Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

248results about How to "Reduced control accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

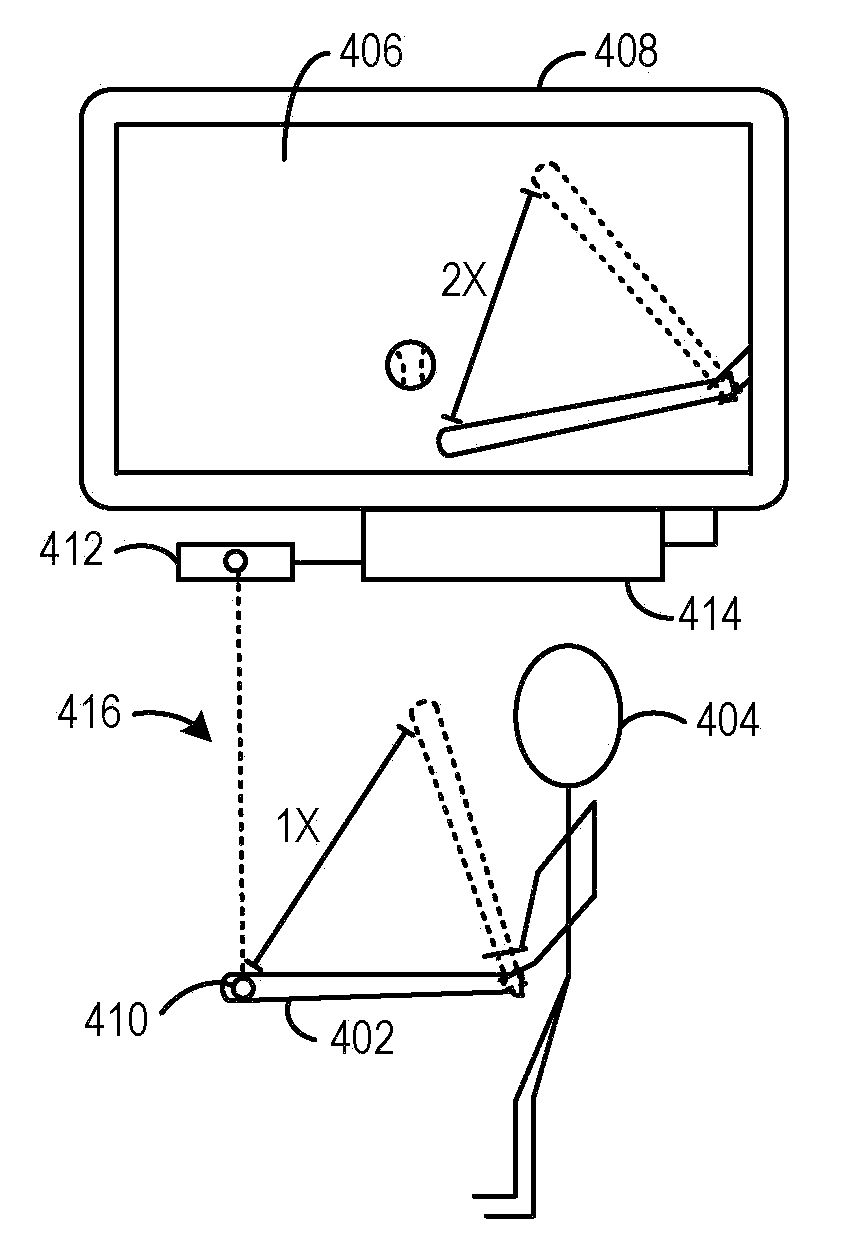

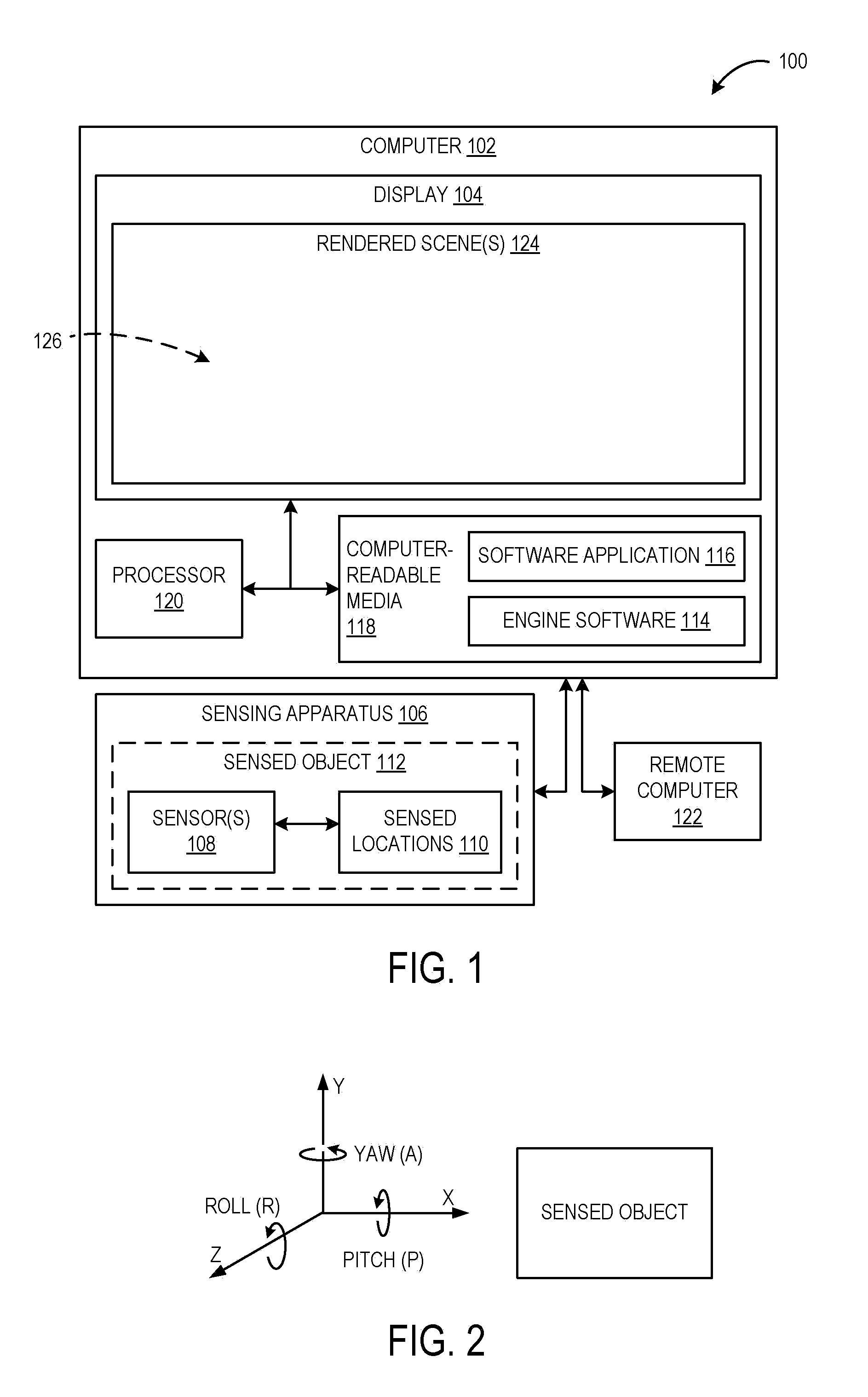

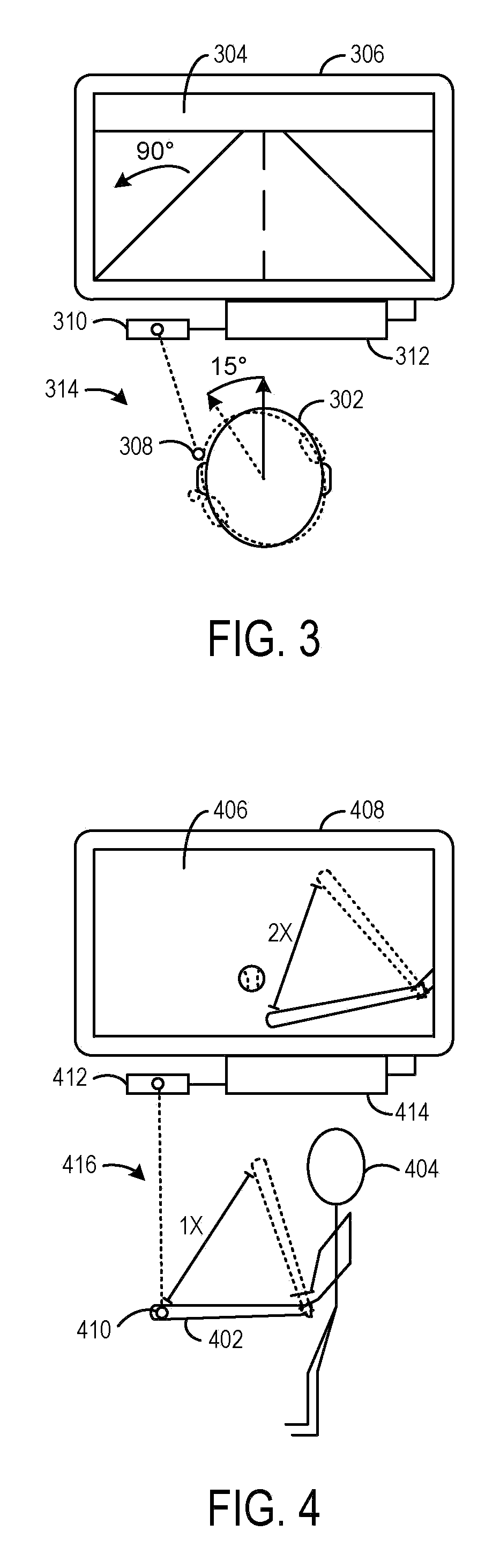

Approach for Merging Scaled Input of Movable Objects to Control Presentation of Aspects of a Shared Virtual Environment

InactiveUS20080211771A1Authenticity of be improveAccurately simulateCathode-ray tube indicatorsVideo gamesApplication softwareUser control

A system for controlling operation of a computer. The system includes, a sensing apparatus configured to obtain positional data of a sensed object controllable by a first user, such positional data varying in response to movement of the sensed object, and engine software operatively coupled with the sensing apparatus and configured to produce control commands based on the positional data, the control commands being operable to control, in a multi-user software application executable on the computer, presentation of a virtual representation of the sensed object in a virtual environment shared by the first user and a second user, the virtual representation of the sensed object being perceivable by the second user in a rendered scene of the virtual environment, where the engine software is configured so that the movement of the sensed object produces control commands which cause corresponding scaled movement of the virtual representation of the sensed object in the rendered scene that is perceivable by the second user.

