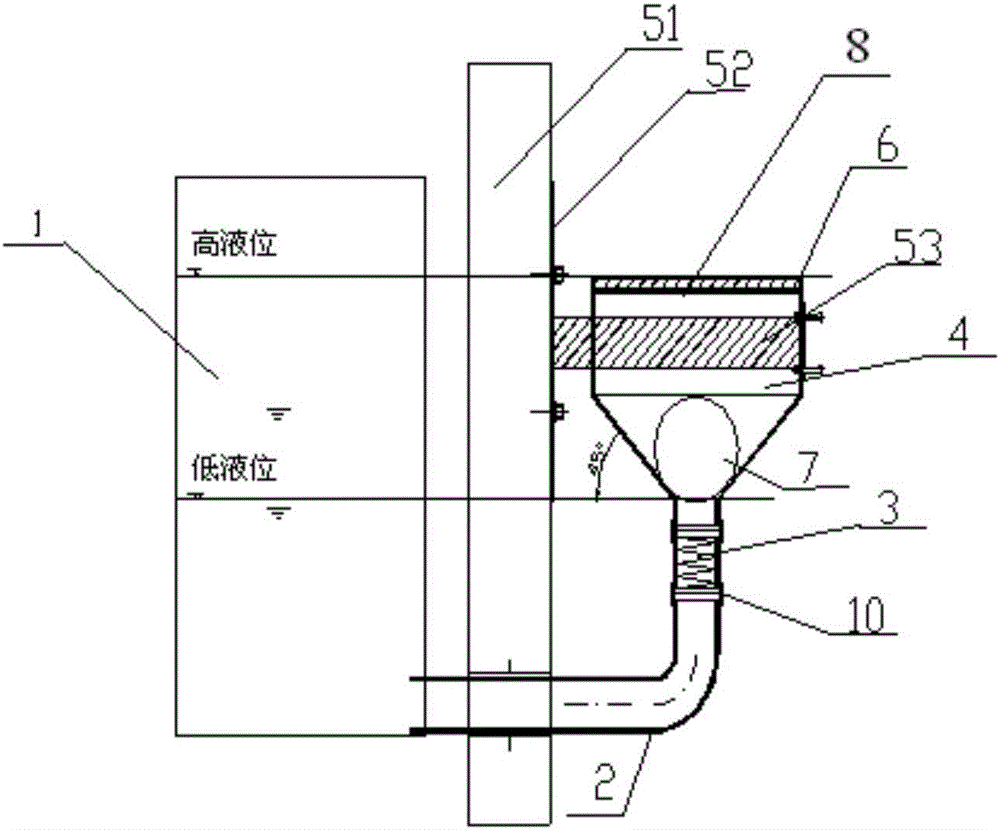

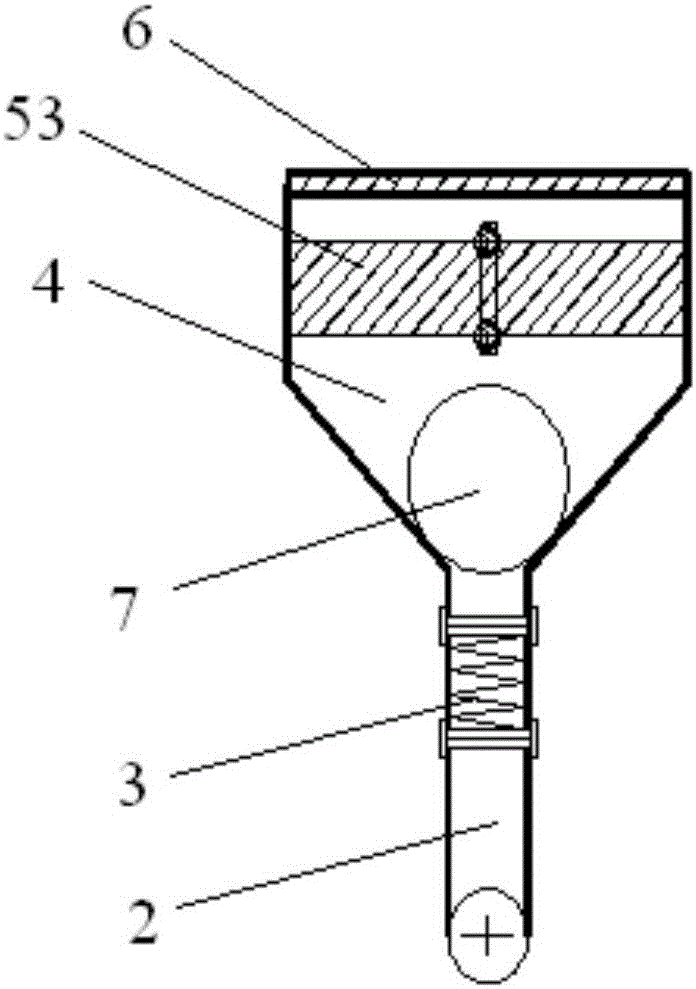

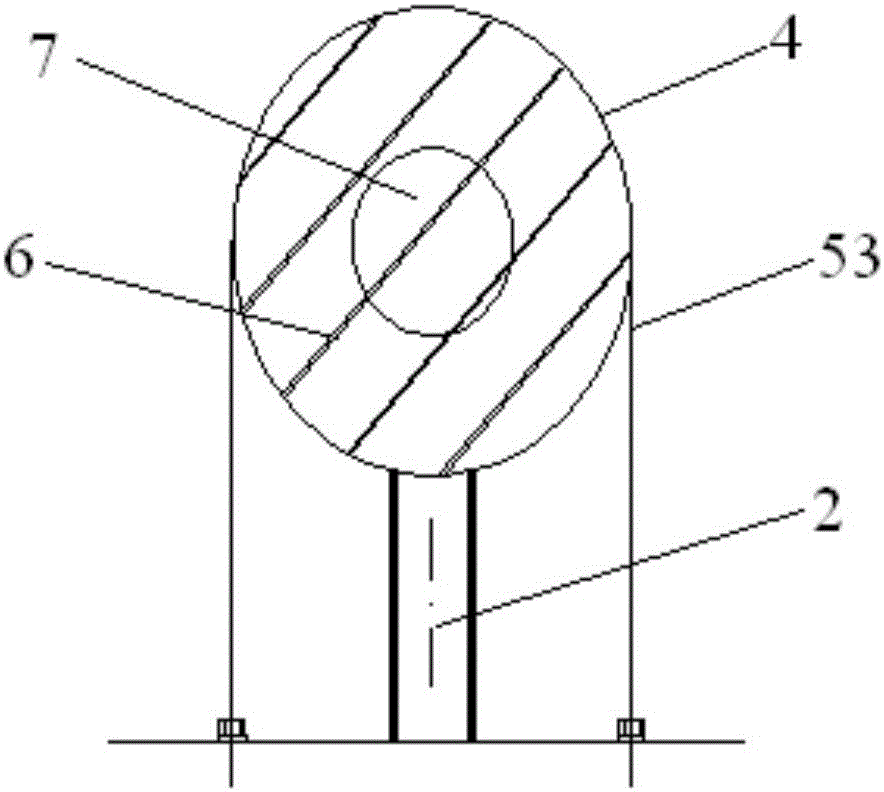

Vapor compression refrigeration unit

InactiveCN101556090AControl liquid levelCompression machines with non-reversible cycleVena contracta diameterProtection mechanism

The invention relates to a vapor compression refrigeration unit comprising a compressor, a condenser, an evaporator and a flash evaporation cylinder. A liquid inlet at the upper end of the flash evaporation cylinder is connected with the condenser, an air outlet at the upper end of the flash evaporation cylinder is connected with an input port of the compressor through a one-way valve, and a liquid outlet at the lower end of the flash evaporation cylinder is connected with the evaporator through a second throttle valve. The flash evaporation cylinder internally comprises a pair of coaxial throttle orifice plates connected with the liquid inlet, a floating ball mechanism, a liquid baffle extending into the liquid, and a liquid level protection mechanism, wherein one of the coaxial throttle orifice plates is fixed, and the other one rotates; the floating ball mechanism is arranged on the liquid and connected with one of the coaxial throttle valve plates; the baffle plate extending into the liquid is arranged between the liquid inlet and the air outlet; and the liquid level protection mechanism is arranged at a position near the air outlet. The invention has the advantages that the vapor compression refrigeration unit can effectively control the liquid level of refrigerating fluid in the flash evaporation cylinder in time and can well automatically adapt to the running under variable working conditions (partial load working condition and variable working conditions of the condenser) of the compressor.

Owner:SHANGHAI HANYE REFRIGERATION MACHINERY

Vapor compression refrigeration unit

InactiveCN101556090BControl liquid levelCompression machines with non-reversible cycleVena contracta diameterProtection mechanism

