Linear controllable capacitor of decrescent capacitance, large-scale rice milling machine starting buffer circuit and electric machinery

A capacitance and capacitor technology, applied in the electrical field, can solve the problems of difficult to use high-power circuits, complex and fragile results, and high cost of capacitors, and achieve the effects of not easy to burn, long service life, and long contact life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

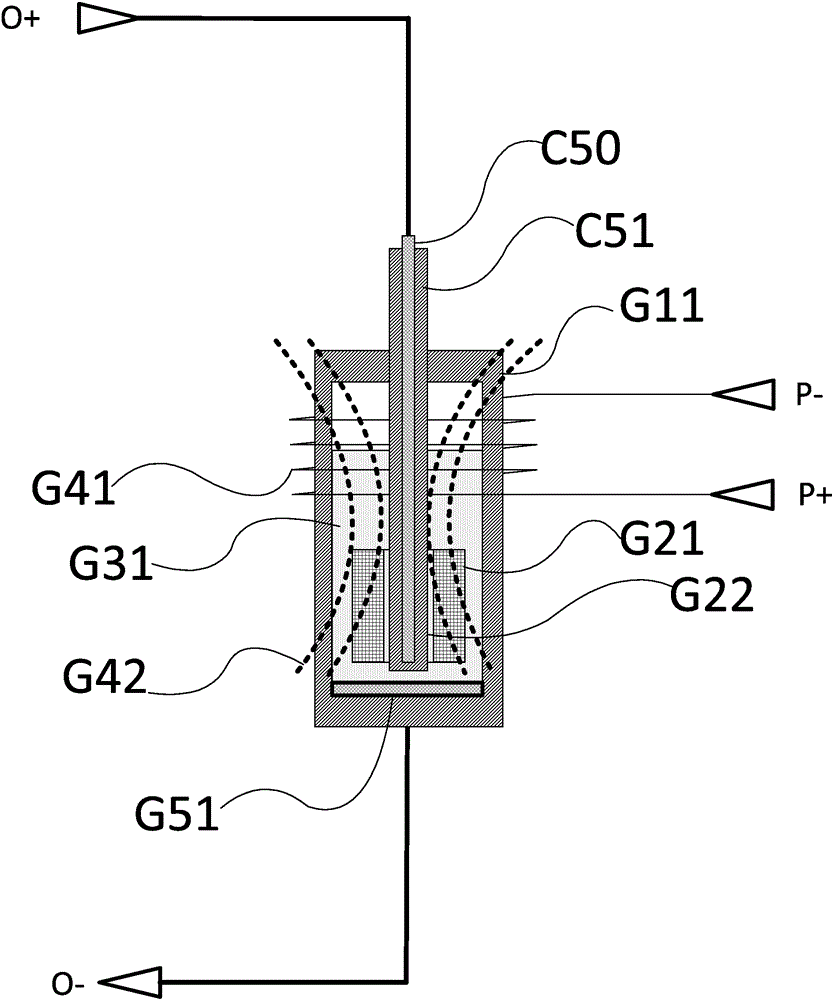

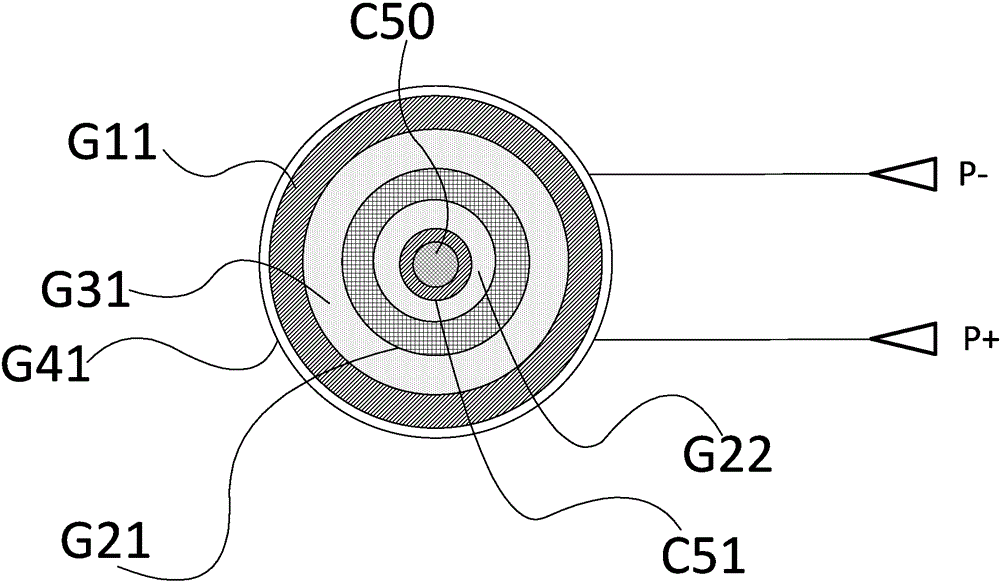

[0034] Implementation example 1, such as Figure 1-2 As shown, a linear controllable capacitor with gradually smaller capacitance is characterized in that it includes an insulating container G11, a conductive liquid G31, an entity G21, a bottom electrode G51, a capacitor rod C50, an insulating layer C51, an electromagnetic coil G41, and a controlled The first node O+ of the path, the second node O- of the controlled path, the first node P+ of the control end, and the second node P- of the control end;

