Method for sealing carbon dioxide

A carbon dioxide and chemical reaction technology, applied in chemical instruments and methods, organic chemistry, carbonate preparations, etc., can solve the problems of high energy consumption for adsorbent regeneration, inconspicuous carbon dioxide, and adsorbent loss, etc., and achieve high cost performance and avoid Energy consumption, the effect of avoiding energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

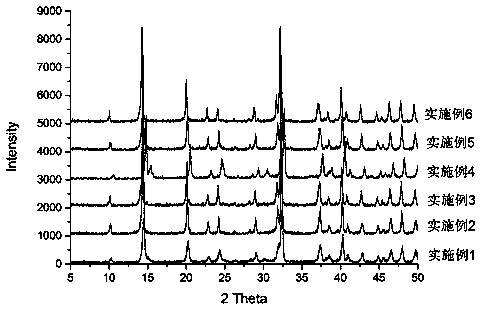

Image

Examples

Embodiment Construction

[0046] Pass the purified power plant tail gas into the reaction bed filled with wet sodium carbonate, and react at 40°C to form sodium bicarbonate;

[0047] Add equal mass of water to sodium bicarbonate, 5% Pd / C (the load of Pd on C is 10%), stir, and feed hydrogen. The hydrogen pressure in the reactor is kept at 1 atmosphere. When the solid disappears and the pH remains constant, the reaction is completed, and the solution is evaporated, centrifuged and dried to obtain a sodium formate solid;

[0048] React the obtained sodium formate solid at 350°C for 35 minutes to complete the dehydrogenation of sodium formate to produce sodium oxalate.

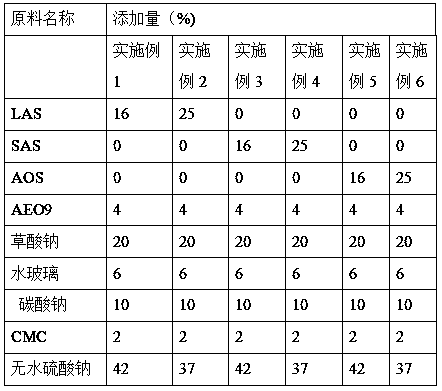

[0049] Above-mentioned gained sodium oxalate is used in different washing powder formulations, and described washing powder preparation process is as follows:

[0050] According to the components and contents in Table 1, the raw materials were weighed. (1) Add deionized water into the batching pot, heat to 50-60°C, start stirring; (2) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com