Owner:SHANGHAI HANYE REFRIGERATION MACHINERY

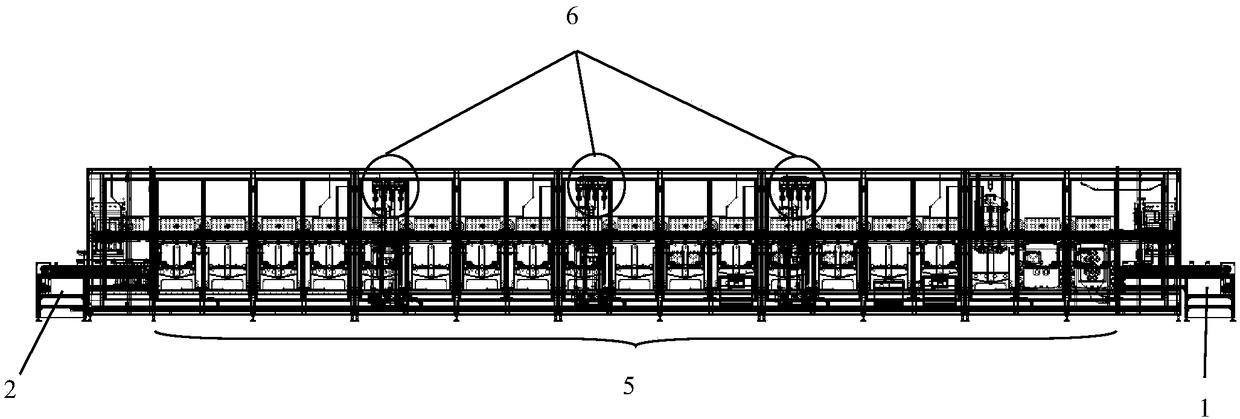

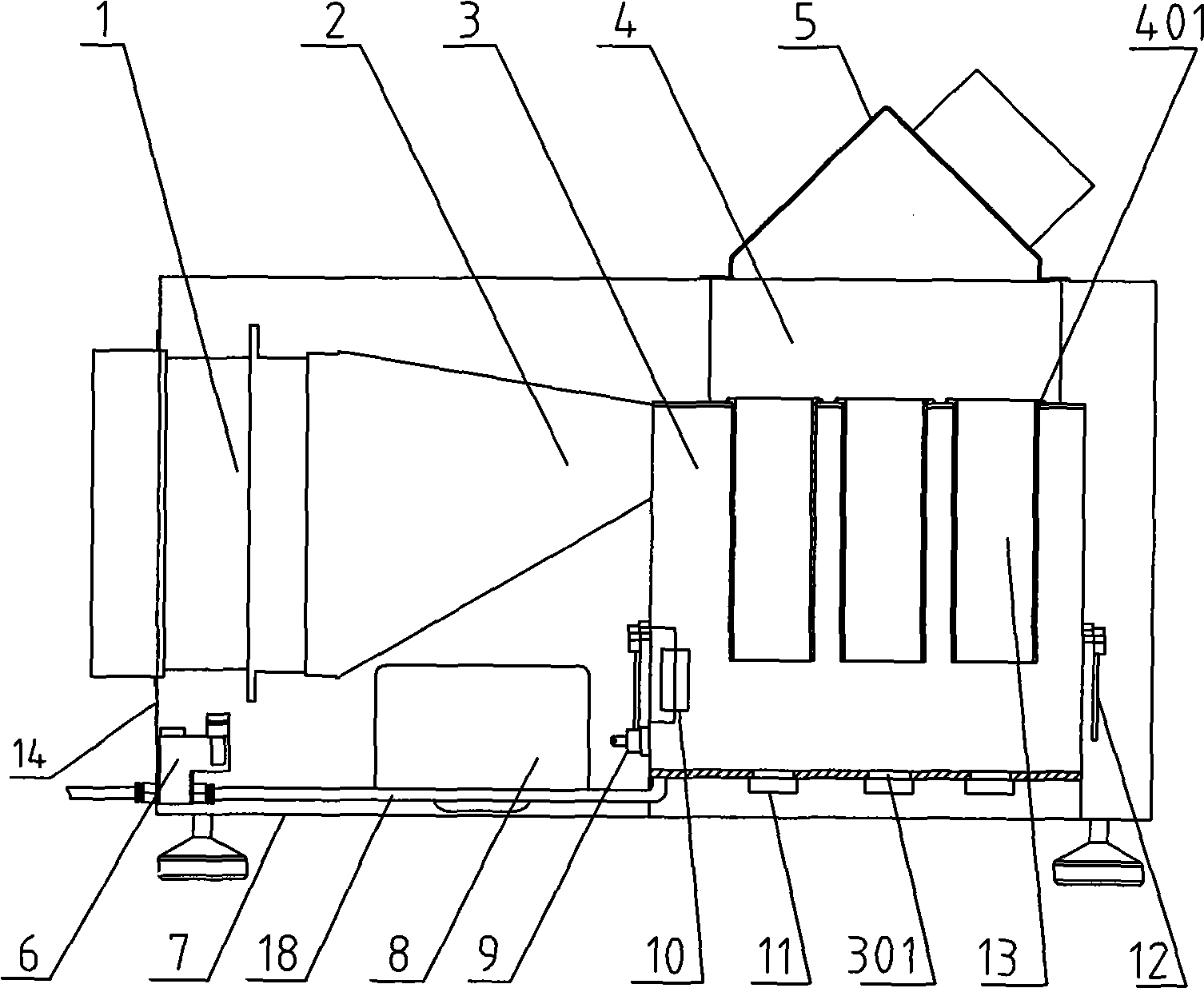

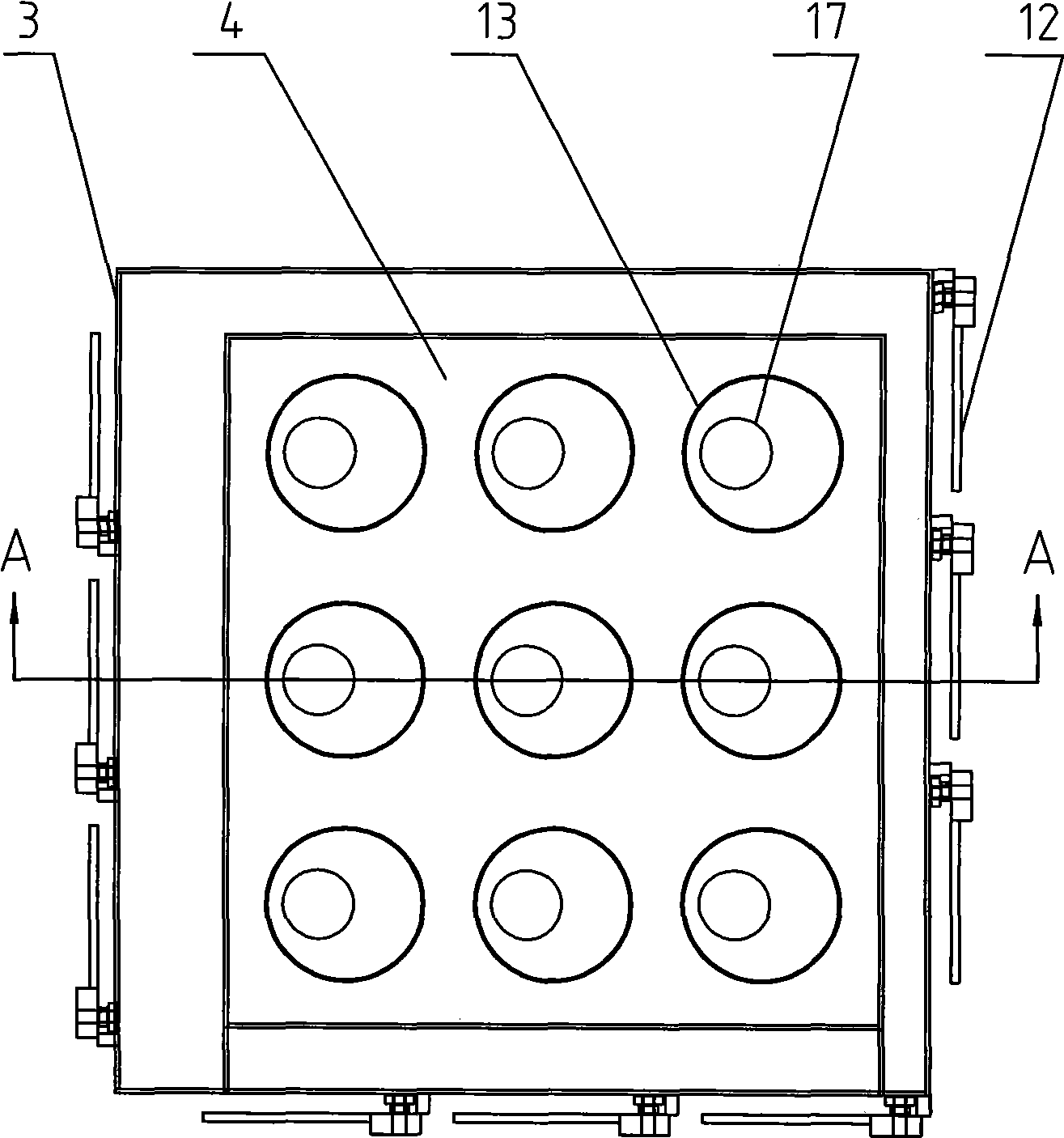

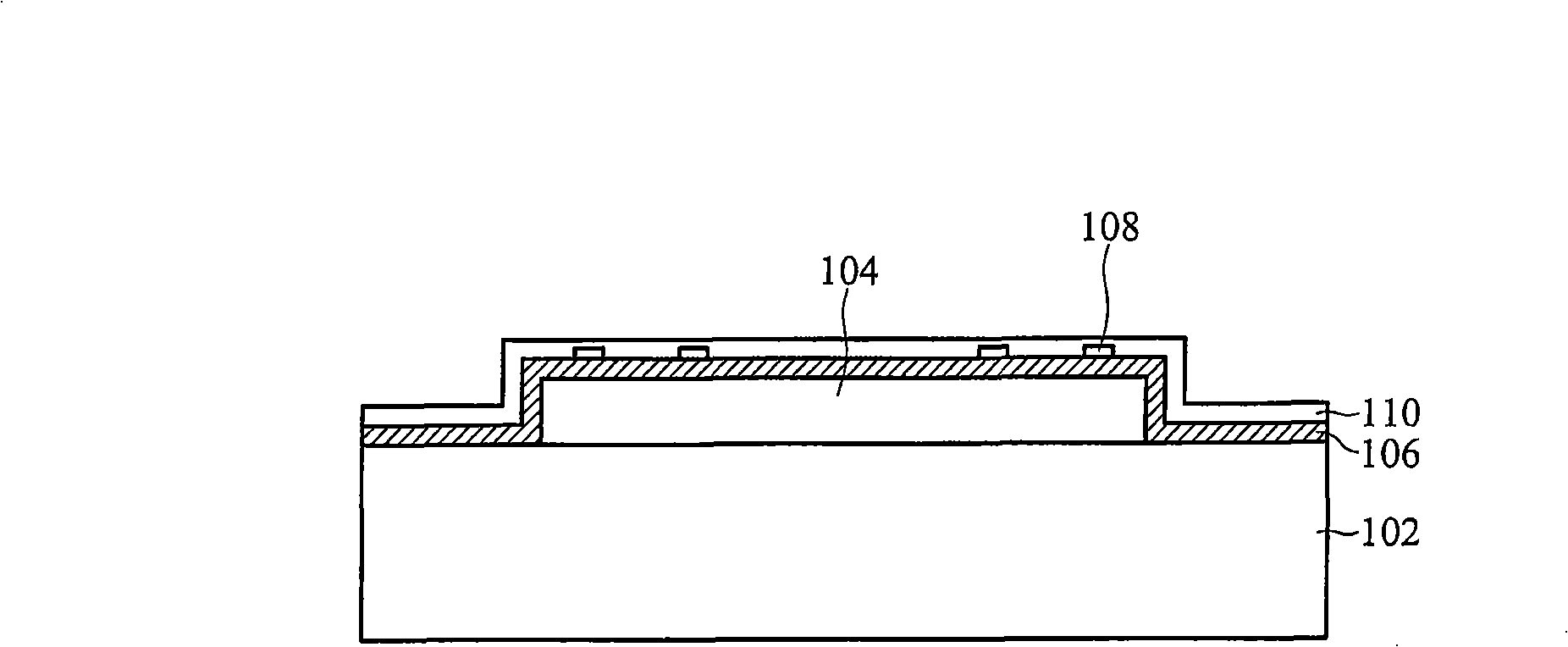

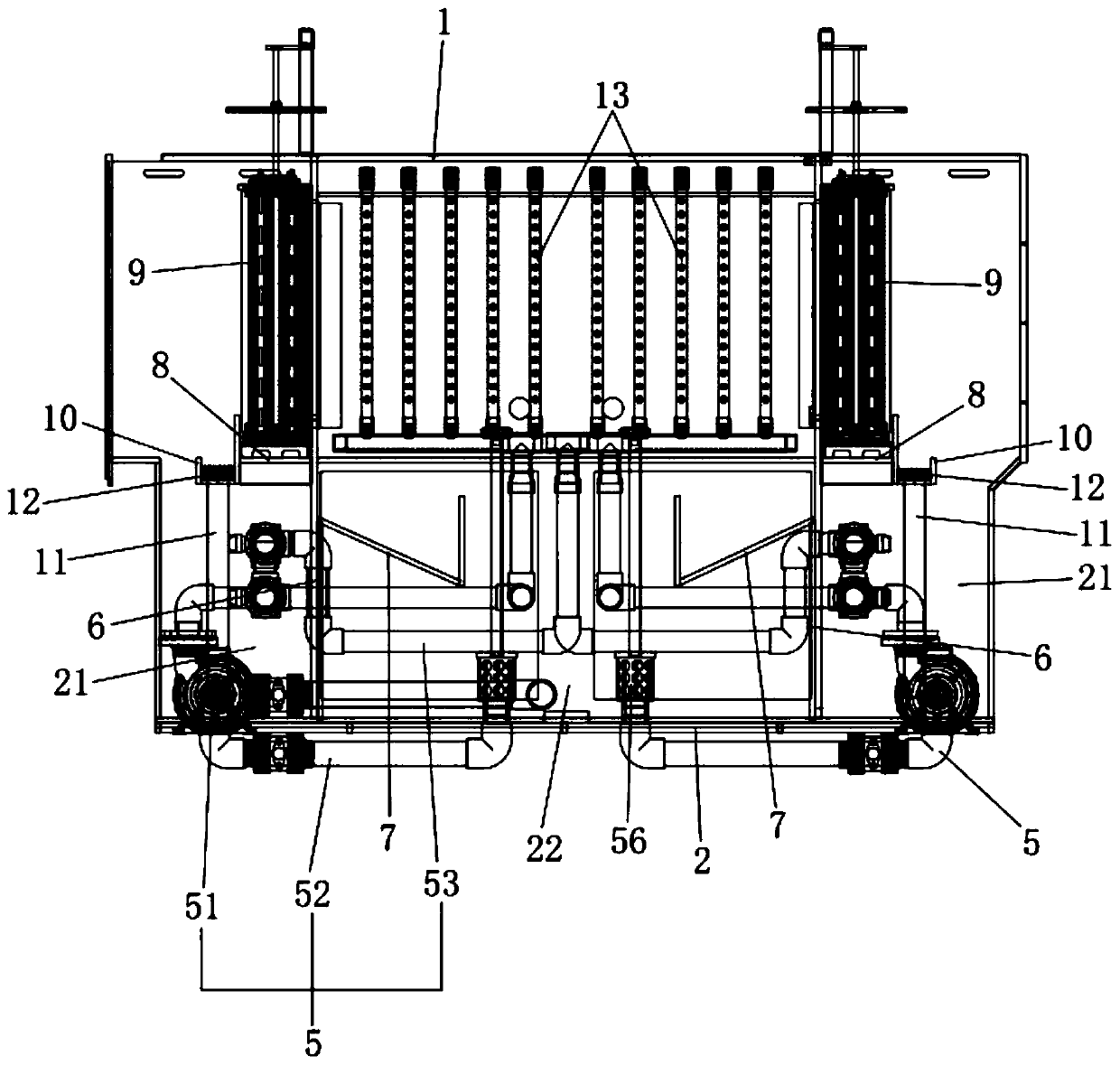

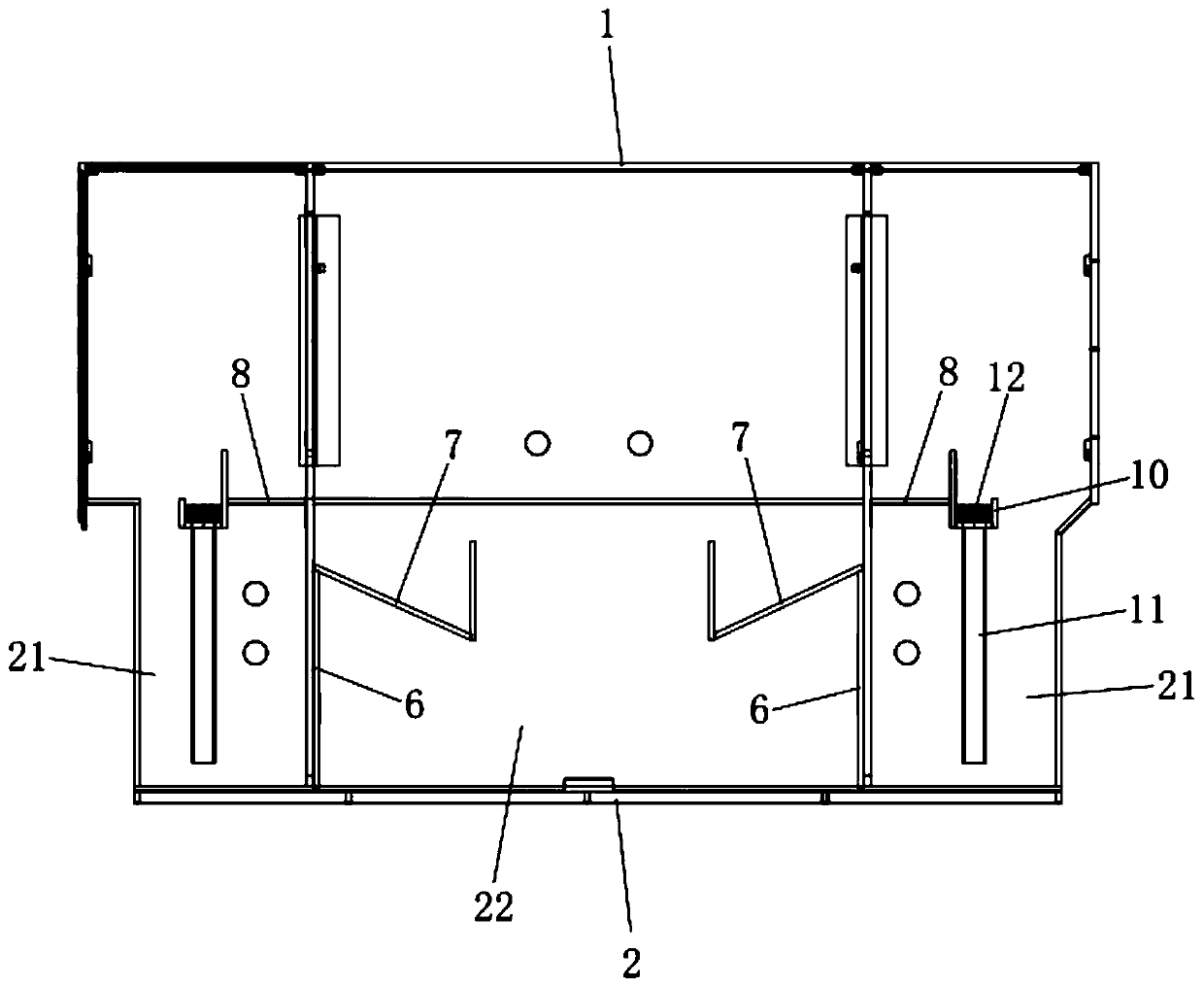

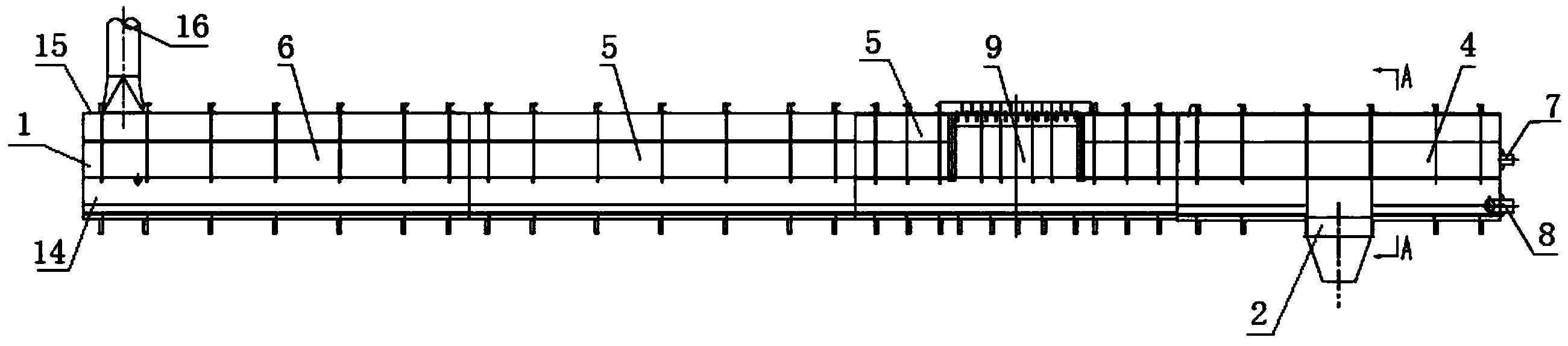

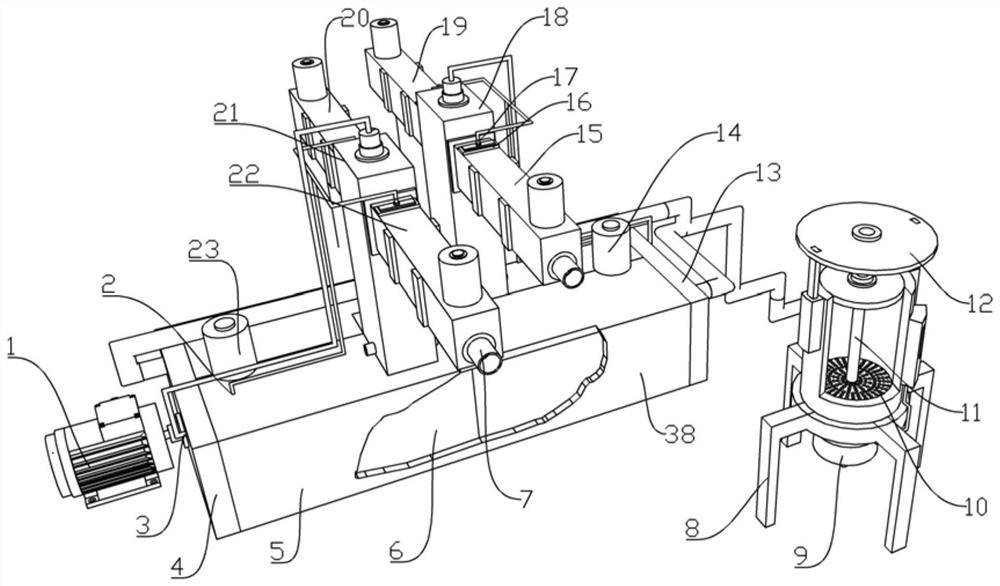

Single crystal texturing cleaning machine

InactiveCN108346714AImprove cleaning capacityGuaranteed circulationFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSingle crystal

