Mixing device capable of realizing automatic and quantitative feeding

A mixing device and automatic technology, which is applied to mixers, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of insufficient mixing ratio precision, high labor intensity of workers, low production efficiency, etc., and achieve the goal of mixing Good effect, increased mixing effect, high feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

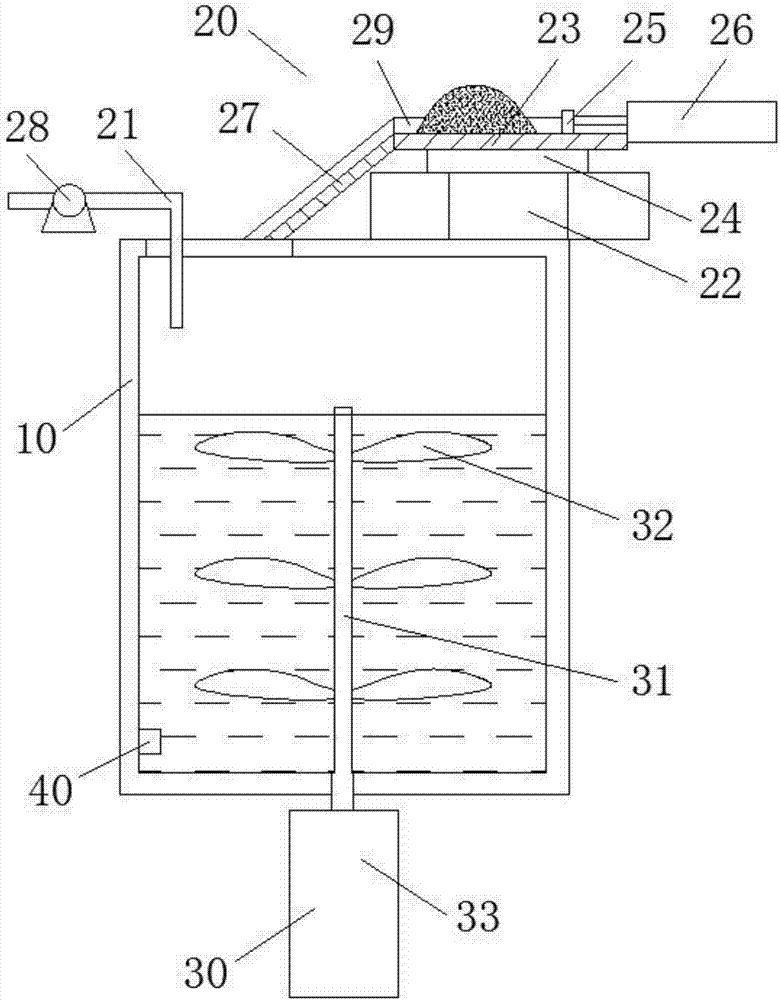

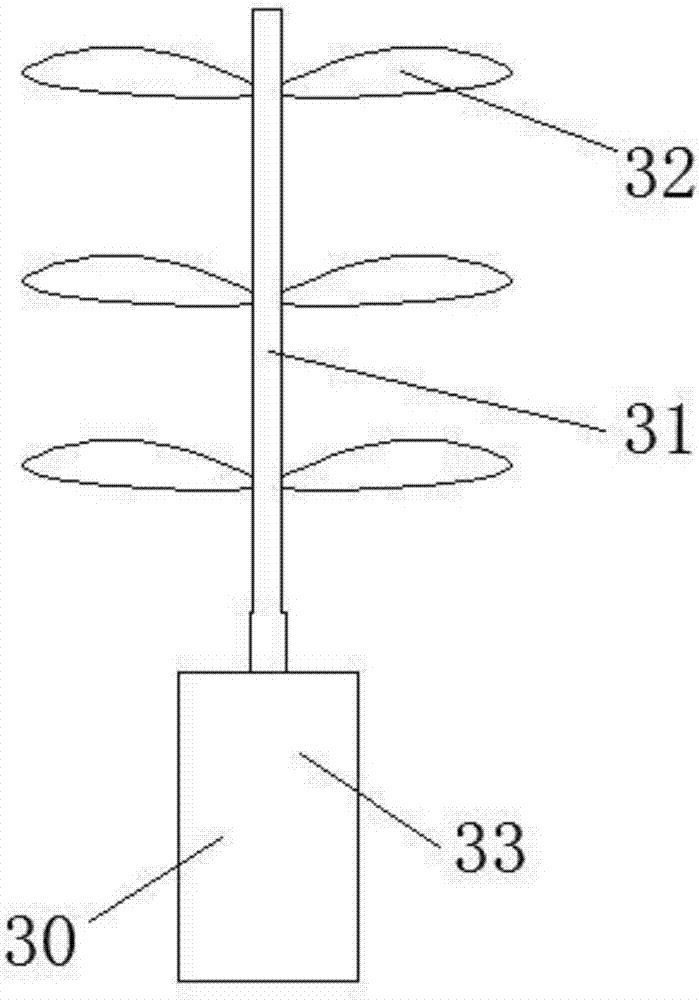

[0022] see figure 1 , figure 1 It is a structural schematic diagram of the automatic quantitative feeding and mixing device of the present invention. The automatic quantitative feeding and mixing device of the present invention includes a mixing tank 10, a feeding component 20, a stirring component 30 and a controller. The upper end of the mixing tank 10 is provided with a feeding opening, the feeding assembly 20 is used to add liquid material and powder material into the mixing tank 10, the stirring assembly 30 mixes the liquid material and powder material evenly, and the controller Signal connection with the feeding assembly 20 and the stirring assembly 30 to control the operation of the feeding assembly 20 and the stirring assembly 30 .

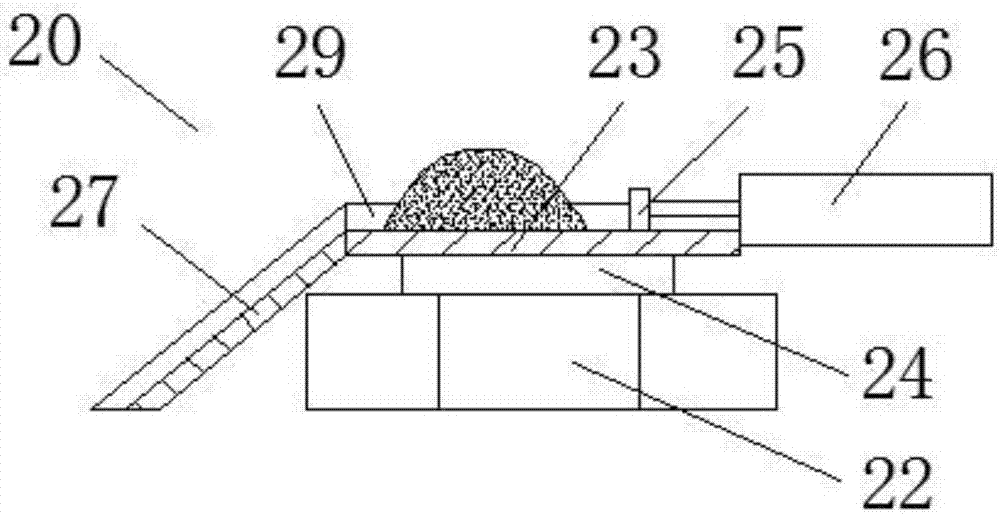

[0023] see figure 2 , figure 2 It is a schematic diagram of the local structure of the feeding assembly. The feeding assembly 20 includes a liquid feeding pipe 21 , a feeding rack 22 , a powder feeding plate 23 , a powder weighing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com