Graphene-based 3D printing non-photocuring model wax and synthesis method thereof

A technology of 3D printing and synthesis method, applied in the field of 3D printing, can solve the problems of low tensile strength and flexural strength, low heat distortion temperature and melt index, etc., achieve small shrinkage, good fluidity and viscosity, and easy demoulding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

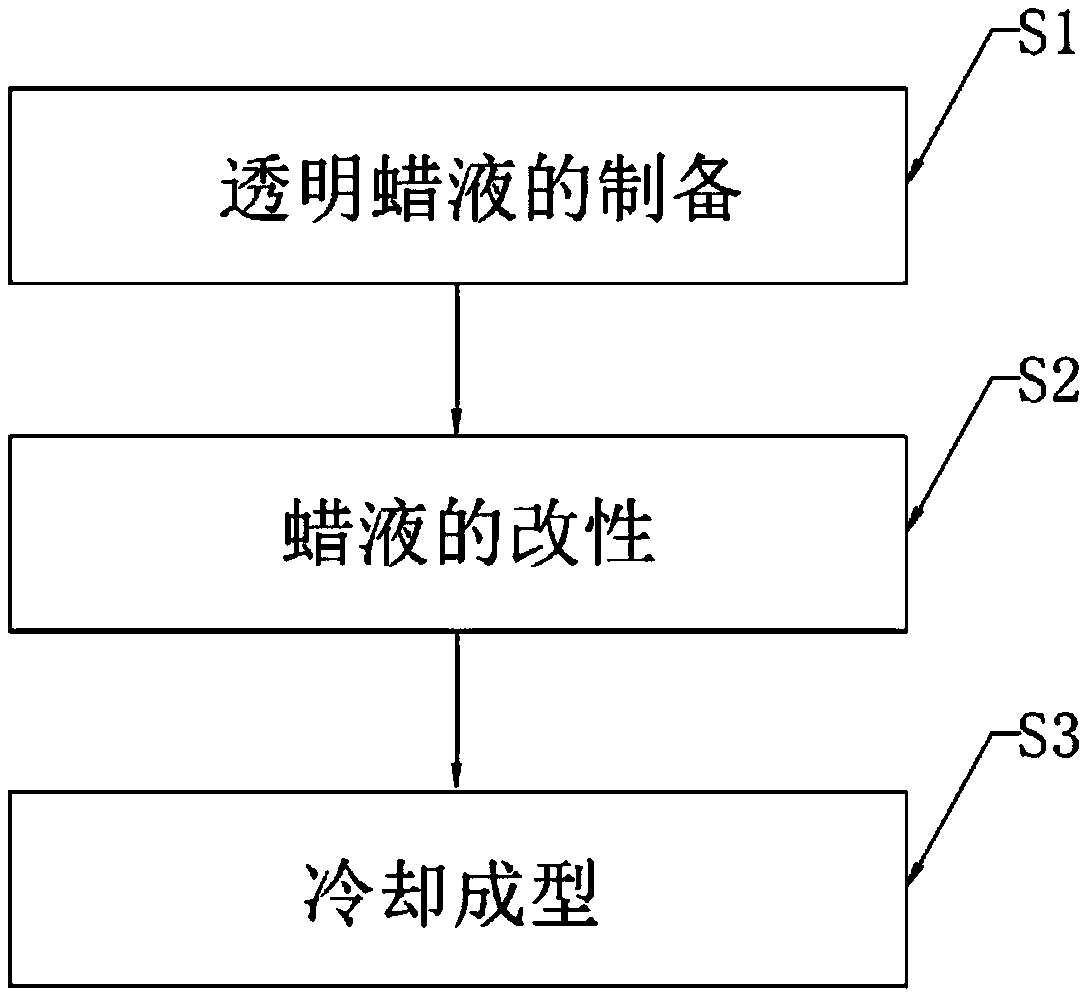

Method used

Image

Examples

Embodiment 1

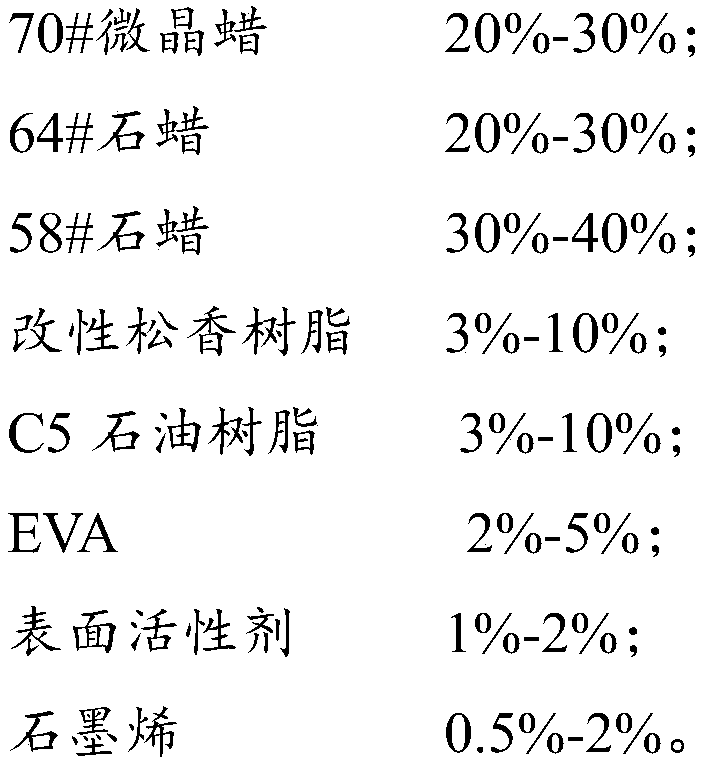

[0027] A graphene-based 3D printing non-light-curing model wax of the present invention, calculated by mass fraction, includes the following components:

