Online hydrochloric acid cyclic utilization method and device on steel acid pickling line

A technology of hydrochloric acid circulation and pickling line, applied in the field of steel pickling, can solve the problems of inability to directly discharge waste acid, high cost, environmental pollution, etc., to avoid waste acid treatment costs and acid replacement costs, reduce energy consumption, The effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

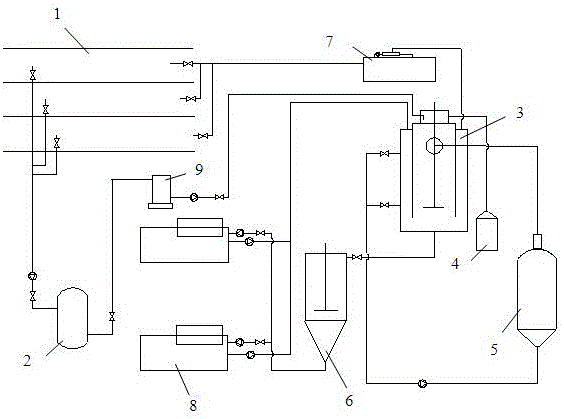

[0032] The on-line hydrochloric acid recycling method and its device on the steel pickling line of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

[0033] Such as figure 1 Shown, the on-line hydrochloric acid recycling method on steel pickling line of the present invention, comprises the following steps:

[0034] Step 1, collect the pickling liquid containing ferrous chloride and hydrochloric acid on the pickling line 1, and transport it to the first filter device 2 to filter out the solid impurities, and then transport the pickling liquid to the vapor-liquid separator 3;

[0035] Step 2, the dosing device 4 adds oxalic acid to the vapor-liquid separator 3, so that the oxalic acid and the pickling liquid are fully reacted by stirring and mixing in the vapor-liquid separator 3;

[0036] Step 3, the mixed liquid is forced to circulate between the vapor-liquid separator 3 and the acid-resistant and high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com