RH vacuum treatment desulfurizing agent used for non-oriented electrical steel, preparation method thereof, and desulfurizing method using same

A technology of oriented electrical steel and vacuum treatment, which is applied in the field of molten steel refining outside the furnace, can solve the problems of large corrosion of refractory materials, risk of carburization of molten steel, slow melting, etc., to achieve the effect of reducing erosion, ensuring continuous processing, and avoiding carburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

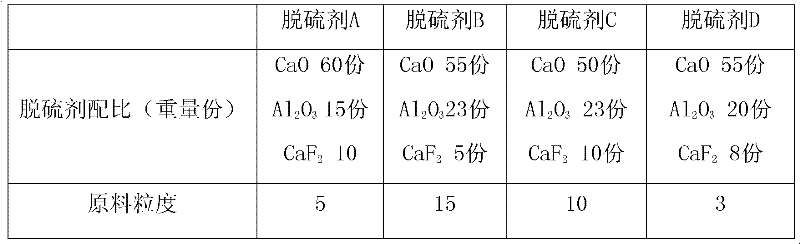

[0028] Embodiment 1 Preparation of desulfurizer of the present invention

[0029] The active lime, calcium aluminate and fluorite are crushed separately, and the particle size of the raw materials is controlled at 5mm during crushing. The component content of each raw material is detected, and the active lime mass percentage components are CaO 85%, SiO 2 6%, MgO 6%, TiO 2 1.0%, P 0.07%, S 0.04%, the mass percentage of calcium aluminate consists of CaO 43%, Al 2 o 3 38%, SiO 2 6%, TiO 2 2.5%, MgO 3.0%, P 0.05%, S 0.07%, the mass percentage of fluorite is CaF 2 85%, SiO 2 10%, P 0.02%, S 0.03%, TiO 2 0.5%, MgO 2.0%. Then according to the component content of each raw material according to parts by weight CaO 60 parts, Al 2 o 3 15 parts, CaF 2 Prepare 10 parts of desulfurizer, i.e. 40 parts by weight of calcium aluminate, 10 parts by weight of fluorite, and 50 parts by weight of active lime. 2 6.4%, MgO 4.4%, TiO 2 1.55%, P 0.057%, S 0.051%, stir and mix th...

Embodiment 2

[0032] Embodiment 2 uses the desulfurization agent desulfurization of the present invention

[0033] The molten steel enters the RH process, the S weight content in the steel is 0.006%, and the RH furnace is used for decarburization treatment. The treatment time is 19min, and the C weight content is 0.004%. At this time, the oxygen activity is 0.0004%. After deoxidation and alloying, add the above-mentioned desulfurizer A in an amount of 4 kg / ton of molten steel, and allow the molten steel to circulate for 6 minutes to end the vacuum desulfurization treatment. Then carry out continuous casting and sample analysis of the molten steel in the tundish, the S weight content is 0.005%, the C weight content is 0.004%, and the rest components all meet the requirements.

Embodiment 3

[0034] Embodiment 3 uses desulfurization agent desulfurization of the present invention

[0035] The molten steel enters the RH process, the S weight content in the steel is 0.007%, and the RH furnace is used for decarburization treatment. The treatment time is 19 minutes, and the C weight content is 0.004%. At this time, the oxygen activity is 0.0004%. After the deoxidation alloying, add the above-mentioned desulfurizing agent B in an amount of 7 kg / ton of molten steel, let the molten steel circulate for 10 minutes, and end the vacuum desulfurization treatment. Then carry out continuous casting and sample analysis of the molten steel in the tundish, the S weight content is 0.005%, the C weight content is 0.004%, and the rest components all meet the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com