Welding method of aluminum alloy sputtering target material for integrated circuit package material

A packaging material and integrated circuit technology, applied in electron beam welding equipment, welding equipment, welding equipment and other directions, can solve the problem of low welding interface welding rate and welding strength, affecting the sputtering performance of the target material, and increasing the grain size of the target material. large and other problems, to achieve the effect of avoiding coarse grains, stable process and reducing welding temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Hot isostatic welding of high-purity Al and copper-chromium alloy backplane

[0040] The high-purity Al (99.9995%) blank is the target blank with a diameter of 350 mm; the copper-chromium alloy C18200 is the back plate with a diameter of 450 mm.

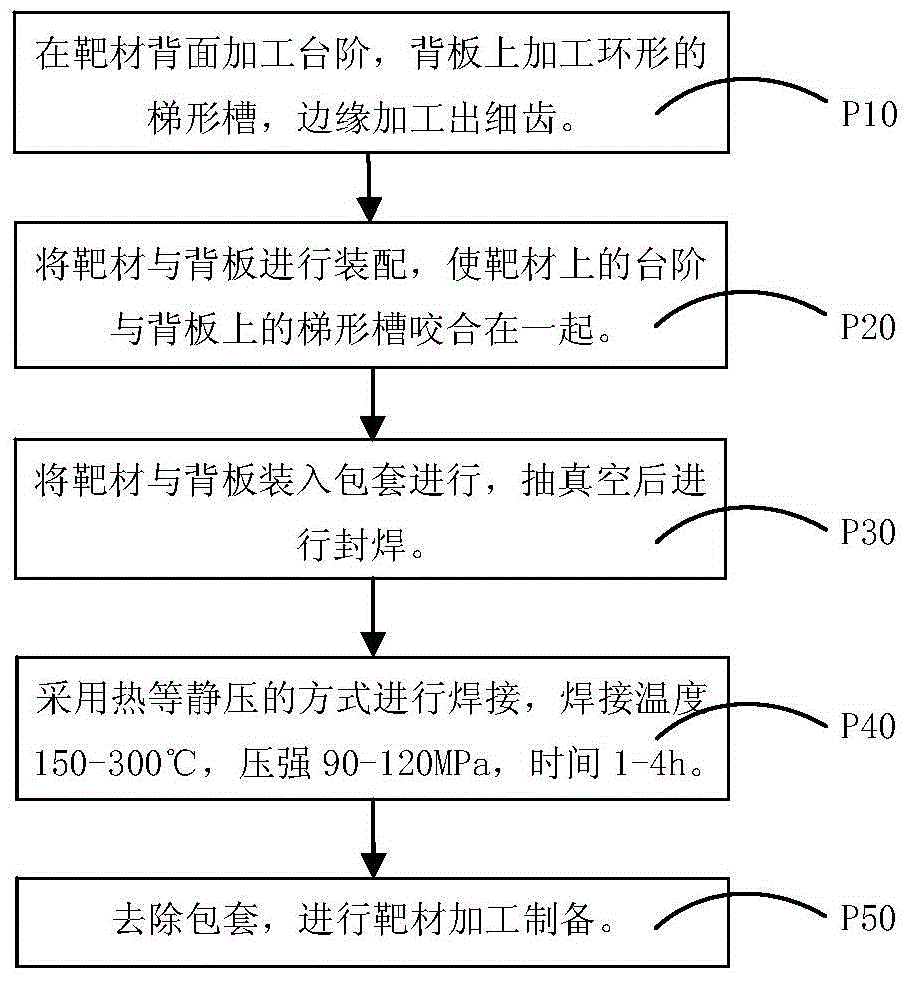

[0041] Follow the steps below:

[0042] (1) Machining target blank and back plate. A plurality of concentric ring-shaped convex teeth are turned on the high-purity Al target blank. The convex teeth are 2mm wide, 3.5mm high and 4mm apart.

