Scandium recovery method

A recovery method and process technology, which is applied to the field of high-efficiency recovery of scandium contained in nickel oxide ore, and can solve the problems of low grade nickel content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] [Leaching process S1]

[0121]First, nickel oxide ore and concentrated sulfuric acid are put into an autoclave, and a slurry containing valuable metals such as scandium and nickel is generated at 245°C for 1 hour, and solid-liquid separation from the slurry contains various The leaching liquid and leaching residue of valuable metals.

[0122] [Neutralization process S2]

[0123] Calcium carbonate is then added to the leach liquor to obtain a neutralized precipitate and a neutralized liquor. The neutralized liquid contains valuable metals such as scandium and nickel, and the neutralized precipitate contains most of the impurities represented by aluminum.

[0124] [Vulcanization process S3]

[0125] Next, hydrogen sulfide gas is blown into the neutralized liquid to form sulfides from nickel, cobalt, and zinc, which are separated from the sulfided liquid.

[0126] [Ion exchange step S4]

[0127] [Adsorption step S41]

[0128] Slaked lime was added as a neutralizing a...

Embodiment 2

[0175] The same scandium oxide ore as in Example 1 above was leached, neutralized, and vulcanized by the same method as in Example 1 above to obtain a sulfide liquid with the composition shown in Table 7.

[0176] Composition of liquid after table 7 vulcanization

[0177] sc

Al

Fe

Th

U

14

2800

1000

0.2

0.7

[0178] (unit is mg / L)

[0179] Carry out ion exchange process and concentration process with the method identical with above-mentioned embodiment 1, redissolve the obtained scandium hydroxide with sulfuric acid, obtain chelating eluent hydroxide solution. Table 8 shows the results of analyzing the composition of the chelate eluent hydroxide solution.

[0180] The composition of table 8 chelating eluent hydroxide solution

[0181] sc

Al

Fe

Th

U

20

11

4

140

220

[0182] (unit is mg / L)

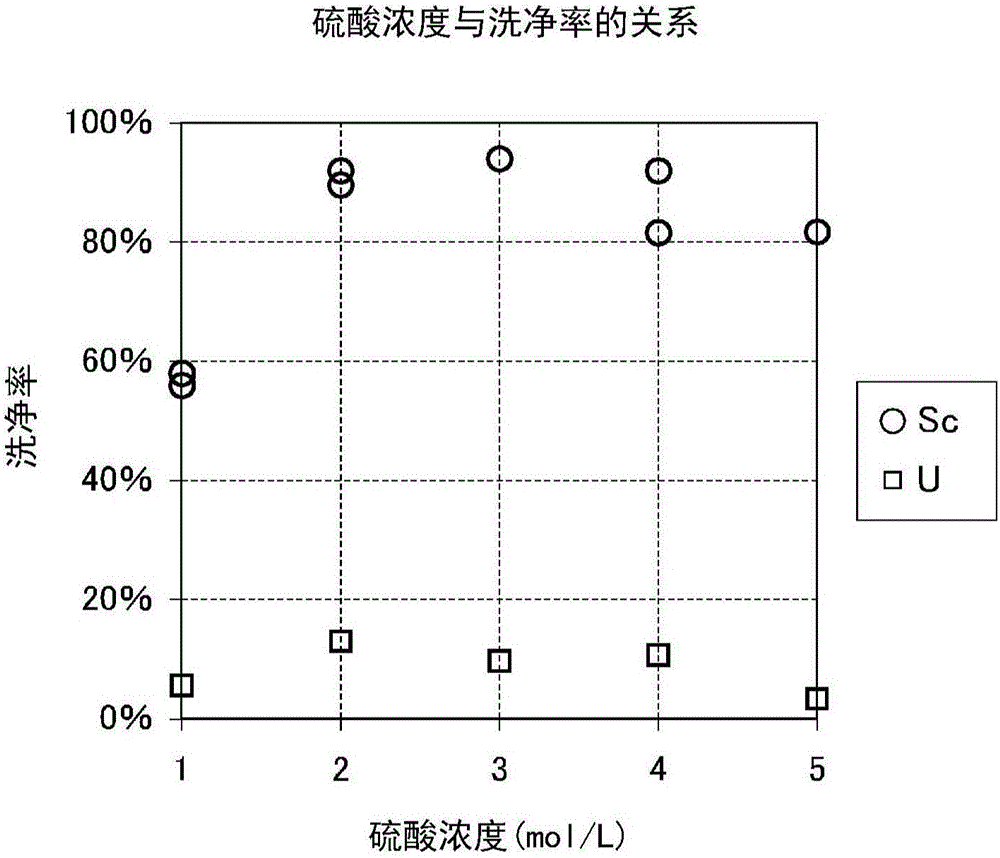

[0183] The chelated eluent hydroxide solution having the composition shown in Table 8 was us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com