[0028]

[0029] In the present embodiment, the melting point of the 70# microcrystalline wax is 70±5°C, and its origin is Sinopec; the softening point of the 64# paraffin wax is 64±5°C, and its origin is Guangzhou; the 58# paraffin wax The melting point is 58±5℃, and the place of origin is Guangzhou.

[0030] In this embodiment, the melting point of the modified rosin resin is 75±5°C, and its origin is Jiangxi, and the melting point of the C5 petroleum resin is 100±5°C, and its origin is Sinopec.

[0031] In this embodiment, the EVA has a melting point of 84±5° C. and is produced in Taiwan, China.

[0032] In this embodiment, the place of origin of the graphene is Nanjing, and the specific surface area is 500-1000m 2 / g, the thermal conductivity is 4000-5000W.m -1 .K -1 .

[0033] In this embodiment, the surfactant i...

Embodiment 2

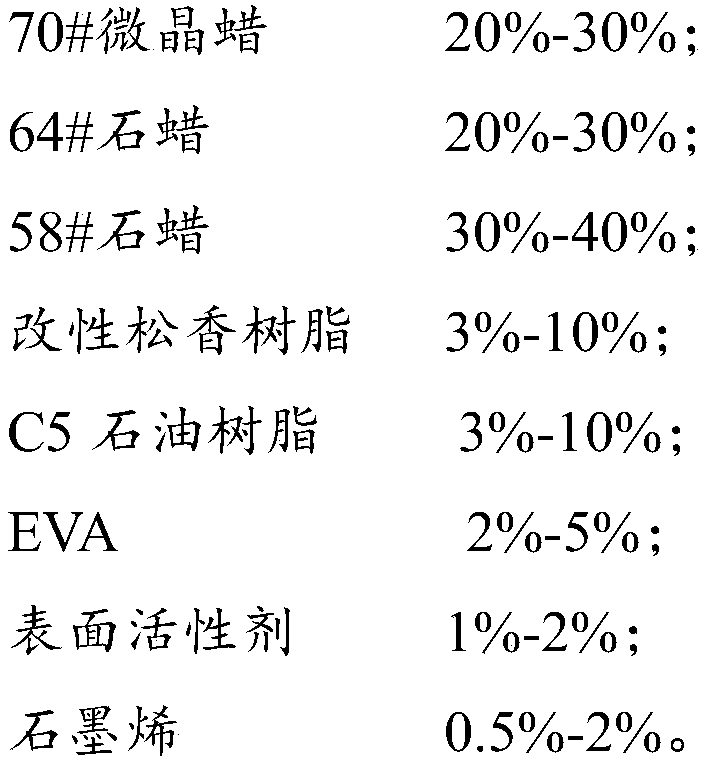

[0039] A graphene-based 3D printing non-light-curing model wax of the present invention, calculated by mass fraction, includes the following components:

[0040]

[0041] In the present embodiment, the melting point of the 70# microcrystalline wax is 70±5°C, and its origin is Sinopec; the softening point of the 64# paraffin wax is 64±5°C, and its origin is Guangzhou; the 58# paraffin wax The melting point is 58±5℃, and the place of origin is Guangzhou.

[0042] In this embodiment, the melting point of the modified rosin resin is 75±5°C, and its origin is Jiangxi, and the melting point of the C5 petroleum resin is 100±5°C, and its origin is Sinopec.

[0043] In this embodiment, the EVA has a melting point of 84±5° C. and is produced in Taiwan, China.

[0044] In this embodiment, the place of origin of the graphene is Nanjing, and the specific surface area is 500-1000m 2 / g, the thermal conductivity is 4000-5000W.m -1 .K -1 .

[0045]In this embodiment, the surfactant is...

Embodiment 3

[0051] A graphene-based 3D printing non-light-curing model wax of the present invention, calculated by mass fraction, includes the following components:

[0052]

[0053] In the present embodiment, the melting point of the 70# microcrystalline wax is 70±5°C, and its origin is Sinopec; the softening point of the 64# paraffin wax is 64±5°C, and its origin is Guangzhou; the 58# paraffin wax The melting point is 58±5℃, and the origin is Guangzhou.

[0054] In this embodiment, the melting point of the modified rosin resin is 75±5°C, and its origin is Jiangxi, and the melting point of the C5 petroleum resin is 100±5°C, and its origin is Sinopec.

[0055] In this embodiment, the EVA has a melting point of 84±5° C. and is produced in Taiwan, China.

[0056] In this embodiment, the place of origin of the graphene is Nanjing, and the specific surface area is 500-1000m 2 / g, the thermal conductivity is 4000-5000W.m -1 .K -1 .

[0057] In this embodiment, the surfactant is one or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com