Owner:NATURALPOINT

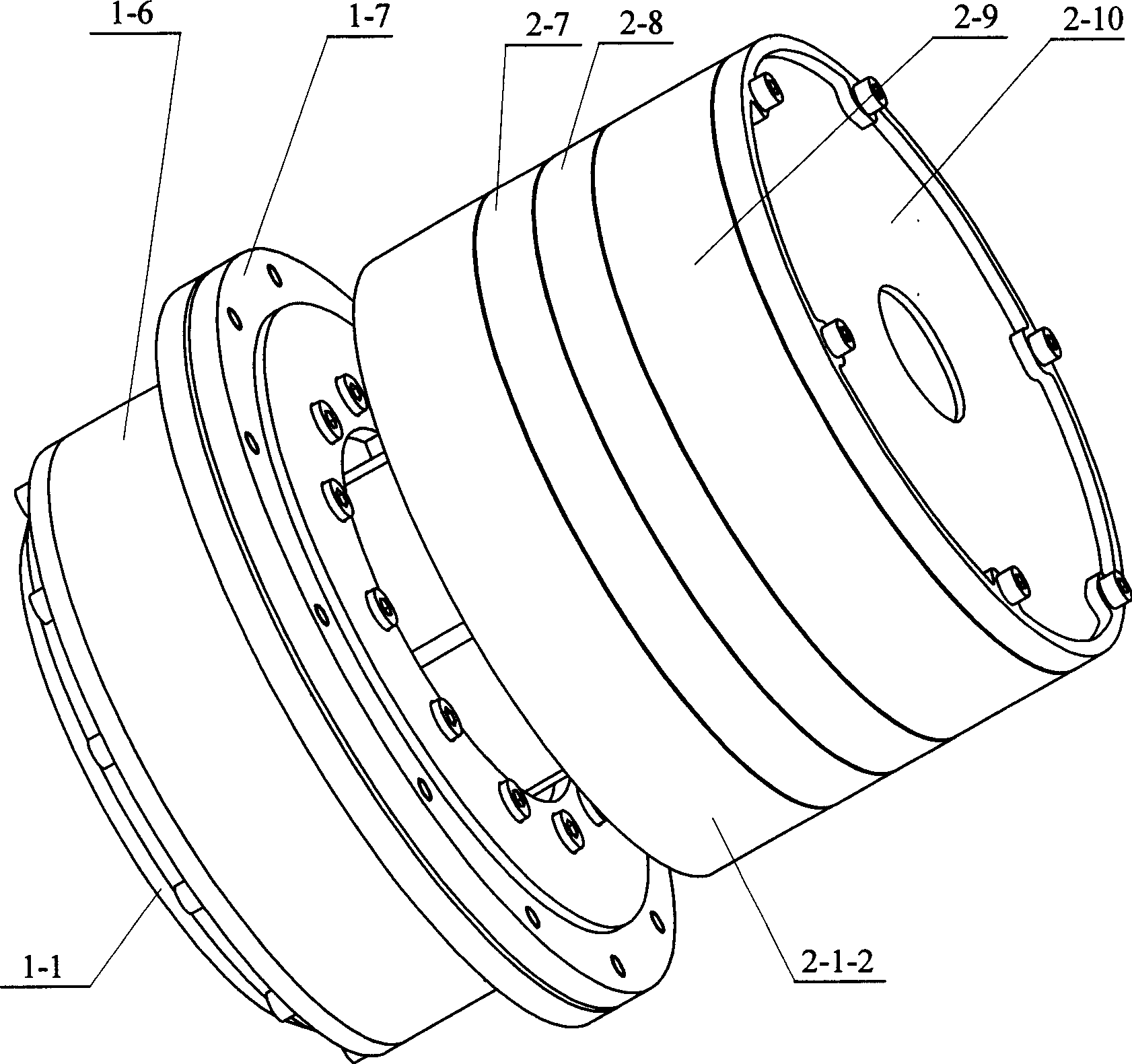

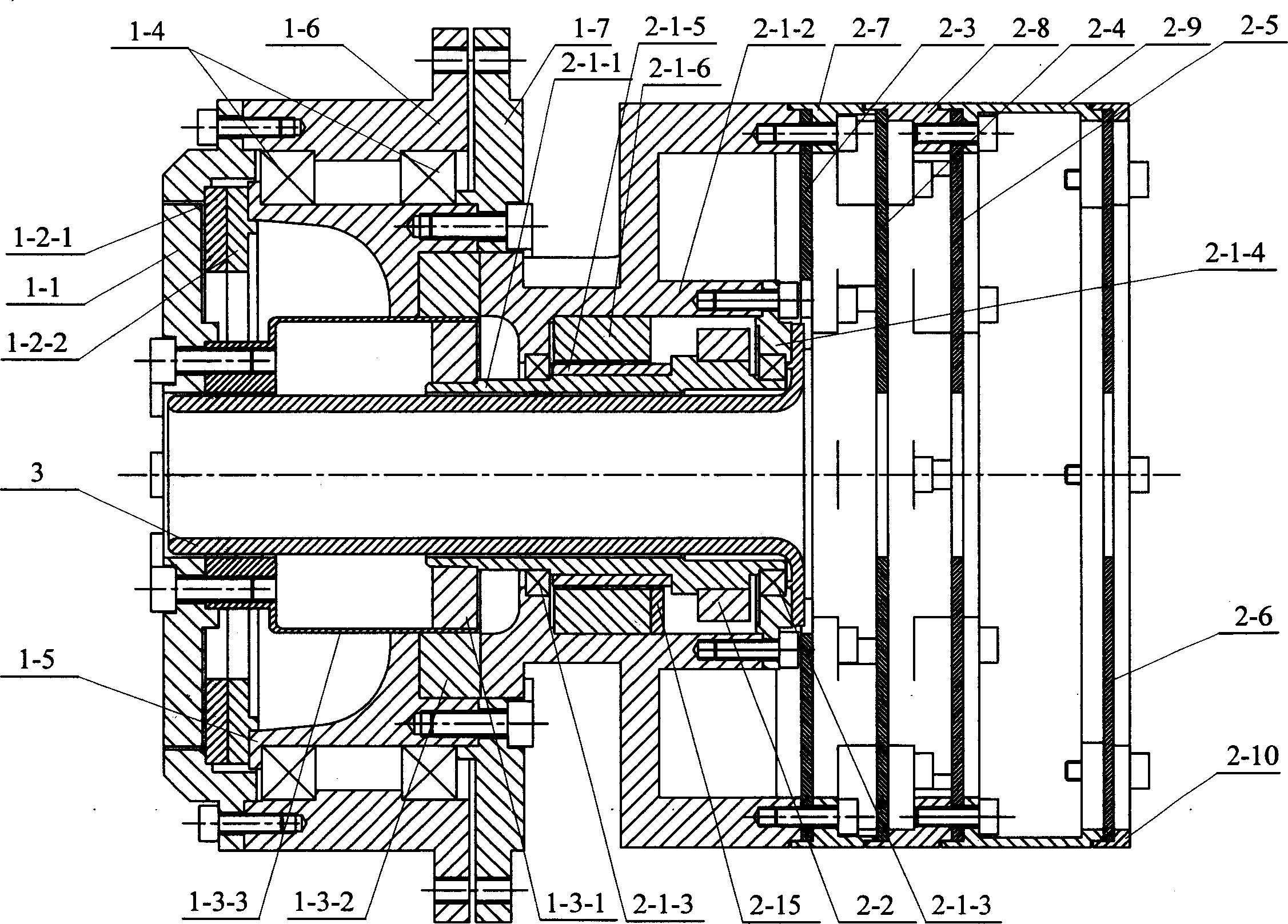

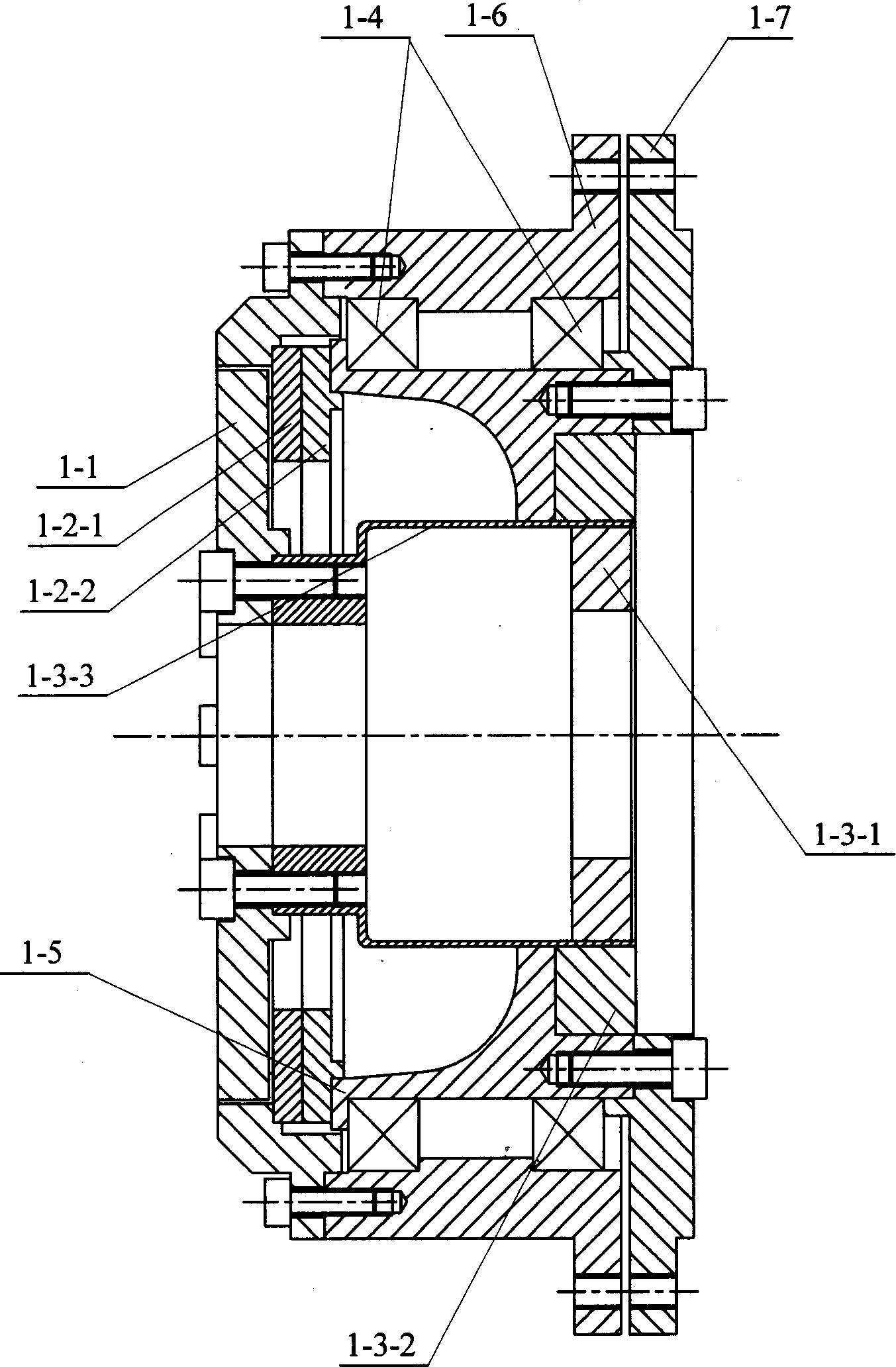

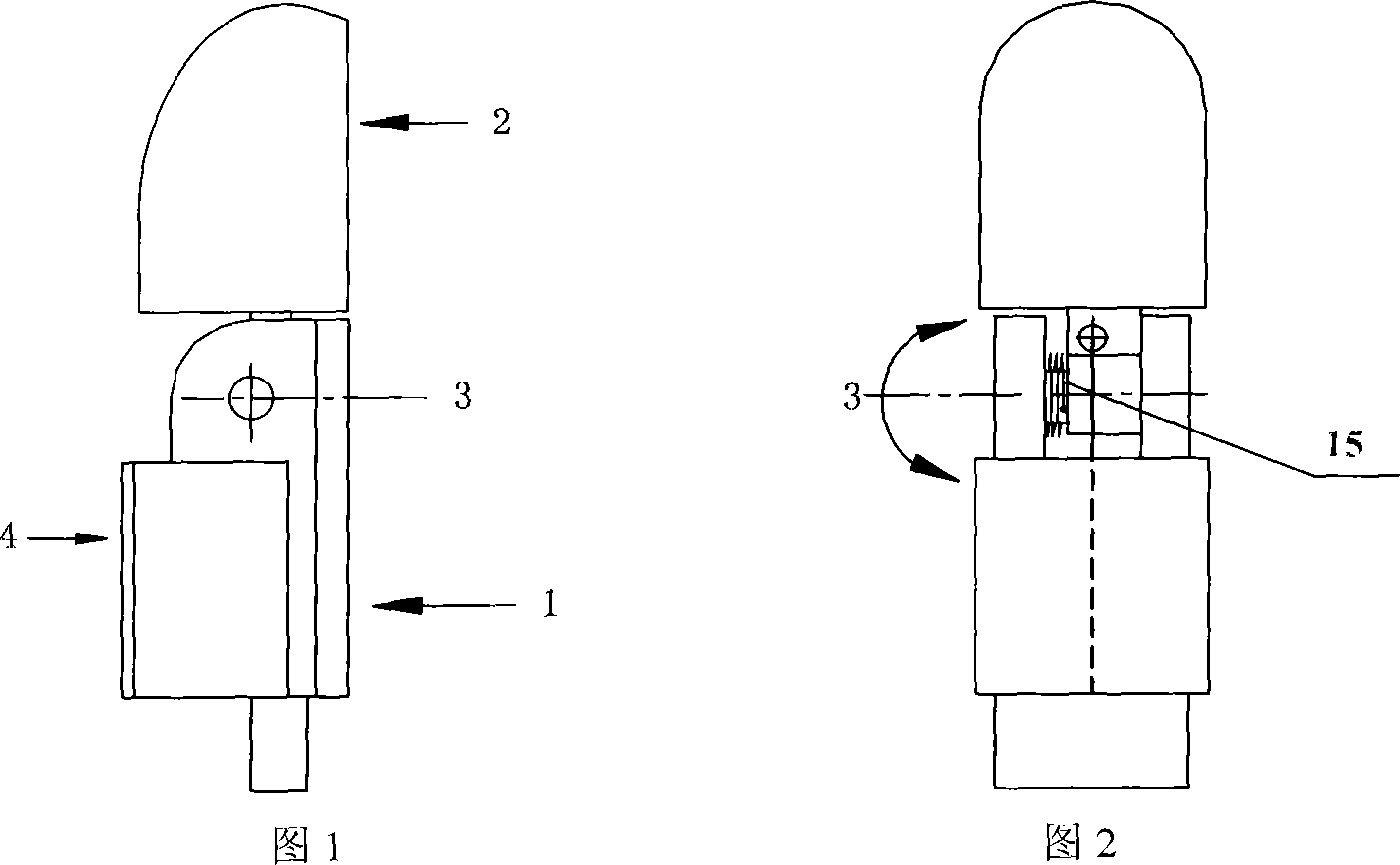

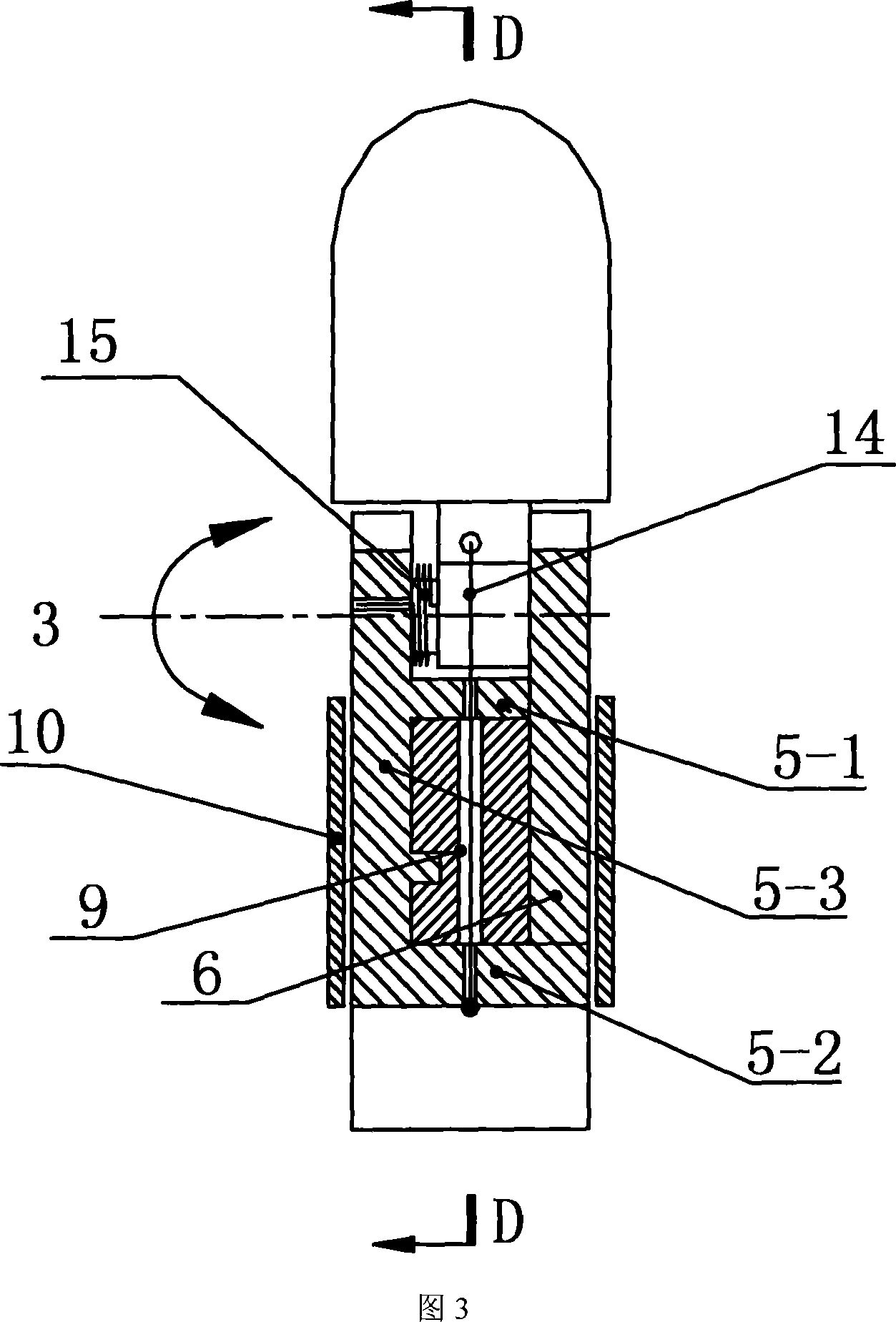

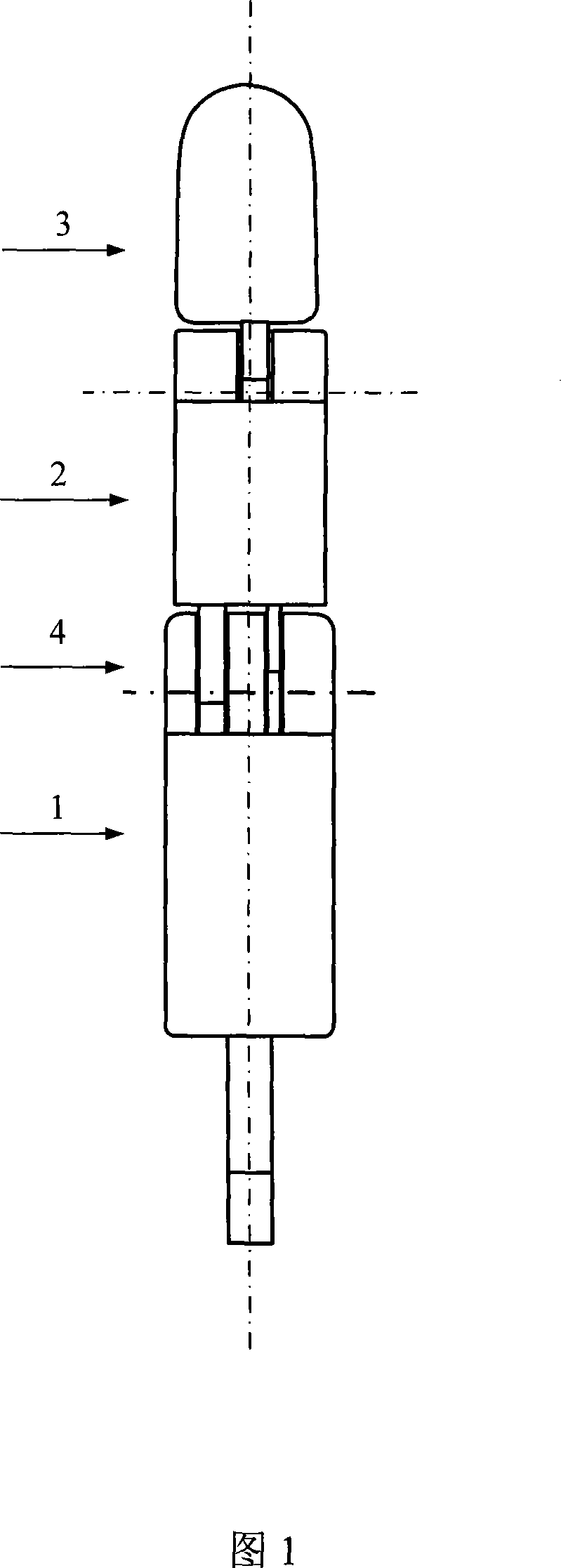

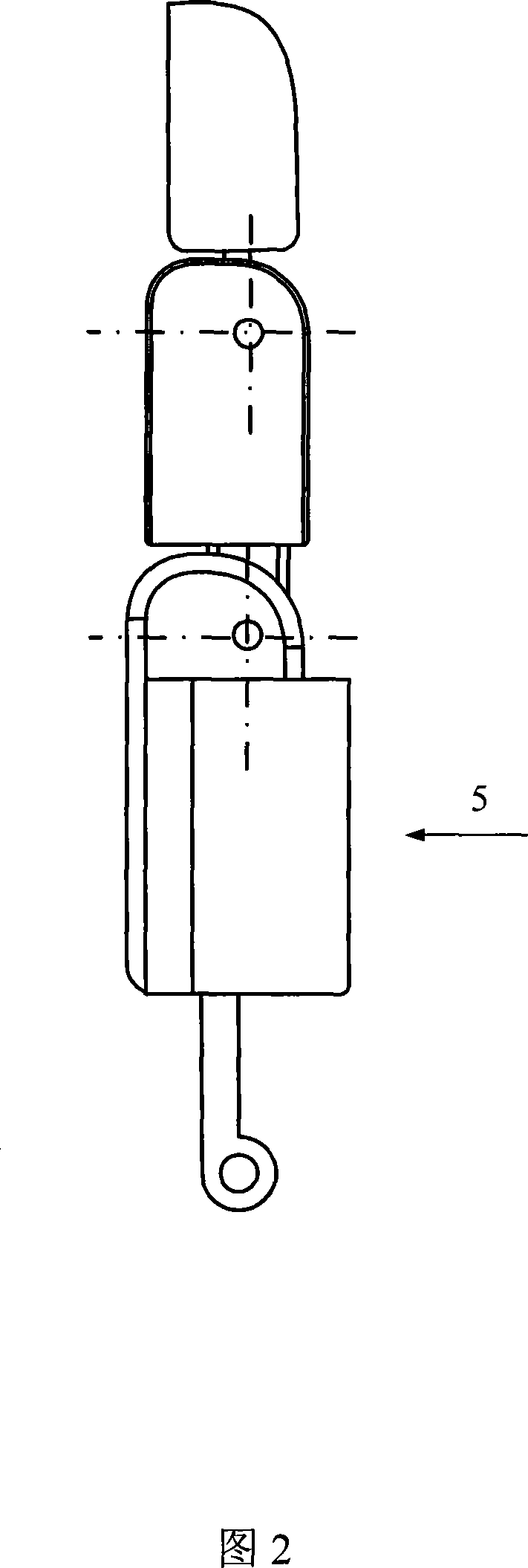

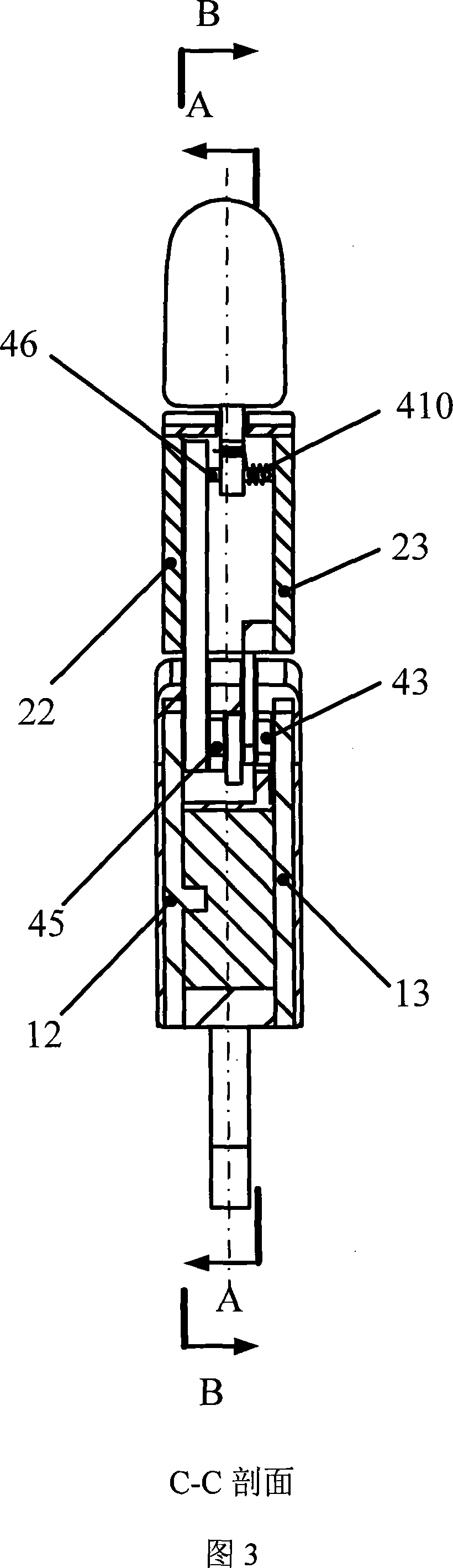

Modularized joint of space manipulator

The invention relates the spacing robot arm joint. The invention aims to the problem of bad safe reliability of spacing mechanical arm joint and complicated structure. The wave generating machine (1-3-1) is fixed in direct current brushless motor, soft wheel (1-3-3) is installed on wave generating machine (1-3-1), hand wheel (1-3-2) is installed on soft wheel (1-3-3), bearing inner ring seat (1-5) is installed on hand wheel (1-3-2), hand wheel (1-3-2) is connected with direct current brushless motor, soft wheel (1-3-3) is connected with torque pick-up (1-1), address sensor is installed between torque pick-up (1-1) and bearing inner ring seat (1-5), torque pick-up (1-1) is connected with bearing out ring seat (1-6), bearing (1-4) is installed between bearing out ring seat (1-6) and bearing inner ring seat (1-5), magnetic code device (2-2) is installed on direct current brushless motor, sleeve (3) is installed in direct current brushless motor, and drive board (2-3), control board (2-4), power board (2-5) and interface board (2-6) are connected with each other by frame, direct current brushless motor and compression ring (2-10). The invention possesses the high intelligentize degree and integration degree.

Owner:HARBIN INST OF TECH

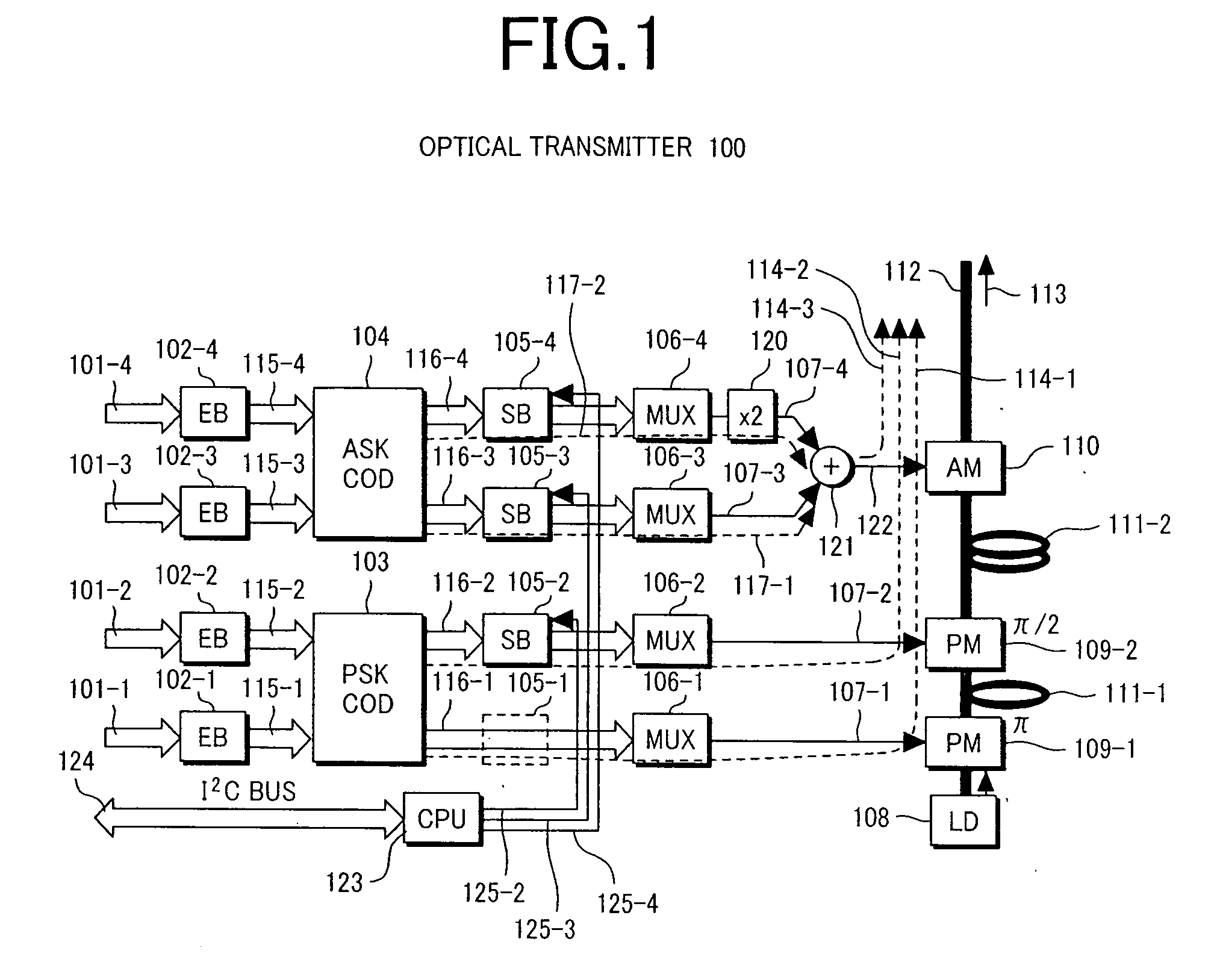

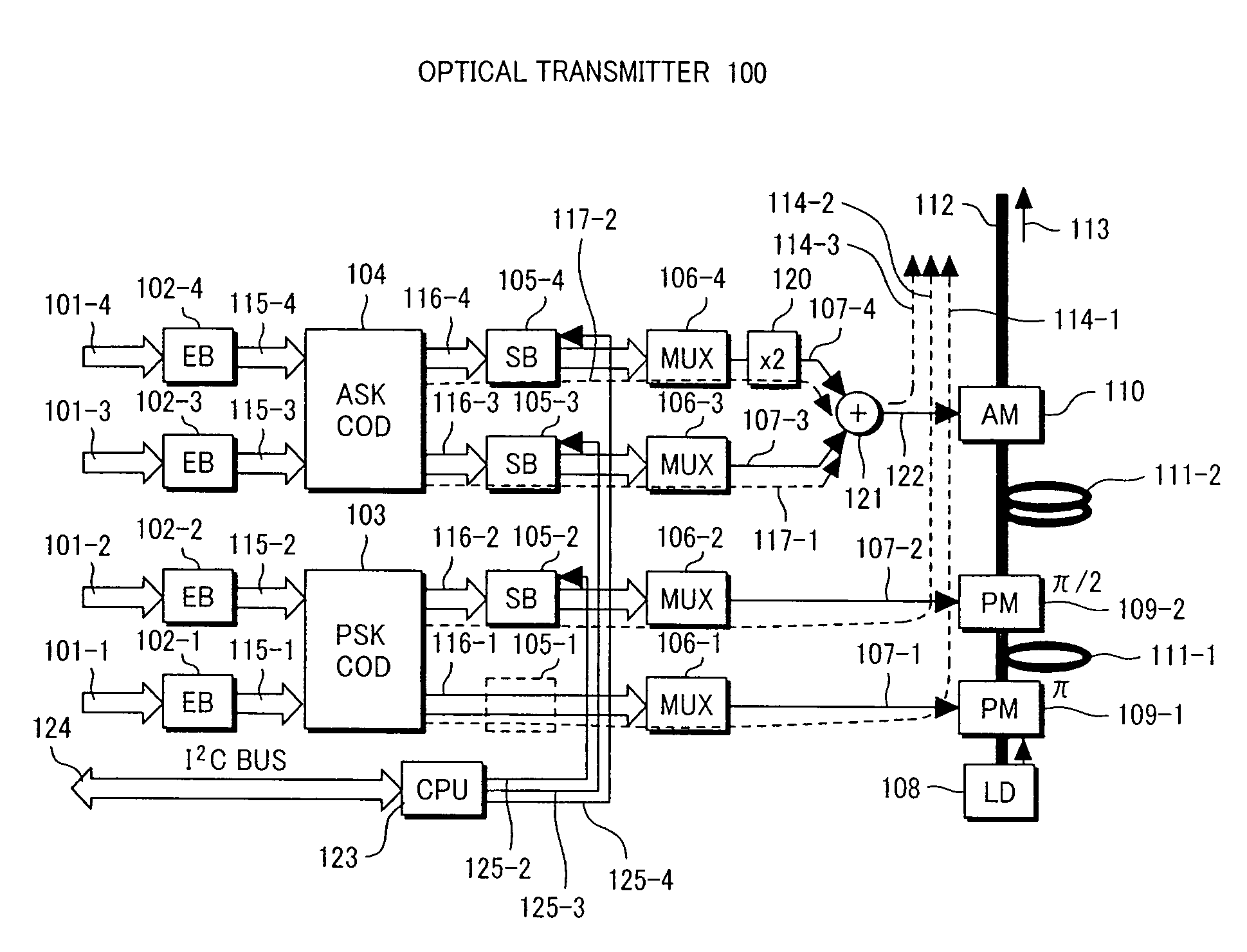

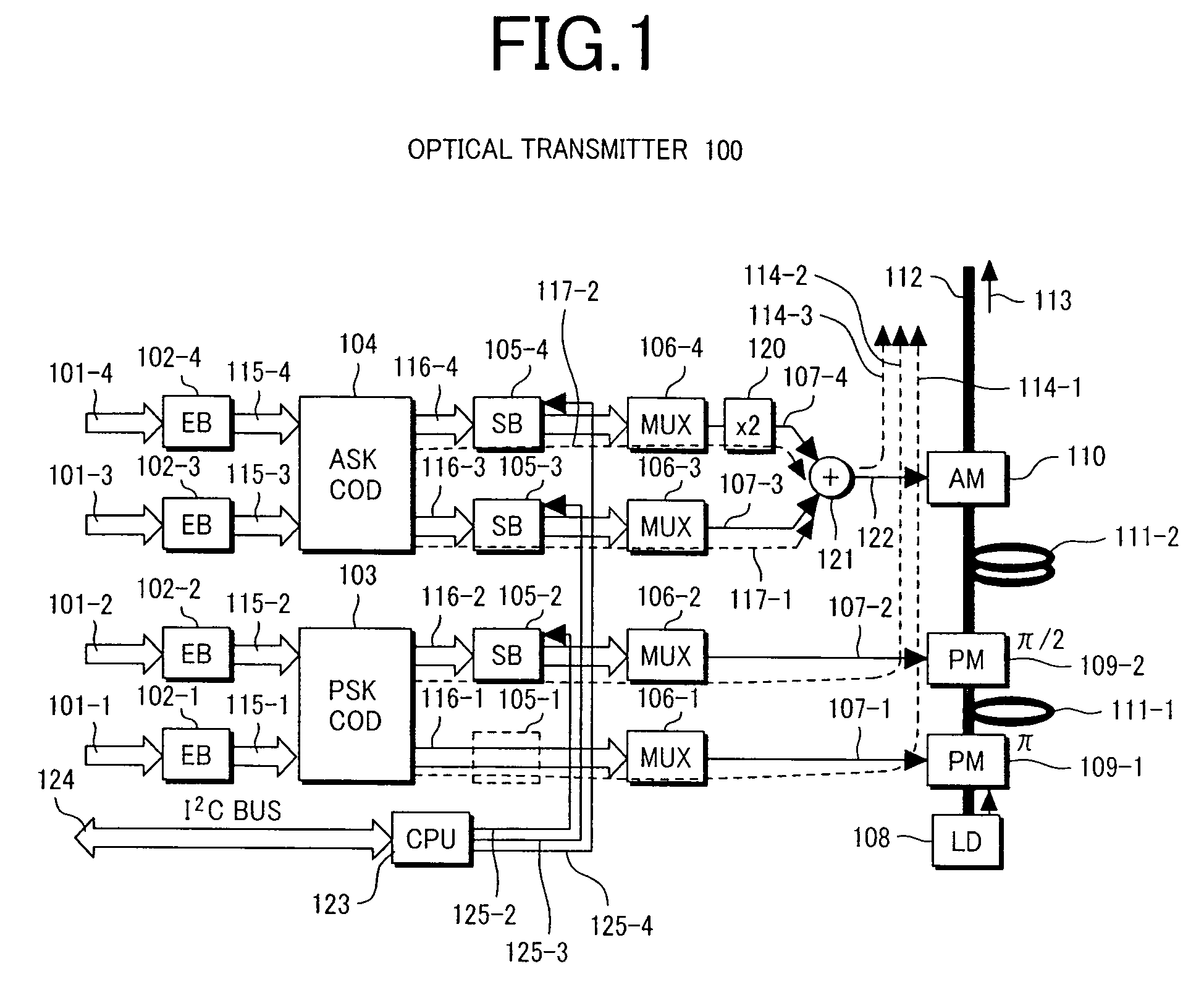

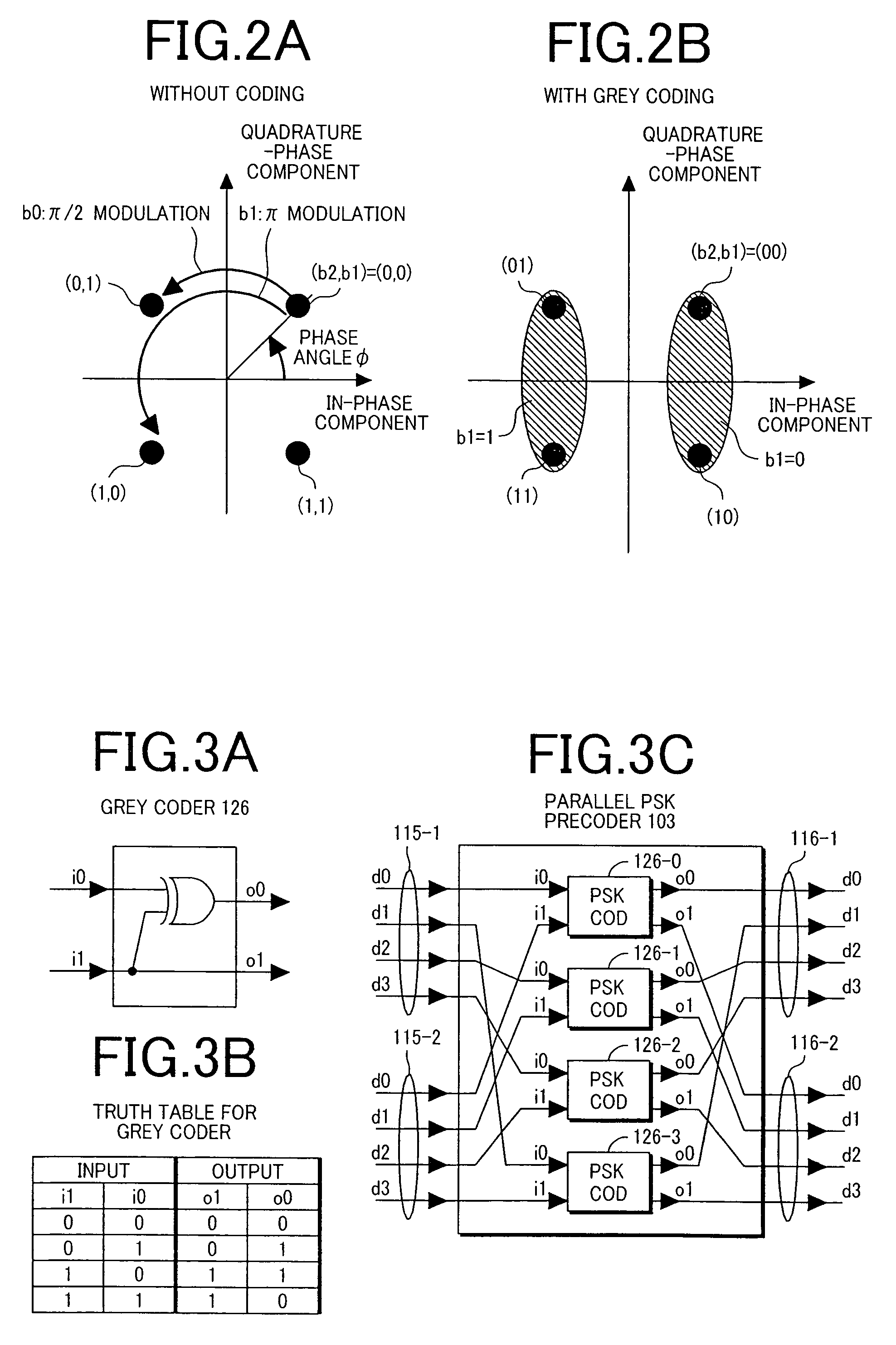

Optical transmission equipment and integrated circuit

InactiveUS20060269294A1Precise adjustmentEasily reproduceTime-division optical multiplex systemsWavelength-division multiplex systemsIntegrated circuitLow speed

Optical transmission equipment, capable of electrically adjusting the delay difference between a plurality of digital signal paths to be connected to a multilevel optical modulation unit or demodulation unit, having multiplexing circuits connected to the digital signal paths and a delay adjustment unit inserted in one of the digital signal paths to adjust delay of N-bit-parallel low-speed digital signals with the timing unit of a bit period of a high-speed serial digital signal to be outputted from multiplexing circuit.

Owner:HITACHI LTD

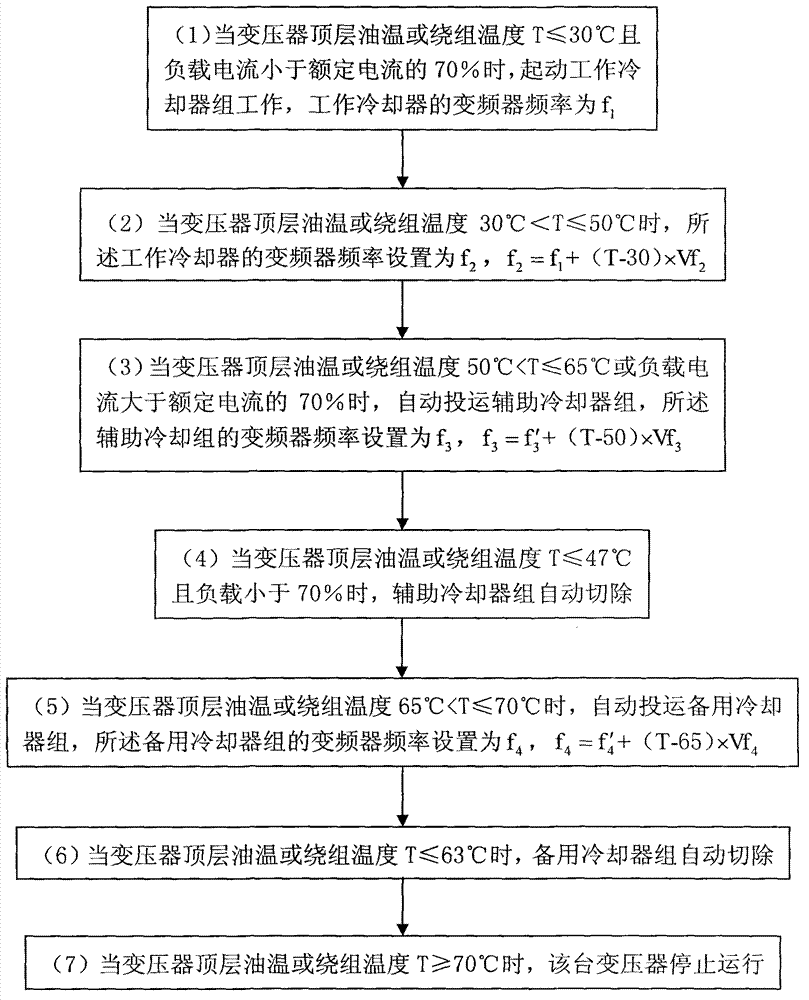

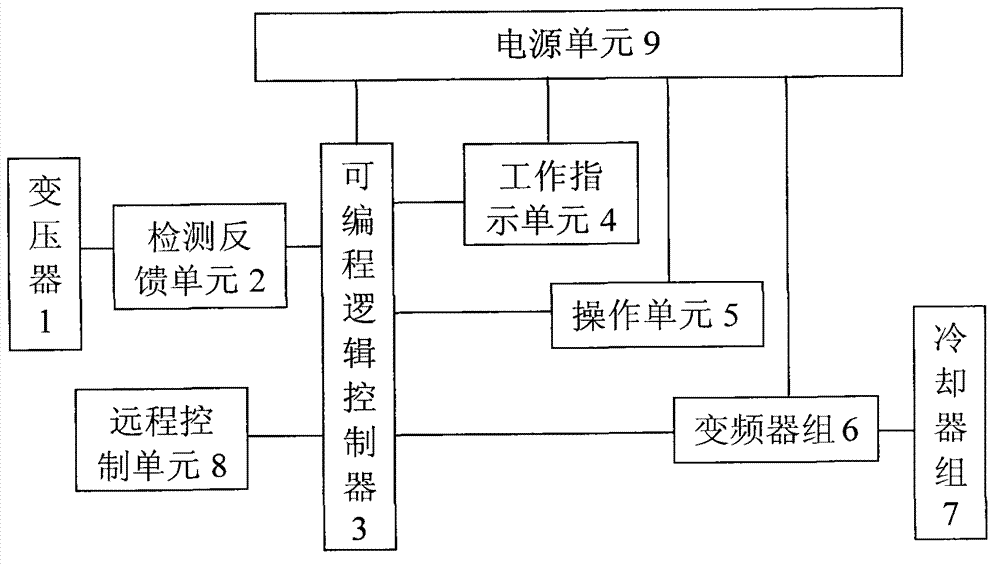

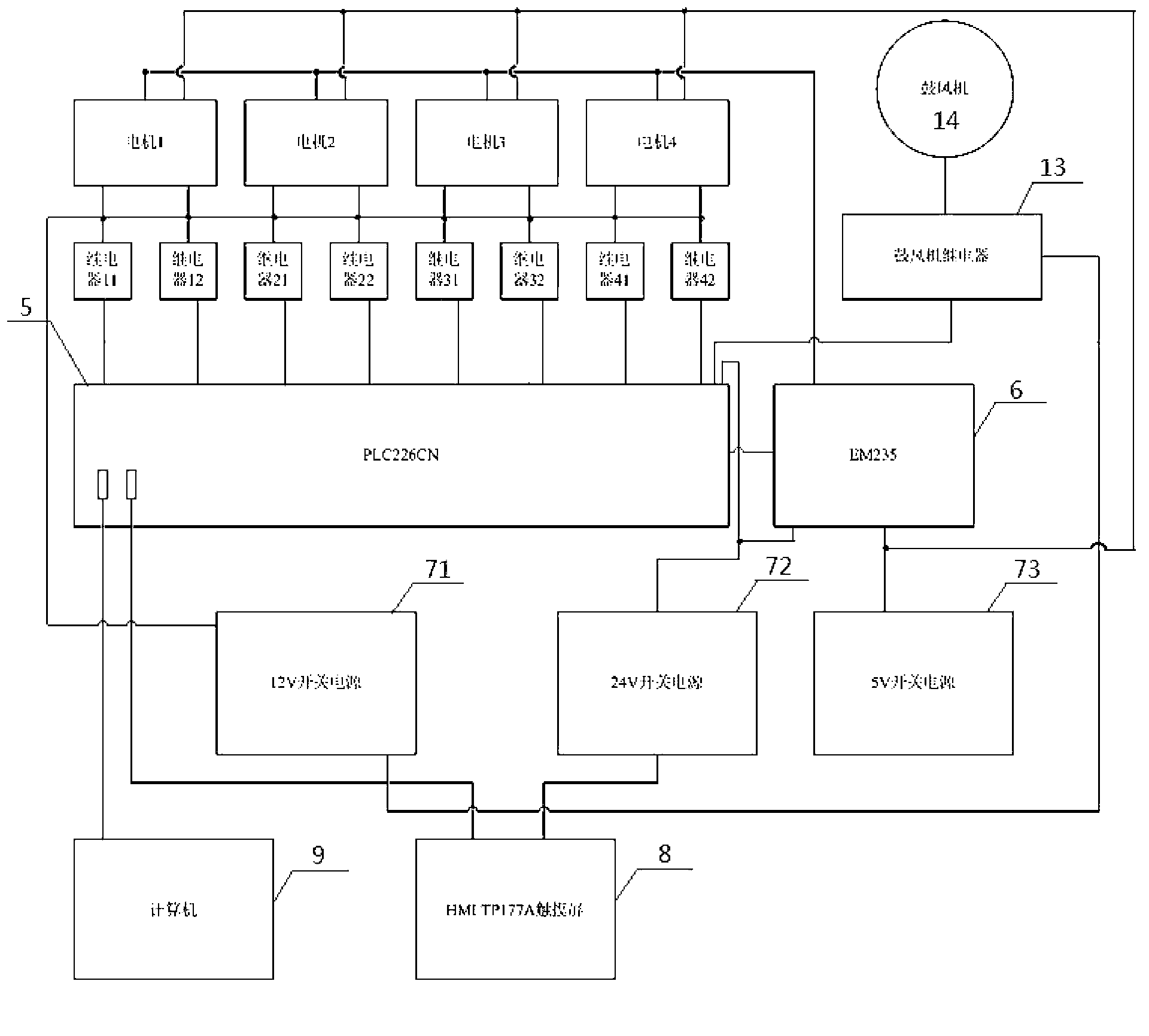

Intelligent air-cooling frequency-changing energy-saving system and method of transformer

