Phenol aldehyde molding compound for commutators

A technology of phenolic molding compound and commutator, which is applied in the field of composite materials to achieve the effects of improving heat resistance, strong bonding ability and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

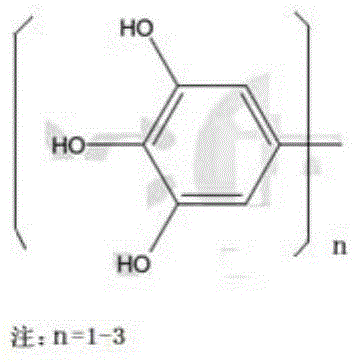

Image

Examples

Embodiment Construction

[0038] The manufacturing method of the molding material of the present invention can adopt the traditional mixing method, and can also adopt the single-screw extrusion method.

[0039]Before kneading or extrusion, pre-mix urethane, inorganic filler (except glass fiber), phenolic resin, melamine resin and curing accelerator, pigment and release agent in a high-speed mixer for 2-6 Minutes, then mix the above mixture with glass fiber in proportion, heat and knead or extrude, and finally granulate to obtain the desired product.

[0040] Below just illustrate the present invention:

[0041] The formulation materials shown in Table 1 are mixed and kneaded or extruded according to the aforementioned manufacturing method, and finally granulated to obtain the desired product. Implementations 1-9 formulations and property data are listed in this table. The dosages of the formulations in the table are expressed in % by weight. The sample pieces for characteristic evaluation were prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com