A single crystal texturing cleaning machine comprises a cleaning body. The cleaning body comprises a plurality of box bodies 5. The front portion of the cleaning body is provided with a material loading bench 1. The rear portion of the cleaning body is provided with a blanking bench 2. A conveyor belt is arranged on the material loading bench 1 and the blanking bench 2. A plurality of mechanical arms 6 used for grabbing a material are arranged above the conveyor belt. One side of the cleaning body is provided with control cabinets 3 and 4 used for regulating and controlling a cleaning processin the cleaning body and monitoring the cleaning process in real time. The control cabinets 3 and 4 are provided with a visual interaction operation interface. Simultaneously, equipment integrates slowly-lifting and hot-air drying functions. On a basis of guarantee productivity, through the slowly-lifting and hot-air drying functions, a single crystal texturing effect is further ensured. Besides,through designing, a groove body can realize a quick exhaust function, a cover plate is included and functions of bubbling, overflow and the like can be realized, the size of the groove body is savedand more functions are realized.

Owner:KUNSHAN SEAGEAR AUTOMATION SYST CO LTD

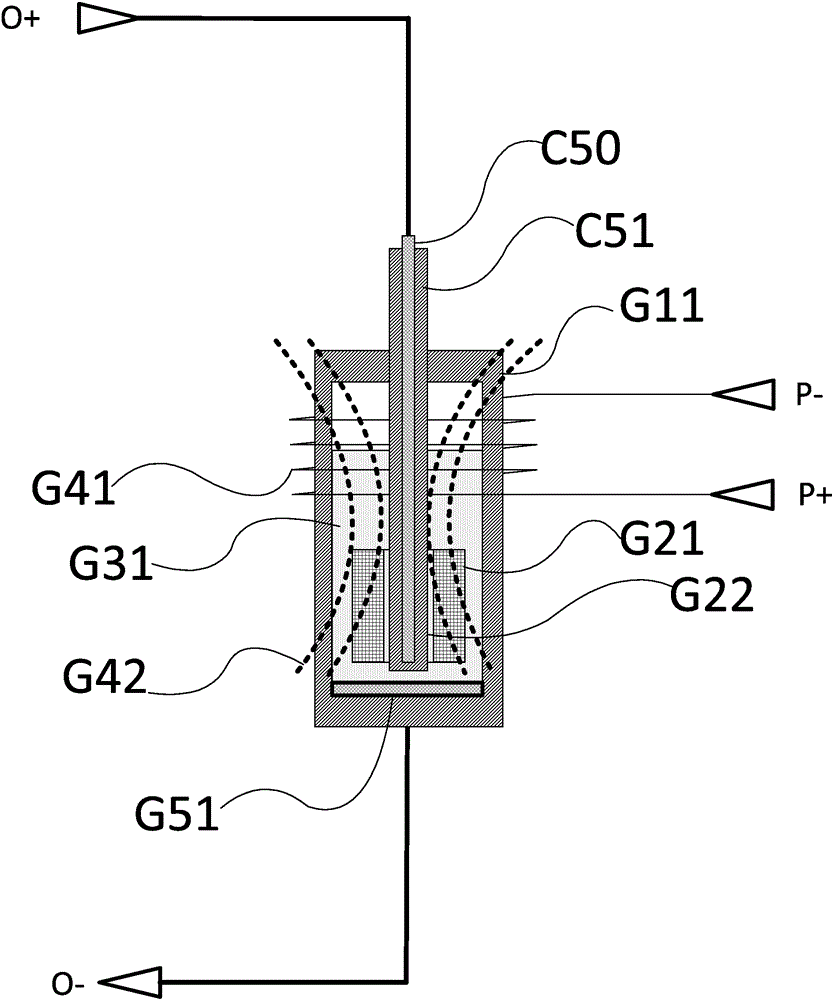

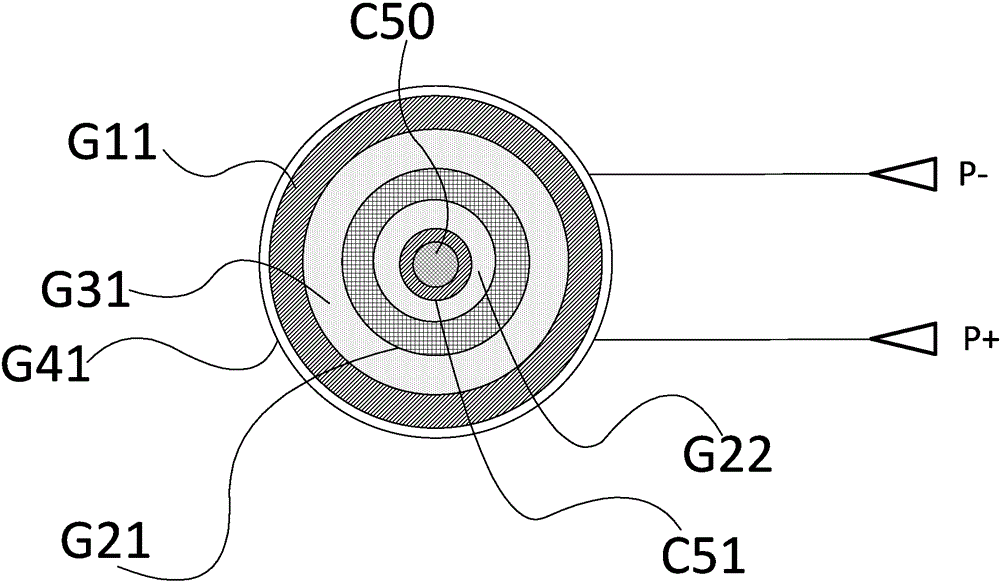

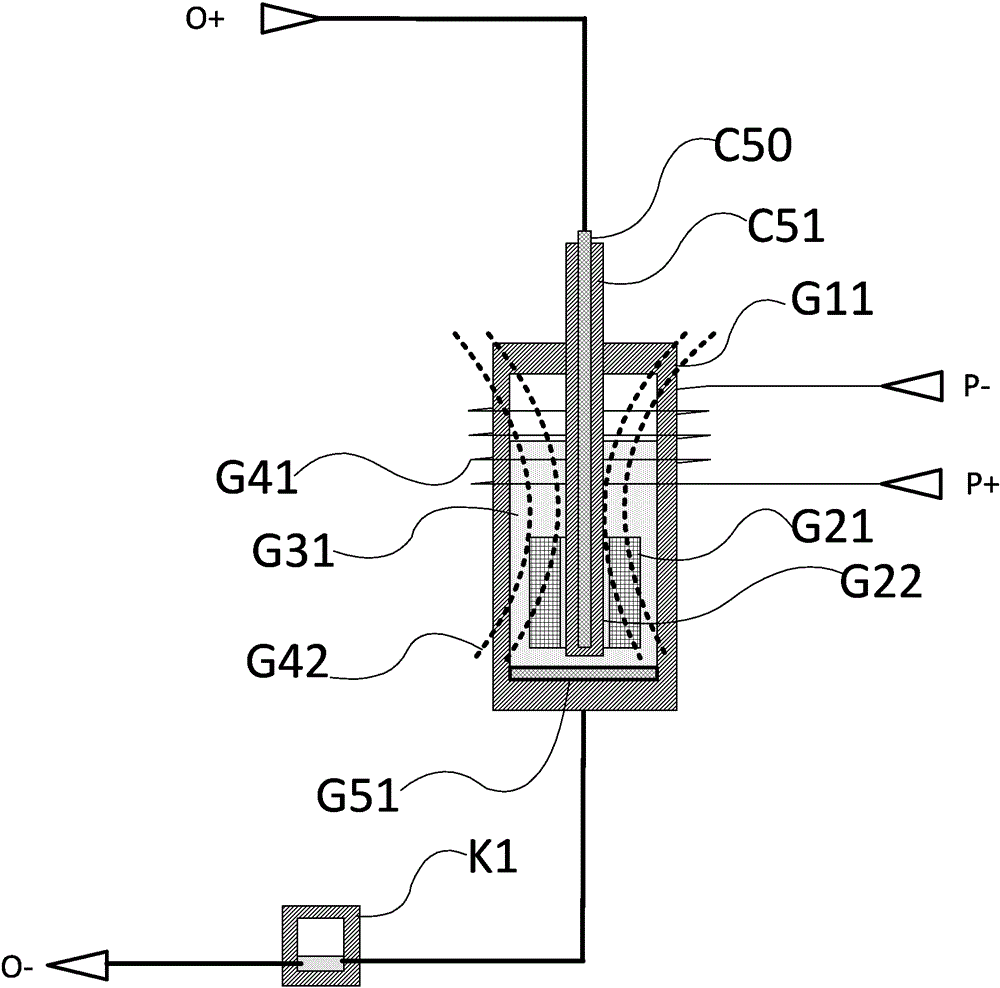

Linear controllable capacitor of decrescent capacitance, large-scale rice milling machine starting buffer circuit and electric machinery

InactiveCN105185591ANot easy to burnExtended service lifeCapacitor with electrode area variationElectric machineryPower circuits

A linear controllable capacitor of decrescent capacitance is characterized by comprising an insulating container (G11), a conducting liquid (G31), an entity (G21), a bottom electrode (g51), a capacitor pole rod (C50), an insulating layer (C51), an electromagnetic coil (G41), a controlled access first node (O+), a controlled access second node (O-), a control end first node (P+) and a control end second node (P-). A large-scale rice milling machine starting buffer circuit and an electric machinery both have the above controllable capacitor. The linear controllable capacitor of decrescent capacitance, the large-scale rice milling machine starting buffer circuit and the electric machinery of the present invention are long in contact service life, low in cost and good in isolation performance, and can be used in the large power circuits, such as a weak current power supply circuit, an electric power circuit, an ultrahigh voltage electric power circuit.

Owner:刘伟

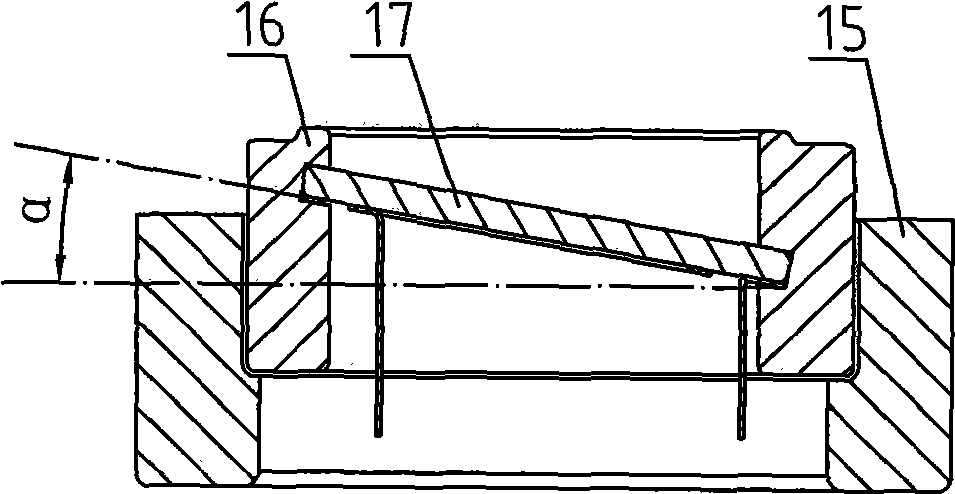

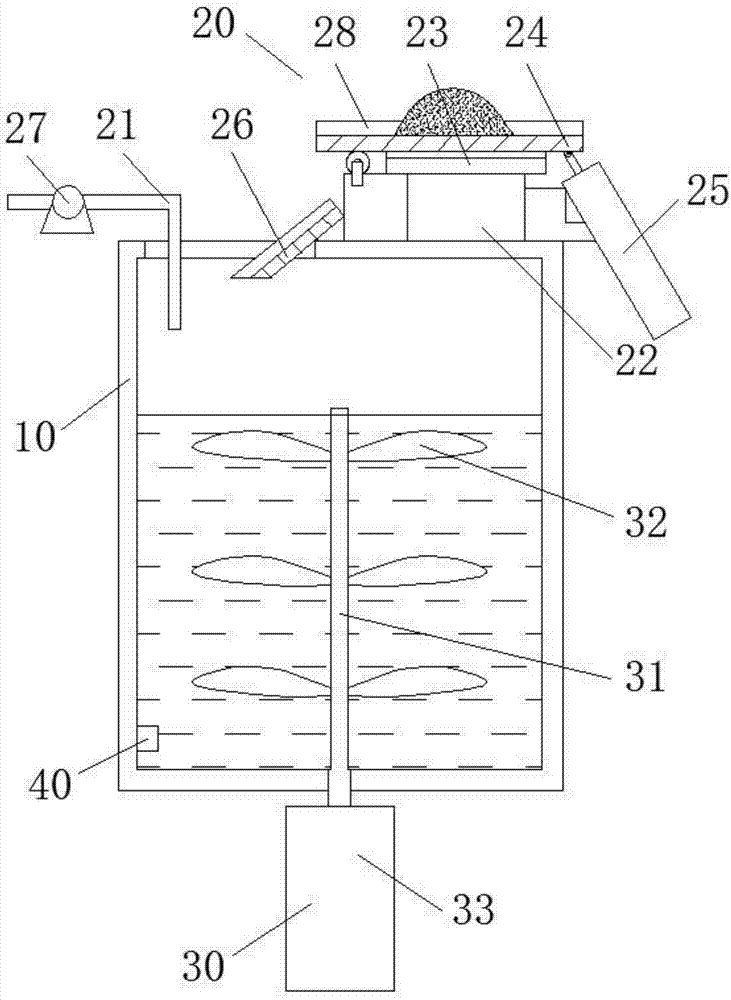

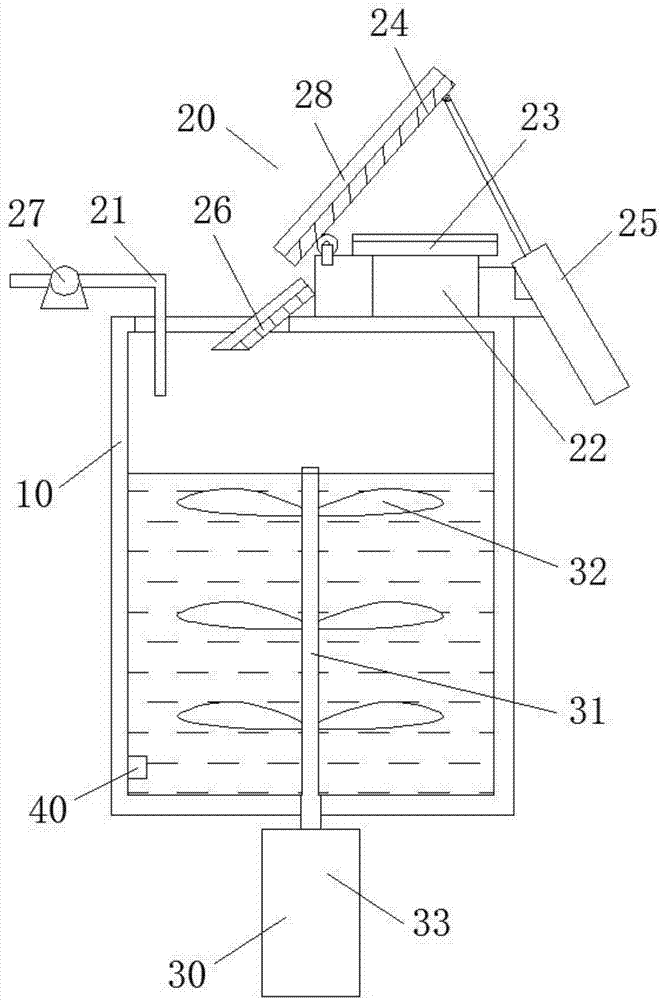

Ultrasonic humidifier

InactiveCN101545664AImprove work efficiencyPromote atomizationSpace heating and ventilation safety systemsLighting and heating apparatusDevices fixationEngineering