ActiveCN103324130AReduced control accuracyTransformers/inductances coolingProgramme control in sequence/logic controllersFrequency changerCooling effect

The invention relates to an intelligent air-cooling frequency-changing energy-saving system and method of a transformer. The intelligent air-cooling frequency-changing energy-saving system and method of the transformer can commonly control the number of operating cooling device sets and a rotation speed of a fan according to top-layer temperature, winding temperature and loaded currents of the transformer. The top-layer temperature and the winding temperature of the transformer serve as frequency modulating and controlling parameters of a frequency converter, the rotation speed of cooling devices and projecting and removing of the cooling device sets are controlled by taking variation of the load currents into consideration. The intelligent air-cooling frequency-changing energy-saving method of the transformer can effectively avoid the fact that an air-cooling frequency-changing energy-saving method of a transformer in the prior art is poor in flexibility, single in operation manner, low in control precision, large in noise and poor in cooling effect as accurate tracking control is not performed according to variation of the oil temperature and the winding temperature of the transformer and can not be economically suitable for all sorts of complicated occasions and circumstances or achieve economical operation of the cooling devices. The problem of wasting resources can be avoided by the intelligent air-cooling frequency-changing energy-saving method of the transformer.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

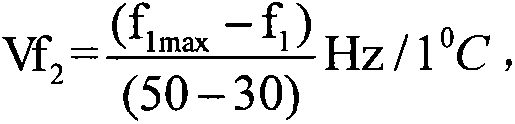

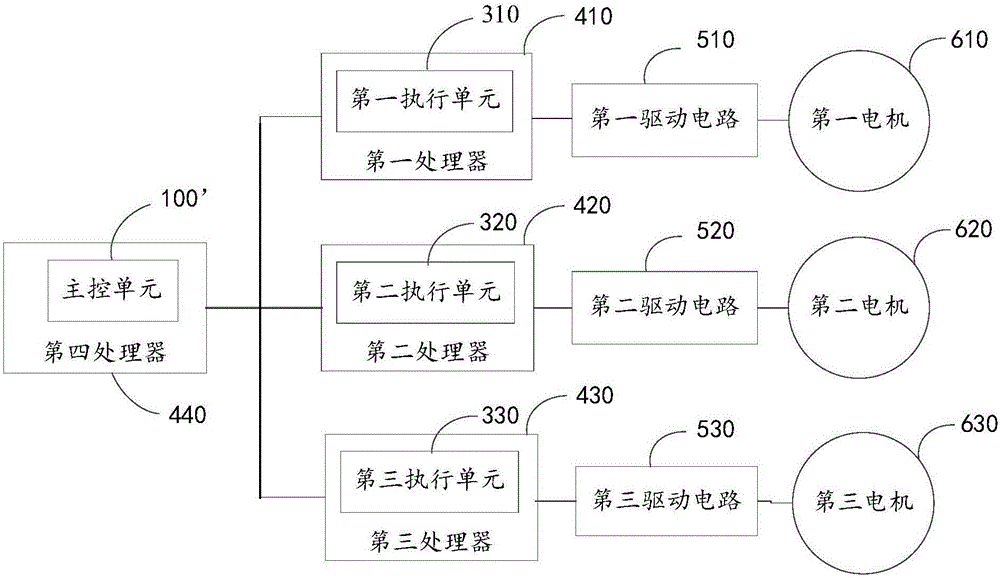

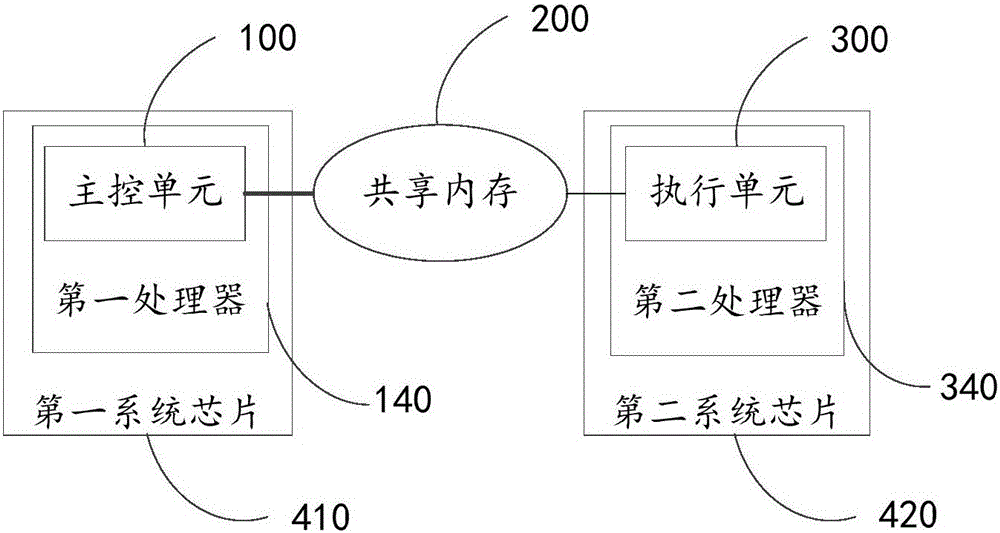

Unmanned aerial vehicle/motor control device and method

PendingCN105978441AReduce control frequencyReduced control accuracyAircraft componentsElectronic commutation motor controlExecution unitMotor control

The embodiments of the invention provide an unmanned aerial vehicle / motor control device and method. The motor control method comprises the following steps: acquiring current attitude information of the load, target attitude information of the load and current operation parameter information of one or more motors on the load, and obtaining control information for controlling the one or more motors according to the current attitude information, the target attitude information and the current operation parameter information; transmitting the control information to a shared memory for storage; and reading the control information from the shared memory and controlling the operation of one or more motors according to the control information. A motor control device according to the invention does not need connection of cables or PCB wiring, thereby reducing hardware size; the motor control device is directly implemented inside a chip through a shared memory, thereby improving the speed and stability of data interaction between a main control unit and an executing unit. Further, a correlation algorithm is adopted for ensuring the no reduction of motor and pan-tilt control frequency and accuracy.

Owner:ZEROTECH (BEIJING) INTELLIGENCE TECH CO LTD

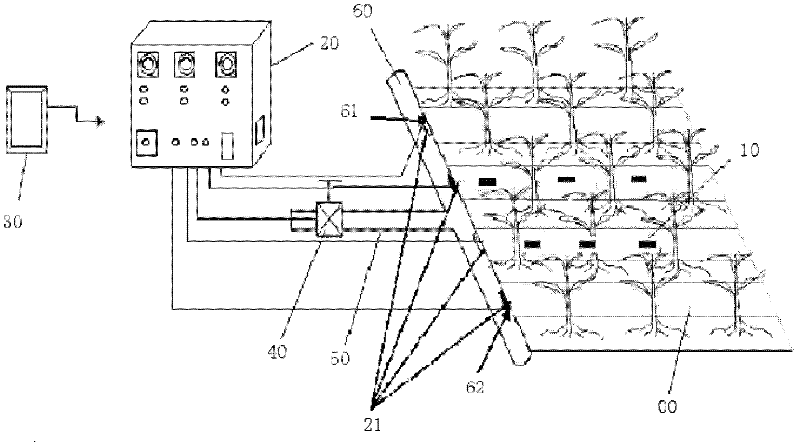

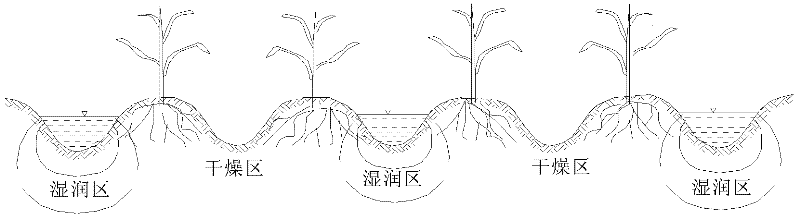

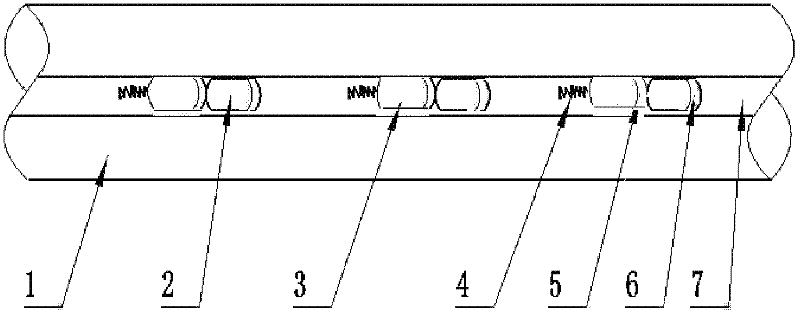

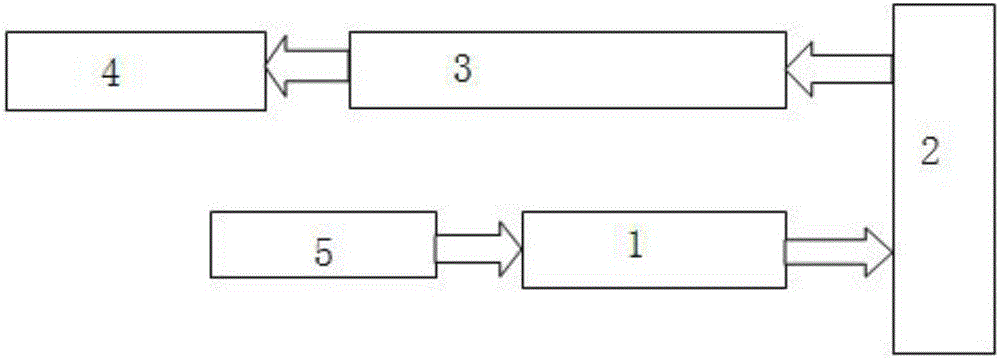

Alternate partial root-zone irrigation controller and alternate partial root-zone irrigation system

InactiveCN102550372ASimple structureRealize intelligent controlWatering devicesCultivating equipmentsMicrocontrollerEngineering

The invention relates to an alternate partial root-zone irrigation controller and an alternate partial root-zone irrigation system. The controller comprises signal acquisition modules, a signal conversion and data processing module and a parameter setup module, wherein the signal acquisition modules are disposed in irrigation gutters on two sides of crops and used for acquiring information of soil moisture, the signal conversion and data processing module is used for controlling gutter spaced alternate irrigation of the crops according to the information received by the signal acquisition modules, and the parameter setup module is used for setting parameters of the signal conversion and data processing module. The alternate partial root-zone irrigation controller is simple in structure, capable of automatically alternately irrigating the crops under full intelligent control by man-machine communication, signals from the sensors and drive of a single chip microcomputer. The alternate partial root-zone irrigation controller simple in structure is laborsaving, timesaving, cost-saving, convenient in operation and easy for large-scale popularization. In addition, traditional electromagnetic control valves are substituted by alternate irrigation valves, so that the alternate partial root-zone irrigation system is simple, cost-reducing and reliable in operation.

Owner:CHINA AGRI UNIV

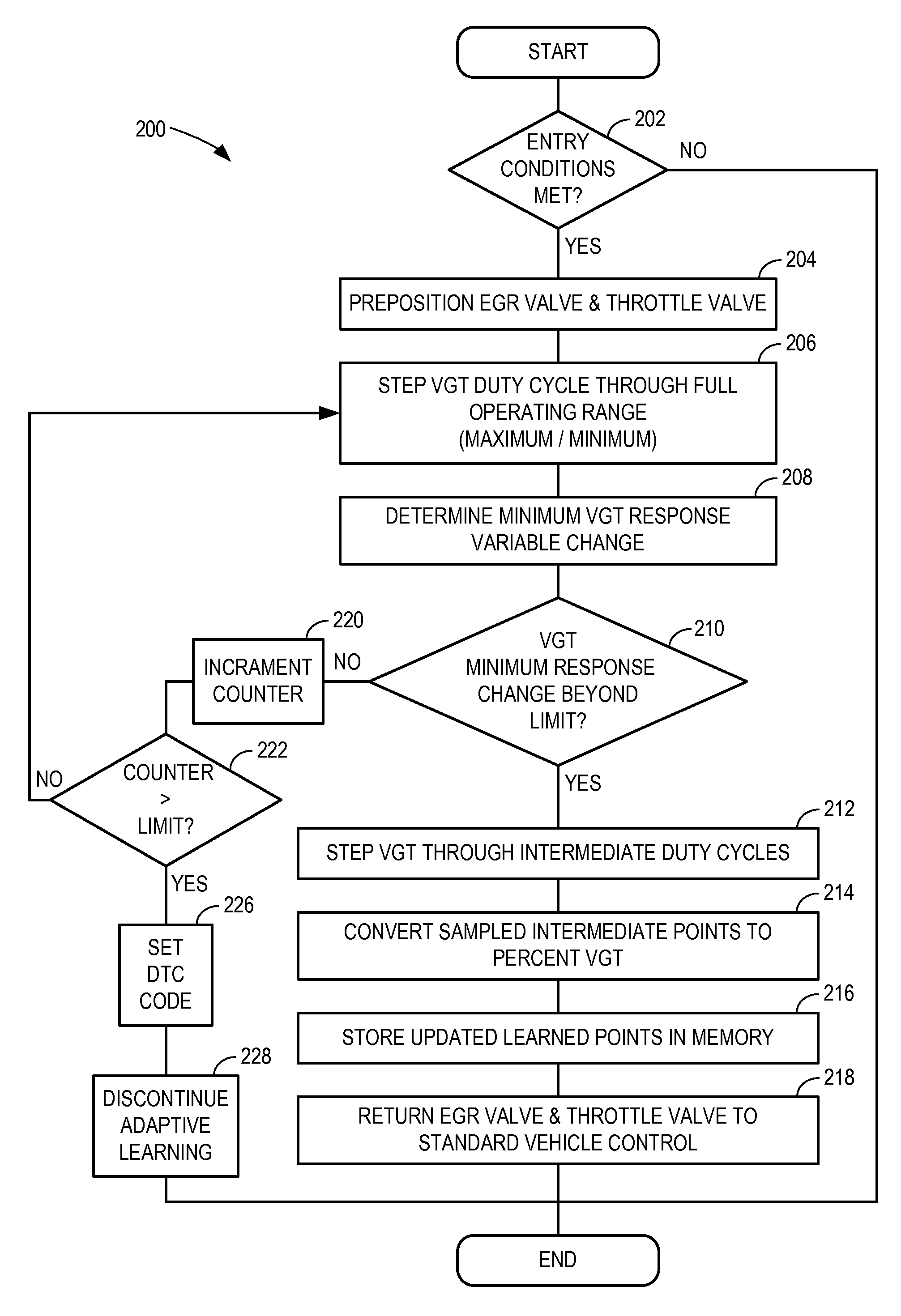

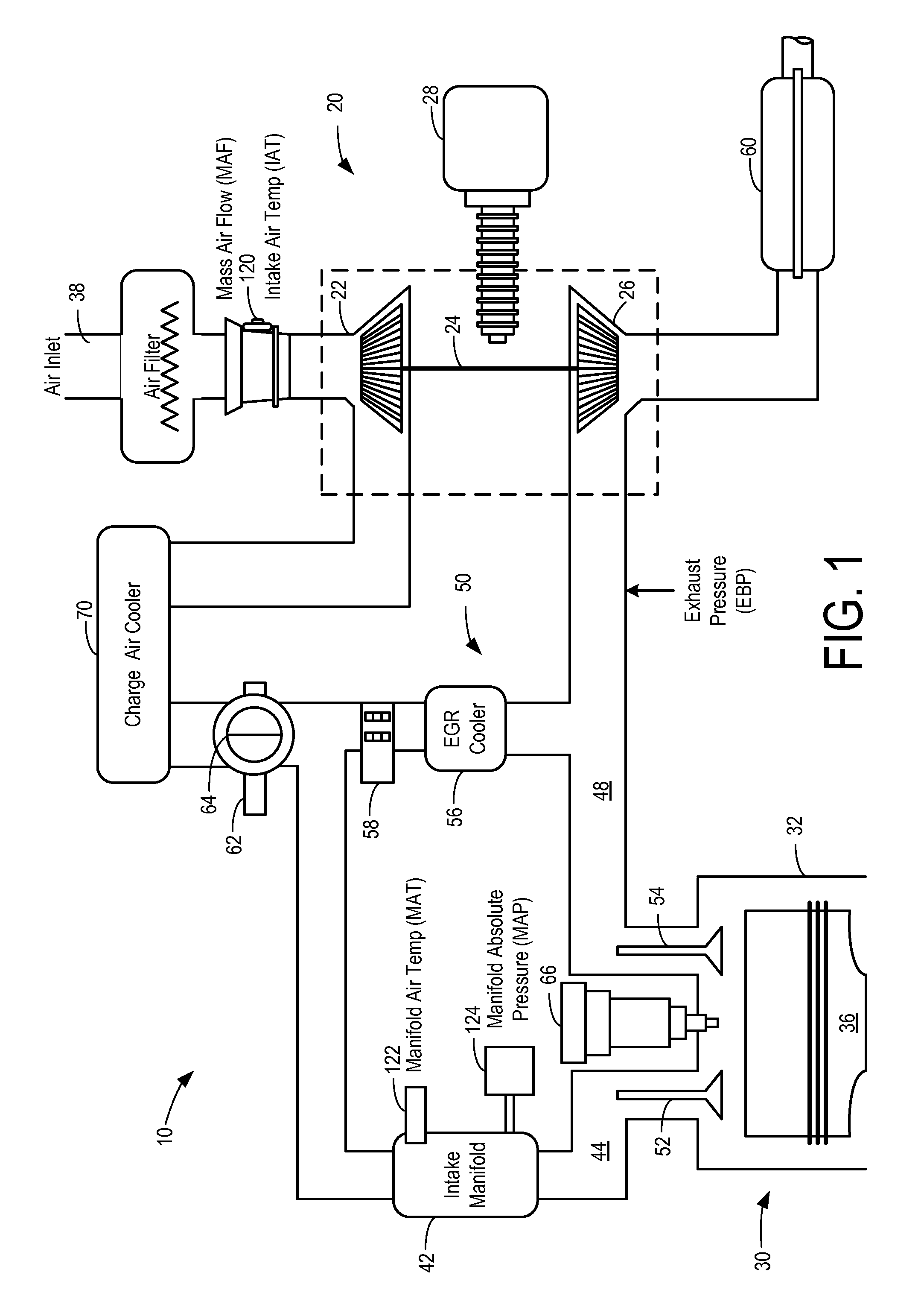

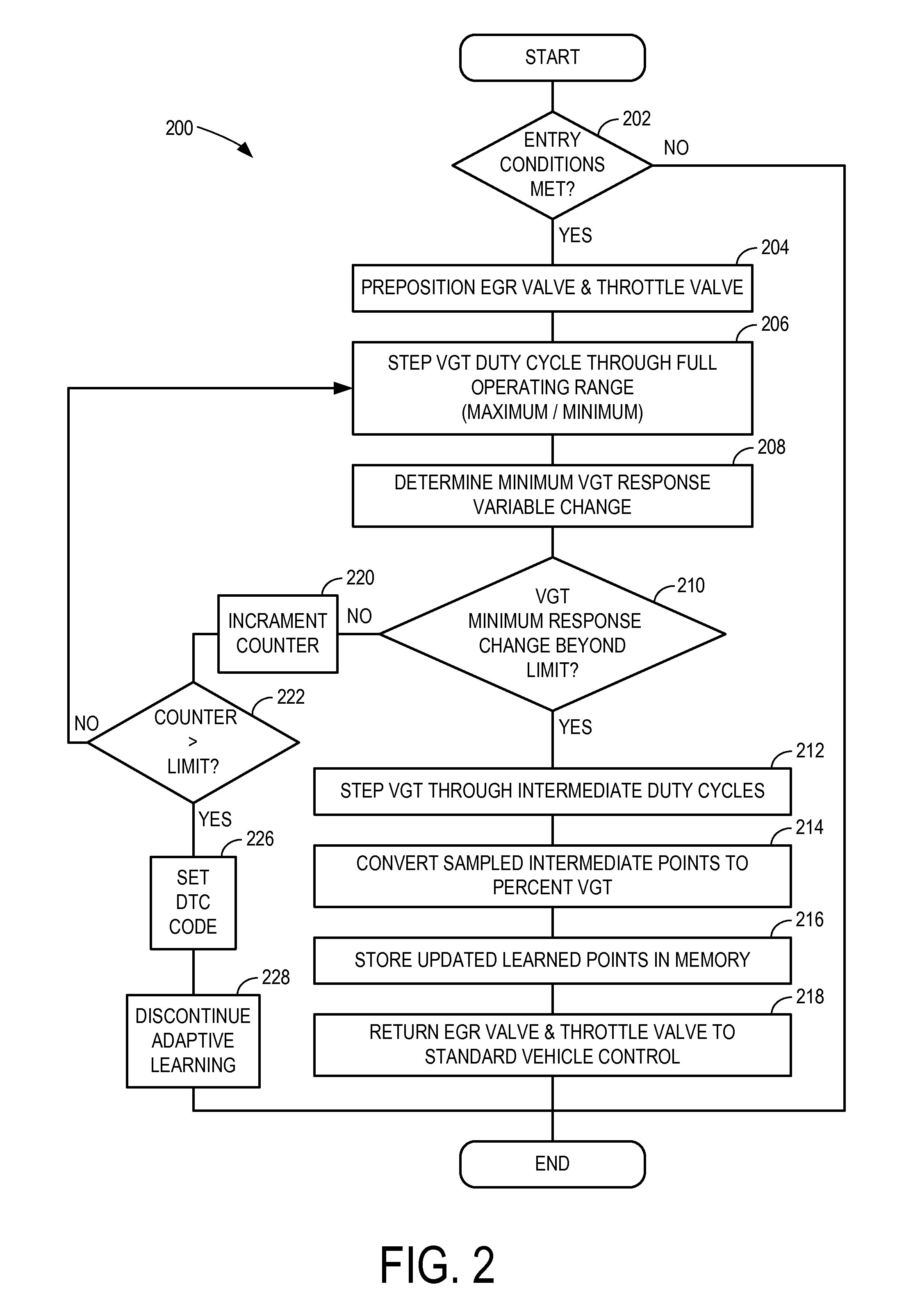

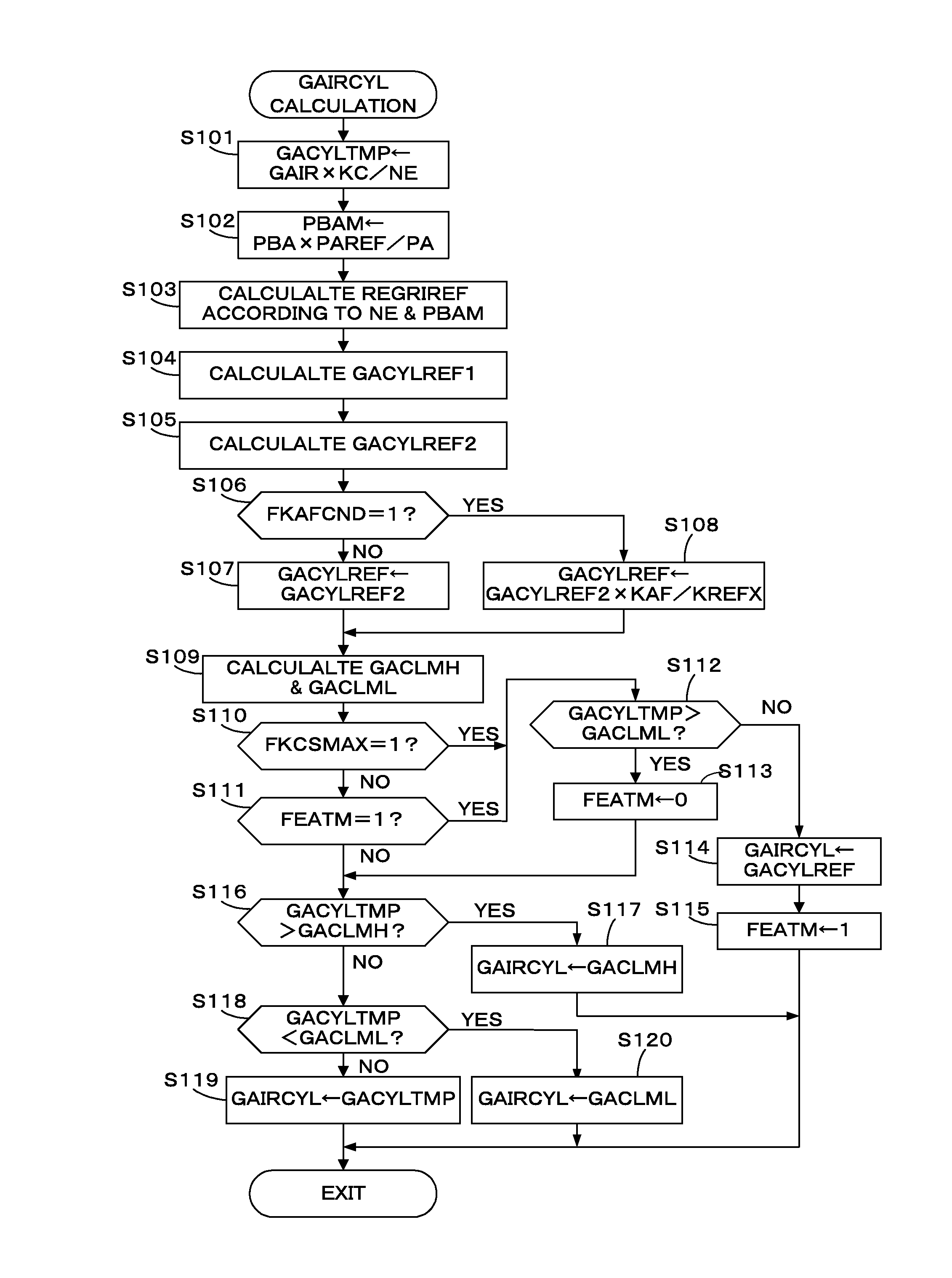

Adaptive learning system and method of vane position for a variable geometry turbocharger

ActiveUS8151567B2Improve performanceImprove efficiencyElectrical controlInternal combustion piston enginesAdaptive learningEngineering

A method of operation for an engine system having a variable geometry turbocharger with a vane is disclosed. In one example, an EGR valve is closed while vane position is adjusted. The method can reduce vane positioning errors during engine operation.

