Process method for reducing corner-cleaning milling vibration of root part of integral closed impeller

A technology of closed impeller and process method, which is applied in the direction of cutting tools, milling cutters, and workpieces used in milling machines, which can solve the problems of easy damage of cutting tools, broken tools, severe cutting hardening, etc., so as to ensure product quality and improve manufacturing process , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

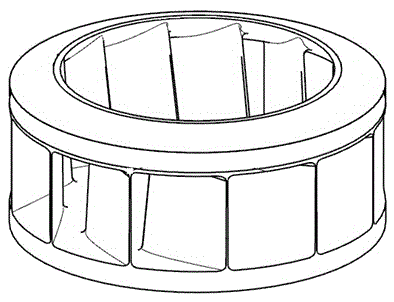

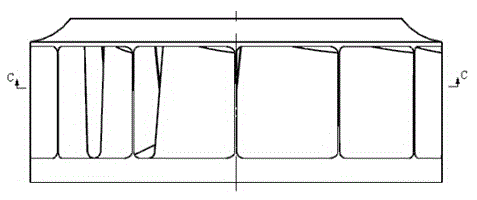

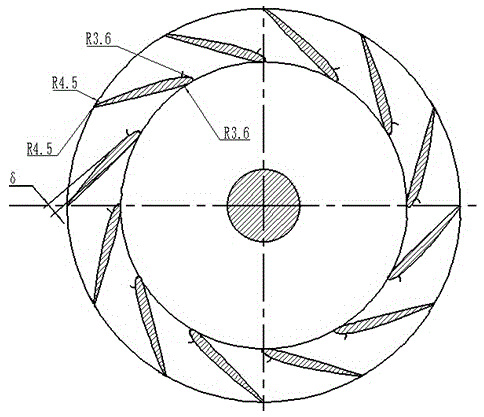

[0025] The process method of reducing the angle-clearing milling vibration at the root of the integral closed impeller of the present invention is to use a hard alloy milling cutter with 0.2 μm to 0.8 μm ultra-fine or ultra-fine particles on the five-axis linkage machining center equipment. Milling of metal-like integral closed impeller system, integral impeller with complex curved surface and deep cavity curved surface structural parts, through the analysis of tool structure, tool cutting trajectory, tool feeding method, feeding direction, cutting depth and tool axis vector parameters It is realized by the selection, the setting of rough and finish machining allowance and the selection of parameters.

[0026] 1. Equipment selection

[0027] Choose a five-axis linkage machining center machine tool with good dynamics and stability.

[0028] 2. Tool sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com