The invention relates to an ultrasonic humidifier. The common ultrasonic humidifier has more defects that a blower is easy to be wetted, the humidifying efficiency is low, and the like. The ultrasonic humidifier comprises a framework, a water tank, the blower, a water inlet device and a mist spraying device, wherein the mist spraying device comprises a mist spraying guide plate, a mist spraying guide pipe, an energy transformation device and a drive plate; and the water tank, the blower, the water inlet device and the mist spraying device are fixed in the framework. The ultrasonic humidifier is characterized in that: the numbers of the mist spraying guide pipe, the energy transformation device and the drive plate are the same; the bottom of the water tank is provided with a bottom plate hole, the energy transformation device is fixed in the bottom plate hole and also comprises an energy transformation sheet, and an included angle is formed between the energy transformation sheet and the horizontal plane; the mist spraying guide pipe is fixed on the mist spraying guide plate and positioned above the corresponding energy transformation device; and the drive plate is fixed on the outer wall of the water tank. The assembly and disassembly of the energy transformation device are convenient, the production cost is low, the service life is long, the efficiency of generating mist is high, and the humidifying effect is good.

Owner:浙江佳为环境科技有限公司

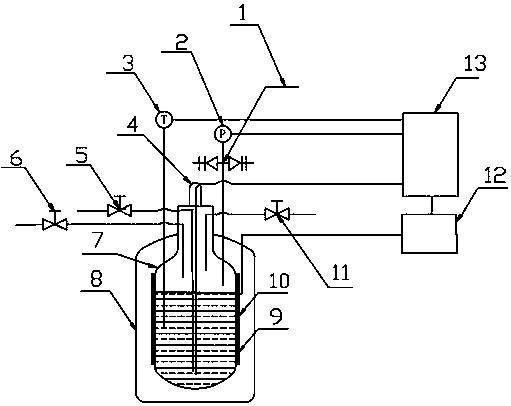

LNG self-pressurization storage tank

InactiveCN110220108AEasy to operateSimple structureVessel mounting detailsContainer filling methodsElectricityEngineering

The invention discloses an LNG self-pressurization storage tank, and relates to the technical field of self-pressurization liquid supply storage tanks for laboratories. A liquid storage tank body of the LNG self-pressurization storage tank is composed of a stainless steel inner container, a stainless steel outer shell, a vacuum insulation interlayer and a valve pipeline, the valve pipeline is arranged at the top of the liquid storage tank body, a pressure sensor, a temperature sensor and a liquid level sensor in an auxiliary thermal pressurization device are arranged at the top of the liquid storage tank body, the pressure sensor, the temperature sensor, the liquid level sensor and a power supply are electrically connected with a control unit correspondingly, a thermal resistor is arrangedon the outer surface of the stainless steel inner container, the outer surface of the thermal resistor is covered with an isolation and heat insulation covering layer, and the thermal resistor is electrically connected with the power supply and the control unit. The LNG self-pressurization storage tank has the advantages that the vaporization degree of LNG in the tank is controlled through the size of the power of the thermal resistor so that the pressure, the liquid level, the temperature and other physical states in the tank can be relatively accurately controlled, the operation is simplerand more convenient, the heat loss of the thermal resistor can be reduced through the isolation and heat insulation covering layer, and the waste is reduced.

Owner:JIANGSU UNIV OF SCI & TECH +1

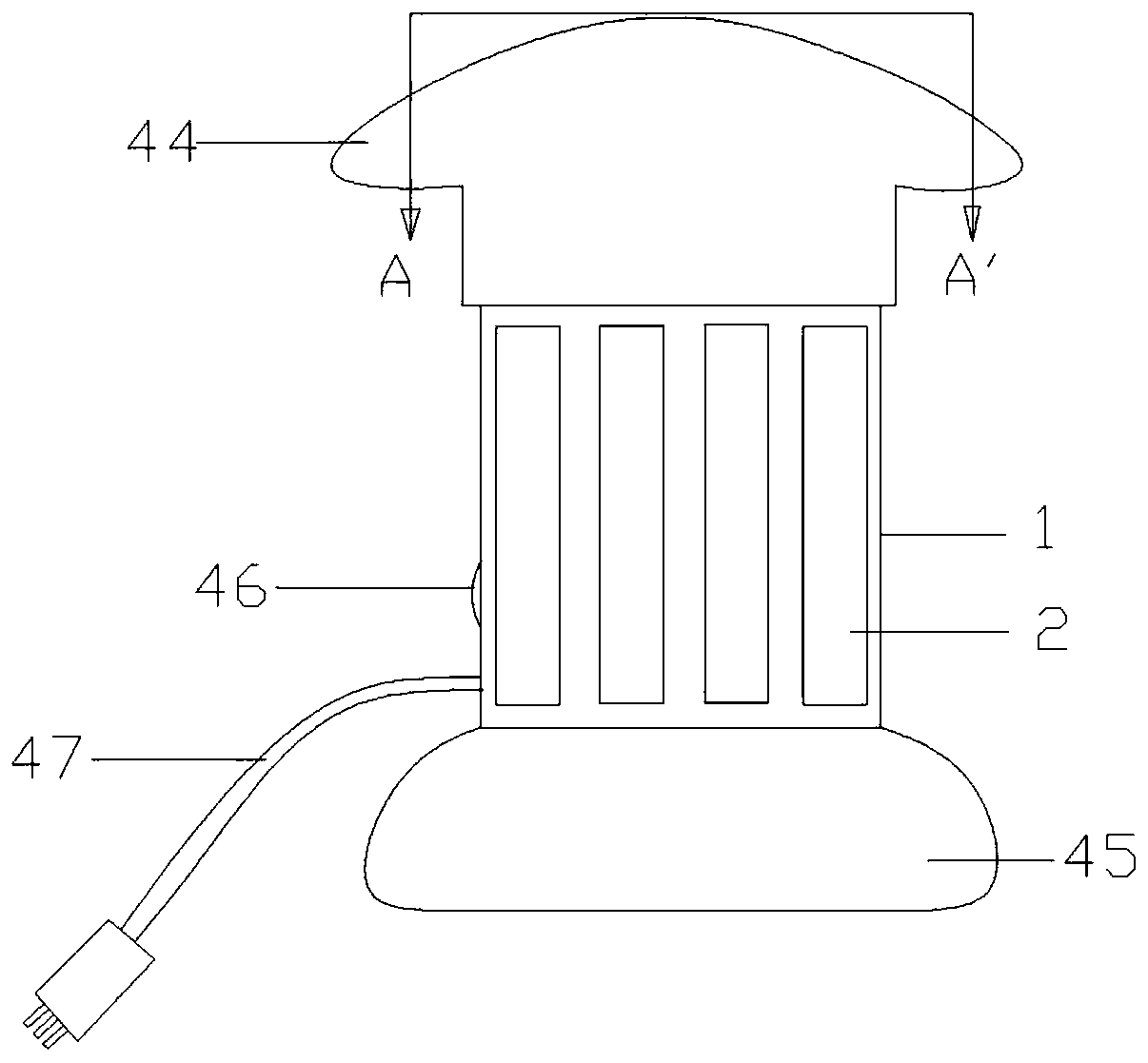

Liquid level detection warning and handling device

PendingCN108106696AControl liquid levelEasy maintenanceLevel indicators by floatsEngineeringLoudspeaker

The invention discloses a liquid level detection warning and handling device. The liquid level detection warning and handling device comprises a liquid storage chamber and a detection tube. The liquidstorage chamber is communicated with the detection tube. A handling device, a valve control device, a warning lamp and a loudspeaker are arranged at the top of the liquid storage chamber fixedly. A liquid level tube penetrating the detection tube is fixedly arranged at the inner bottom of the detection tube. A plurality of liquid inlet grooves are formed in the bottom of the side wall of the liquid level tube. A hollow ball is connected to the central position of the inner bottom of the liquid level tube through an elastic rope. A liquid level warning plate is arranged on the outer wall of the liquid storage chamber fixedly. An infrared emitter and an infrared receiver are arranged on two sides of the inner wall of the detection tube symmetrically. The liquid level detection warning and handling device has the advantages that whether or not the liquid level height in a container exceeds a warning height can be detected timely and accurately through a simple structure, and the liquid level height can be controlled automatically; through the detachable detection tube, parts in the detection tube are maintained and replaced conveniently; operation is facilitated, and enterprise production cost is saved greatly.

Owner:NANJING TAOTESI SOFTWARE TECH CO LTD

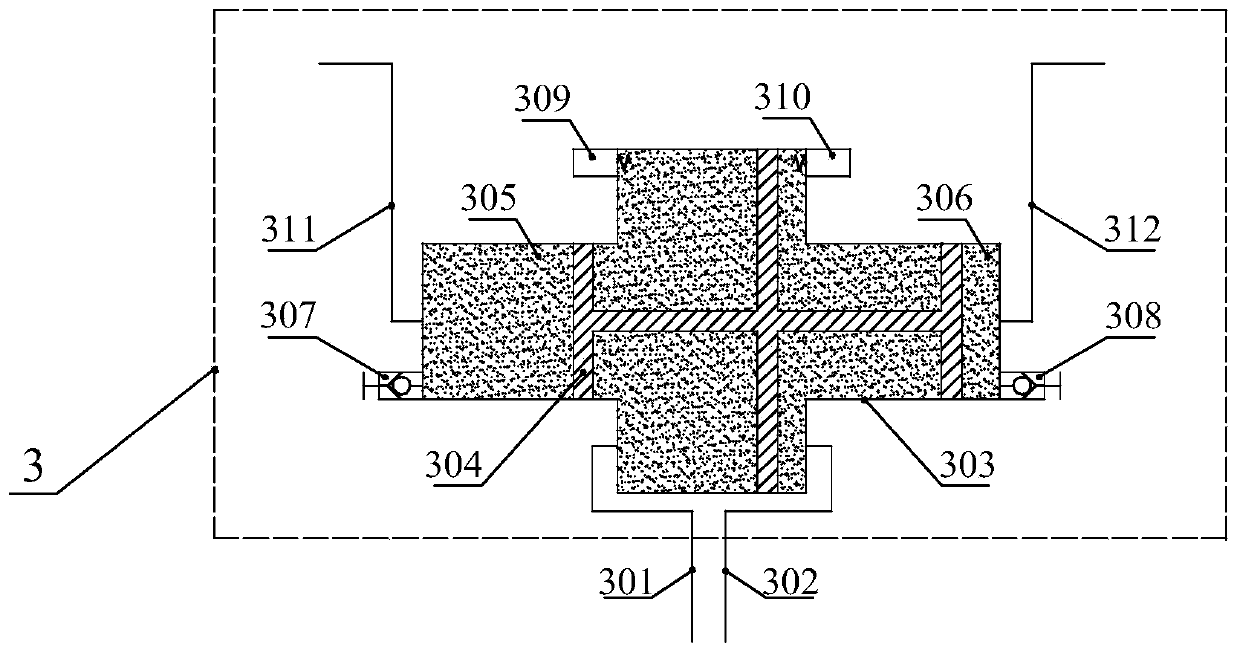

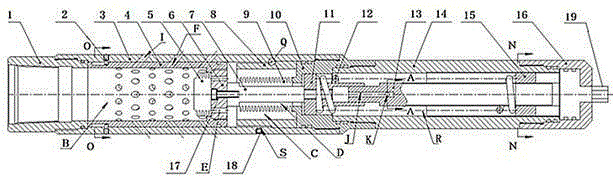

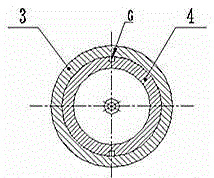

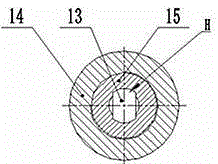

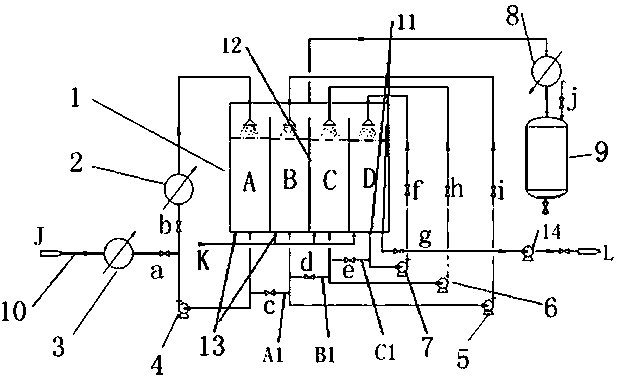

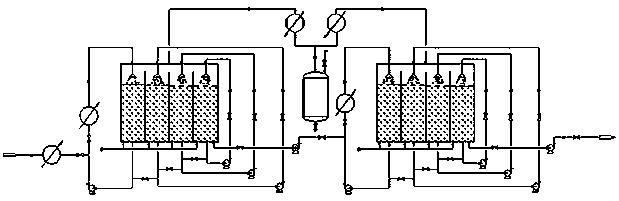

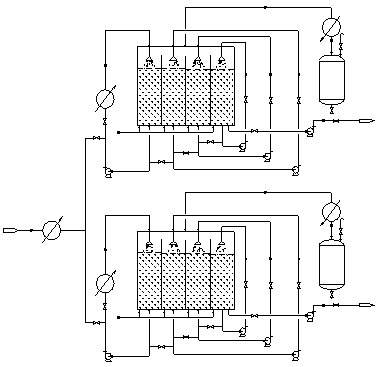

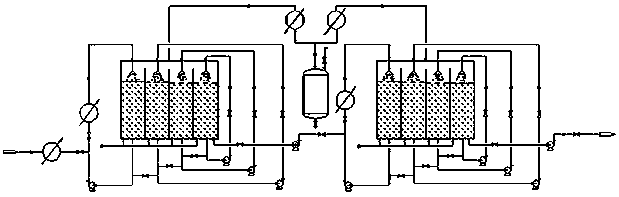

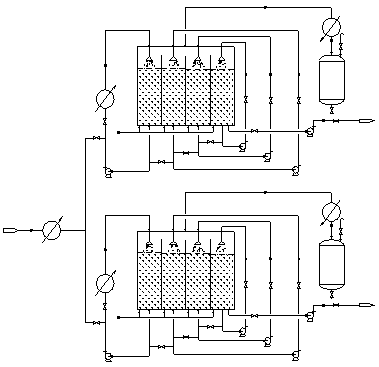

Swinging reversing two-stage pressurization zero-clearance type ionic liquid compressor

ActiveCN111365211AReduced control accuracyReduce energy consumptionPositive displacement pump componentsPump controlIonic liquidPiston

The invention belongs to the technical field of compressors, and particularly relates to a swinging reversing two-stage pressurization zero-clearance type ionic liquid compressor. Ionic liquid compressors use ionic liquid instead of metal pistons to generate high pressure under isothermal condition, however, an existing ionic liquid compressor uses 5-stage compression, and is complex in structure,difficult to machine and high in cost, so that the construction and development of a hydrogen refueling station are limited. The swinging reversing two-stage pressurization zero-clearance type ionicliquid compressor comprises a hydraulic mechanism and a gas pressurization mechanism which are mutually connected; the gas pressurization mechanism comprises a hydraulic swinging assembly, the hydraulic swinging assembly is connected with a first-stage gas pressurization assembly, and the hydraulic swinging assembly is connected with a second-stage gas pressurization assembly; and the hydraulic swinging assembly is connected with the hydraulic mechanism through a reversing assembly. According to the compressor, the structure is simple, machining is convenient, the control precision is high, the energy consumption is low, the clearance volume is zero, the universality is strong, hydrogen is not polluted and the cost is low.