Owner:FORD GLOBAL TECH LLC

Edge error control method in optical lens small grinding head optical machining

ActiveCN108555729AReduced control accuracyReduce polishing costsOptical surface grinding machinesAutomatic grinding controlOptical processingSurface shape

The invention belongs to the technical field of optical element machining, and particularly discloses an edge error control method in optical lens small grinding head optical machining. The edge errorcontrol method comprises specific steps that firstly, a workpiece is measured to obtain a surface shape error, an appropriate quadratic term is added to the surface removing amount for adjustment, and the edge machining difficulty is lowered; meanwhile, a polishing path is abstracted to discrete sampling points, and a removing function of each sampling point is calculated according to a removingfunction model; then, the residence time is solved through a space variation deconvolution algorithm; and finally, a control program is generated according to the polishing path and the residence time, and polishing is carried out on the workpiece. The removing function changing along with the position is adopted to solve the residence time, and the removing amount of the edge part can be precisely controlled; the non-linear deconvolution algorithm can adapt to the shifting removing function; and by means of the surface shape adjusting technology, the convergence difficulty of the edge error is lowered to the maximum extent. According to the edge error control method, the requirement for the control precision of a polishing system is relatively low, and therefore the small grinding head polishing cost can be reduced, and the machining efficiency is improved.

Owner:FUDAN UNIV

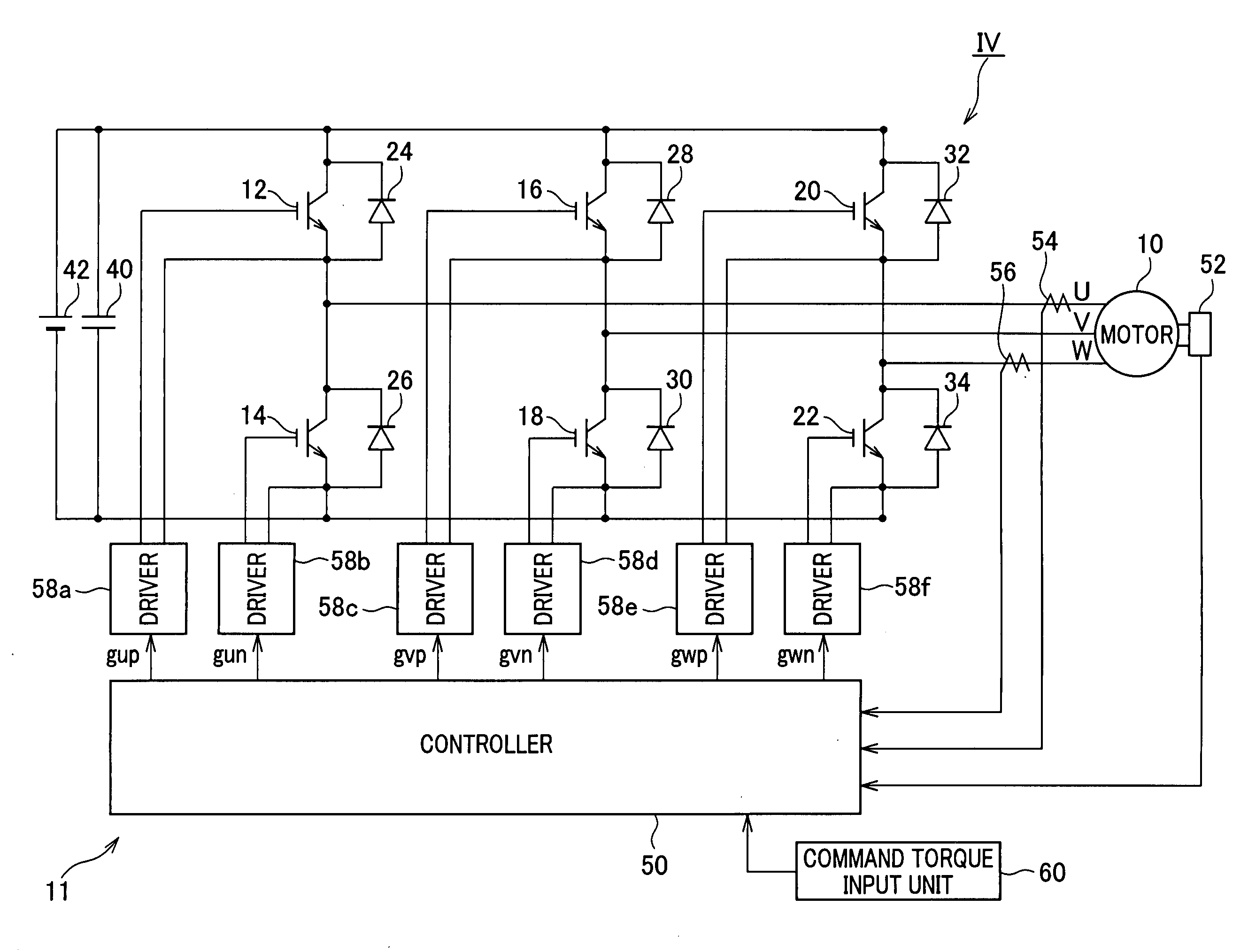

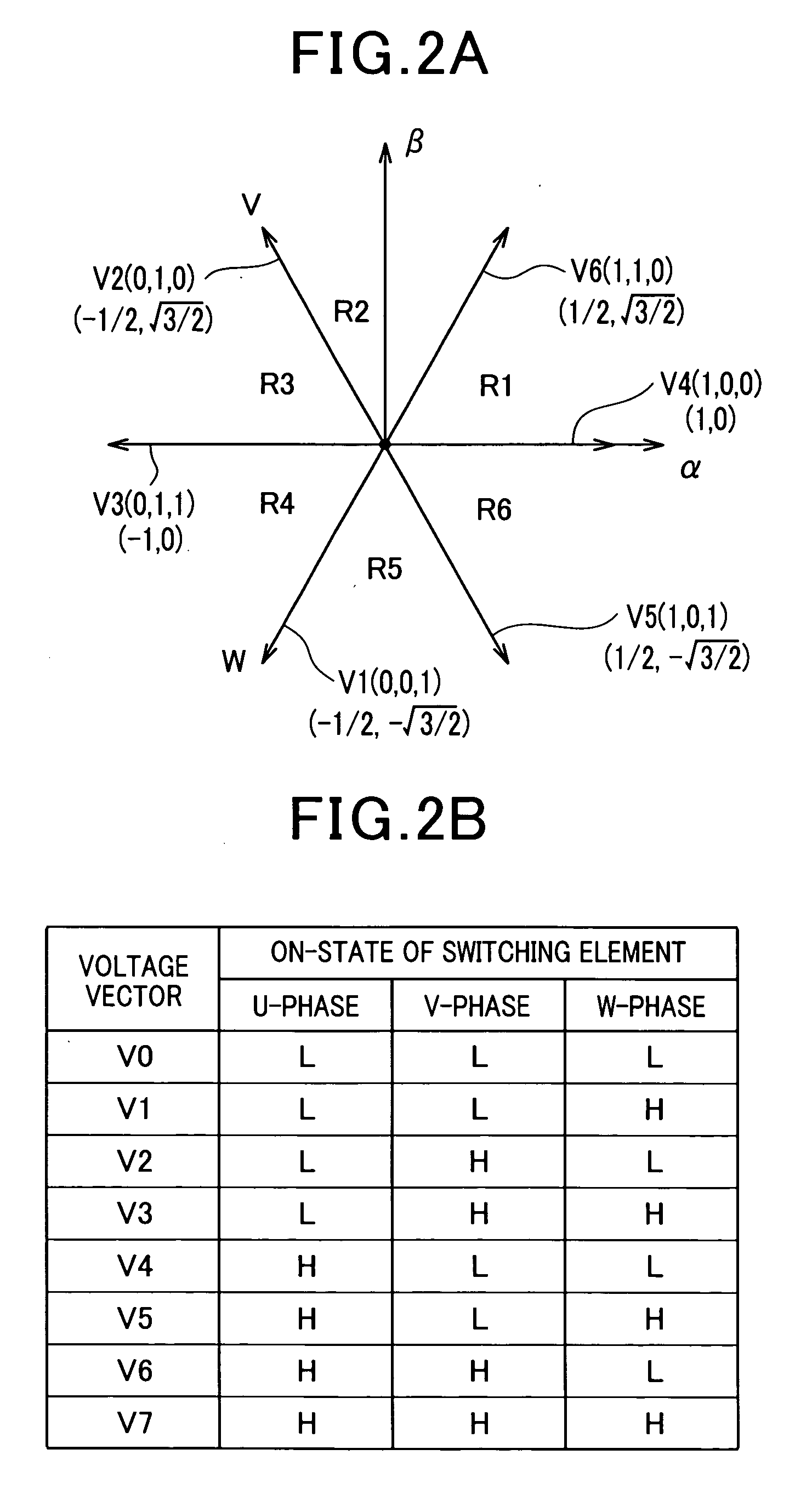

Control system for multiphase rotary machines

ActiveUS20090160377A1Reduce percentageReduced control accuracySynchronous motors startersVector control systemsRotary machineVoltage

A control system is designed to use a plurality of voltage vectors expressing a switching mode for a switching circuit to thereby control a difference between a current actually flowing through a multiphase rotary machine and a command current value therefor within an allowable range. The plurality of voltage vectors include a zero vector that allows line-to-line voltages in the multiphase rotary machine to be all zero, and a plurality of non-zero vectors that allow at least one of line-to-line voltage in the multiphase rotary machine to be nonzero. A drive unit is configured to switch only one phase of the switching element for each shift of the switching mode to thereby shift, in accordance with a preset switching pattern, the switching mode from a specified one of the plurality of non-zero vectors to the specified one of the plurality of non-zero vectors via the zero vector.

Owner:DENSO CORP

A 5-DOF (degree of freedom) air-float motion simulator

InactiveCN105185188AHeight adjustableEasy dockingCosmonautic condition simulationsSimulatorsRolloverGas cylinder

A 5-DOF air-float motion simulator comprises a translation platform and an attitude platform. The translation platform comprises a ball surface air-float bearing, a rollover-preventing mechanical stop device, an elevating column, a first air pressure pipeline, a first controller, three plane air-float bearings, a translation platform installation panel, and a translation platform lithium battery. The attitude platform comprises an attitude platform installation panel, 2N air bottles, a second air pressure pipeline, an iGPS, four cold air nozzle, an inertial navigation system, a second controller, three fly wheels, a center of mass adjustment system, and an attitude platform lithium battery. The translation platform accomplishes translation movement in the X and Y directions, the attitude platform accomplishes rotation with respect to the pitch axis, roll axis and yaw axis, so that the simulator achieves simulation of spatial attitude rotation and track translation movement of a spacecraft.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

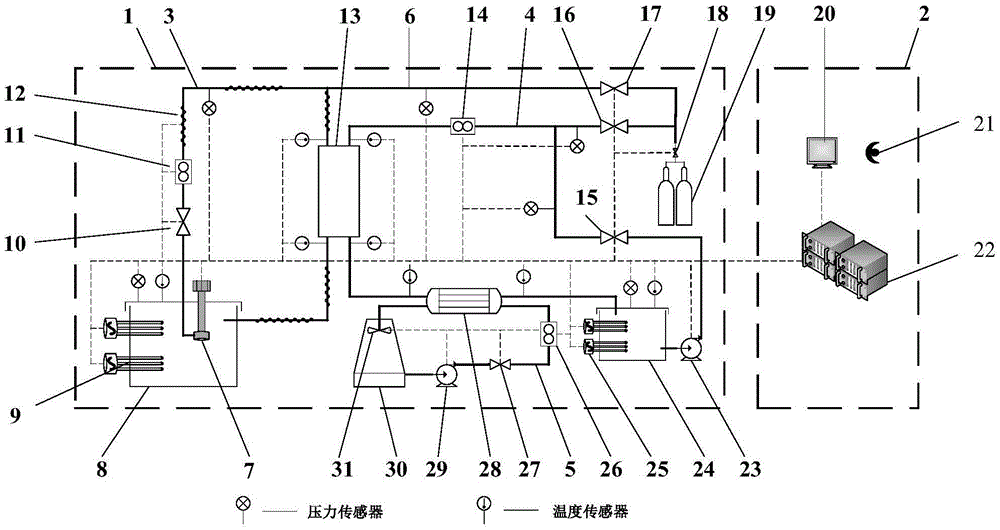

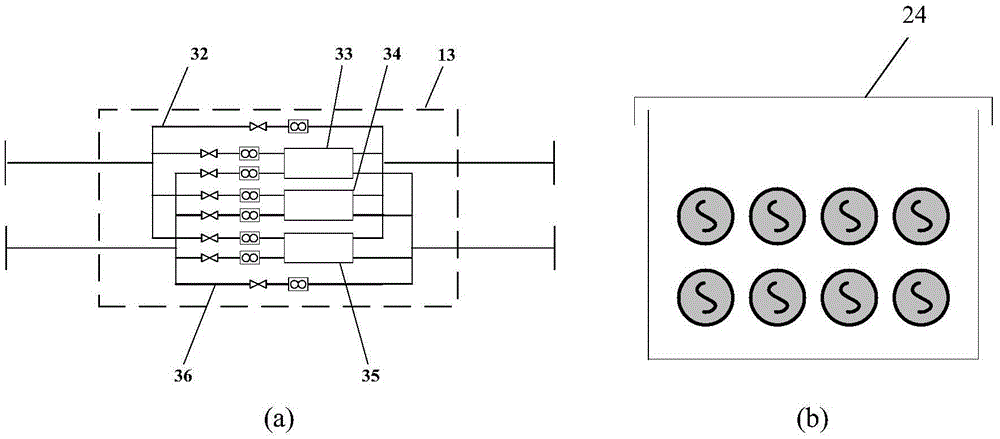

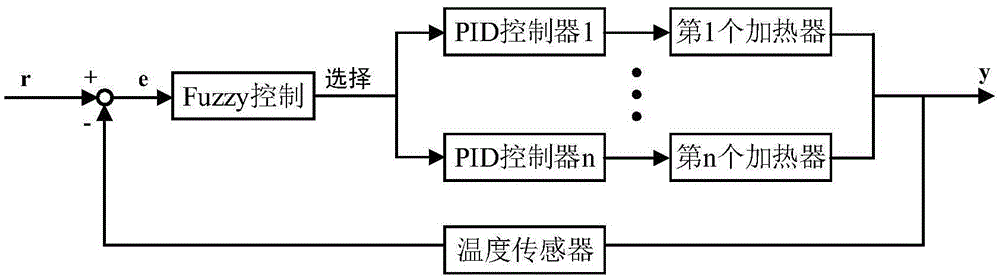

Fused salt heat exchange experimental device and control method thereof

ActiveCN105605955AReduce consumptionSmall amount of workHeat storage plantsEducational modelsHeat conductingEngineering

The invention discloses a fused salt heat exchange experimental device and a control method thereof. The experimental device comprises a high-temperature fused salt circulating circuit, a heat-conducting oil circulating circuit, a cooling water circulating circuit and a control system, wherein the high-temperature fused salt circulating circuit and the heat-conducting oil circulating circuit are separately connected with parallel fused salt heat exchange experimental sections; the heat-conducting oil circulating circuit and the cooling water circulating circuit are separately connected with a heat-conducting oil heat exchanger and a cooling water heat exchanger; the control system is a Fuzzy-PID (Proportion Integration Differentiation) control system, and has the characteristics of rapid response control, high control precision and easiness for realization. According to the fused salt heat exchange experimental device and the control method thereof disclosed by the invention, the project quantity of replacing the experimental sections is reduced; meanwhile, the experimental sections are simultaneously performed by intelligent control, so that the consumption of energy sources is reduced to a great degree, and accurate control over temperature and flow can be realized; meanwhile, aiming at the control over the parallel experimental sections, huge contribution on energy conservation is realized. Experimental operation personnel are away from an experimental table area, and intelligent automation is completely realized, so that the security of the experimental personnel is realized.

Owner:XI AN JIAOTONG UNIV

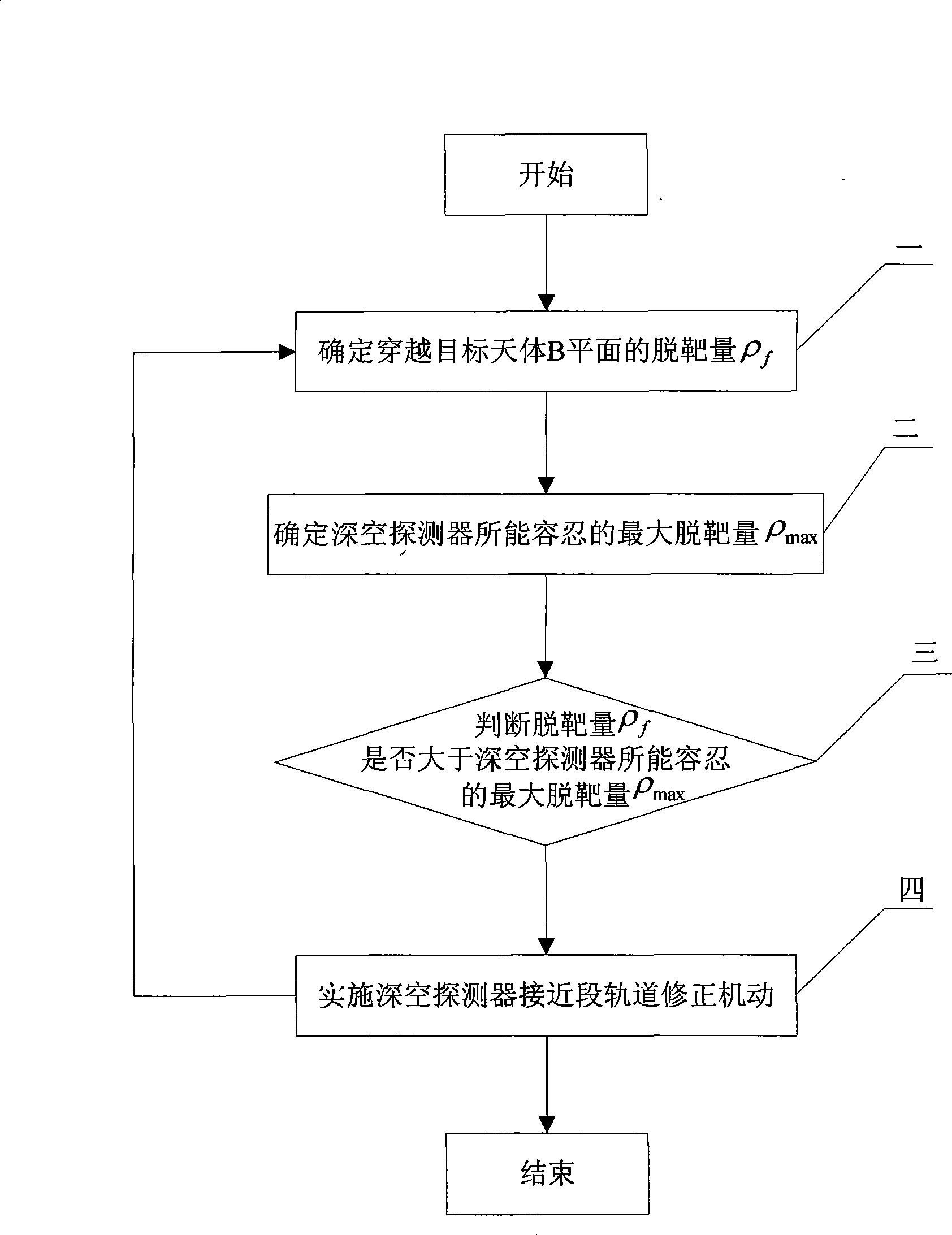

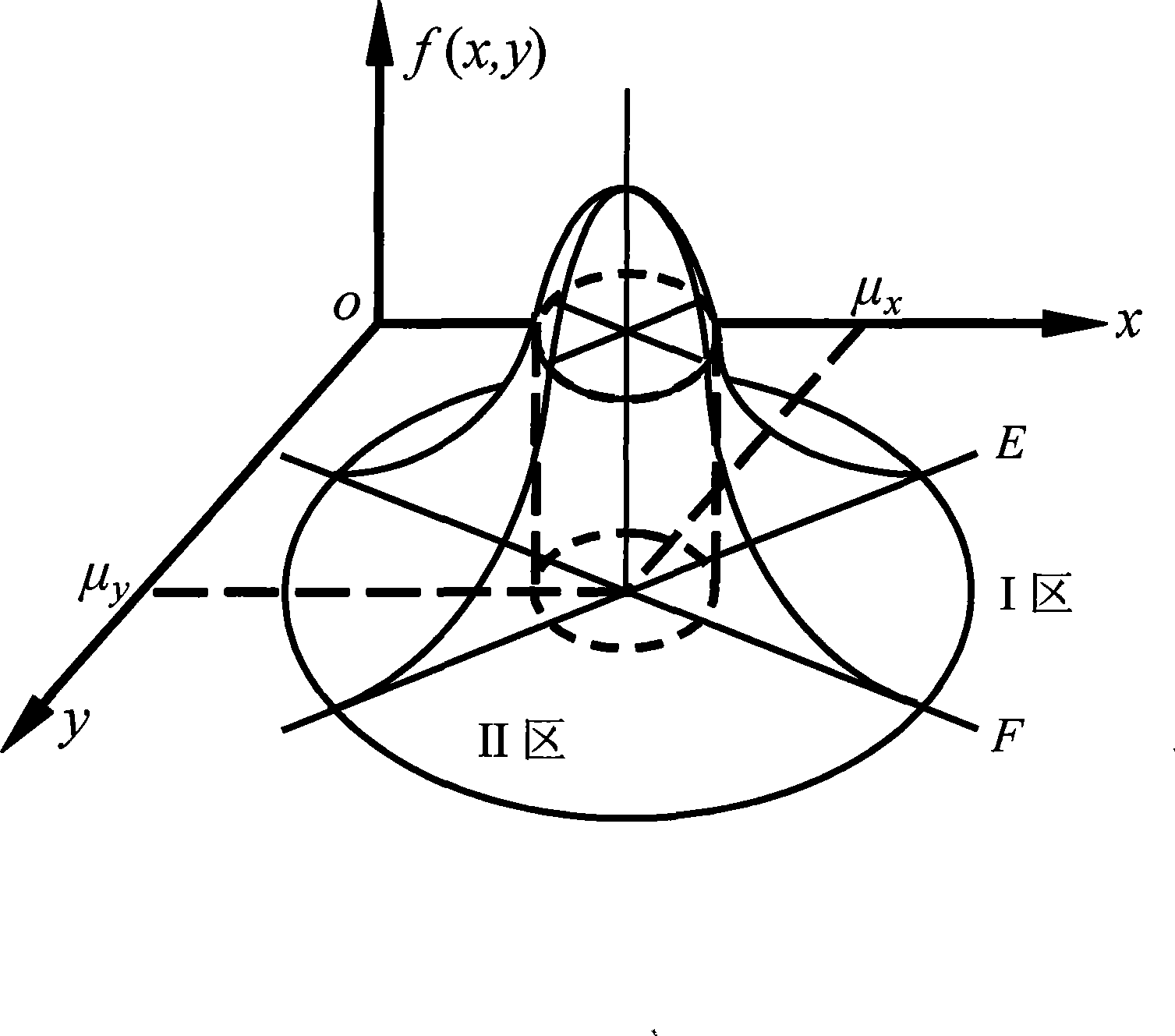

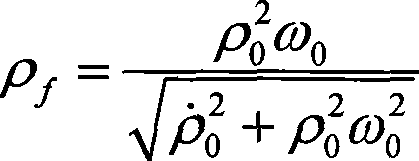

Medication maneuvering time selecting method for deep space detector approaching orbit

InactiveCN101462597AMeet the requirements of brake implementationReduce consumptionArtificial satellitesNavigation by astronomical meansAviationCelestial body

The invention relates to a method for selecting time of deep space probe approach orbit correction maneuver, which belongs to the field of spaceflight and aviation and solves the problems of deep space probe approach orbit correction maneuvering time including low control precision, great calculation amount and poor independency in the prior method for selecting time of deep space probe approach section orbit correction maneuver. The method comprises: 1, determining miss distance rhof passing through the B plane of an object celestial body; 2, determining the acceptable maximum miss distance rhomax of a deep space probe; 3, judging whether the miss distance rhof is more than the acceptable maximum miss distance rhomax, if yes, executing step 4; otherwise, returning to step 1; and 4, executing deep space probe approach section orbit correction maneuver. The method not only can save fuel at a rate of 6m / s, but also can ensure that final passing-through precision is increased by more than 100m as compared with ground station designated maneuver time precision under the same condition and reaches within 250m.

Owner:HARBIN INST OF TECH

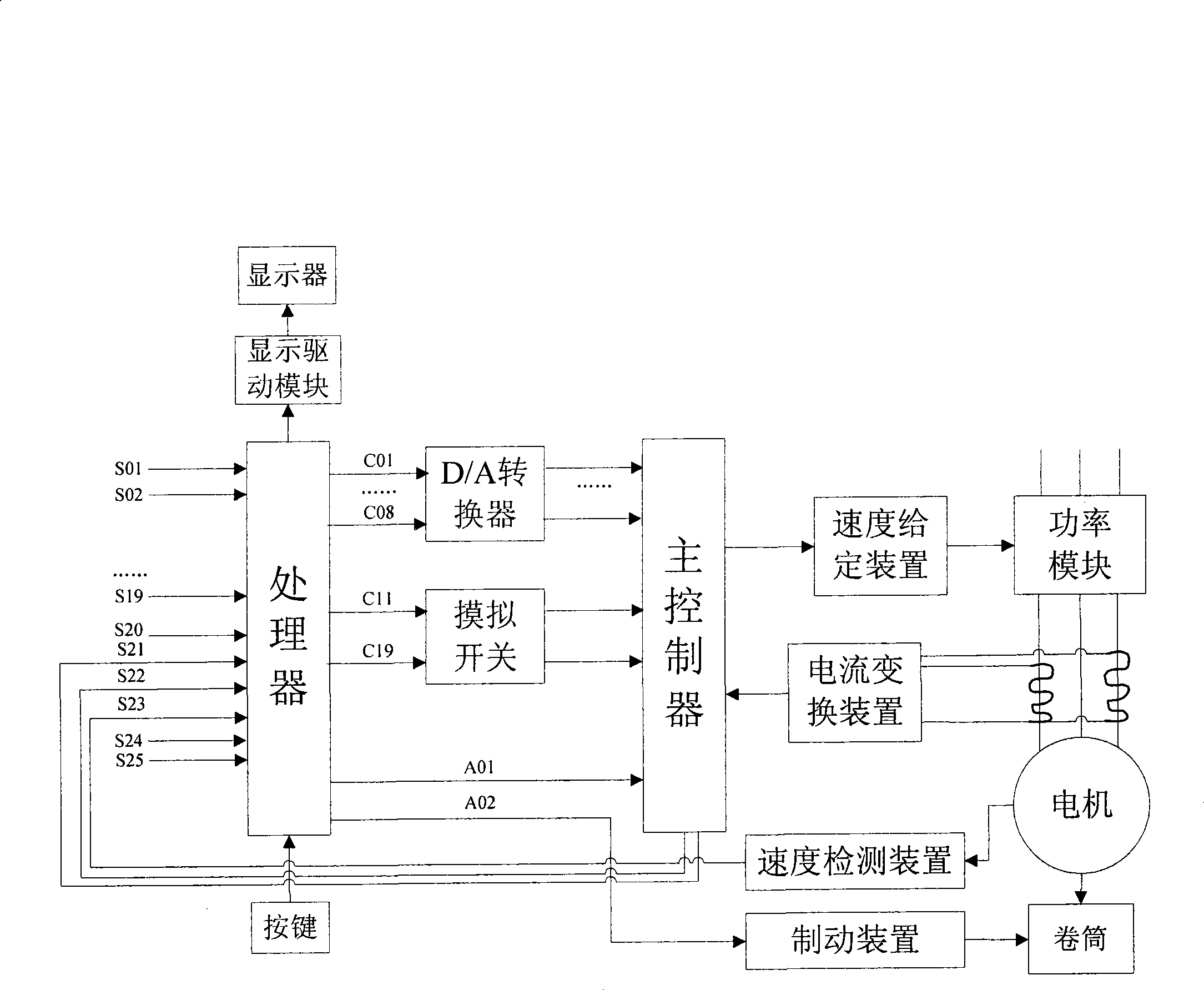

Pressure and speed regulating system for semi-digital AC stator

InactiveCN101388640AImprove work performanceHigh adjustment accuracyAC motor controlEngineeringControl theory

The invention relates to a semi-digitalization direct current stator variable voltage speed control system, which comprises a main controller, a speed setting device, a power module, a current transformation device, a motor, a reel and a processor which is used to adjust parameters, wherein the process is used to adjust the parameters, receives a plurality of input signals which pass through analog to digital conversion, and outputs the signals after comparison processing adjustment, the system also comprises a D / A conversion module which is connected with an output end of the process, is used to convert a part of digital signals which are output by the processer into analog control signals, and outputs the analog control signals to the main controller, wherein the main controller controls the motor to operate according to the analog control signals. The system of the invention realizes parameter arrangement and adjustment through increasing the processer and has the advantages of high adjusting precision, stable working performance and strong anti-interference ability. The system only needs to input parameters of an original device into a new device in in-situ device replacement. The maintenance quantity is reduced and the safe production has more reliable guarantee. The electronic over-speed and hook gliding preventing protection is increased, and the system safety is increased.

