Steel plate for hardening and tempering type low temperature pressure vessel and method for producing steel plate

A technology for pressure vessels and steel plates, which is applied in the field of metallurgy and can solve problems such as difficulty in manufacturing enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

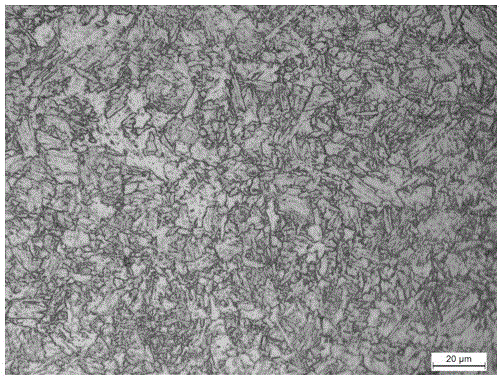

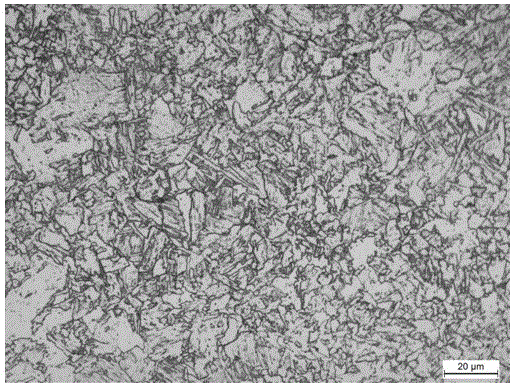

[0041] A group of experimental results are provided here as an example. The composition of the steel is consistent, and the steelmaking, continuous casting, forging billet heating and rolling processes are consistent. The difference lies in the subsequent quenching and tempering heat treatment process system. Quality treatment process, performance testing and metallographic structure are used as comparative examples.

[0042] 1) Steelmaking: A furnace of steel is smelted, and its actual chemical composition (% by weight) is, C: 0.0686%, Si: 0.232%, Mn: 1.454%, Al: 0.05%, Cr: 0.256%, Ni: 0.452 %, Mo: 0.22%, Nb: 0.04%, V: 0.043%, Ti: 0.03%, Cu: 0.0151%, S: 0.001%, P: 0.0042%, N: 0.0039%, O: 0.0028%, and the balance is Fe, Cu content is low and the system is residual. Casting into a continuous casting slab with a specification of 220mm'2280mm'2100mm; the slab has undergone thermal inspection, stack cooling for 48 hours, and surface inspection of the slab before entering the furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com