Owner:XI AN JIAOTONG UNIV

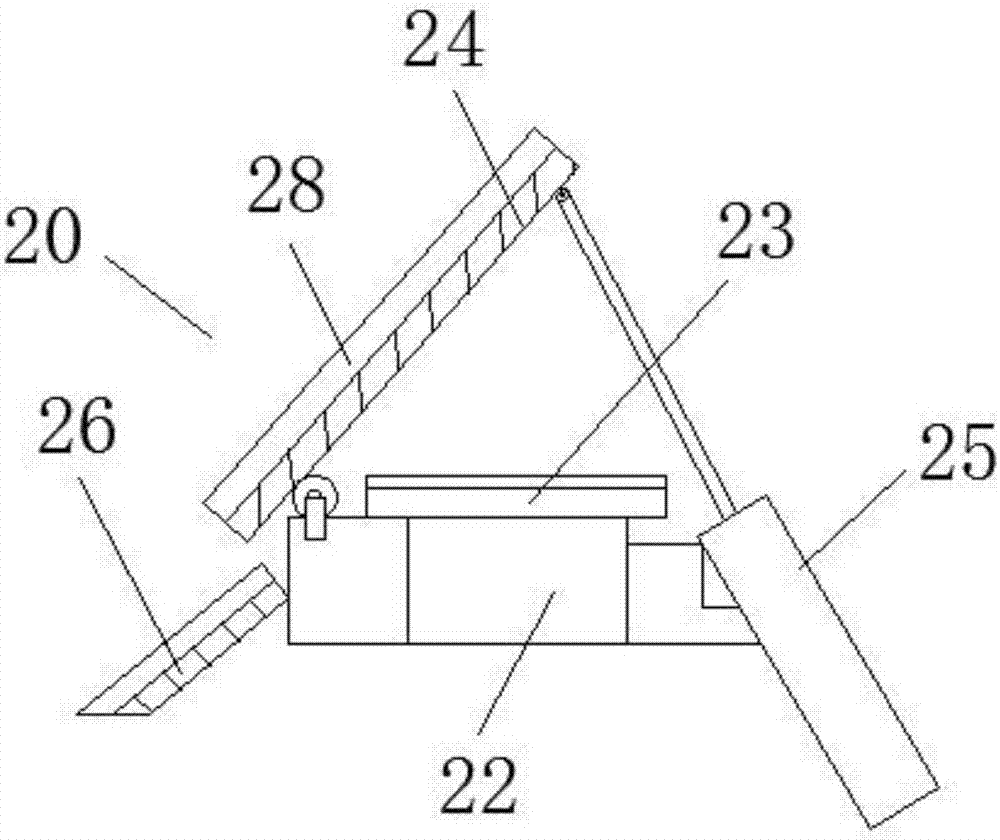

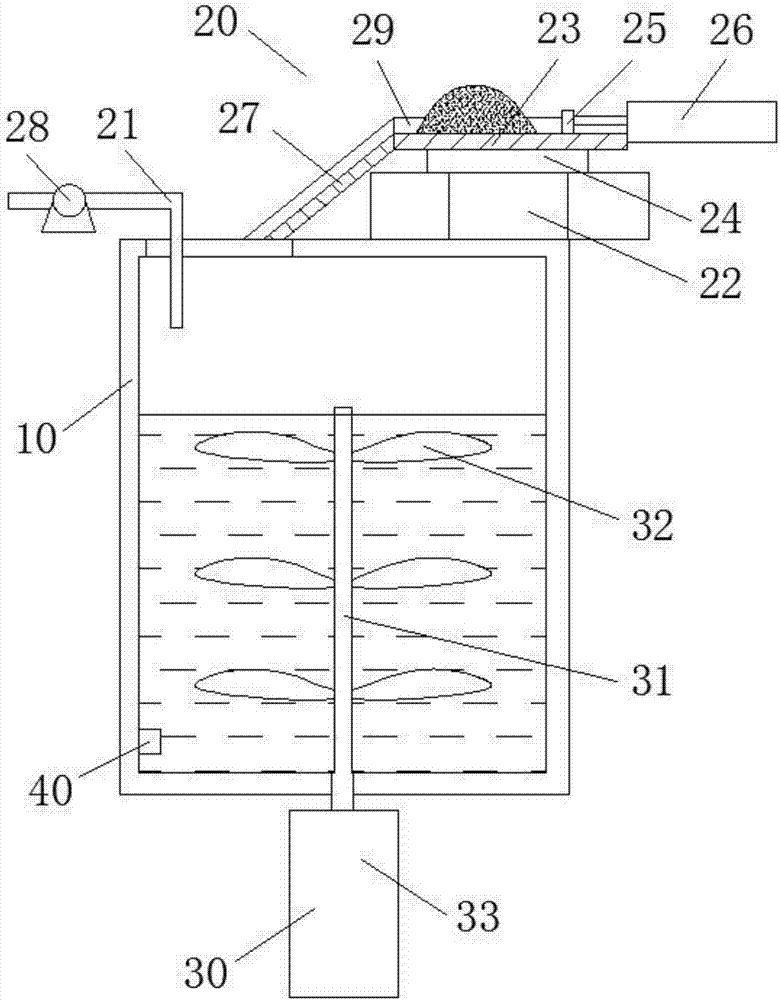

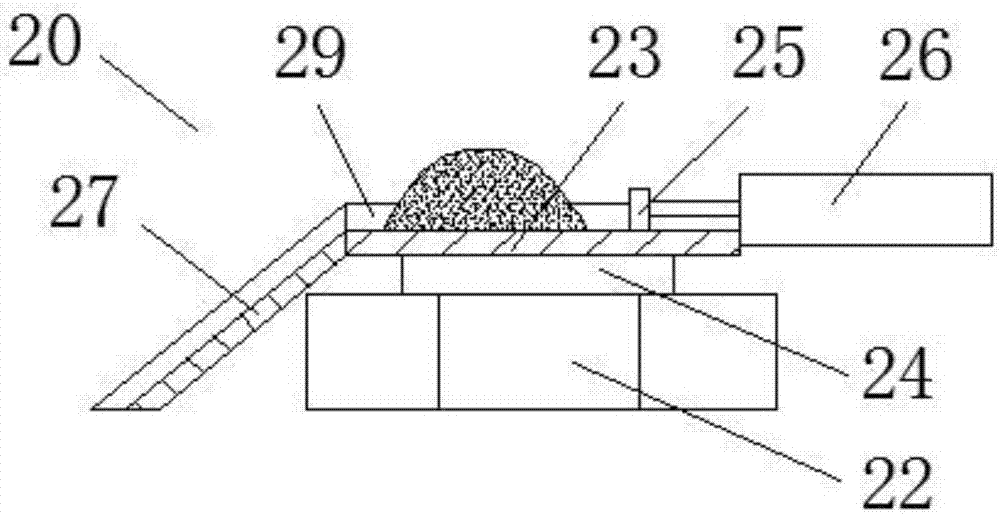

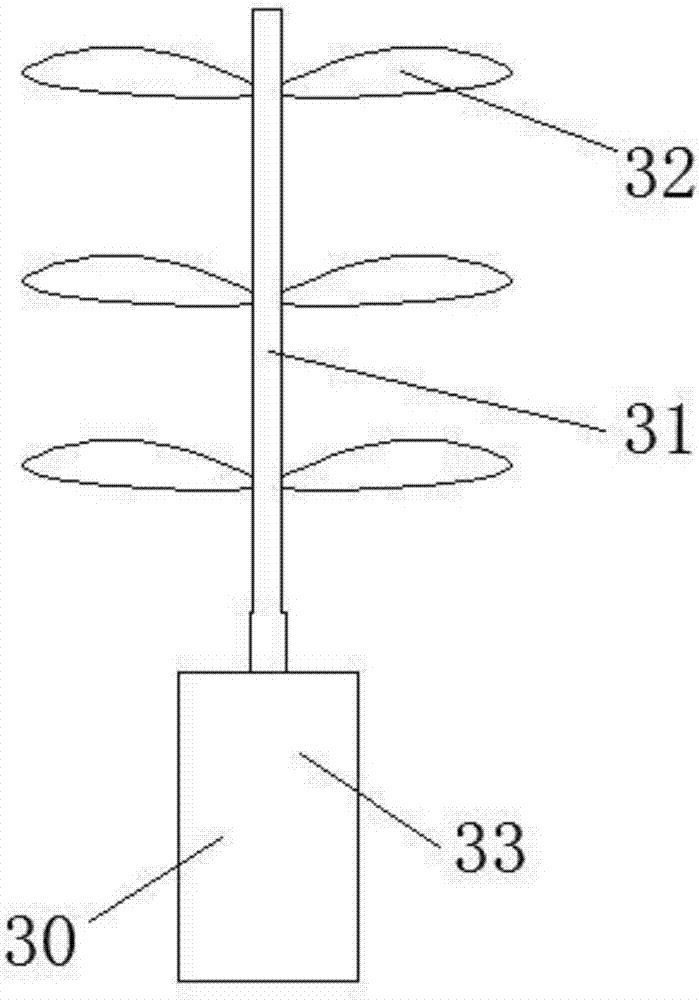

Automatic quantitative feeding device

InactiveCN107441990AImprove feeding accuracy and feeding efficiencyImprove feeding accuracyRotary stirring mixersTransportation and packagingGastric tube feedingFeeding tube

The invention relates to an automatic quantitative feeding device which comprises a mixing tank and a feeding component, wherein a feeding hole is formed in the upper end of the mixing tank; the feeding component comprises a liquid material feeding tube, a powder material feeding rack, a powder material weighing sensor, a powder material feeding plate and a feeding cylinder, wherein the outlet of the liquid material feeding tube extends into the feeding opening of the mixing tank; the powder material feeding rack is arranged on the mixing tank; a powder material feeding plate is pivoted with the powder material feeding rack; the powder material weighing sensor is fixed on the powder material feeding rack and is positioned below the powder material feeding plate; the piston rod of the feeding cylinder is connected with the powder material feeding plate and is used for driving the powder material feeding plate to rotate and feed materials.

Owner:台山市兰宝磨具有限公司

Mixing device capable of realizing automatic and quantitative feeding

InactiveCN107362721AImprove feeding accuracy and feeding efficiencyImprove the mixing effectRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention relates to a mixing device capable of realizing automatic and quantitative feeding. The mixing device comprises a mixing tank and a feeding component, wherein the upper end of the mixing tank is provided with a feeding opening; the feeding component comprises a liquid material feeding pipe, a powdery material feeding plate, a powdery material weighing sensor and a powdery material pushing plate; the outlet of the liquid material feeding pipe extends into the feeding opening of the mixing tank; the powdery material feeding plate is fixed on the powdery material weighing sensor and is located above the feeding opening; and the powdery material pushing plate is slidably arranged on a powdery material feeding plate. According to the invention, the feeding component is arranged; the powdery material weighing sensor is used for measuring the mass of a fed powdery material in real time so as to realize accurate controlling of the mass of the powdery material; and the powdery material pushing plate pushes the powdery material into the mixing tank, so automatic and quantitative feeding is realized, and feeding accuracy and feeding efficiency of the powdery material are improved.

Owner:台山市兰宝磨具有限公司

Hydraulic automatic blowout control controller

The invention provides a hydraulic automatic blowout control controller which comprises an upper joint, an outer casing pipe, a piston, a connection sleeve, a sealing sleeve and a tailstock. The hydraulic automatic blowout control controller is characterized in that the circumferential face of the piston and the circumferential face of the outer casing pipe are provided with a plurality of corresponding inclined holes; the lower end of the piston is connected with a piston plug provided with a liquid inlet through a thread, a polytetrafluoroethylene corrugated pipe is connected with the piston plug, and the piston plug is connected with a transmission shaft; the transmission shaft is sleeved with the corrugated pipe and forms an air cavity, the corrugated pipe is in sealing connection with the transmission shaft, and one end of an opening of the corrugated pipe is fixedly connected with the connection sleeve; the lower end of the transmission shaft is connected with s spring seat, the spring seat and an adjusting rod are sleeved with springs, the lower end of the adjusting rod is provided with a key, and the adjusting sleeve is internally provided with a key groove.

Owner:LIAONING XINHUA INSTR CO LTD

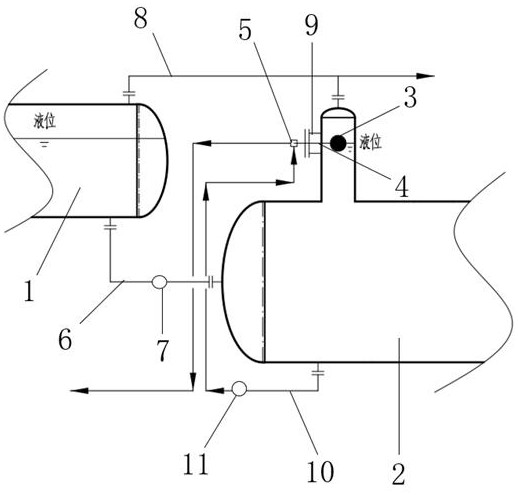

Device for controlling oil-water interface of split equipment

PendingCN112698670AControl liquid levelRealize automatic adjustmentLevel controlFluid removalOil waterWater tanks

The invention provides a device for controlling an oil-water interface of split equipment, and relates to the technical field of crude oil treatment. The device comprises an oil-gas-water separator and a settling water purification tank, the oil-gas-water separator is communicated with the settling water purification tank, and a floater connecting rod mechanism is arranged at the upper end of the settling water purification tank and comprises a floating ball, a connecting rod and a control valve. The floating ball is arranged in the settling water purification tank, the connecting rod penetrates through the outer wall of the settling water purification tank and is fixedly connected with the floating ball, and the end, away from the floating ball, of the connecting rod is fixedly connected with a control valve. By arranging the floater connecting rod mechanism, the liquid level of the oil-gas-water separator can be controlled, the liquid level of the settling water purifying tank can be controlled, and the technical problems that an oil-water interface can be adjusted only after production stopping and tank cleaning, the process is complex, consumption is large, and the period is long can be solved.