Owner:SHANGHAI ZHIDA ELECTRONICS

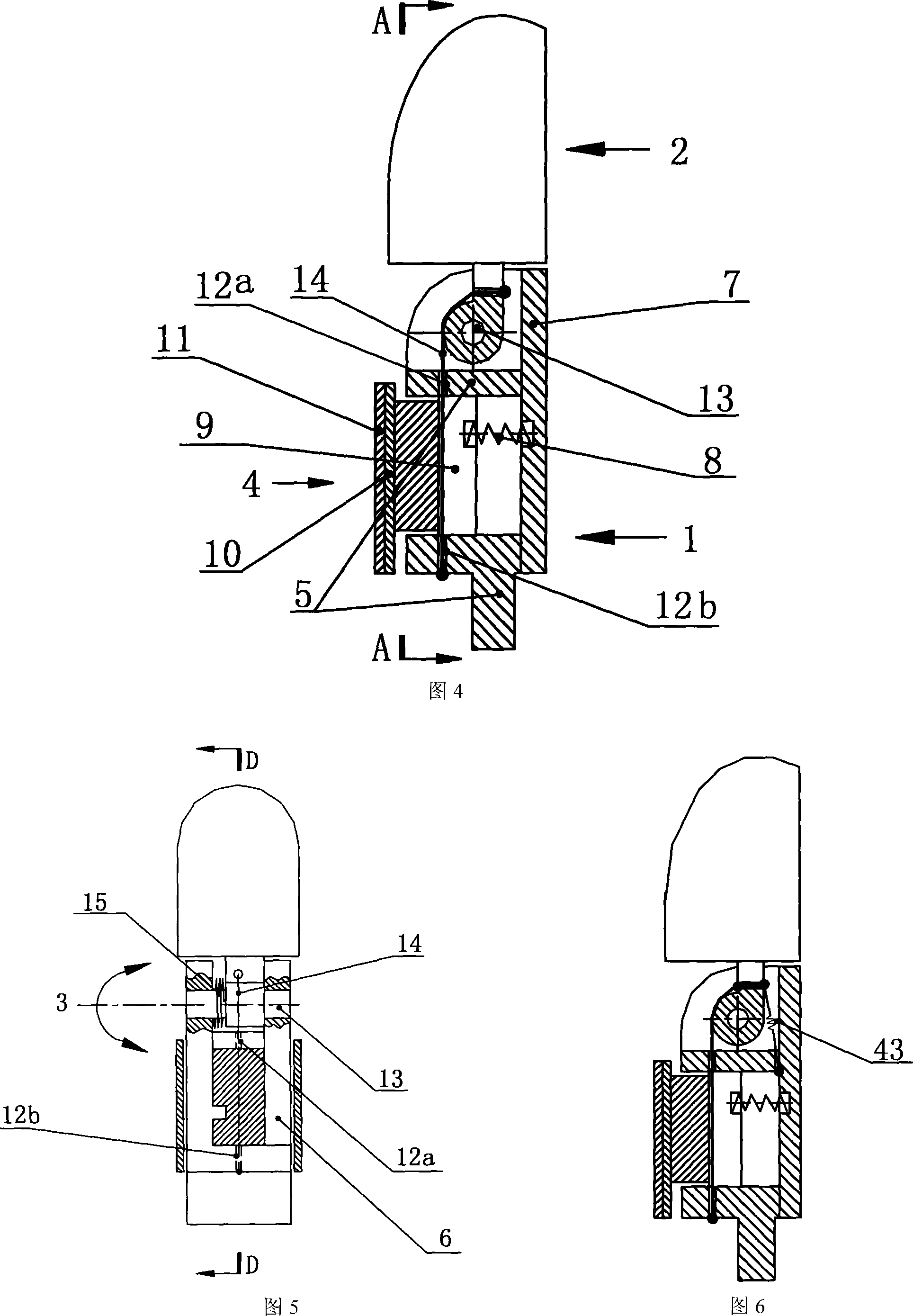

Tendon-channel under-driven mechanical finger device

The invention relates to tendon link under-actuated mechanical finger device which includes the first and second finger sections, under-actuated joint. The under-actuated joint includes joint axis, drive slider, tendon line, and spring piece. The joint axis is set at the first finger section. The second one is set at the joint axis. One end of the tendon line is fixed at the end of the second finger section. Another end is passed through the upper of the first one and connected with its lower. The drive slider is embedded in the first finger section and touched with the tendon line. The spring piece is set between the first and second knuckles. The device can be used as impersonated one finger or parts, or connected in series to form high under-actuated finger. The device has the advantages of simple, reliable structure, little volume, light weight, low control system demand.

Owner:TSINGHUA UNIV

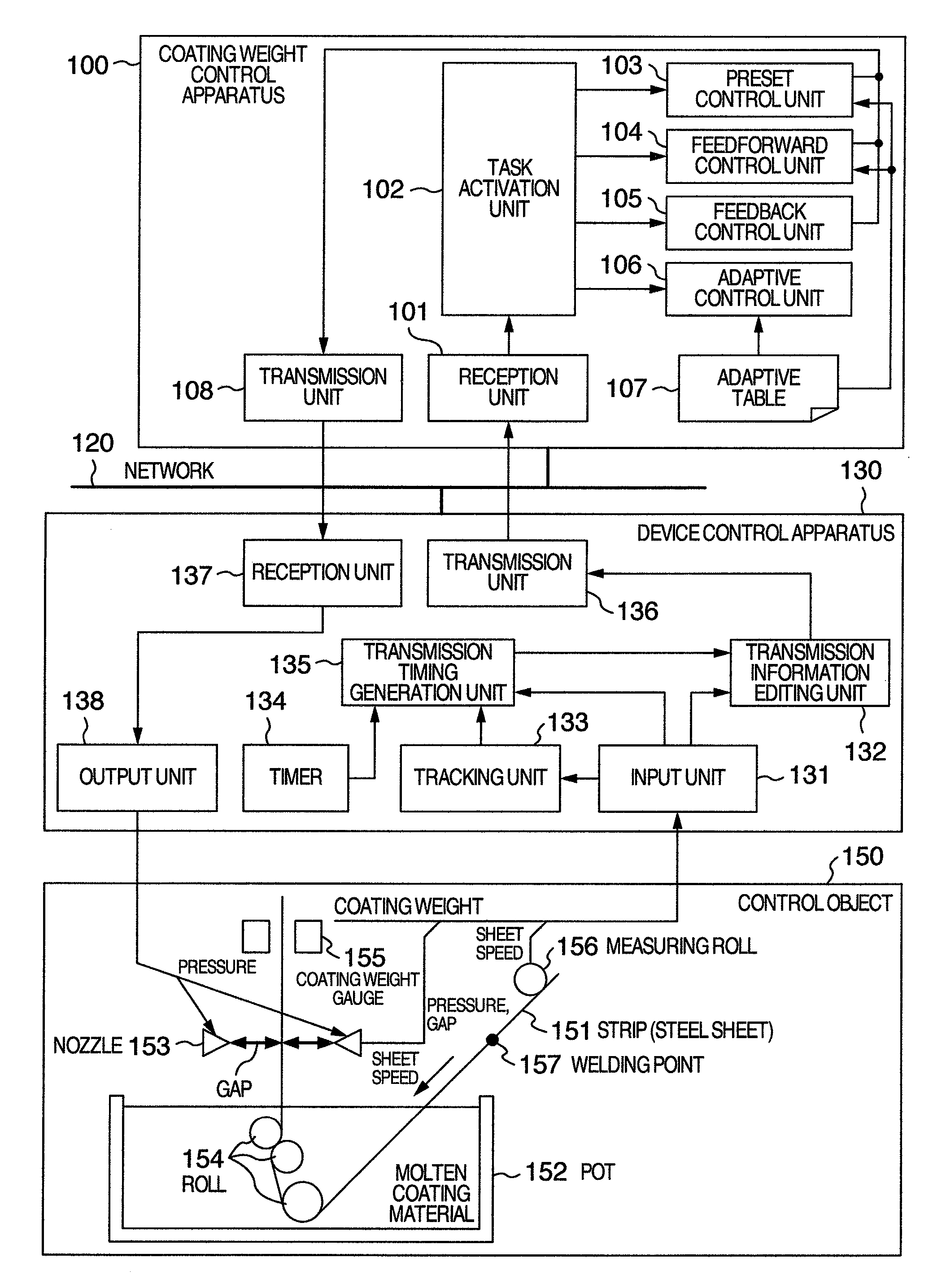

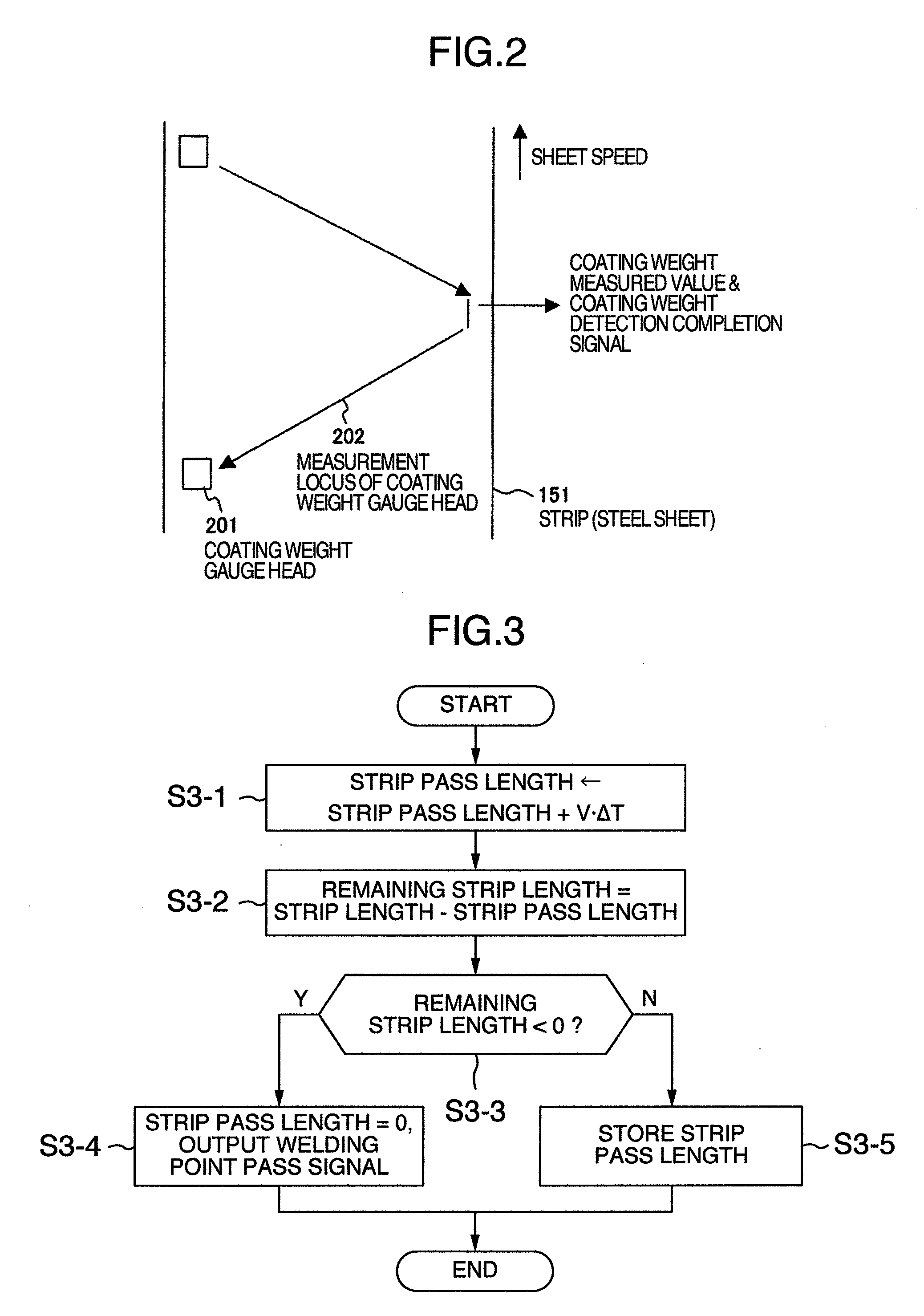

System and method for controlling plating amount

InactiveUS20080026134A1Sequencing is complicatedLong calculation timeHot-dipping/immersion processesLiquid surface applicatorsStrip steelBiological activation

An apparatus for performing a coating weight control calculation and an apparatus for generating an activation timing of each process in coating weight control are separately managed. A strip welding point pass event, a completion event of scan measurement of a steel strip in a width direction by a coating weight gauge, and a constant period event are related respectively to activation timings of preset control, feedback control and feedforward control respectively of a coating weight. In a coating weight control apparatus and method, the activation timing generation apparatus is equipped with a function of calculating a timing of changing a pressure reference avoiding insufficient coating in accordance with response characteristics of a pressure as an operation terminal, and if a target coating weight is changed from thin coating to thick coating, generating a preset control activation reference in accordance with the calculation result.

Owner:HITACHI LTD

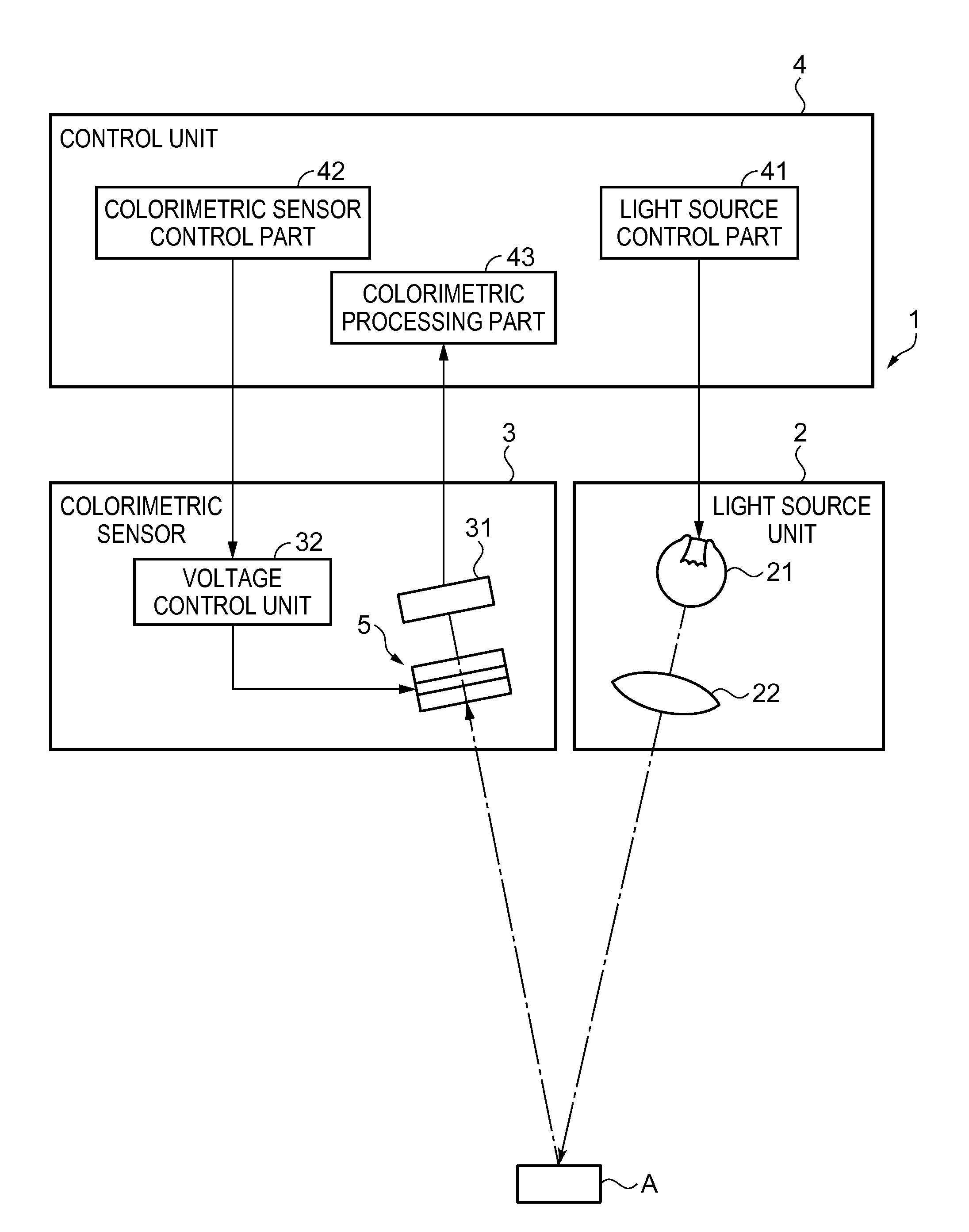

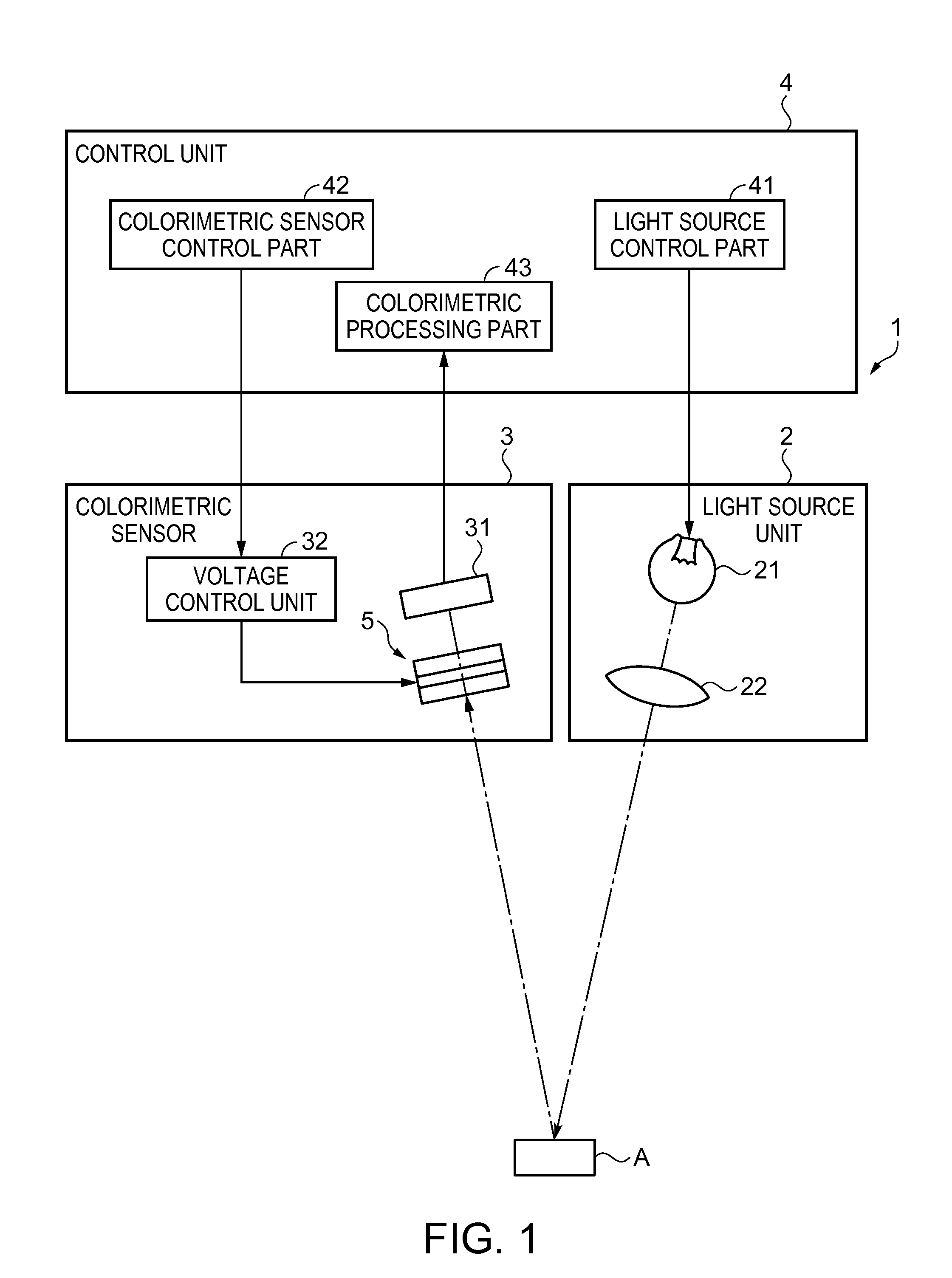

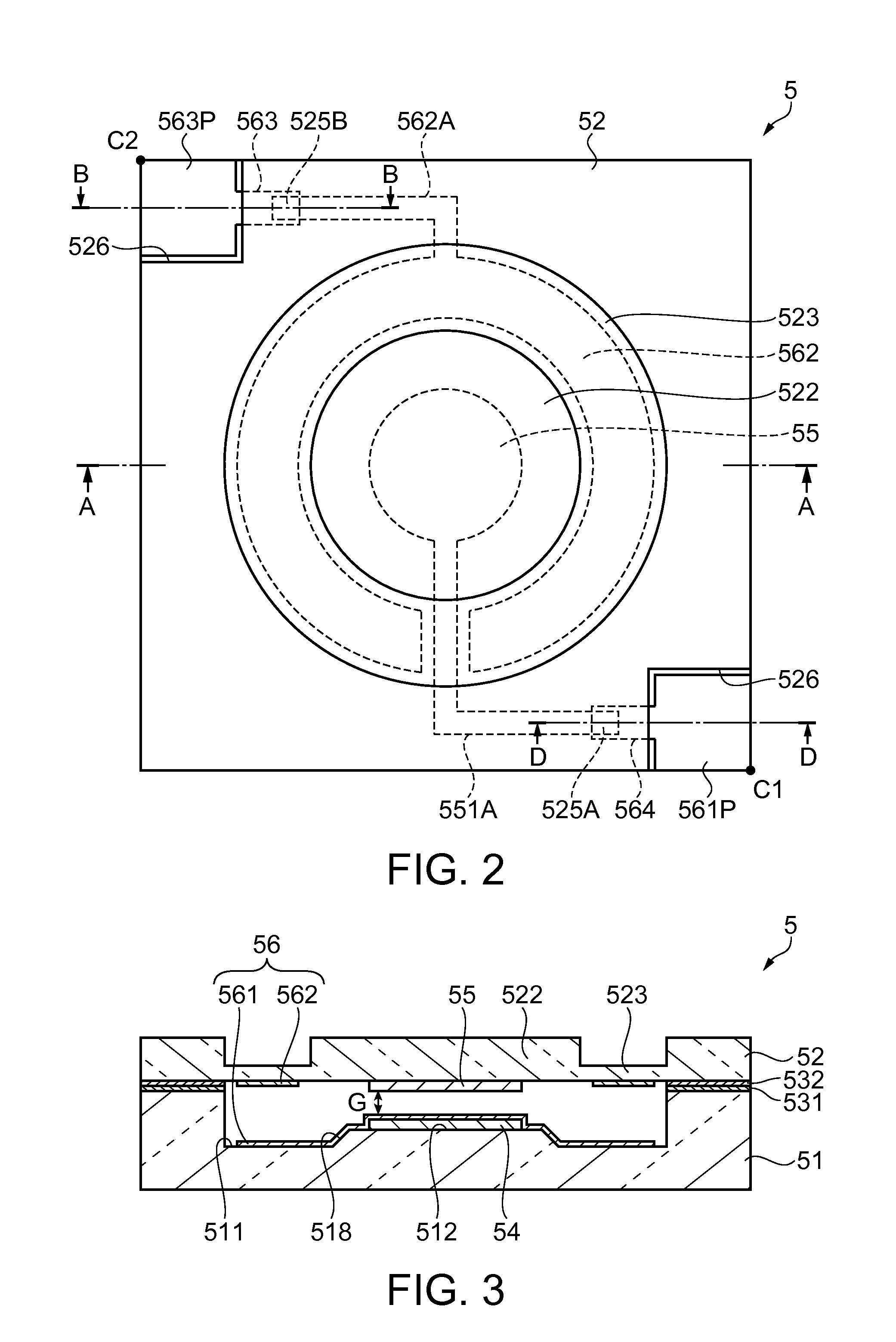

Optical filter, optical filter module, and photometric analyzer

InactiveUS20120300208A1Reduce impactReduced control accuracyRadiation pyrometryColor measuring devicesElectrodeOptical filter

An optical filter includes fixed substrate, a movable substrate opposed to the fixed substrate, a first reflection film provided on a surface of the fixed substrate facing the movable substrate, a second reflection film provided on the movable substrate and opposed to the first reflection film across a gap, a first electrode formed to cover the first reflection film and to extend beyond an outer circumference of the first reflection film, and a second electrode provided on a surface of the movable substrate facing the fixed substrate and opposed to a part of the first electrode, and the first electrode is formed of a light-transmissive material, and the first electrode and the second reflection film are electrically connected at the same potential.

