Zinc-bromine flow battery diaphragm applicable to laser welding, and preparation method thereof

A zinc-bromine flow battery and laser welding technology, applied in fuel cells, battery pack components, circuits, etc., can solve problems such as negative effects and no records

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

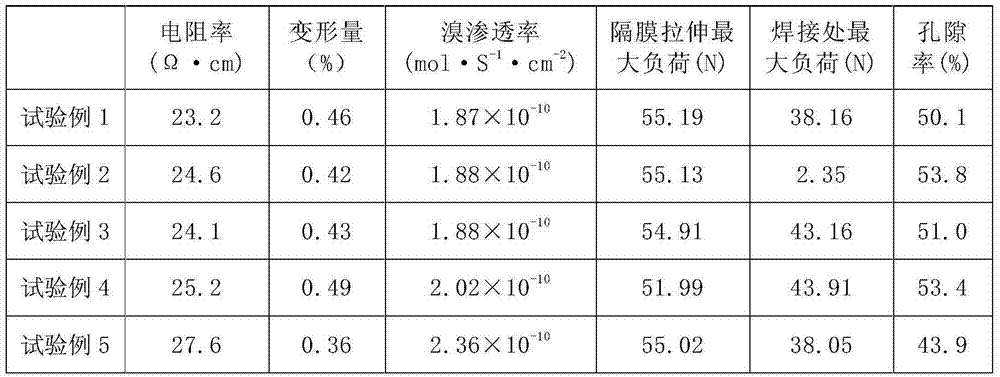

Examples

Embodiment 1

[0059] Embodiment 1 of the present invention: a method for preparing a zinc-bromine flow battery diaphragm suitable for laser welding, comprising the following steps:

[0060] (1) Weigh the specific surface area as 200m 2 / g of fumed silica (brand AEROSIL200) 240g and plasticizer (special oil for PE separators) 500g, mix and stir for 30 minutes;

[0061] (2) Weigh 240g of PE raw materials (120g of UHMWPE with a molecular weight of 5 million and 120g of HDPE with a molecular weight of 200,000), 10g of a color masterbatch (such as plasblak un2014) that absorbs 900-1000nm laser energy and 10g of an antioxidant, and add the mixture obtained in step (1) In the material, stir again for 30 minutes;

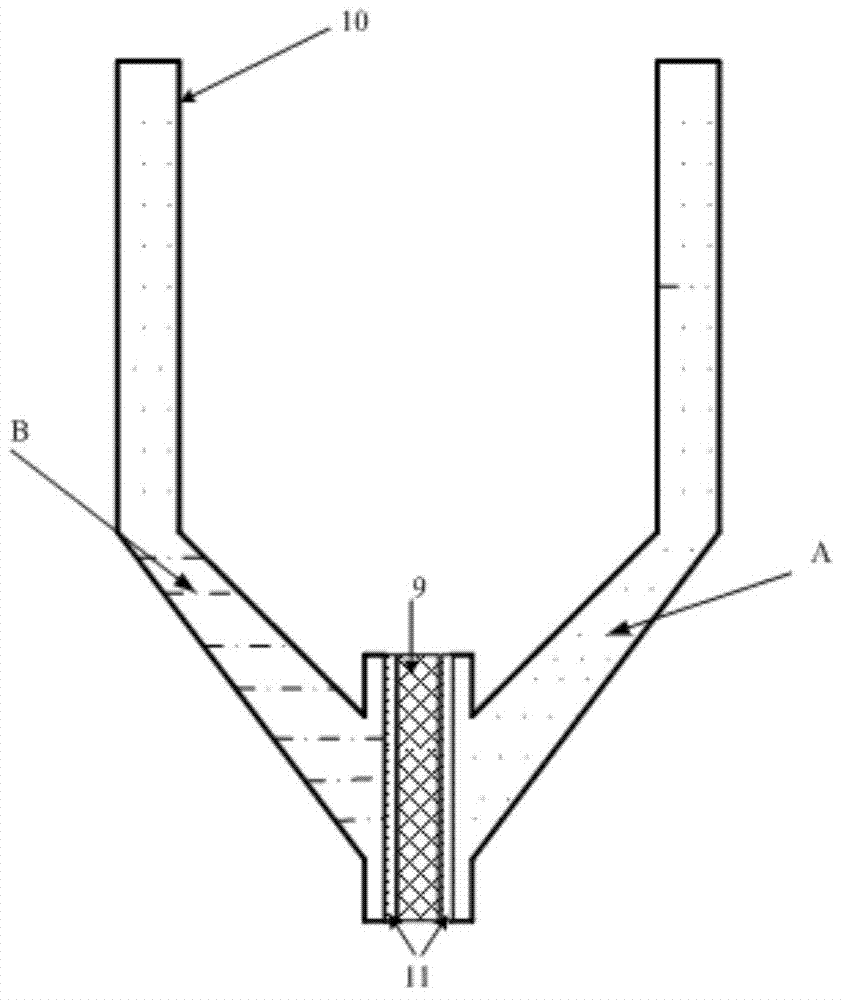

[0062] (3) The mixture obtained in step (2) enters the extruder through the feeder, extruded through the "T" die of the extruder, and then rolled to a thickness of 0.6mm by four-roll calendering. The melt temperature at exit is 180°C, the extrusion pressure is 15Mpa, and the melt resid...

Embodiment 2

[0064] Embodiment 2 of the present invention: a method for preparing a zinc-bromine flow battery separator suitable for laser welding, comprising the following steps:

[0065] (1) Weigh the specific surface area as 300m 2 / g of fumed silica 300g and plasticizer (special oil for PE separator) 350g, mix and stir for 30 minutes;

[0066] (2) Weigh 320g of PE raw materials (192g of UHMWPE with a molecular weight of 5 million and 128g of HDPE with a molecular weight of 150,000), 20g of a color masterbatch (such as Polyblack-2778) that absorbs 900-1000nm laser energy and 10g of an antioxidant, and add the obtained product in step (1) In the mixture, stir again for 30 minutes;

[0067] (3) Feed the mixture obtained in step (2) into the extruder for extrusion molding, use a "T" die to extrude the sheet, and then use four-roll calendering to calender to a thickness of 0.8mm. The melt temperature is 170°C, the extrusion pressure is 10Mpa, and the melt residence time is 1min;

[0068]...

Embodiment 3

[0069] Embodiment 3 of the present invention: a method for preparing a zinc-bromine flow battery diaphragm suitable for laser welding, comprising the following steps:

[0070] (1) Weigh the specific surface area as 100m 2 100g of fumed silica per gram and 650g of plasticizer (30% DOP is added to the special oil for PE separator), mix and stir for 30 minutes;

[0071] (2) Weigh 180g of PE raw materials (120g of UHMWPE with a molecular weight of 4 million and 60g of HDPE with a molecular weight of 50,000), 50g of a color masterbatch (such as plasblak un2014) that absorbs 900-1000nm laser energy, and 20g of an antioxidant, and add the mixture obtained in step (1) In the material, stir again for 30 minutes;

[0072] (3) Feed the mixture obtained in step (2) into the extruder for extrusion molding, use a "T" die to extrude the sheet, and then use four-roll calendering to calender to a thickness of 1.0mm. The melt temperature is 200°C, the extrusion pressure is 20Mpa, and the melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com