Owner:SINO TECH CO LTD +1

A continuous glycerin esterification acid reduction device

ActiveCN108330001BSmall footprintAchieve the purpose of continuous glycerol esterification and acid reductionFatty acid esterificationOrganic compound preparationCommunicating vesselsGlycerol

The invention relates to a continuous glycerol esterification and deacidification device. The device comprises a glycerol esterification reaction tank, a heater, a raw material pre-heater and the like, wherein the glycerol esterification reaction tank is internally divided into a plurality of compartments through baffle plates; an internal cycle is formed among the first compartment, circulating pumps and the heater; a raw material feeding pipeline with a raw material pre-heater is connected between the heater and the circulating pump through a pipeline; bottom outlets of the middle compartments are connected with the circulating pumps respectively; outlets of the circulating pumps are connected with top inlets of the middle compartments respectively; the bottom outlet of the final compartment is connected with a circulating pump and a product discharging pipeline; the outlet of the circulating pump is connected with the top inlet of the final compartment; the bottom outlets of the compartments are connected through a pipeline with a valve in sequence. According to the continuous glycerol esterification and deacidification device provided by the invention, the baffle plates are arranged and the circulating pumps are combined to use; multi-kettle serial connection continuous glycerol esterification and deacidification reaction in one reaction tank is realized by utilizing a communicating vessel principle; the device has the advantages of few equipment quantity, small occupied area, controllable staying time, low acid value of a product, small heat loss, benefits to industrialized production and the like.

Owner:ZHEJIANG UNIV OF TECH

Three-level refining method and system for disinfectant steam

InactiveCN102526780AImprove disinfection effectImprove efficiencyGaseous substancesChemicalsThree levelDisinfectant

Provided are a three-level refining method and a system for disinfectant steam. The three-level refining method comprises the steps of firstly using ultrasonic atomization technology to primarily atomize disinfectant liquid; secondly, utilizing mixed refining technology to shock hot air to scatter disinfectant atomization gas, utilizing air flow to lead the atomized gas to be crashed, cut and broken, effectively breaking molecular groups of disinfectant atomization gas, and secondarily refining disinfectant atomization gas; finally, using efficient steam technology to enable mixed gas of disinfectant and air to be fully in contact with the inner wall of an evaporator to be heated to be evaporated, enabling the atomization gas to be refined thirdly, and achieving the purpose of inputting super fine grain disinfectant steam. The three-level refining method and the system for disinfectant steam use method combination of ultrasonic atomization, air flow milling and an evaporation three-level refining method to obtain micron disinfectant steam grains, thereby remarkably improving decontamination effect and decontamination efficiency when the disinfectant steam serves as decontamination steam.

Owner:BEIHANG UNIV +1

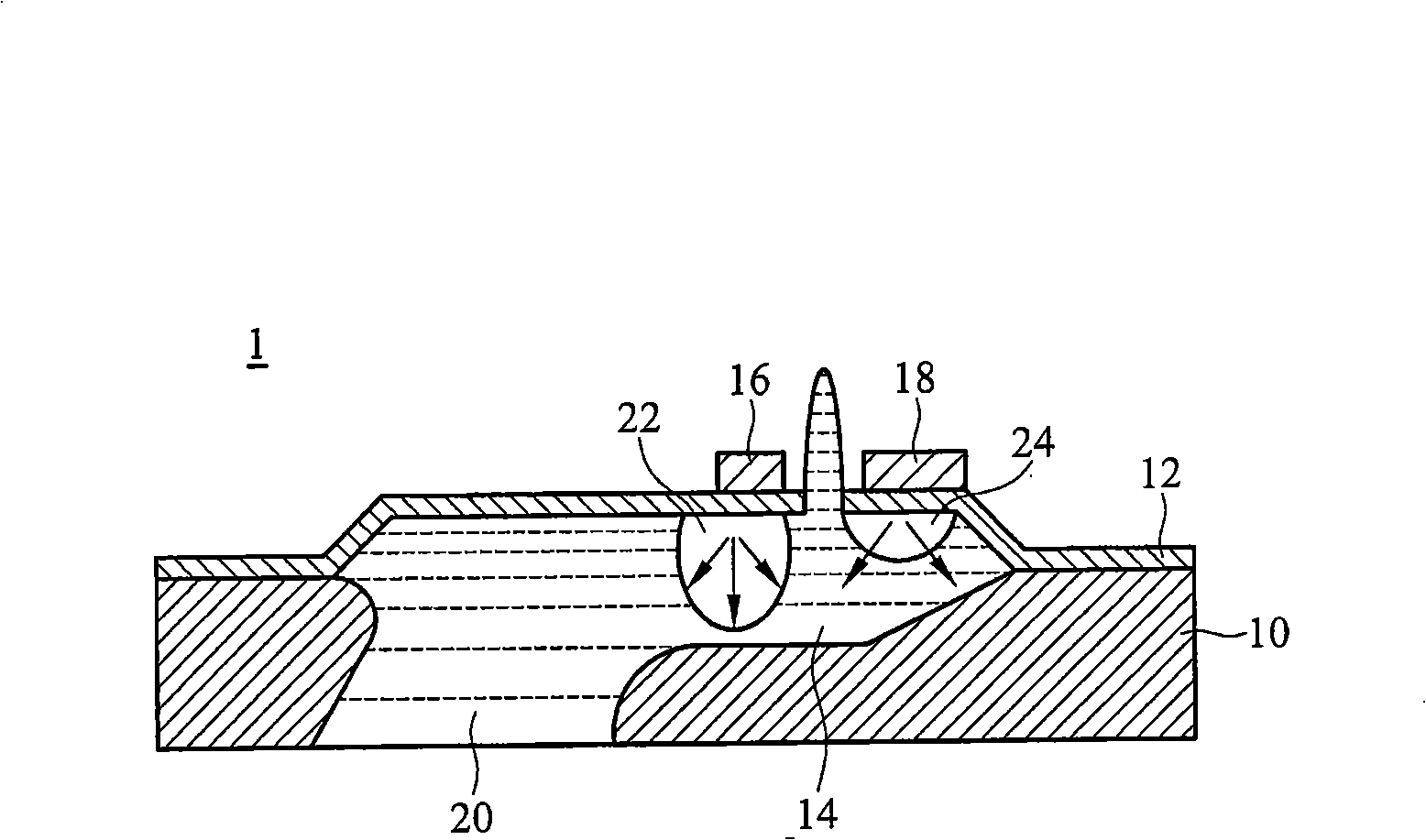

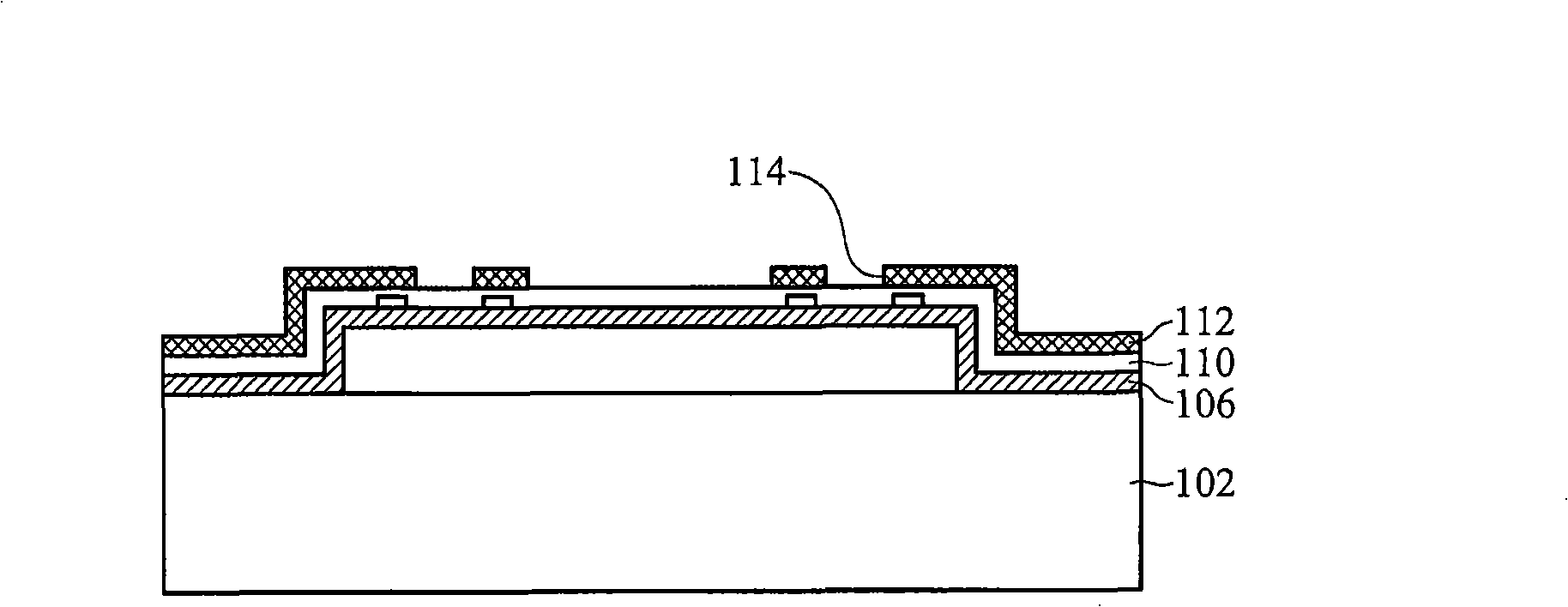

Single-block fluid injection device and production and control method thereof

The invention provides a single block fluid injection device and a preparation and control method of the single block fluid injection device. The single block fluid injection device comprises a substrate, a structure layer which is arranged on the substrate; furthermore, a fluid chamber is formed between the structure layer and the surface of the substrate, so as to receive the fluid; the single block fluid injection device also comprises a liquid surface control unit which is formed on the structure layer and an injection hole which passes through the liquid surface control unit and the structure layer, so as to be communicated with the fluid chamber. The liquid surface height of the fluid in the injection hole is regulated by the liquid surface control unit, so as to inject the ink drops with different fluxes and directions.

Owner:BENQ CORP

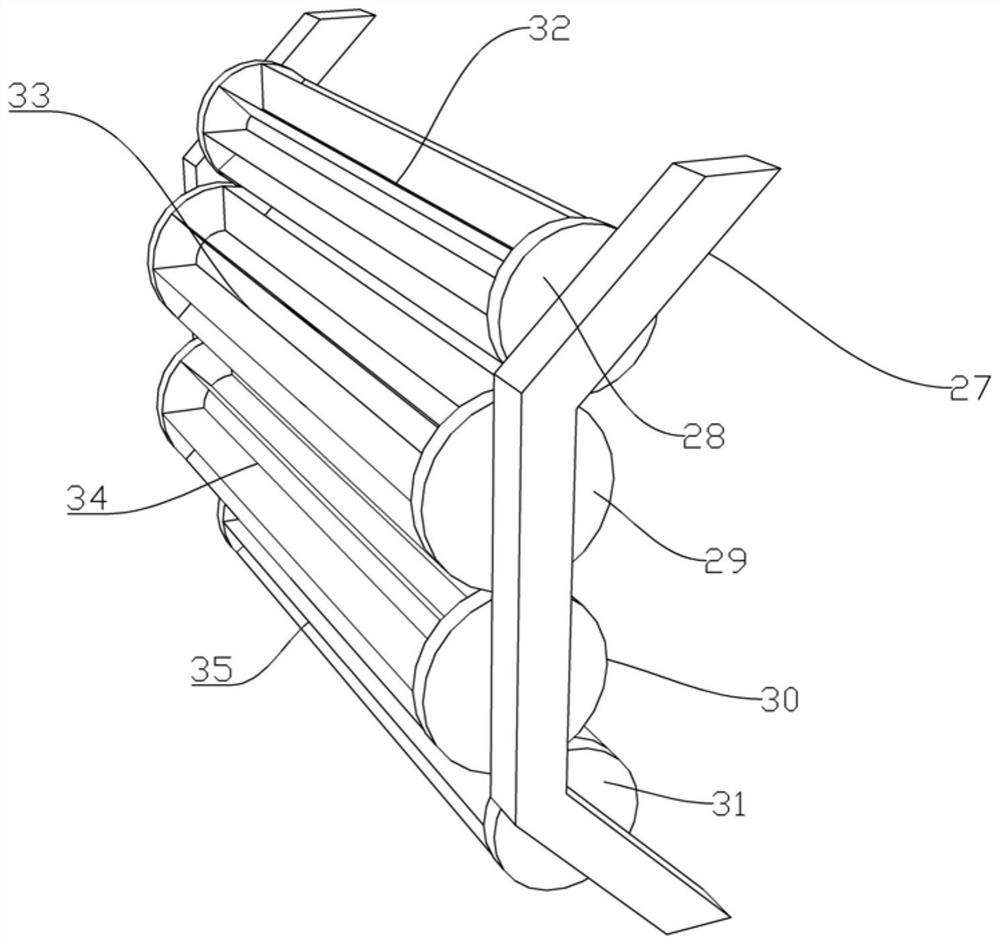

Adjustable wiredrawing cooling device

The invention discloses an adjustable wiredrawing cooling device. The adjustable wiredrawing cooling device comprises a cooling pond, a plurality of vertically-arranged movable rods are mounted in thecooling pond, the lower ends of the movable rods are slidably connected with the cooling pond, a slide rail with an upper rail and a lower rail in parallel is mounted on the inner wall of the coolingpond, the movable rods penetrate through the slide rail, the upper ends of the movable rods are fixedly connected with the slide rail, first guiding wheels are mounted on the side faces of the movable rods respectively, threaded rods are rotatably connected with the interiors of the movable rods, the threaded rods are sleeved with sliding blocks in a threaded mode, the sliding blocks are slidablyconnected with the inner walls of the movable rods, and the side faces of the movable rods are provided with strip-shaped openings communicated with the threaded rods. The adjustable wiredrawing cooling device can adjust the movable rods and the first guiding wheels, a user can adjust the positions of the first guiding wheels according to demands, the steel wire can be stretched again by adjusting the route length of the steel wire passing in the cooling pond, and the cooling time of the steel wire is prolonged or shortened.