Owner:SEIKO EPSON CORP

Optical transmission equipment and integrated circuit

InactiveUS7515832B2Reduced control accuracyEasy to adjustTime-division optical multiplex systemsWavelength-division multiplex systemsMultiplexingLow speed

Owner:HITACHI LTD

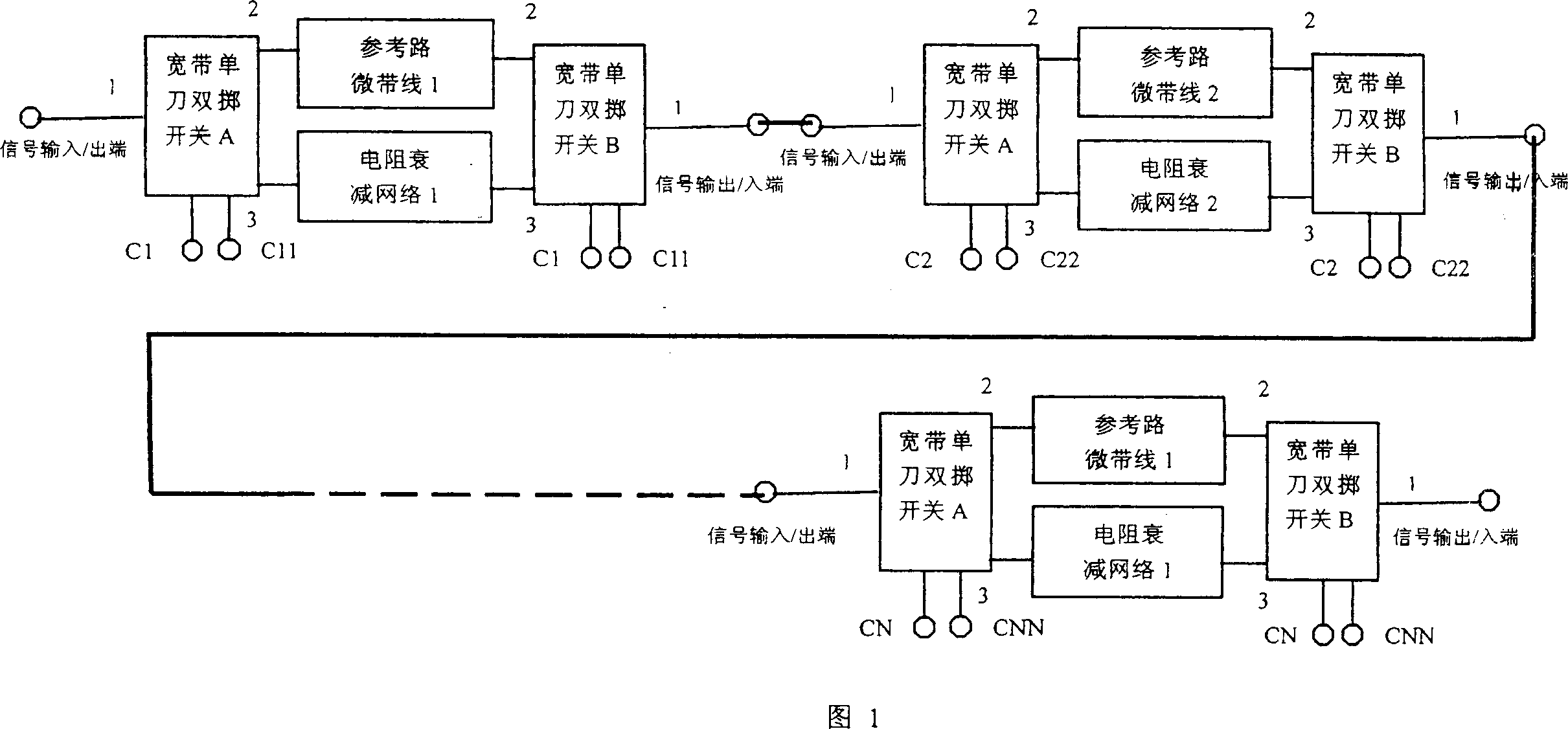

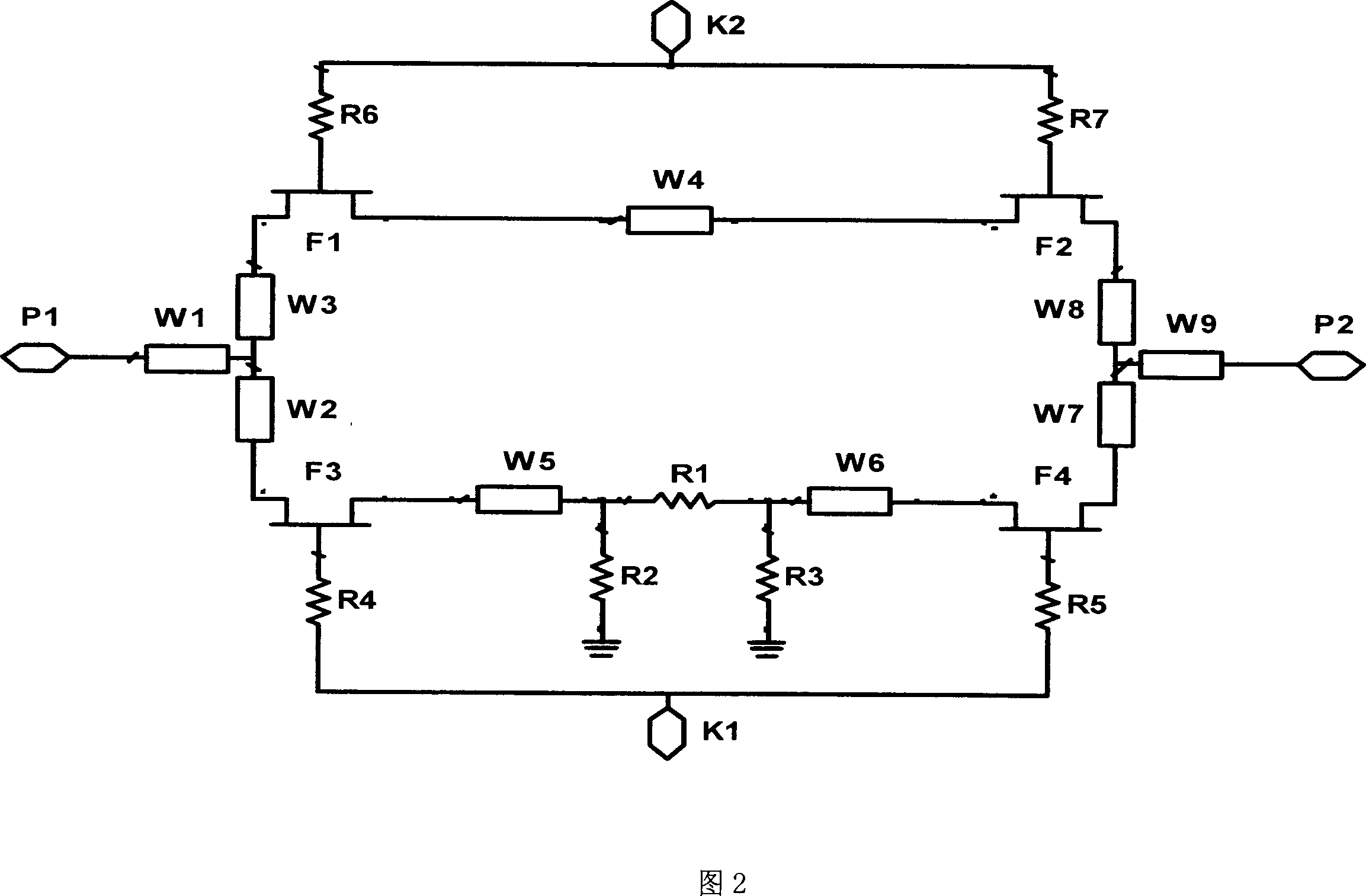

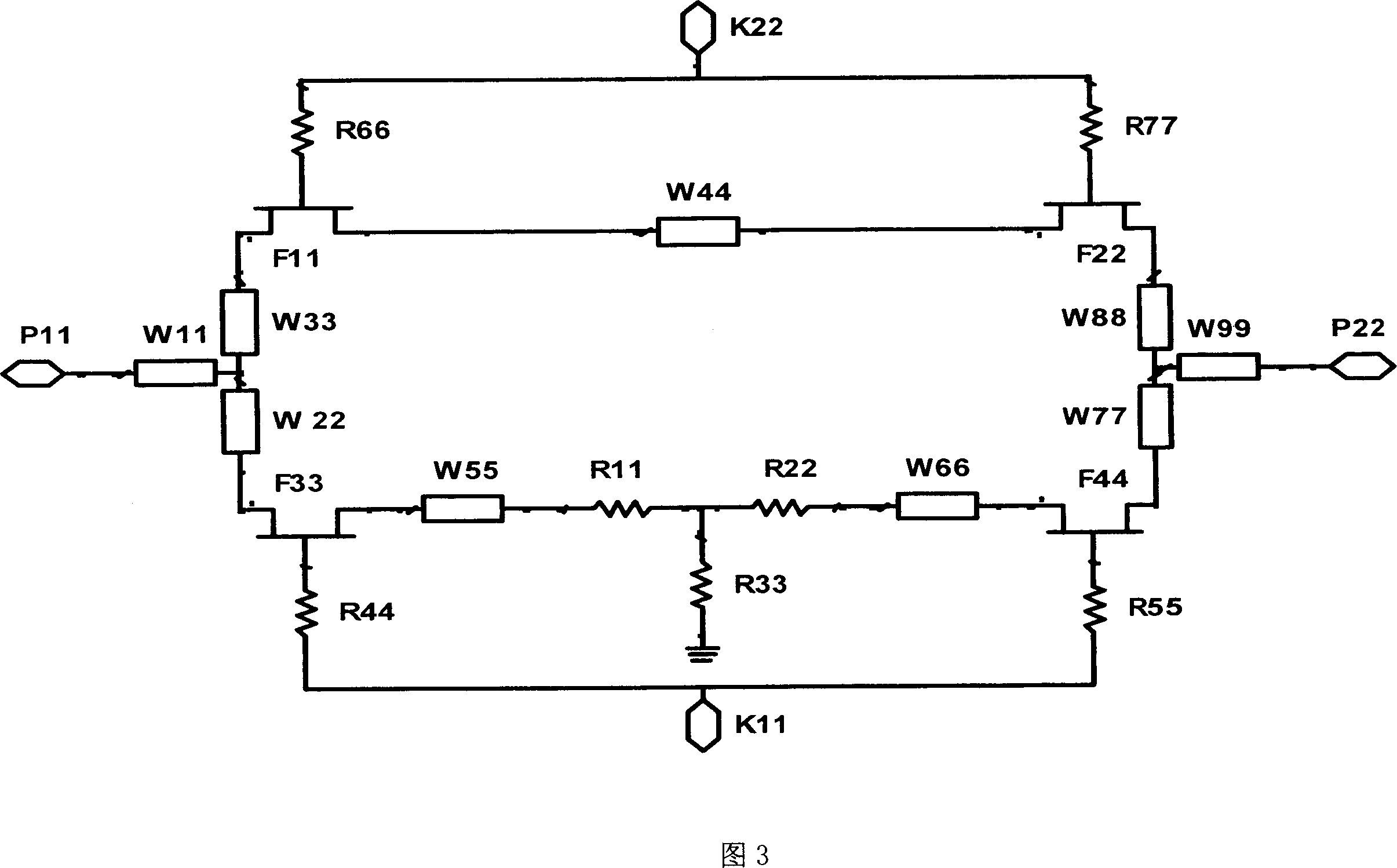

Low phase differential broadband digital attenuator IC of microwave and millimeter wave

InactiveCN1968013ASimple topologySimple structureFrequency-independant attenuatorsElectrical resistance and conductanceElectricity

The invention relates to a microwave millimeter wave low-phase-different wide-frequency digit attenuation integral circuit, wherein it is formed by one or more attenuation integral circuits; said circuit is formed by two wide-band single-pole double-throw switches, reference micro band, resistance attenuation network, input / output and two controllers; the controller functions right signal on two single-pole double-throw switches, the reference micro band will be connected or stopped, and the attenuation network will be stopped or connected; two branches outputs signal with fixed attenuation values and fixed phase. The invention has simple structure and wide work frequency, etc.

Owner:NANJING UNIV OF SCI & TECH

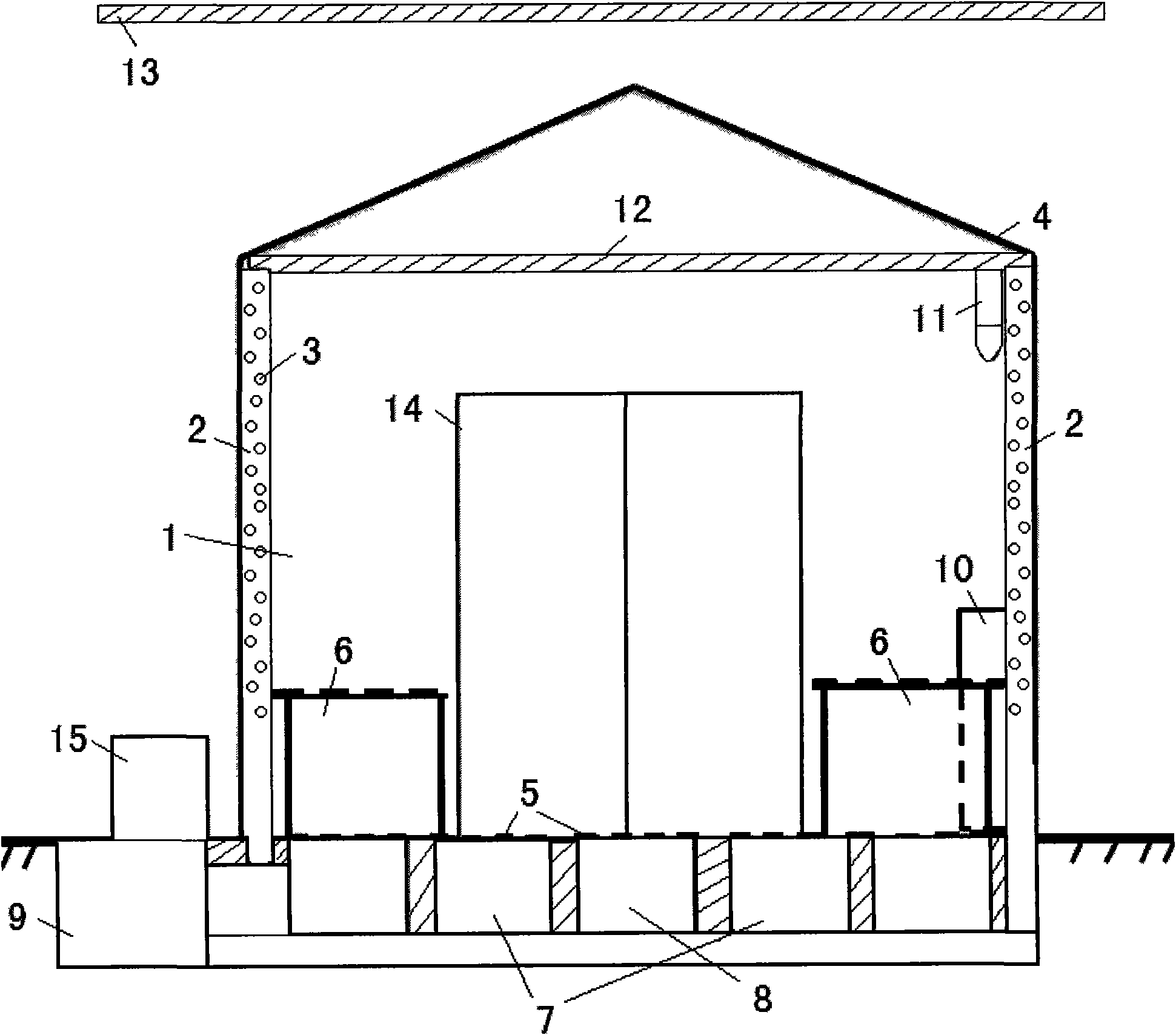

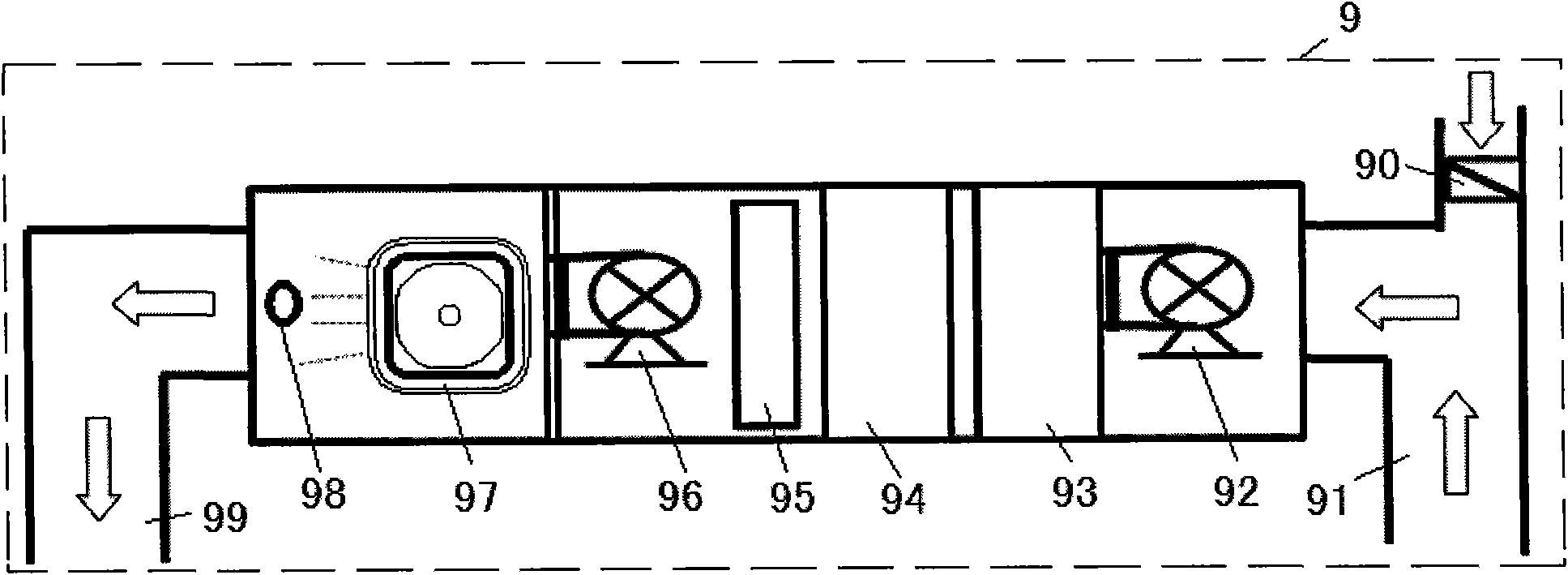

Environmental-control type closed greenhouse

ActiveCN101627707ASmall gradientReduce air exchangeClimate change adaptationGreenhouse cultivationGratingControl system

The invention relates to an environmental-control type closed greenhouse which comprises a closed greenhouse, wherein a plurality of support upright posts are arranged in the greenhouse, a ceiling is supported at the top parts of the support upright posts, a columnar air duct on which air vents are overspread is attached to the support upright post, enclosing and covering materials are arranged outside the greenhouse enclosed by the support upright posts and the ceiling, a grating-type air-supply perforated plate is paved on the ground, a plurality of cultivating beds are positioned on the air-supply perforated plate, a plurality of air-supply ducts and air-return ducts are arranged at the lower part of the air-supply perforated plate at intervals, a functional air duct is arranged outside the greenhouse, all air-supply ducts are arranged at an air-supply port of the function air duct in parallel, one end of each air-return ducts is connected at an air-return port of the functional air duct in parallel, and the air-return port of the functional air duct is also communicated with the bottom parts of all upright posts; an embedded network environmental-control system and a sensor module are arranged in the greenhouse; and an inner shading device and an outer shading device are respectively arranged at the inner side and the outer side of the ceiling. The invention can be widely applied to various scientific experimental studies or actual production fields, such as environmental control, plant environment physiological feedback, inheritance breeding, plant information detection, and the like, and is especially suitable for the safety test of transgenic plant cultivation.

Owner:BEIJING SHENGYANGGU SCI & TECH

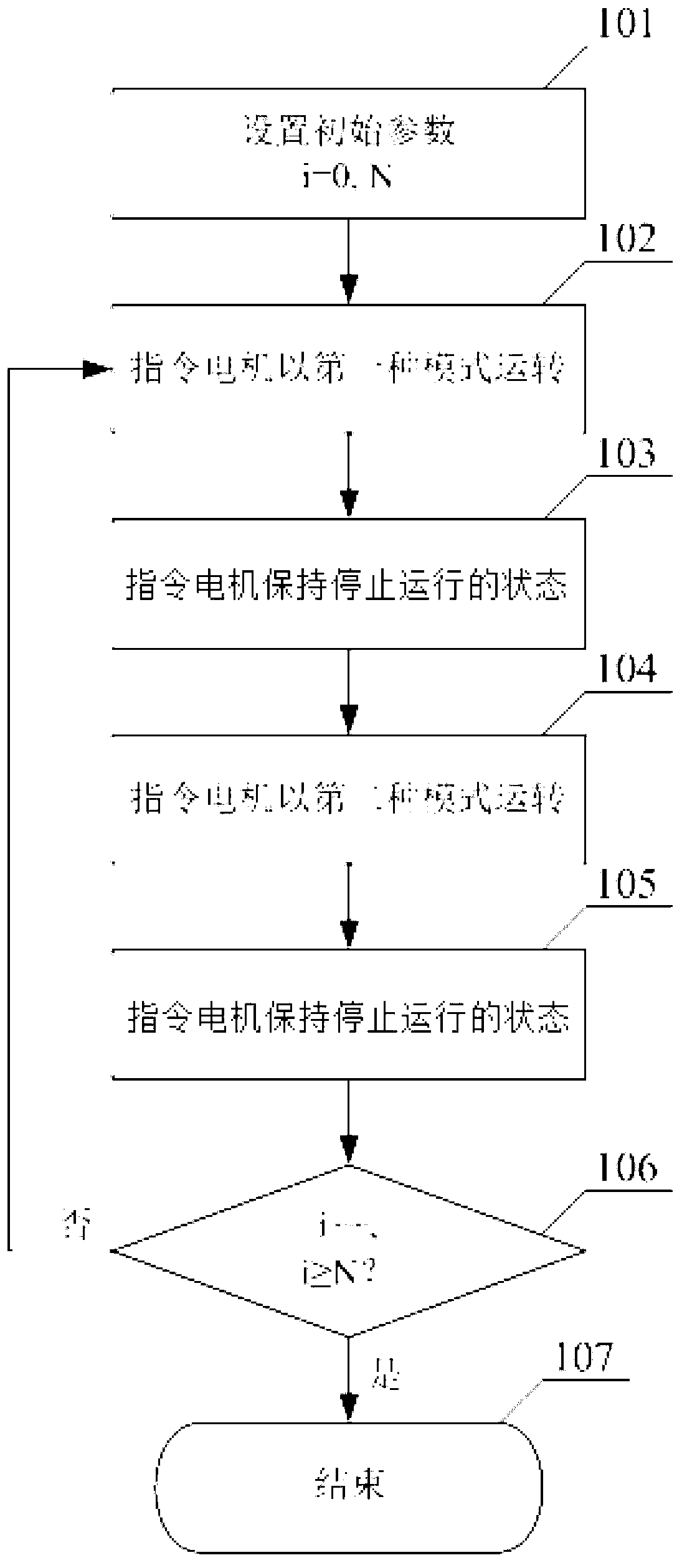

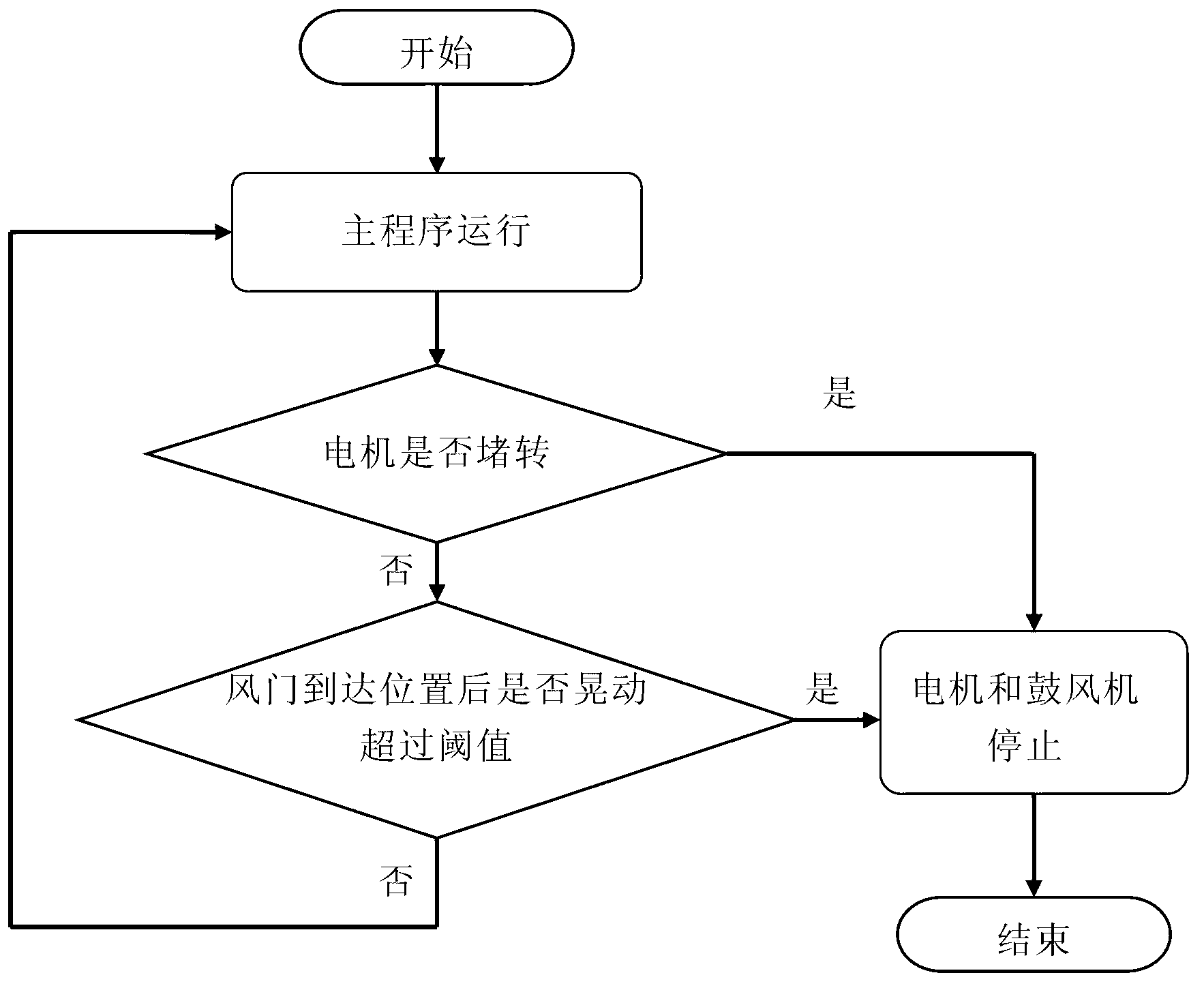

Method and device for testing durability of air door of automobile air conditioner

InactiveCN103076166ADurability Testing SafetyHigh precisionMachine part testingAutomobile air conditioningStop time

The invention discloses a method and a device for testing the durability of an air door of an automobile air conditioner. The air door of the automobile air conditioner is driven by using a plurality of motors. The method comprises the following steps of: setting a first feedback voltage, a second feedback voltage, first stopping time, second stopping time and a target cycle index; instructing each motor to run and making the feedback voltage of each motor get close to the first feedback voltage; when the feedback voltage of each motor reaches the first feedback voltage, instructing each motor to stop running within the first stopping time; instructing each motor to run and making the feedback voltage of each motor get close to the second feedback voltage; when the feedback voltage of each motor reaches the second feedback voltage, instructing each motor to stop running within the second stopping time; and adding one cycle index, and if the cycle index is smaller than a target cycle index, repeating cycles, otherwise, ending the testing. According to the method and the device, testing of the durability of the air door of the automobile air conditioner and electric stopping of the motors are realized, stopping positions and time can be set, and testing is more reliable and safer.

Owner:SHANGHAI BEHR THERMAL SYST

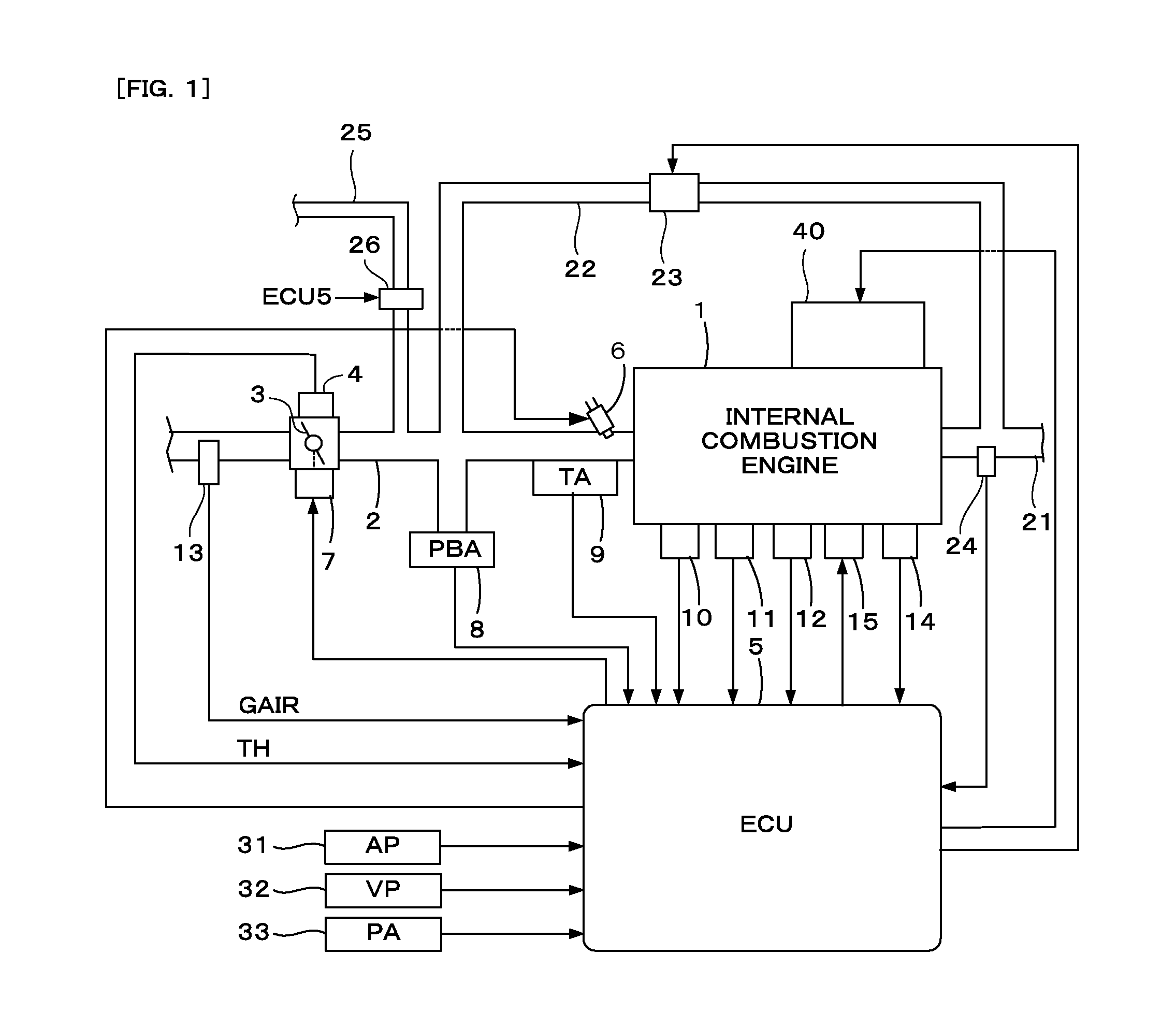

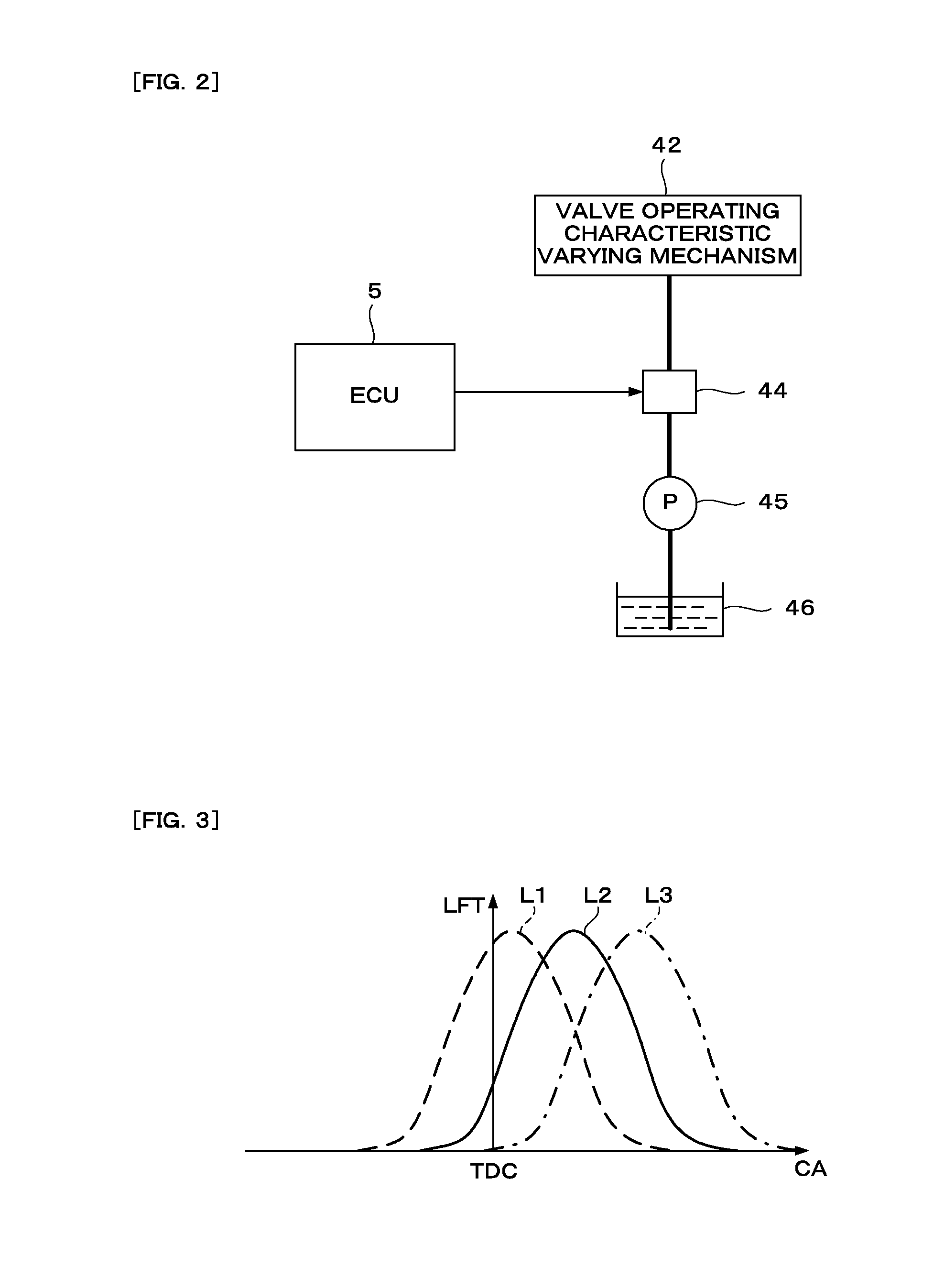

Control apparatus for internal combustion engine

ActiveUS20140338636A1Improve calculation accuracyImprove accuracyElectrical controlInternal combustion piston enginesLower limitExternal combustion engine

A control apparatus for an internal combustion engine having a throttle valve disposed in an intake passage of the engine is provided. A wide-open intake air amount, which is an intake air amount corresponding to a state where the throttle valve is fully opened, is calculated, and a theoretical intake air amount, which is an intake air amount corresponding to a state where no exhaust gas of the engine is recirculated to a combustion chamber of the engine, is calculated according to the wide-open intake air amount and the intake pressure. An air-fuel ratio correction amount and a learning value thereof are calculated according to the detected air-fuel ratio, and a reference intake air amount is calculated using the intake pressure, the engine rotational speed, the air-fuel ratio correction amount, and the learning value. A lower limit value of the detected intake air amount is set according to the reference intake air amount, and a limit process is performed for limiting the detected intake air amount within a range of values which are equal to or greater than the lower limit value. An amount of the evaporative fuel / air mixture supplied to the intake passage is calculated, and the limit-processed intake air amount is corrected using the evaporative fuel / air mixture amount to calculate an intake gas amount. An exhaust gas recirculation ratio is calculated using the theoretical intake air amount and the intake gas amount.

