Shift control method for multi-stage motor

A shift control, motor technology, applied in the direction of single motor speed/torque control, DC motor speed/torque control, excitation or armature current control, etc. Wide range of applications, difficult to guarantee vacuum environment, etc., to achieve the effect of simple manufacturing process, low cost, and guaranteed performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

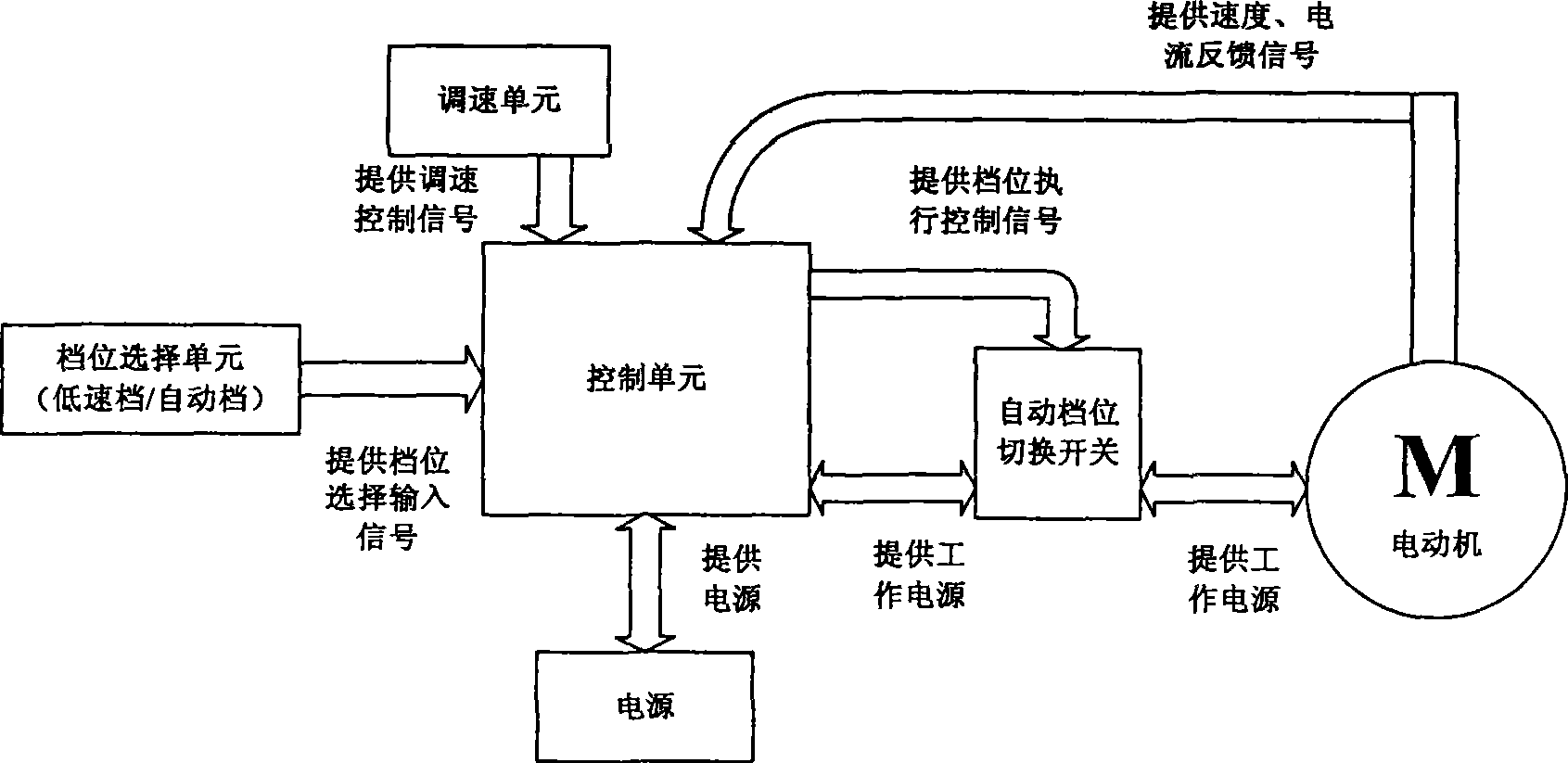

[0027] The present invention will be further described below in conjunction with the drawings and embodiments.