Owner:湖州市练市创鑫金属拉丝厂

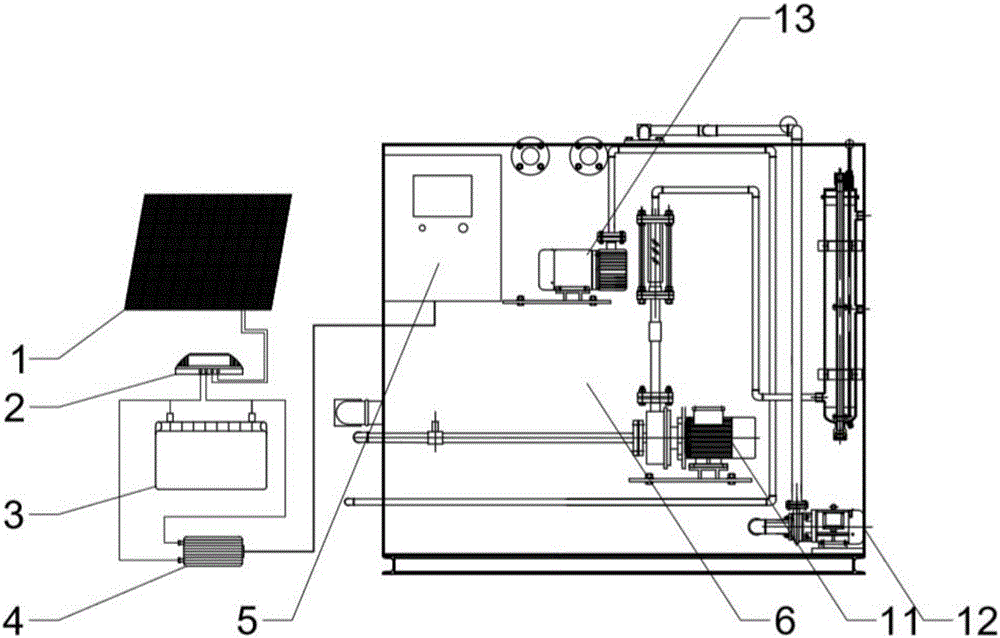

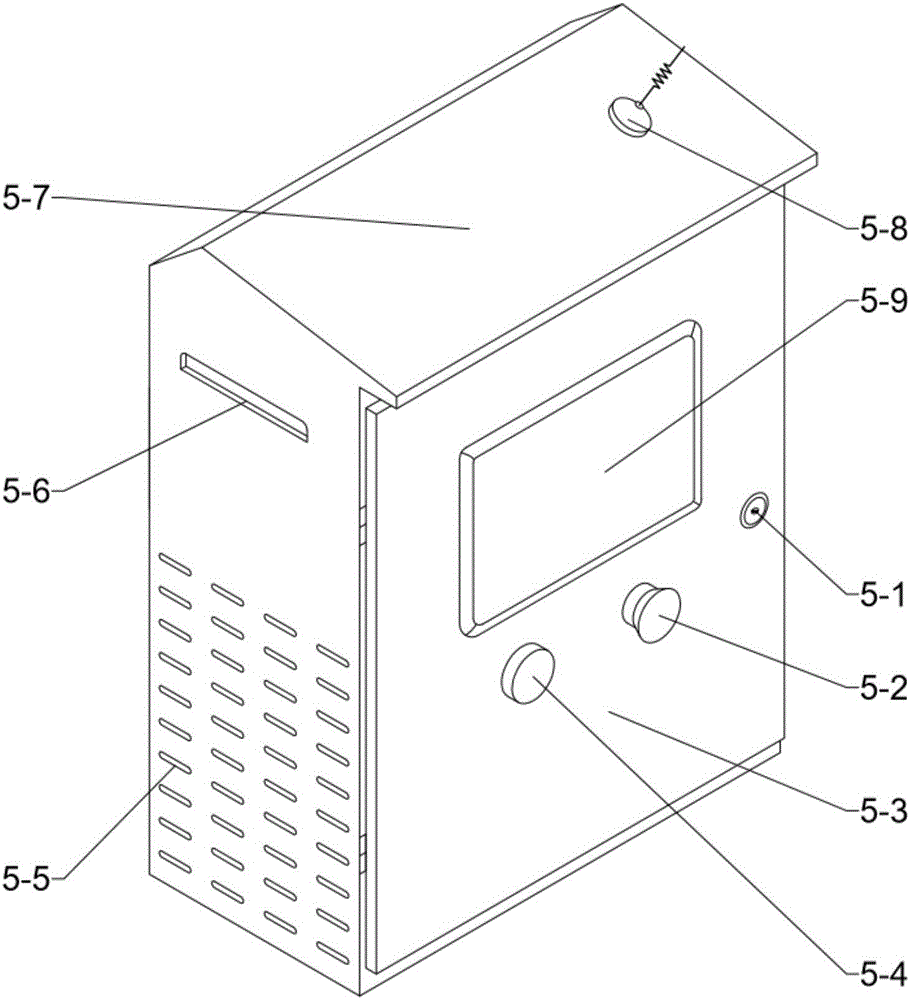

Optical self-driven intelligent vessel sewage recycling apparatus and control method thereof

ActiveCN106774139ASave electricity on boardImprove work efficiencyProgramme control in sequence/logic controllersEngineeringSewage treatment

The invention provides an optical self-driven intelligent vessel sewage recycling apparatus and a control method thereof; a solar panel is arranged at the top of a vessel and connected with a controller, the controller is connected with two battery packs, the battery packs are connected with an inverter, the inverter is connected with an electric cabinet which is suspended in the front of the vessel sewage recycling apparatus and is connected with a level meter, a temperature and a heater in the vessel sewage recycling apparatus as well as a device to be controlled through internal junction terminals. In order to overcome the technical barriers of an existing vessel sewage treatment apparatus supporting system, such as poor intuitiveness of electric control process, operational difficulty, low efficiency, poor reliability and low operating performance, and also the problem that the vessel sewage recycling apparatus is unable to operate independently of a power supply system of the vessel, the invention provides an remotely-operable photovoltaic generation system and electric control system combine allowing optical self-driven intelligent operation for the vessel sewage treatment apparatus.

Owner:HARBIN ENG UNIV

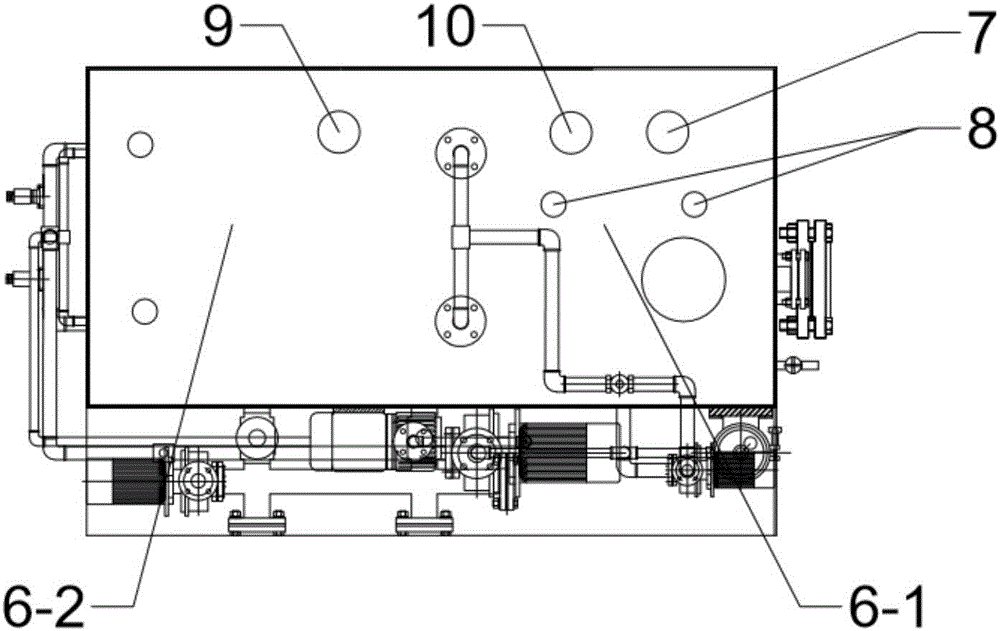

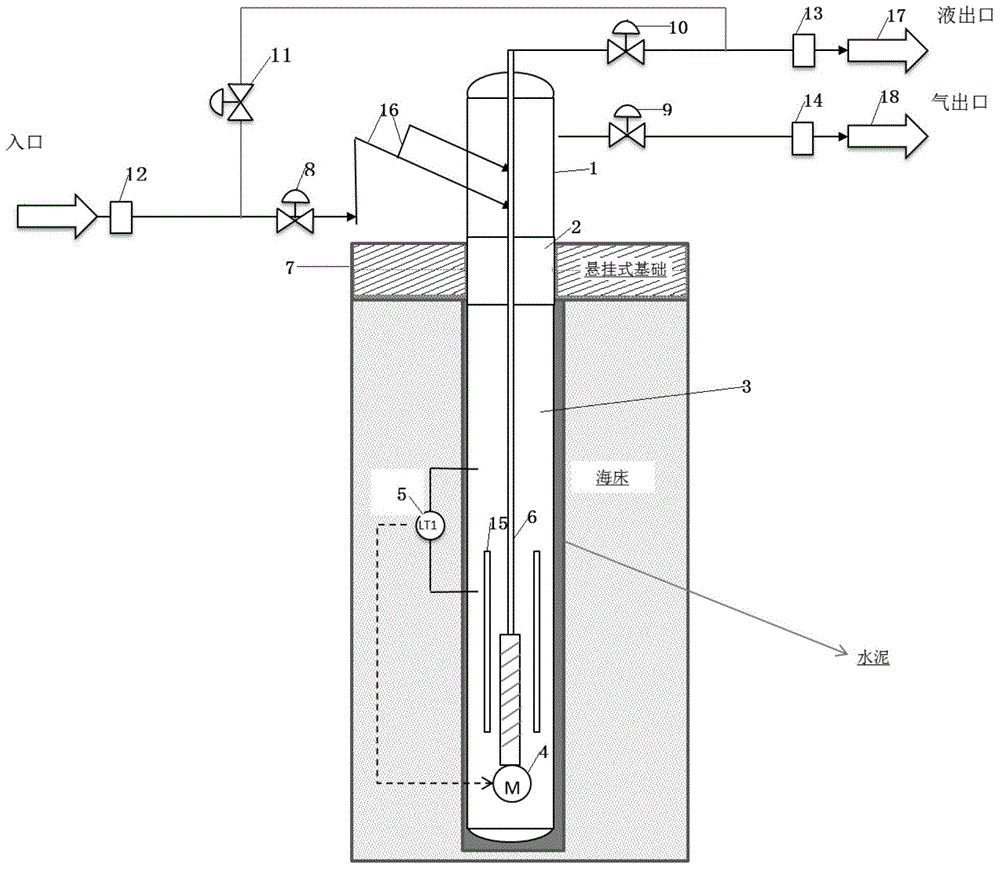

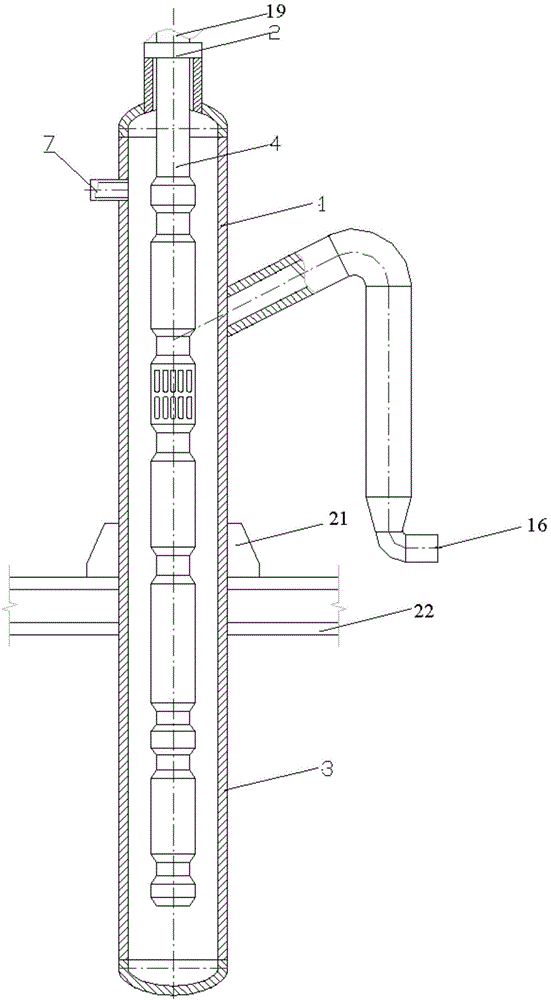

Caisson type underwater gas-liquid separator

The invention discloses a caisson type underwater gas-liquid separator comprising a gas-liquid cyclone separator body and a caisson type slug flow catcher. The gas-liquid cyclone separator body is communicated with at least two feeding pipelines. The feeding pipelines and the gas-liquid cyclone separator body are arranged in an inclined mode. The gas-liquid cyclone separator body is provided with a gas phase outlet and a liquid phase outlet. The bottom of the gas-liquid cyclone separator body is communicated with the caisson type slug flow catcher. The bottom of the caisson type slug flow catcher is provided with an electric submersible pump. The electric submersible pump is connected with the motor. An outlet of the electric submersible pump is connected with a liquid conveying pipe. The liquid conveying pipe penetrates through the caisson type slug flow catcher and the gas-liquid cyclone separator body in sequence and is communicated with the liquid phase outlet in the gas-liquid cyclone separator body. According to the caisson type underwater gas-liquid separator, due to the fact that the slug flow catcher installed in a caisson type is in butt joint with the efficient gas-liquid cyclone separator body, the manufacturing difficulty of the separator is greatly reduced, and the underwater installation difficulty is also reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Reflow defoaming system of electroplating process tank

The invention discloses a reflow defoaming system of an electroplating process tank. The system involves an upper tank body, a flow guiding tank body, a lower tank body, a overflow box and a defoamingdevice, wherein the upper tank body is provided with a through port for allowing a to-be-plated board to pass through, the flow guiding body is arranged on one side of the upper tank body and communicates with the upper tank body through the through port, the lower tank body is located below the upper tank body, the bottom of the lower tank body is provided with a partition plate for partitioningthe interior space of the lower tank body into a reflow area and a defoaming area, a bubble layer above the electroplating liquid or cleaning liquid in the reflow area overflows from the top of the partition plate and enters the defoaming area, the overflow box communicates with a plate passing liquid discharging port at the side, opposite to the upper tank body, of the flow guiding tank body, the lower part of the overflow box communicates with a drainage pipe leading to the reflow area, the defoaming device is located above the defoaming area, and a negative pressure area is formed above the defoaming area to suck air bubbles in the reflow area and perform shear elimination on the bubbles. According to the system, a overflow pipe is arranged between the upper tank body and the lower tank body, the partition board and the defoaming device are arranged in the lower tank body, bubbles in the electroplating solution or cleaning liquid obtained by reflow can be eliminated, and the influence of bubbles on the electroplating quality of the product is reduced.

Owner:广德东威科技有限公司

Continuous glycerol esterification and deacidification device

ActiveCN108330001ASmall footprintAchieve the purpose of continuous glycerol esterification and acid reductionFatty acid esterificationLiquid carbonaceous fuelsGlycerolCommunicating vessels

Owner:ZHEJIANG UNIV OF TECH

Cracking and permeability increasing device capable of pressurizing liquid nitrogen to dissolve coal body and permeability increasing experiment method

ActiveCN109630087AEasy to observeSimple structureSurveyOther gas emission reduction technologiesIsolation valveEngineering

The invention discloses a cracking and permeability increasing device capable of pressurizing liquid nitrogen to dissolve coal body containing gas, which comprises a heat preservation cylinder, wherein the center of the top wall of the heat preservation cylinder is downwards connected with an inner cylinder, and a gap is formed between the bottom end of the inner cylinder and the bottom wall of the heat preservation cylinder; the middle part of the inner cylinder is horizontally provided with a pressure-resistant metal mesh sheet which divides the upper part and lower part of the inner cylinder into a coal body cavity and a liquid inlet cavity; the middle part of the inner cylinder is provided with an isolation valve, the isolation valve is used for separating the inner cylinder, and the valve rod of the isolation valve extends out of the heat preservation cylinder in the horizontal direction; the top wall of the heat preservation cylinder, at the top end of the inner cylinder, is in threaded connection with an inner cylinder cover, and a threaded shaft body is arranged on the inner cylinder cover; the invention also discloses a permeability increasing experiment method which can be used to carry out liquid nitrogen leaching coal body experiments under the conditions of different gas adsorption pressures of the coal body, can better control the specific size of the liquid nitrogen leaching coal body, is suitable for repeatedly carrying out permeability increasing experiments on the coal body under different experiment conditions, is favorable for obtaining an optimal permeability increasing scheme and provides technical support for the exploitation and utilization of coal bed gas.