Owner:HONDA MOTOR CO LTD

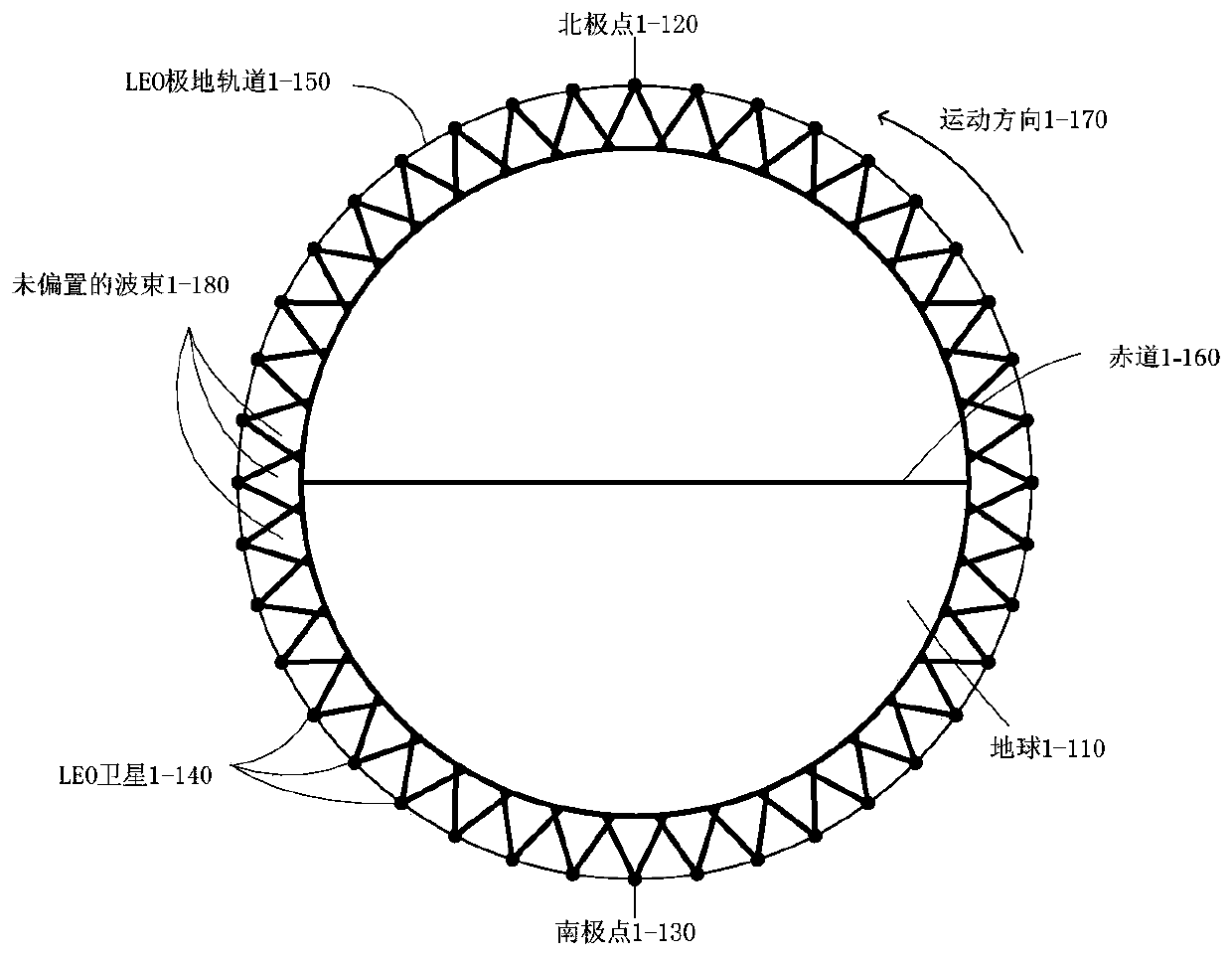

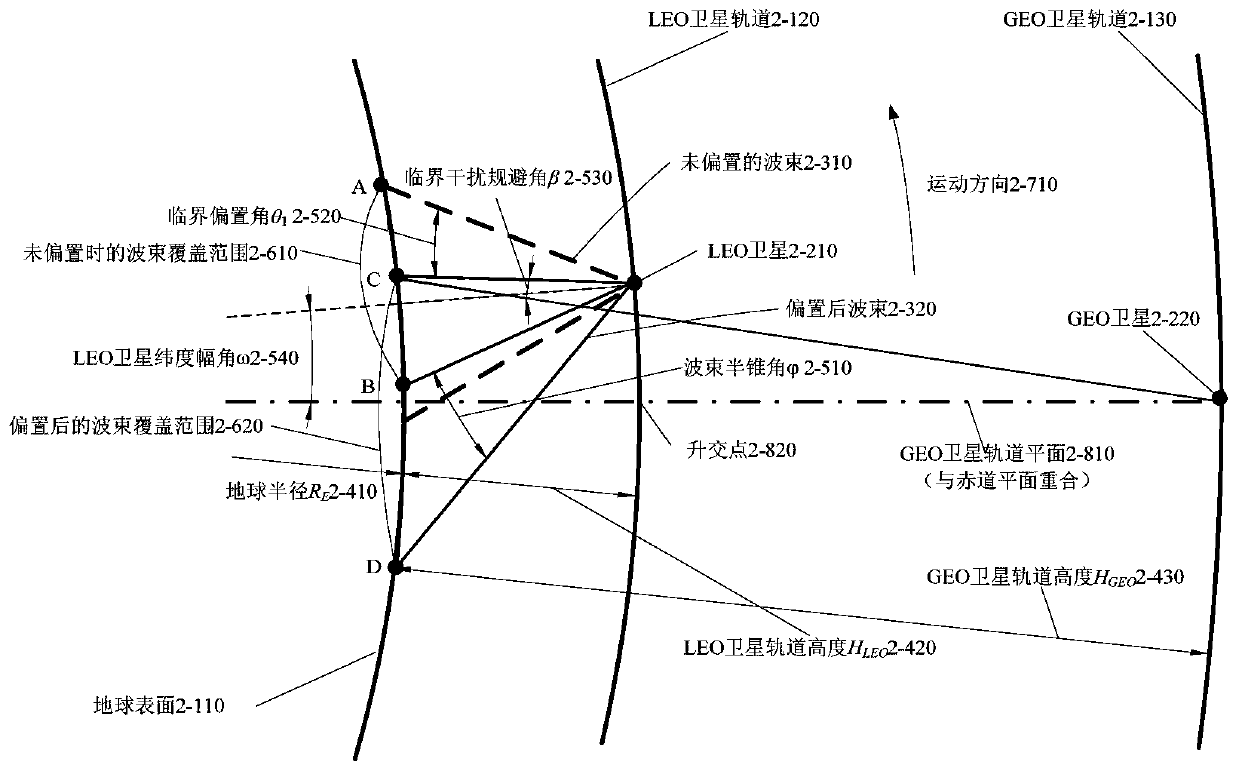

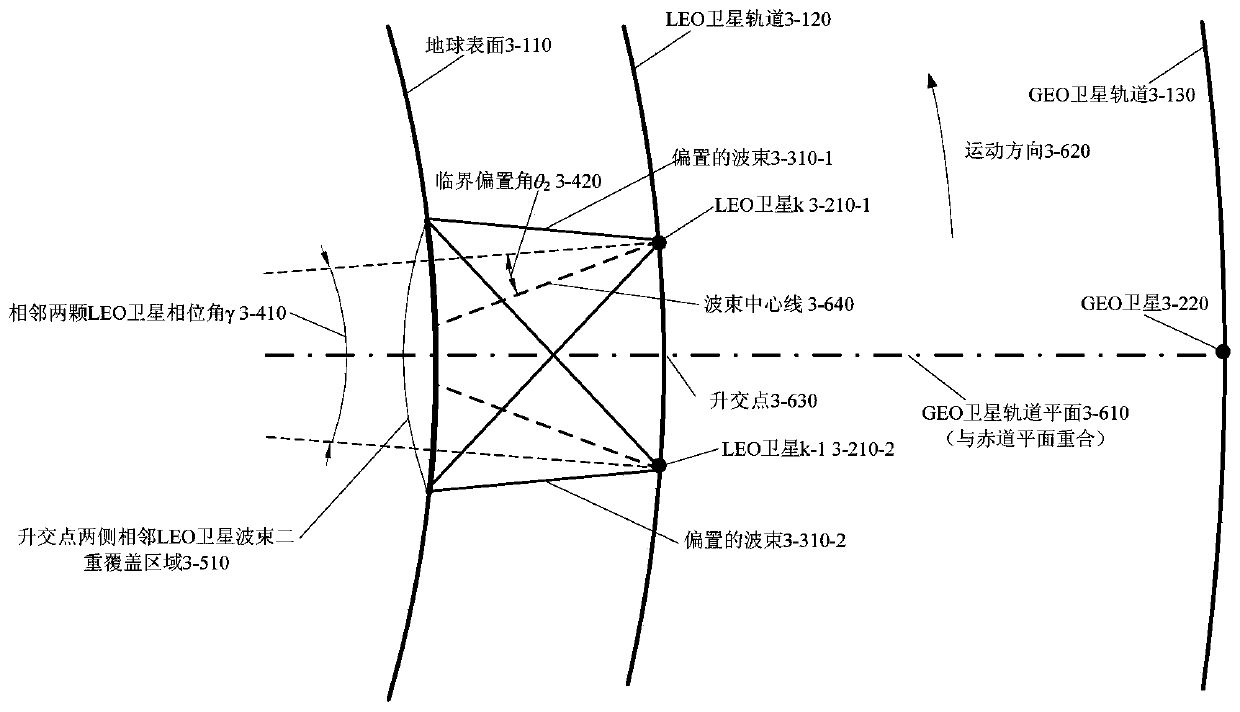

Method for sharing radio frequency spectrum based on beam constant offsetand low-orbit communication satellite system

ActiveCN110417453AReduced control accuracyControl accuracy is not restrictedActive radio relay systemsNetwork planningNear-equatorial orbitFrequency spectrum

The invention relates to a method for sharing a radio frequency spectrum with a high-orbit communication satellite running in a near-equatorial orbit including an earth synchronous satellite based onbeam constant offset and a low-orbit communication satellite system. The method comprises the steps that low -orbit communication satellites complete conversion of a transmitting beam constant offsetstate near the North-South poles and the equator, the beam offset directions are opposite before and after each implementation, and the beam offset degree is a fixed constant; the low-orbit communication satellites close to the equator all deflect towards the equator; and during the beam offset conversion near the North and South poles, services are provided by the beams of other low-orbit communication satellites in two other orbits adjacent to each other on both sides of the current orbit. During implementation of beam offset conversion near the ascending node and the descending node, beam coverage services are provided by adjacent low-orbit communication satellites located on the other side of the ascending node or the descending node in the same orbit.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

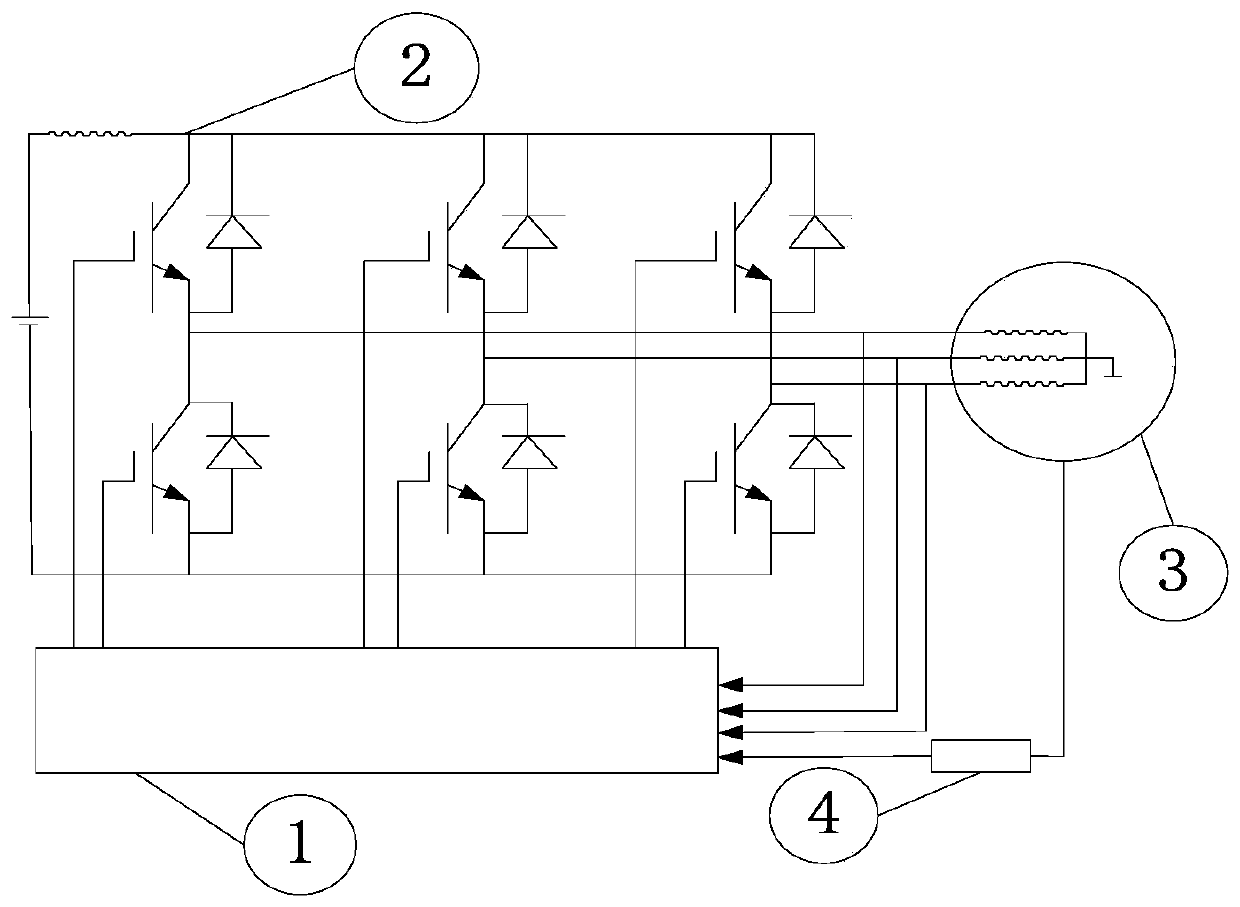

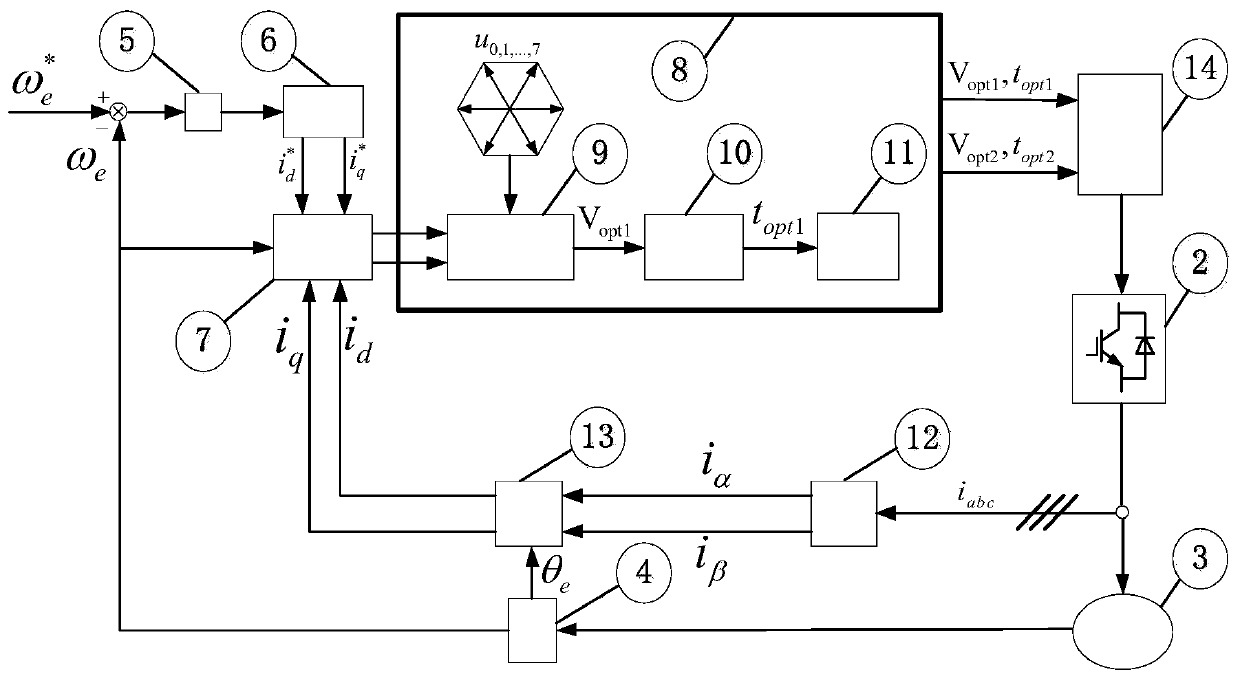

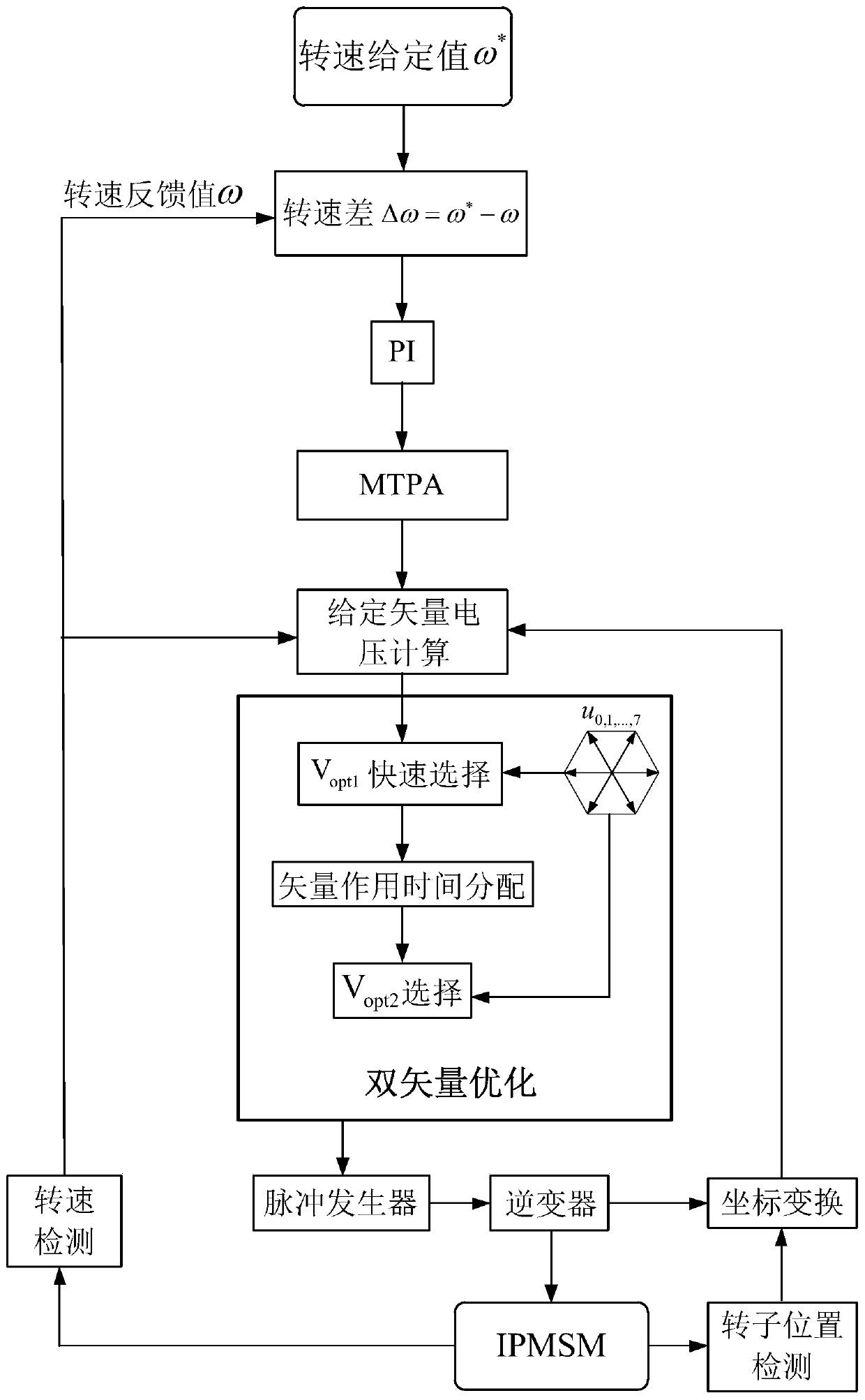

Model predictive control method of embedded permanent magnet synchronous motor

ActiveCN110336501ASimple structureFast dynamic responseElectric motor controlVector control systemsStatorVoltage vector

The invention is a model predictive control method of an embedded permanent magnet synchronous motor. The method includes the following steps: S1, establishing a discrete mathematical model of an embedded permanent magnet synchronous motor; S2, optimizing a model predictive control value function, calculating the d-axis and q-axis components of a given deadbeat voltage vector, substituting the d-axis and q-axis components ud and uq of seven basic voltage vectors into the value function, and selecting a voltage vector minimizing the value function g as a first optimal voltage vector Vopt1 for output; S3, optimizing the design of a dual-vector model predictive controller, carrying out voltage vector selection again on the basis of Vopt1 to determine a second optimal voltage vector Vopt2, andselecting a voltage vector Vj minimizing the value function g as a second optimal voltage vector Vopt2 through the value function; and S4, generating and sampling a three-phase stator current. The method can be applied to an embedded permanent magnet synchronous motor to suppress the stator current ripple.

Owner:HEBEI UNIV OF TECH

Underactuated drive finger device of imitating cascaded connection of hand of robot

A cascaded under-driven artificial finger of robot for simulating human finger has an active slide block inlaid in the first finger segment, a middle joint with the gear axle between the first and second finger segments and fixed to the second finger segment and the gear engaged with rack bar, the small and big gears on a single axle which along with two gear axles of middle joint are on the first finger segment, a synchronizing belt with lower gear fixed to small gear axle and upper gear fixed to the final joint axle on the second finger segment, and the third finger segment on the final joint axle.

Owner:TSINGHUA UNIV

Adaptive Learning System and Method of Vane Position for a Variable Geometry Turbocharger

ActiveUS20080295513A1Accurate estimateImprove accuracyElectrical controlInternal combustion piston enginesAdaptive learningMechanical engineering

A method of operation for an engine system having a variable geometry turbocharger with a vane, the vane having a variable position is provided. The method includes adjusting a vane of the variable geometry turbocharger through a range of operation by stepping through a plurality of vane positions and holding at each of the plurality of positions, the range spanning from a substantially minimum position to a substantially maximum position of the variable geometry turbocharger, and adjusting operation of the engine based on a response to the vane adjustment.

