Styrene-butadiene latex degassing device and degassing method

A technology of styrene-butadiene latex and degassing device, which is applied in separation methods, liquid degassing, chemical instruments and methods, etc., can solve the problems of large fluctuation of product quality, difficult process control, long degassing time, etc. Volume and processing speed, control of liquid level, and the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

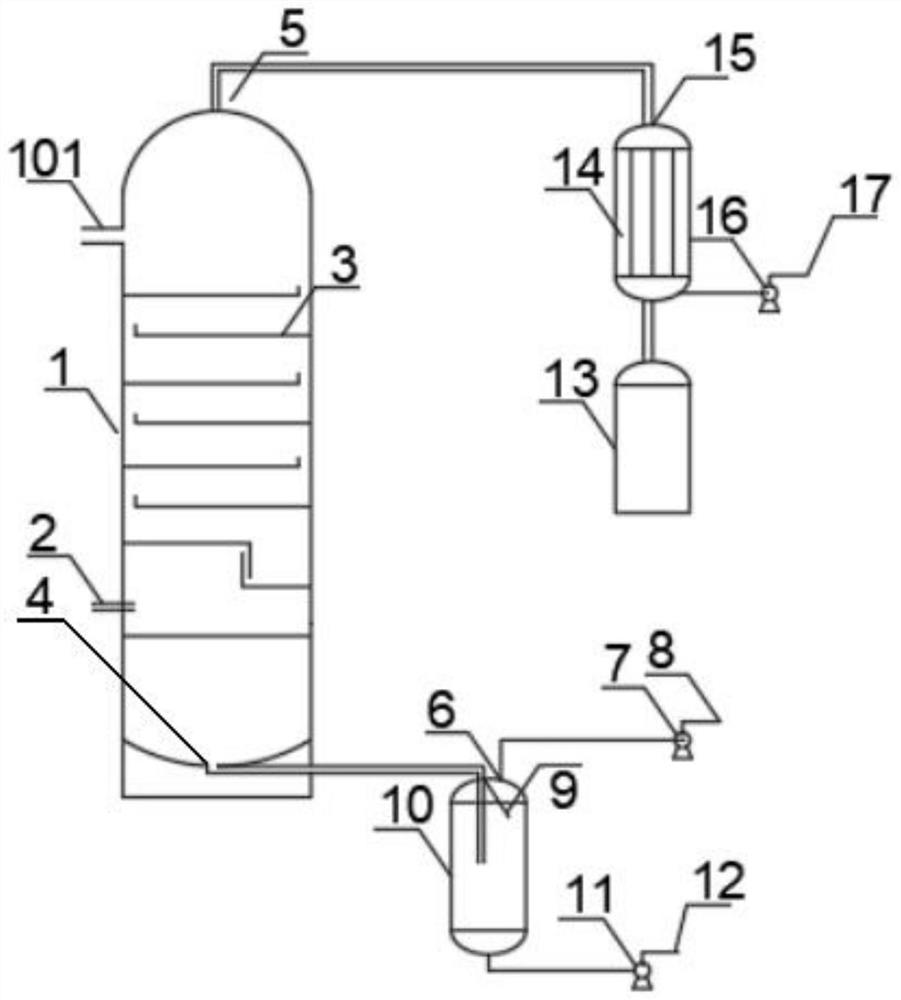

[0037] refer to figure 1 with figure 2 , a styrene-butadiene latex degassing device, comprising a degassing tower 1, a tower top vacuum system communicated with the tower top gas phase outlet 5 at the top of the degassing tower 1, and a tower bottom latex outlet 4 communicating with the degassing tower 1 bottom The tower kettle vacuum system;

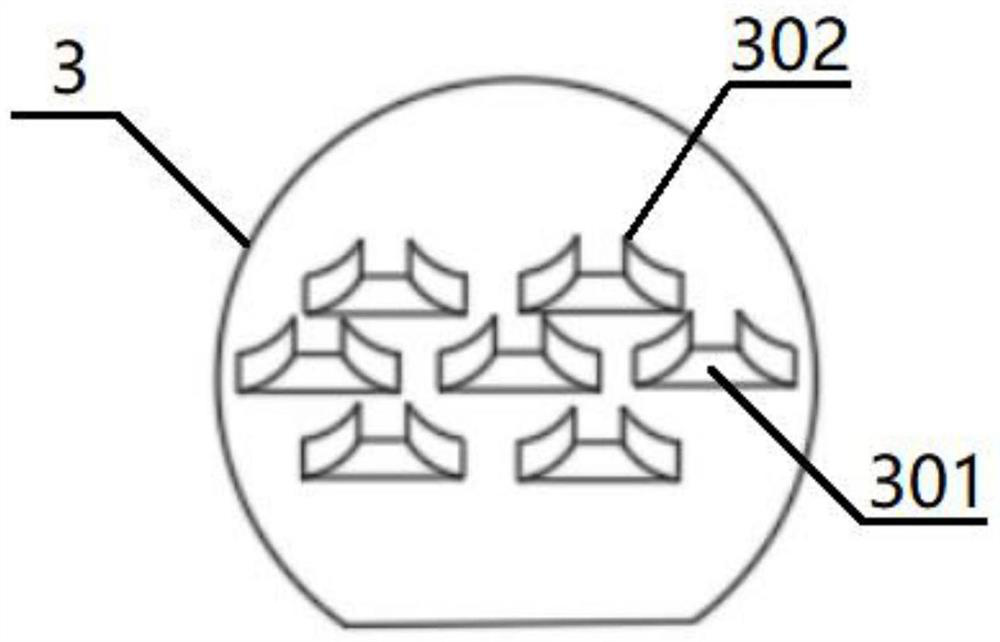

[0038] The main body of the degassing tower 1 is a cylindrical hollow structure. There are six vertical trays 3 fixed to the inner wall of the degassing tower 1. The diameter of the trays 3 is consistent with the inner diameter of the degassing tower 1. A plurality of steam outlets 301, steam outlets 301 are rectangular, opposite sides are provided with a pair of upwardly bent elongated tray openings 302, a gap is opened on one side of the tray 3, and the gaps of adjacent trays are arranged alternately. A steam inlet 2 is provided on the side wall of the degassing tower below the lowermost tray 3, and a latex inlet 101 is provided on...

Embodiment 2

[0050] An anti-flooding baffle 9 is arranged below the gas phase outlet 6 of the liquid seal tank to prevent liquid flooding. The anti-flooding baffle 9 forms an included angle of 45° with the vertical centerline of the liquid-sealed tank 10 . Others are the same as embodiment 1.

Embodiment 3

[0052] The vacuum pump 16 at the top of the tower and the vacuum pump 7 at the bottom of the tower are respectively connected with the differential pressure interlocking control device. The pressure difference between the top and the bottom of the tower is monitored and automatically adjusted through the differential pressure interlock control device. Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com