Owner:HENAN POLYTECHNIC UNIV

Water sealing moving integrated type ventilation dust removing cover

The invention discloses a water sealing moving integrated type ventilation dust removing cover which comprises a ventilation cover groove body and a ventilation pipe. The ventilation cover groove body comprises an opening end and a sealed end. The sealed end is provided with a dust removing air pipe connector. Sealing cooling liquid is contained in the ventilation cover groove body. A cavity is formed between the position above the liquid level of the sealing cooling liquid and the sealed end. The middle section of the ventilation pipe is placed in the sealing cooling liquid. An air outlet section of the ventilation pipe extends to the cavity. An air inlet section of the ventilation pipe extends to the outer portion of the ventilation cover groove body from the opening end. Compared with an existing sealing mode of a moving ventilation groove by belt sealing, the water sealing integrated type ventilation dust removing cover is good in sealing effect, low in air leakage, good in dust removing effect and suitable for dust removing processing of high-temperature dust-containing air flow.

Owner:MOUNTOP GRP CO LTD

Chitosan oligosaccharide chelated ferrous preparation method and device

ActiveCN114405428AImprove the mixing effectWell mixedProcess control/regulationSugar derivativesChemistryEngineering

The invention provides a chitosan oligosaccharide chelated ferrous iron preparation device which comprises a first-stage mixing pipe, a second-stage mixing pipe and a mixing pool which are sequentially arranged from top to bottom, and the mixing pool is further connected with a suction filtration device; one end of the first-stage mixing pipe is connected with a water inlet pipe through a flow switch, the upper part of the first-stage mixing pipe is also provided with a feeding box for quantitative feeding, a plurality of stirring structures for mixing fed objects with water are arranged in the first-stage mixing pipe, and the other end of the first-stage mixing pipe is connected with the side wall of the second-stage mixing pipe; a plurality of first-stage mixing pipes are distributed on the second-stage mixing pipe, the first-stage mixing pipes are symmetrically arranged on the two sides of the second-stage mixing pipe, and a plurality of first mixing plates which are obliquely arranged upwards are arranged on the side wall, close to the first-stage mixing pipes, of the second-stage mixing pipe; the mixing effect can be remarkably improved through the first-stage mixing pipe, the second-stage mixing pipe, the stirring structure and the mixing pool structure, and a well-mixed and PH-value-adjusted mixed solution is automatically and continuously provided for the suction filtration device.

Owner:湖南德邦生物科技股份有限公司

Liquid level adjusting device

The invention discloses a liquid level adjusting device. The liquid level adjusting device is used for adjusting the liquid level in needed liquid storage equipment connected with the liquid level adjusting device. The liquid level adjusting device comprises a drain pipe, a telescopic pipe, a liquid level control mechanism and an adjustable fixing mechanism. The drain pipe, the telescopic pipe and the liquid level control mechanism are sequentially connected. The adjustable fixing mechanism is used for fixing the liquid level control mechanism. The drain pipe is communicated with the interior of the needed liquid storage equipment. The telescopic pipe and the liquid level control mechanism are vertically arranged beside the needed liquid storage equipment. An upper port of the liquid level control mechanism is an overflow opening. The adjustable fixing mechanism achieves liquid level adjustment of the liquid level control mechanism along with telescopic motion of the telescopic pipe. Through the telescopic pipe and the adjustable fixing mechanism matched with the telescopic pipe, the height of the liquid level control mechanism can be flexibly and conveniently adjusted, the liquid level in the needed liquid storage equipment can be controlled, the structure is simple, and operation is convenient. Through a float valve structure, opening and closing of the drain pipe are achieved, the liquid level can be controlled, and a water backflow prevention effect can be achieved.

Owner:汪传发

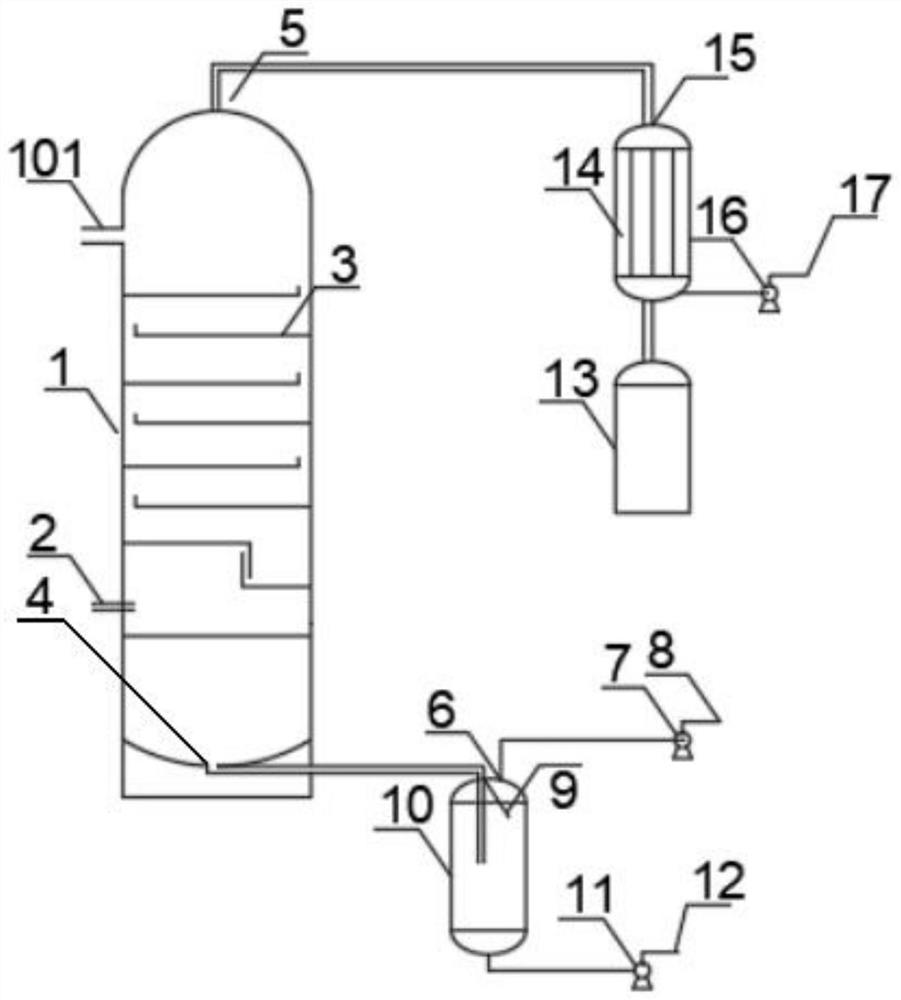

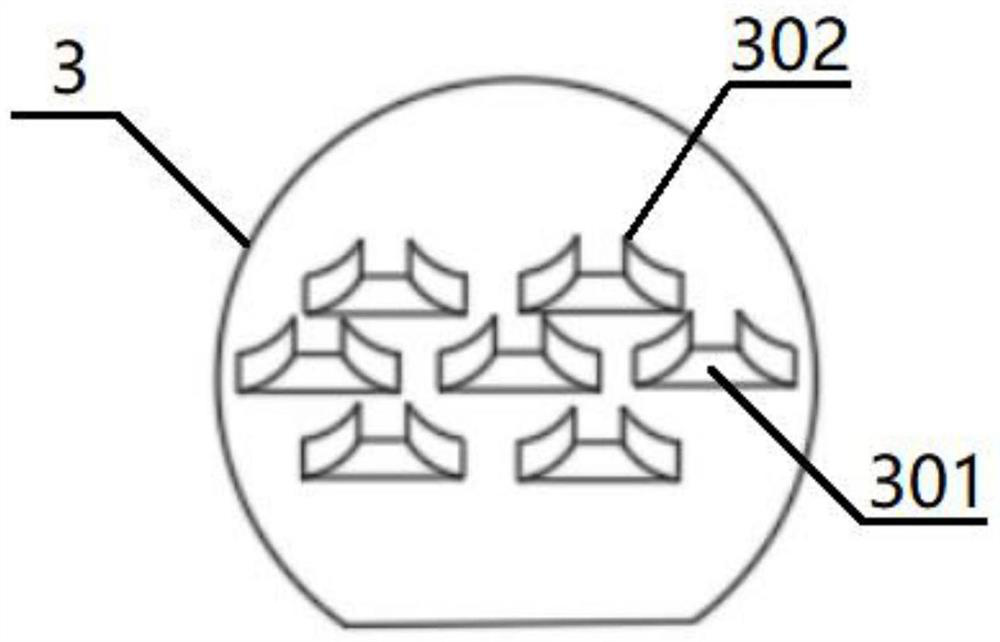

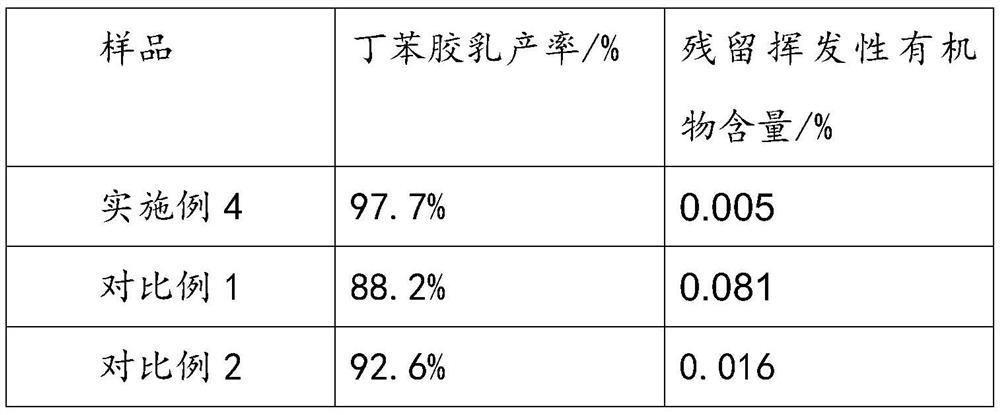

Styrene-butadiene latex degassing device and degassing method

The invention discloses a styrene-butadiene latex degassing device which comprises a degassing tower, a tower top vacuum system and a tower kettle vacuum system, the tower top vacuum system comprises a condenser gas phase inlet, a tower top condenser and a liquid receiving tank which sequentially communicate through a pipeline, the condenser gas phase inlet communicates with a tower top gas phase outlet, and the tower top condenser is connected with a tower top vacuum pump; and the tower kettle vacuum system comprises a liquid seal tank and a tower bottom vacuum pump communicating with a gas phase outlet of the liquid seal tank. The VOC removal efficiency and the latex yield are increased by controlling the pressure difference between the tower top vacuum pump and the tower bottom vacuum pump and maintaining the pressure in the degassing tower, and the situation that the temperature of steam at the bottom of the tower is increased and latex crusting is avoided due to the fact that the system resistance is too large can be effectively prevented.

Owner:JINING MING SHENG NEW MATERIALS CO LTD

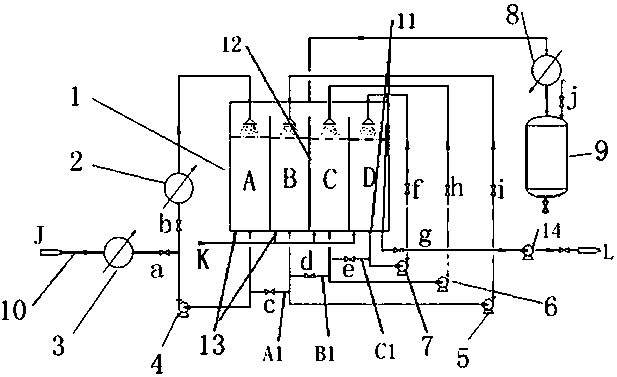

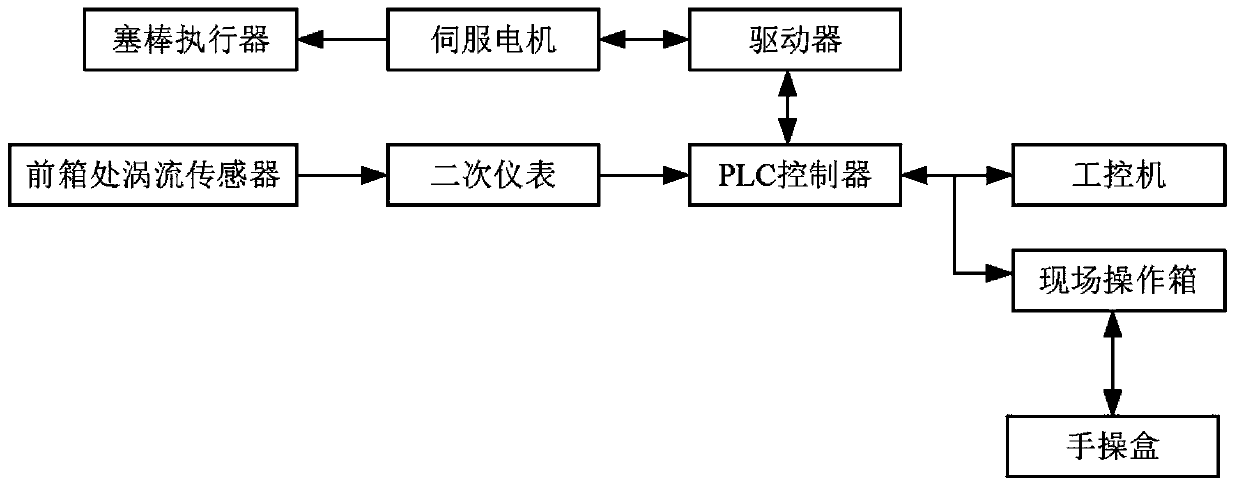

Front box liquid level control system and using method thereof

InactiveCN110794882AAccurate measurementAccurate control of the openingLevel controlProgrammable logic controllerControl system

The invention discloses a front box liquid level control system and a using method thereof. The control system comprises a manual operation box, an on-site operation box, an industrial personal computer, a PLC (programmable logic controller), a secondary instrument, an eddy current sensor at a front box, a driver, a servo motor and a stopper actuator. According to the invention, the eddy current sensor at a front box is arranged and is used for detecting a liquid level height of molten aluminum in the front box; the eddy current sensor generates an electromagnetic signal to generate eddy currents on the surface of molten aluminum; an induction signal is generated at an eddy current sensor coil at the front box by the eddy current and the signal intensity changes with a distance between thesurface of the molten aluminum to the bottom of the eddy current sensor at the front box, so that the liquid level of the molten aluminum can be accurately measured and the test precision can reach + / -0.3 mm.

Owner:HENGYANG RAMON SCI & TECH CO LTD

Intelligent ecological bionic mosquito killing device

The invention discloses an intelligent ecological bionic mosquito killing device which comprises a shell, a carbon dioxide gas generator and an artificial sweat feeder, wherein the carbon dioxide gasgenerator and the artificial sweat feeder are arranged in the shell. The intelligent ecological bionic mosquito killing device is characterized by further comprising a gas-liquid mixer and an atomizer, wherein the gas-liquid mixer is arranged in the shell, and the atomizer is arranged in the gas-liquid mixer. A first air outlet pipeline of the carbon dioxide gas generator extends into the gas-liquid mixer through a first air inlet of the gas-liquid mixer, a first liquid outlet pipeline of the artificial sweat feeder is communicated with the atomizer through a first liquid inlet of the gas-liquid mixer, a plurality of first air outlets are formed in the gas-liquid mixer and used for discharging carbon dioxide gas and atomized artificial sweat after mixing, and the first air outlet pipelineand the first liquid outlet pipeline adjust the flow of the carbon dioxide gas and the artificial sweat by equal proportion through a synchronous switch. The intelligent ecological bionic mosquito killing device can uniformly mix and cooperatively control the carbon dioxide gas and the artificial sweat.

Owner:ZHEJIANG WANLI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com