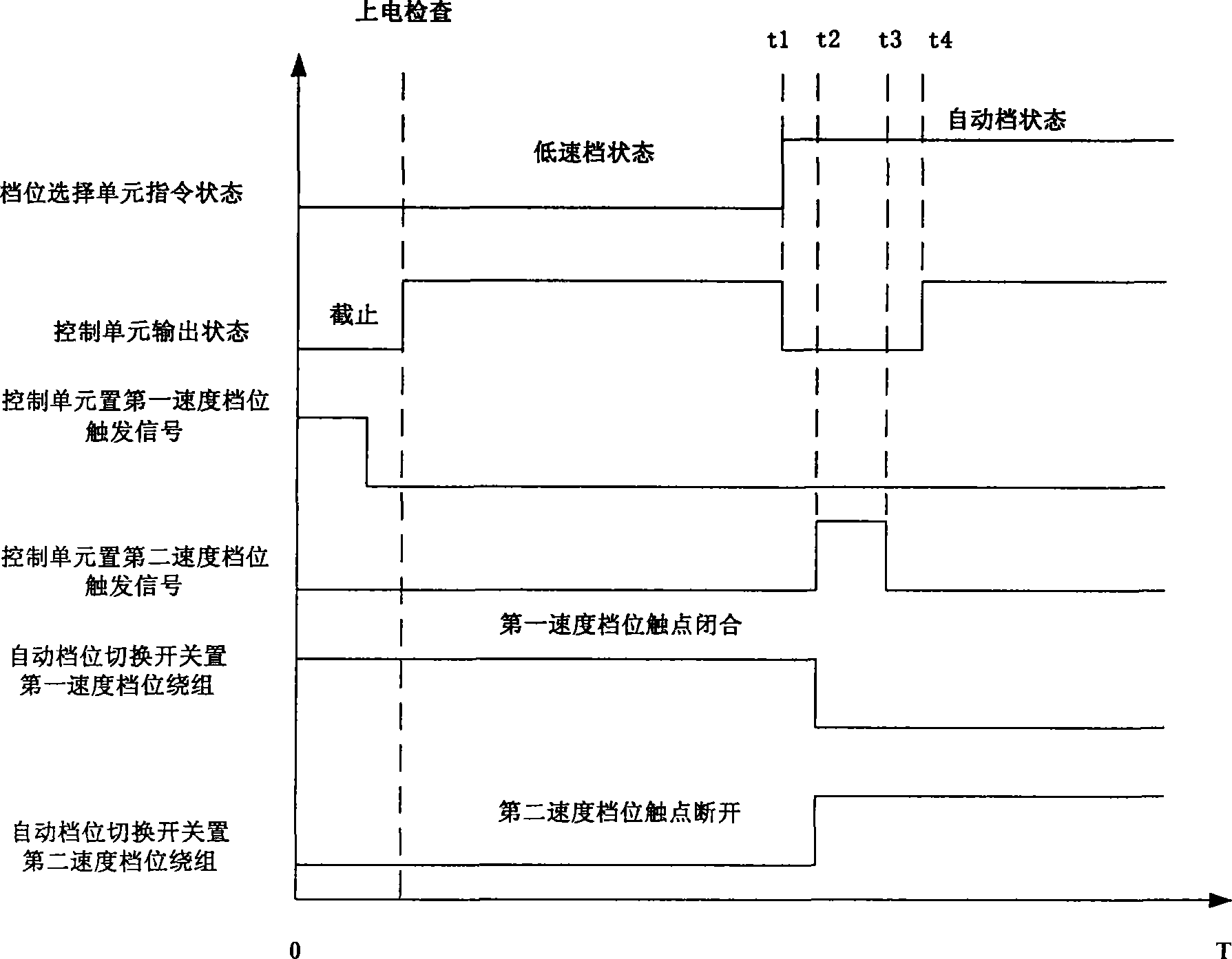

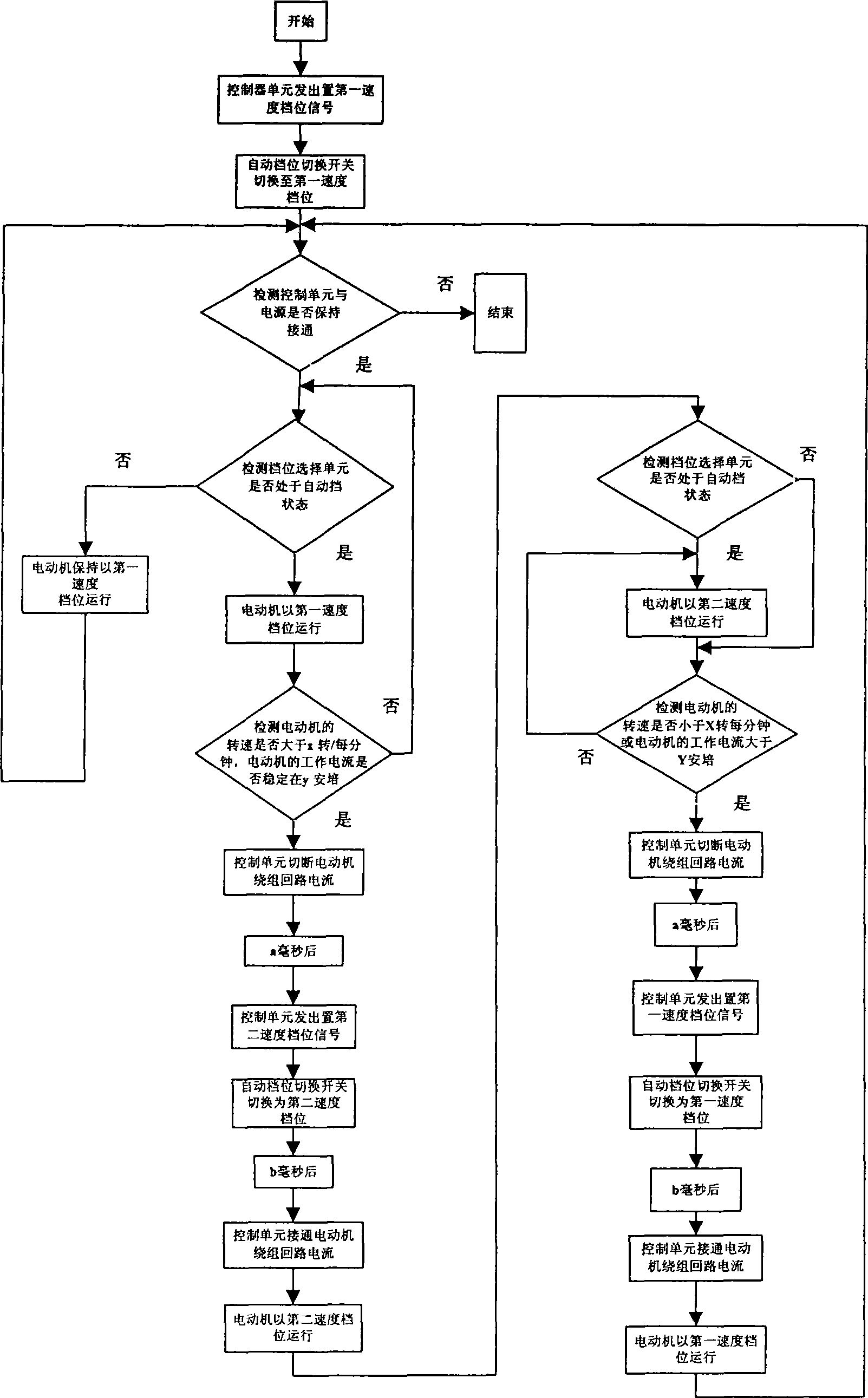

[0028] Combine figure 2 , image 3 Take the two-speed motor shift control process as an example.

[0029] A two-speed motor shift control method, the steps are as follows:

[0030] First, preset the first speed gear and the second speed gear on the automatic gear shift switch, and the rotation speed value of the motor corresponding to the first speed gear is smaller than the rotation speed value of the motor corresponding to the second speed gear;

[0031] Then, the automatic gear selector switch is placed in the first speed gear; if the gear selector is in the automatic gear state, the automatic gear shift function is activated, and the motor speed is automatically adjusted according to the change of the motor load. If the gear selection unit is in a low-speed gear state, the constant-speed driving function is activated, and the automatic gear selector switch is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com