A continuous glycerin esterification acid reduction device

A glyceride and acid-reducing technology, applied in fatty acid esterification, organic chemistry, petroleum industry and other directions, can solve the problems of unfavorable continuous production, back-mixing of materials in the kettle, long residence time, etc., to avoid direct short-circuit, The effect of reducing back mixing and low acid value of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

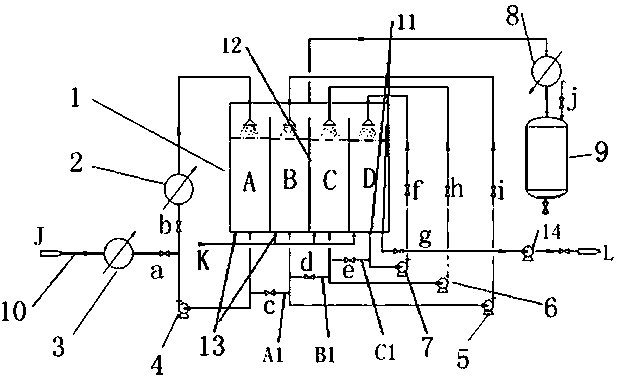

[0039] Such as figure 1 As shown, it is a device for a single glycerol esterification reaction tank 1, and three parallel baffles 12 are arranged in the glycerin esterification reaction tank 1, and the glycerin esterification reaction tank 1 has 4 compartments respectively, and the first compartment is respectively A, the second compartment B, the third compartment C, the fourth compartment D, the discharge pipe at the bottom of each compartment is divided into two paths, the discharge pipe at the bottom of the first compartment A passes through the first circulating pump 4, The heater 2 is connected to the feed inlet at the top of the first compartment A to form an internal circulation of the feed liquid in the first compartment A, and the outlet pipe at the bottom of the first compartment A passes through the first branch pipe A1 and the second compartment The discharge pipe at the bottom of B is connected, and the third valve c is arranged on the first branch pipe A1; the d...

Embodiment 2

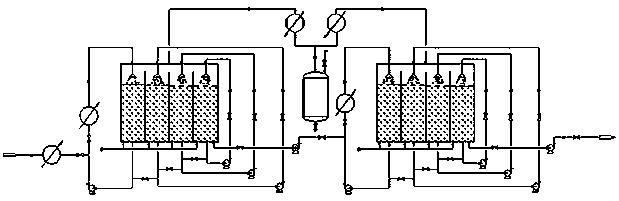

[0042] Such as figure 2 As shown, the continuous glycerol esterification acid reduction device of this embodiment is operated in series by two glycerol esterification reaction tanks 1, and the baffles 12 in each glycerol esterification reaction tank 1 are distributed as follows Figure 4 As shown, the glycerol esterification reaction tank 1 is divided into four compartments by three baffles 12, forming a continuous glycerin esterification acid reduction device with eight kettles connected in series. The first glycerol esterification reaction tank 1 The reaction product material at the outlet port enters the heater 2 from the feed pipe of the second glycerin esterification reaction tank 1 to be heated, and then enters the compartment of the second glycerin esterification reaction tank 1 to continue the reaction. The two glycerin esterification reaction tanks 1. The gas outlets on the top are respectively connected to the respective condensers 8 through pipelines. After the gas...

Embodiment 3

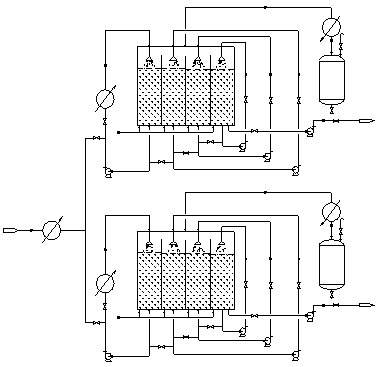

[0044] Such as image 3 As shown, in this embodiment, two glycerol esterification reaction tanks 1 work in parallel, and each glycerin esterification reaction tank 1 is composed of four compartments to form a four-tank series reactor, and then two sets of four-tank series reactors are connected in parallel to form A continuous glycerol esterification acid-reducing device has been established. The raw materials are preheated by the preheating reactor 3 and then divided into two routes. One route enters the first glycerin esterification reaction tank 1 for reaction, and the other route enters the second glycerin esterification reaction tank. Tank 1 reaction, the reaction of each glycerol esterification reaction tank 1 is the same as that of the single glycerol esterification reaction tank 1 in Example 1, which is applicable to the working conditions of mass production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com