Owner:FORD GLOBAL TECH LLC

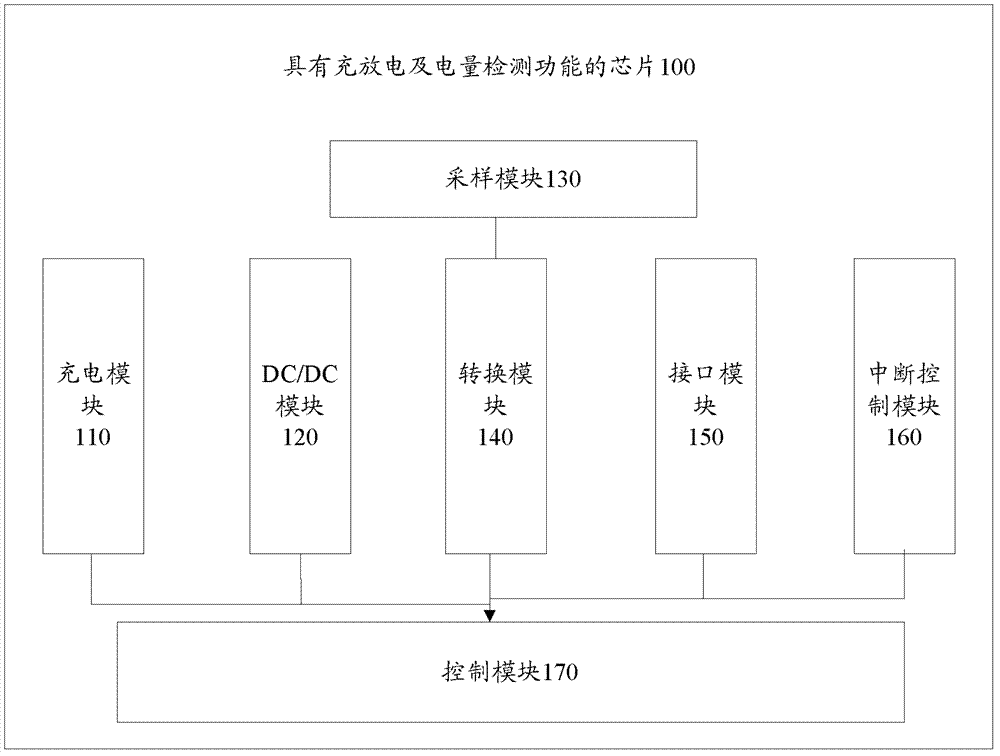

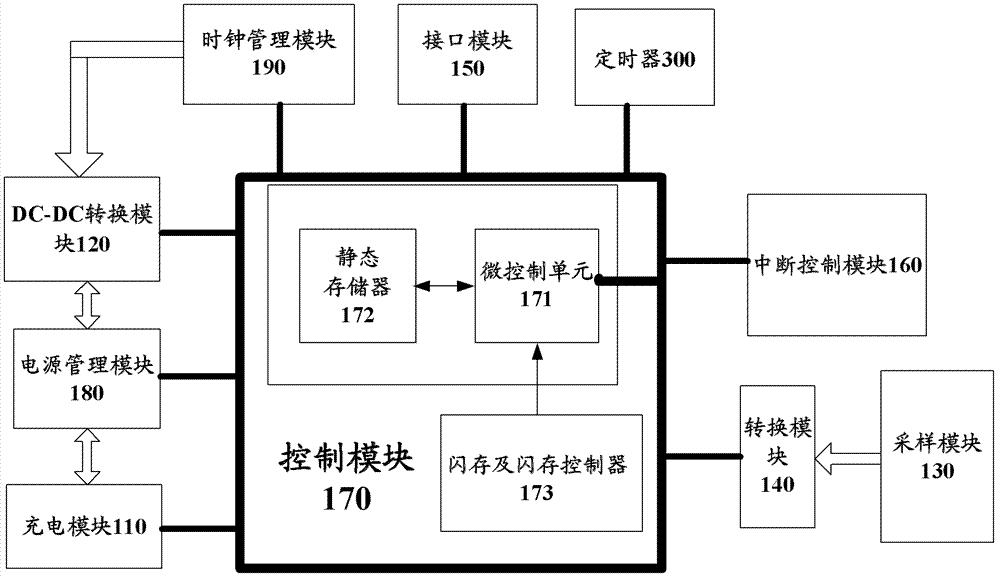

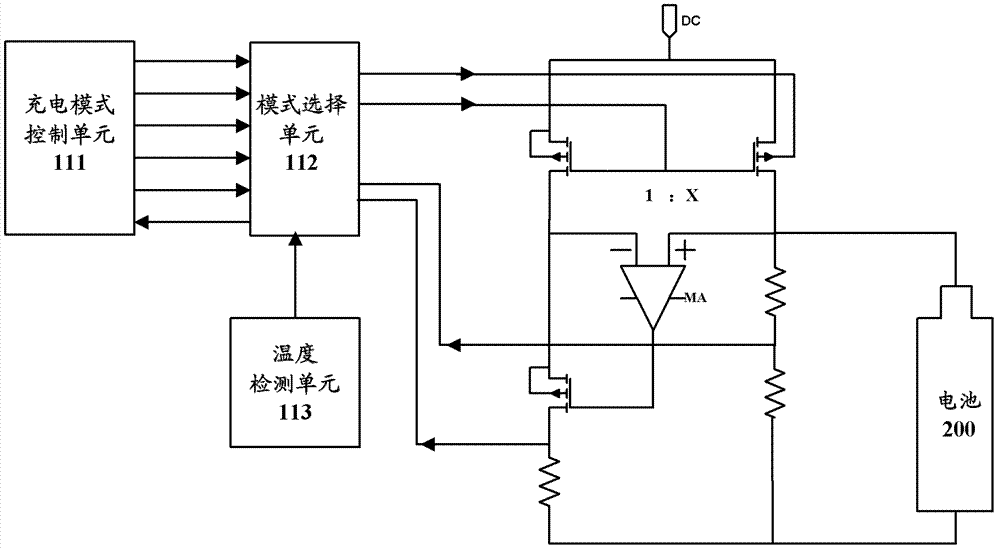

Chip with charge-discharge function and electric quantity detecting function

ActiveCN103117567AReduce areaRealize intelligent controlBatteries circuit arrangementsElectric powerElectrical batteryComputer module

The invention discloses a chip with a charge-discharge function and an electric quantity detecting function. The chip comprises a charging module, a direct current / direct current (DC / DC) conversion module, a sampling module, a conversion module, an interface module, an interruption control module and a control module. The charging module is used for managing the charging of a battery, the DC / DC conversion module is used for receiving power supply from the battery, and supplying power to a load, the sampling module is used for sampling the temperature, the voltage and the current of the battery, the conversion module is used for converting signals of the temperature, the voltage and the current into digital signals of the temperature, the voltages and the current, the interface module is used for communicating with the exterior of the chip, the interruption control module is used for controlling that an interruption source of the chip dispatches interruption requirements, and the control module monitors available remaining capacity and total available capacity of the battery according to the digital signals of the temperature, the voltage and the current, controls the charging module and the DC / DC conversion module and communicates with the exterior of the chip through the interface module and responses to the interruption requirements. The chip with the charge-discharge function and the electric quantity detecting function are not only flexible in application, but also simple in structure and low in power consumption.

Owner:BYD SEMICON CO LTD

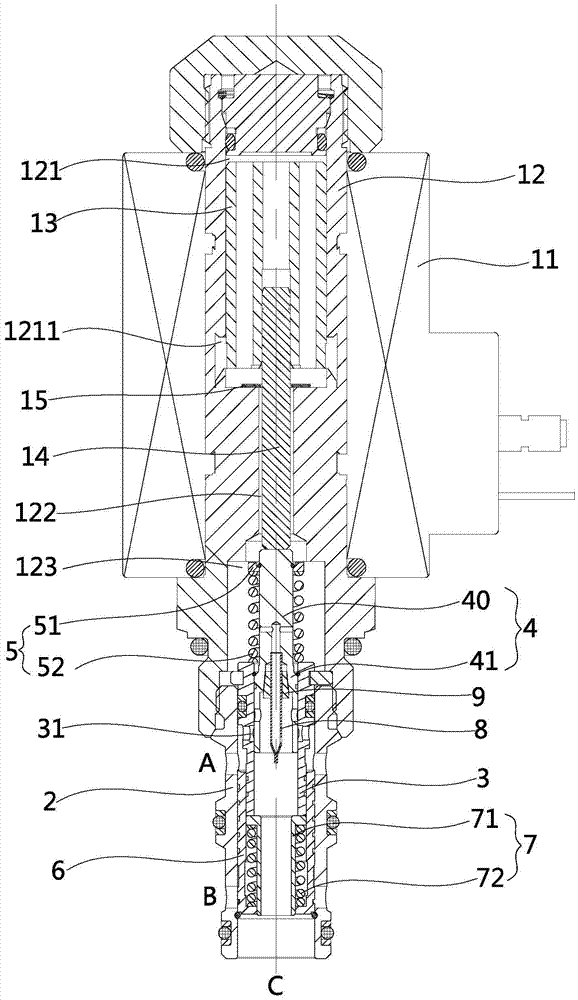

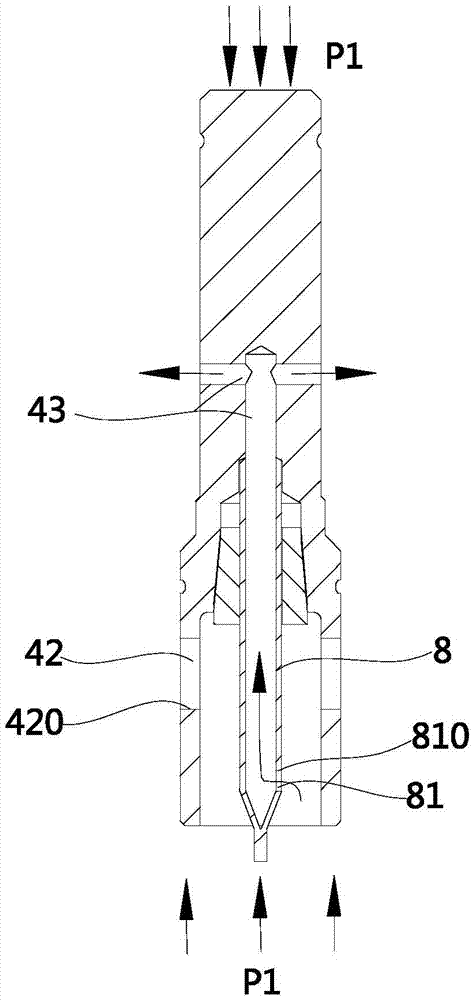

Electromagnetic proportional flow valve

ActiveCN105443837AReduced control accuracyHigh control precisionOperating means/releasing devices for valvesSlide valveControl systemEngineering

The invention discloses an electromagnetic proportional flow valve, and belongs to the technical field of hydraulic control valves. The electromagnetic proportional flow valve solves the technical problem that an existing electromagnetic proportional flow valve is poor in stability and low in control accuracy. The electromagnetic proportional flow valve comprises an electromagnetic driving mechanism, a valve sleeve, a valve base and a throttle valve element; the valve sleeve is fixedly connected between the electromagnetic driving mechanism and the valve base, and the electromagnetic driving mechanism is used for pushing the throttle valve element to downwards move in the valve base in the axial direction; a pressure release channel is arranged in the throttle valve element, and a variable throttle opening is formed in the lateral wall of the throttle valve element; and a pressure guide pipe is further arranged in the throttle valve element, the upper end of the pressure guide pipe is communicated with the pressure release channel, and a pressure guide opening is further formed in the pressure guide pipe and located below the variable throttle opening. The electromagnetic proportional flow valve is mainly applied to high-speed and low-speed switching control systems for execution mechanisms such as oil cylinders and motors.

Owner:浙江三尚智迪科技有限公司

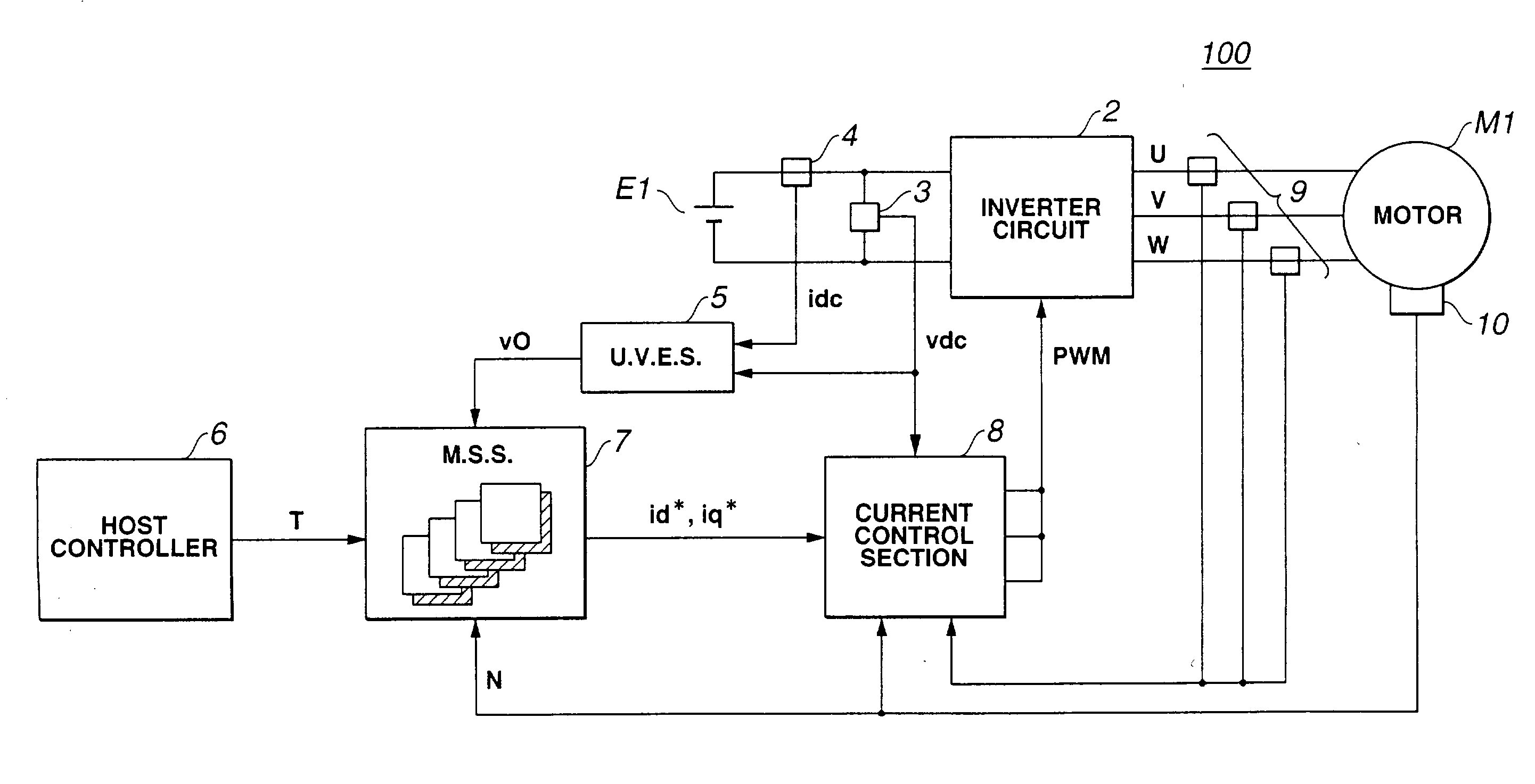

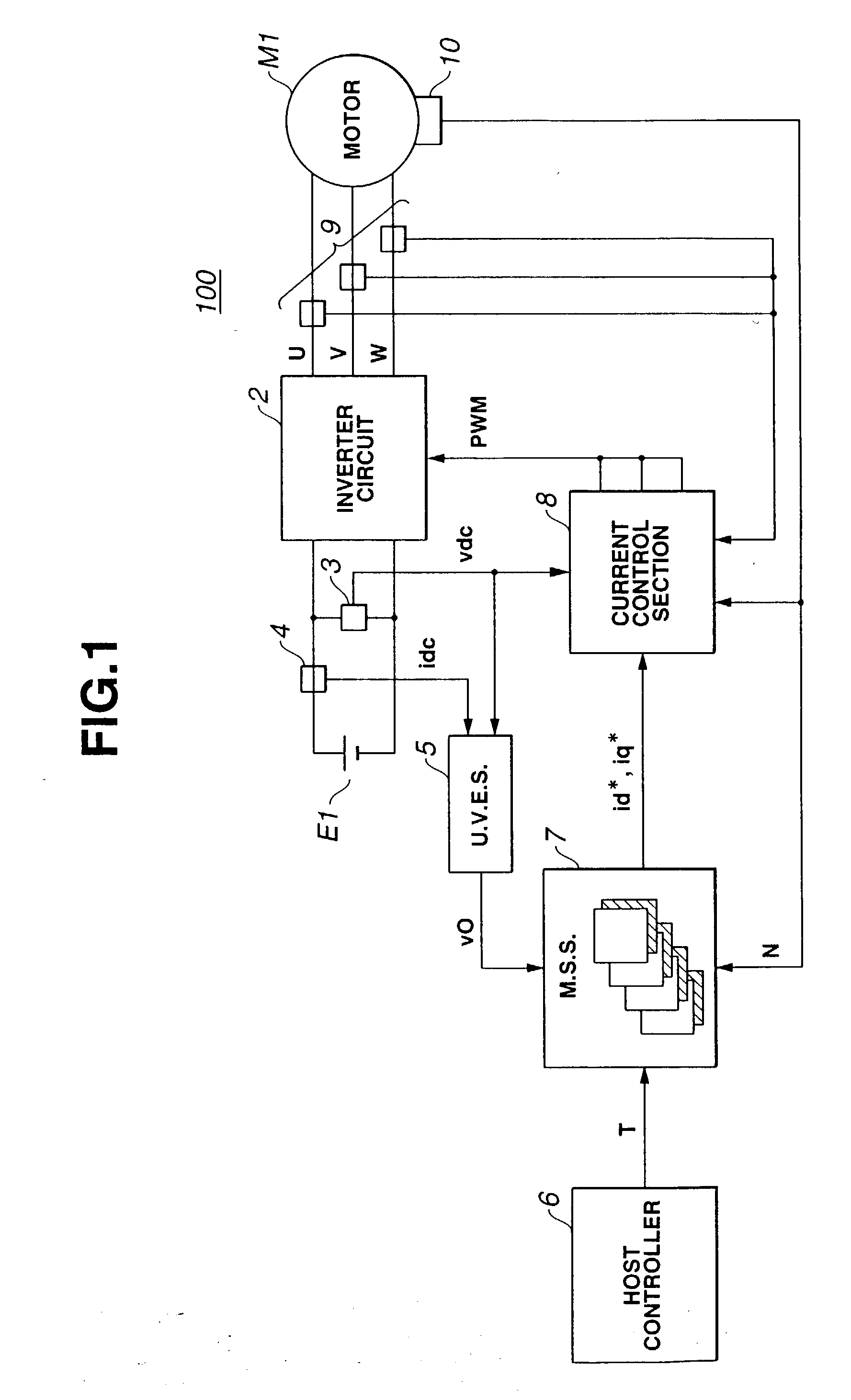

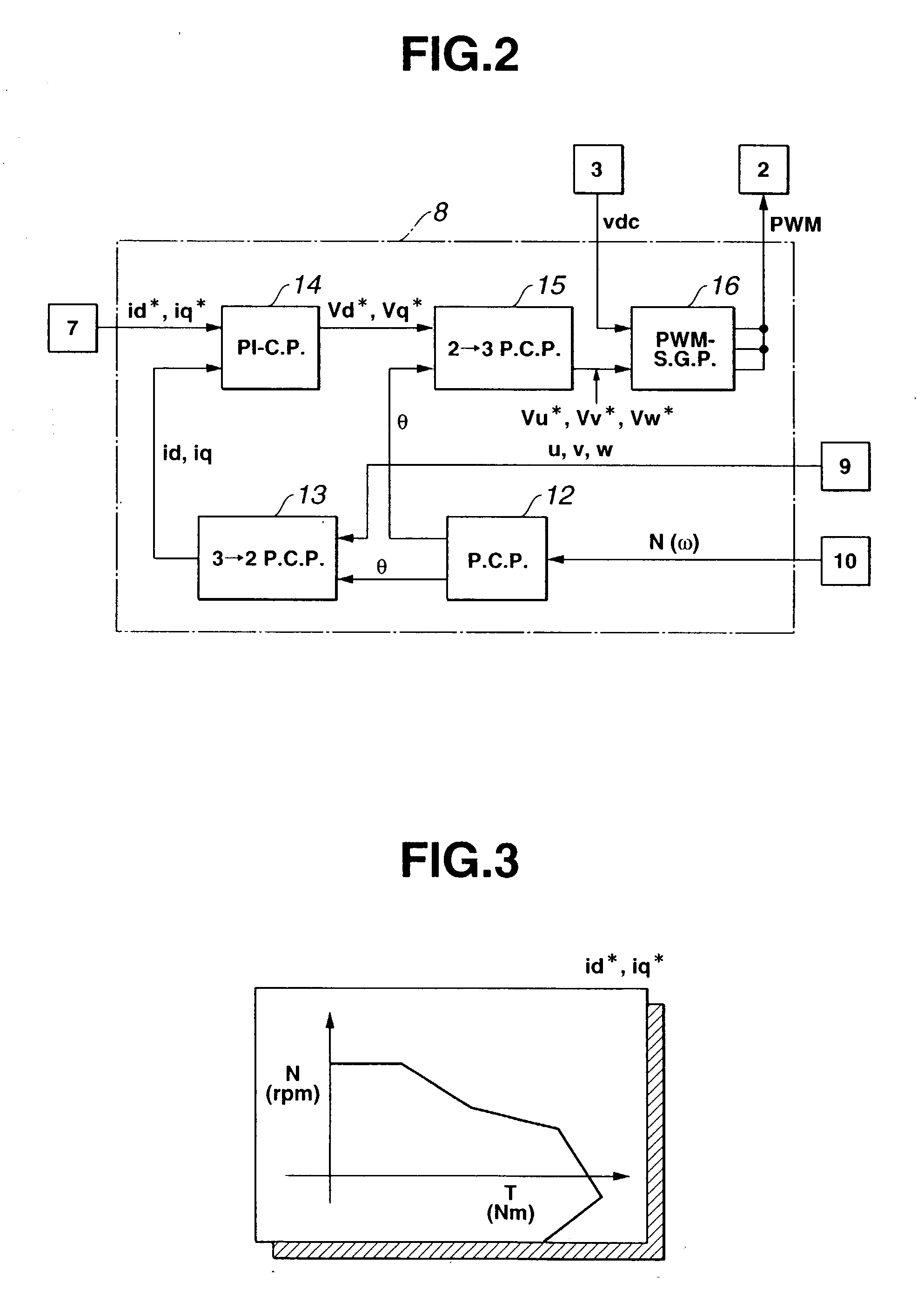

Control system of electric motor

InactiveUS20020190672A1Reduced control accuracyReduce efficiency of motorDC motor speed/torque controlElectric motor controlControl systemEngineering

A control system of an electric motor powered by a battery comprises an inverter circuit that inverts a direct current fed from the battery to an alternating current fed to the electric motor; and an output controlling circuit that controls an output of the inverter circuit to adjust operation of the electric motor. The output controlling circuit includes a first section that detects a magnitude of output voltage of the battery; a second section that, based on the detected output voltage, derives an unloaded voltage that would be outputted from the battery when the battery is unloaded; a third section that, based on the unloaded voltage, looks up an appropriate current command from maps that store various current commands with respect to operation condition of the motor; and a fourth section that, based on the looked up current command, controls the output of the inverter circuit.

Owner:NISSAN MOTOR CO LTD

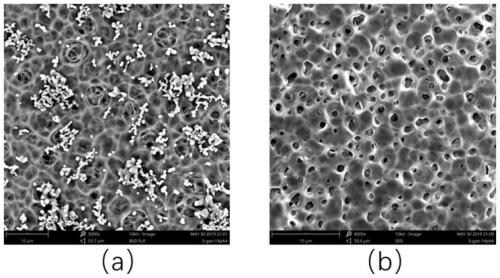

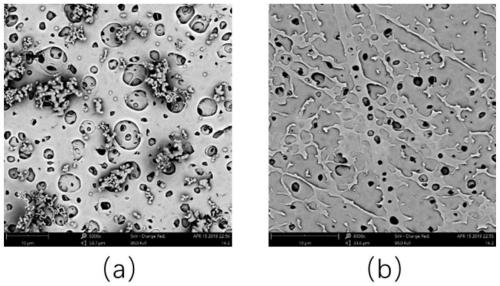

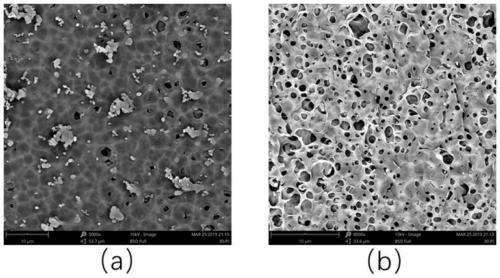

Porous polyimide film and preparation method and application thereof

InactiveCN110256717AReduced control accuracyReduce porosityCell component detailsPorosityPolyamic acid

The invention discloses a porous polyimide film and a preparation method and application thereof. Binary anhydride and diamine are subjected to low-temperature polycondensation reaction in a polar solvent to generate a precursor polyamic acid PAA solution; additives are added into the precursor polyamic acid PAA solution and stirred to form a casting film solution; the casting film solution is defoamed, scraped, coated on a glass plate and immersed in a coagulation bath; then the glass plate is taken out and naturally dried; and the porous polyimide film is obtained through thermal imidization or chemical imidization treatment. The preparation method does not need high temperature and high pressure, has simple requirements on film making equipment, and is favorable for realizing large-scale industrial application. In addition, the film has adjustable thickness, porosity of more than 40%, high liquid absorption rate, good lithium ion electrolyte wettability and excellent high temperature resistance, and is expected to become one of the diaphragm materials for the next generation of lithium ion batteries.

Owner:杭州阳名新能源设备科技有限公司

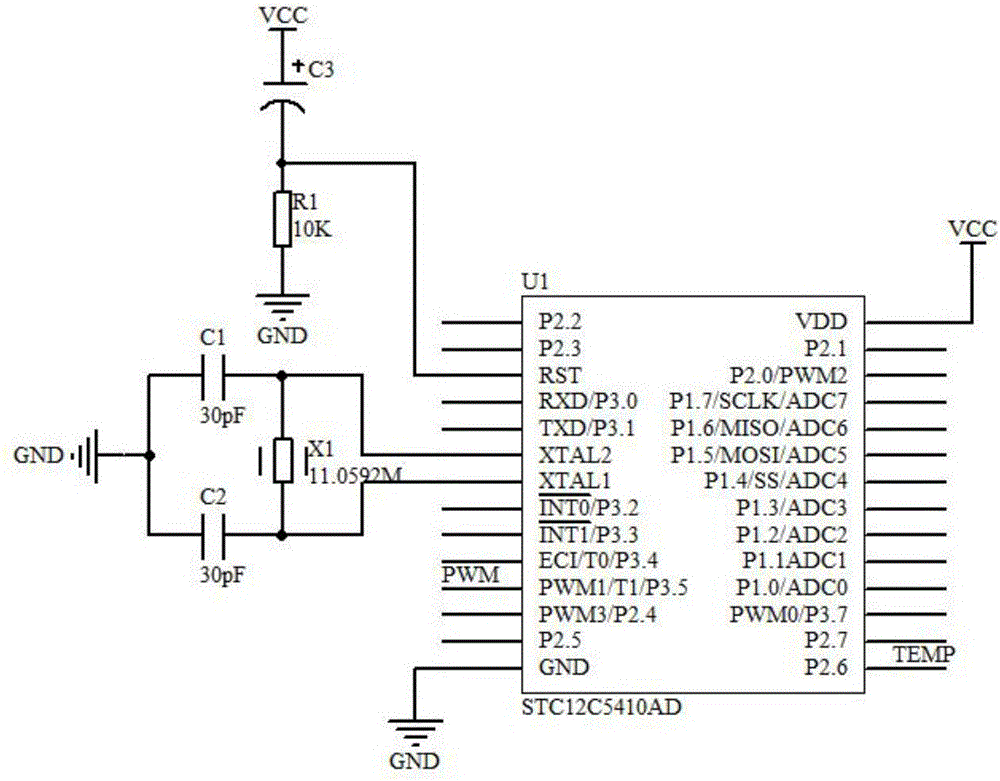

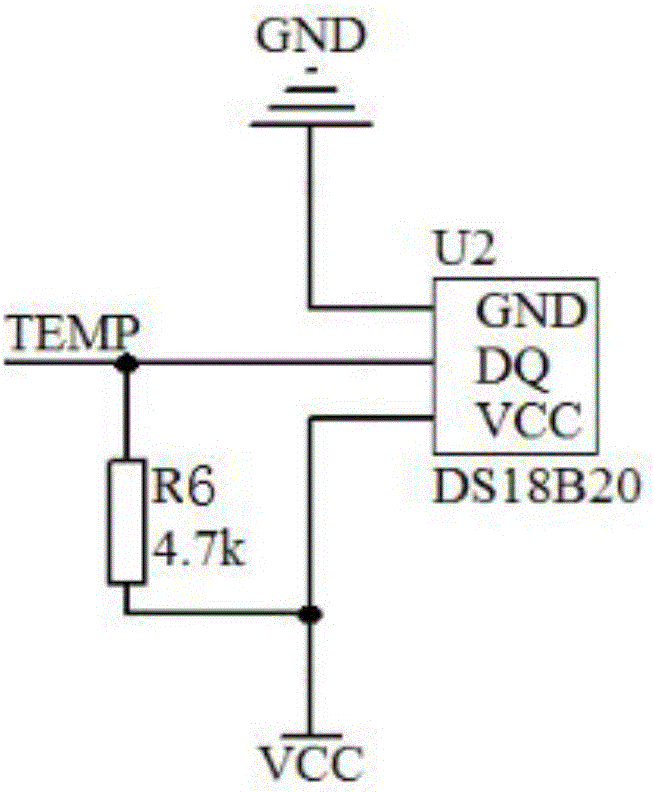

Semiconductor laser temperature control system based on TEC

InactiveCN105786047ALow integrationLow power efficiencyTemperatue controlMicrocontrollerMicrocomputer

The invention relates to a semiconductor laser temperature control system based on TEC. It is characterized in that the temperature control system comprises a temperature sensor, a one-chip microcomputer, a TEC digital PWM power drive circuit and a TEC heat dissipation module. The TEC heat dissipation module comprises a TEC, a refrigeration block, a heat dissipation aluminum plate and an exhaust fan. The cold surface and the hot surface of the TEC are both coated with heat conducting silicone grease. The cold surface of the TEC is clung to the refrigeration block and the hot surface of the TEC is clung to the heat dissipation aluminum plate. The exhaust fan is arranged under the heat dissipation aluminum plate; one end of the temperature sensor is connected with the semiconductor laser, and the other end is connected with an input-output pin of the one-chip microcomputer; the PID algorithm is stored inside the one-chip microcomputer; the output end of the one-chip microcomputer is connected with one end of the TEC digital PWM power drive circuit; the other end of the TEC digital PWM power drive circuit is connected with a TEC wiring terminal of the TEC heat dissipation module; the circuit structure of the TEC digital PWM power drive circuit is that a base of a triode Q1 is connected with the output end of the one-chip microcomputer; the output end of the one-chip microcomputer is connected with a power supply terminal VCC through a resistor R2.

Owner:HEBEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com