[0035] The insulating container G11 has a stable shape. The shape of the insulating container G11 is cylindrical, and the container of the insulating container G11 is cylindrical.

[0036] The conductive liquid G31 is contained in the cavity of the insulating container G11, the volume of the conductive liquid G31 is smaller than the volume of the insulating container G11, and the volume of the conductive liquid G31 is larger than half of the volume of the insulating container G...

Embodiment 2

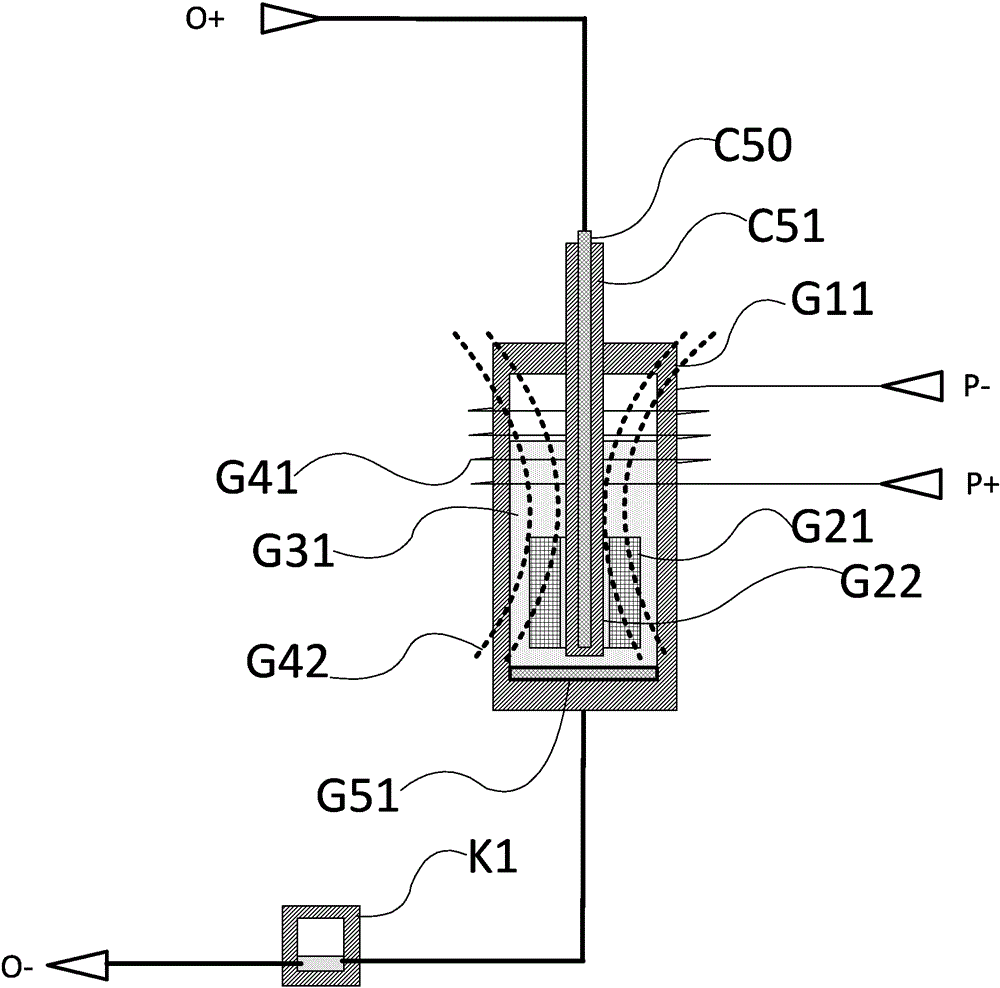

[0046] Implementation Example 2: A modification is made on the basis of implementation example 1, so that a tilt switch K1 is connected in series between the bottom electrode G51 and the second node O- of the controlled channel, so as to prevent the capacitor from being used when it is placed incorrectly.

Embodiment 3

[0047]Embodiment 3. An electric machine having the linearly controllable capacitor with gradually smaller capacitance described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com