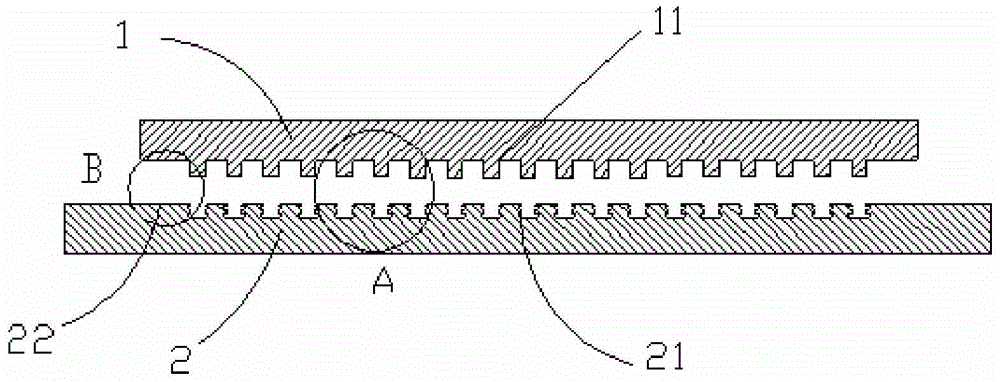

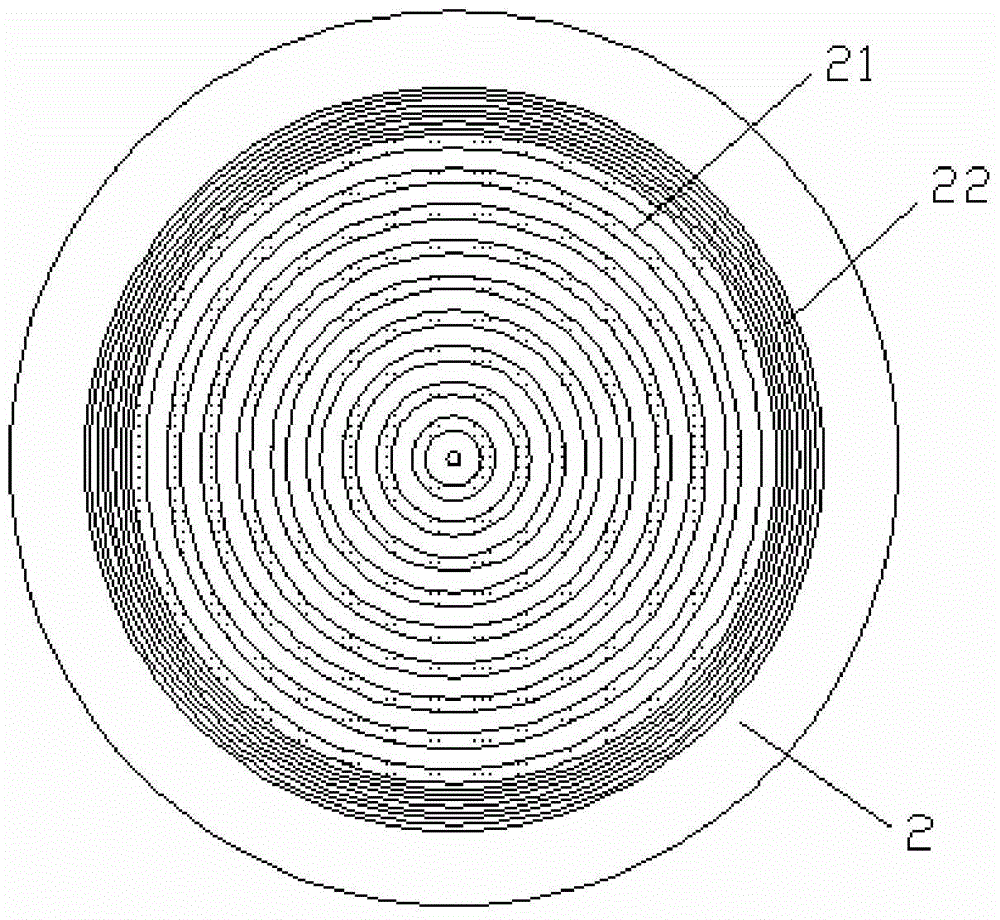

[0043] (2) Machined backplane. Grooves are carved out on the copper chrome back plate, the shape is as Figure 4 The I kind of groove in, the width is 2mm, deep 3mm, spacing 4mm. Two indentations 211 parallel to the bottom of the groove are respectively provided on the two side walls of the groove, so that the groove on the back plate corresponds to the protruding teeth on the back of the target blank and has the same cross-sectional area. Such as Image 6 As shown, there are...

Embodiment 2

[0048] Embodiment 2 Hot isostatic pressing welding of high-purity AlCu4 alloy (99.9995%) and copper-nickel-silicon-chromium alloy backplane

[0049] The high-purity AlCu4 alloy blank (99.9995%) is the target blank, with a diameter of 450 mm; the back plate copper-nickel-silicon-chromium alloy C18000, with a diameter of 530 mm.

[0050] Follow the steps below:

[0051] (1) Machining the target blank. A plurality of concentric annular convex teeth are machined on the high-purity AlCu4 target blank. The convex teeth are 2.5mm wide, 2mm high, and 5mm apart.

[0052] (2) Machined backplane. Grooves are carved out on the copper chrome back plate, the shape is as Figure 4 Type III trapezoidal groove, the upper width of the trapezoid is 2.5mm, the bottom width is 4.17mm, the depth is 1.5mm, and the spacing is 5mm. Make the groove on the back plate equal to the cross-sectional area corresponding to the position of the protruding teeth on the back of the target blank. Carry out fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com