Manganese steel strip having an increased phosphorus content and process for producing the same

A manganese steel, weight percentage technology, applied in the field of austenitic manganese steel strip and manufacturing austenitic manganese steel strip, can solve problems such as affecting mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The different possibilities for producing the manganese steel according to the invention are firstly explained by way of example.

[0046] In a first option, pig iron is produced in a blast furnace or by a smelting reduction process such as the Corex or Finex process. Pig iron can also be prepared by the Tecnored method. For example, the pig iron is then converted to steel in an oxygen top-blown process (eg LD (Linz-Donawitz) / BOF (Bottom Oxygen Furnace) process). Vacuum degassing (such as the Ruhrstahl-Heraeus (RH) process) can be performed prior to steel casting, and a ladle furnace can be used to heat and alloy the molten metal. In the second option, an electric arc furnace (EAF) is used to prepare the steel and an AOD converter is used to decarbonize the liquid steel, which may be particularly suitable for manganese steels. Likewise, ladle furnaces can be used to heat and alloy the molten metal before casting steel.

[0047] The steel thus produced can be further ...

PUM

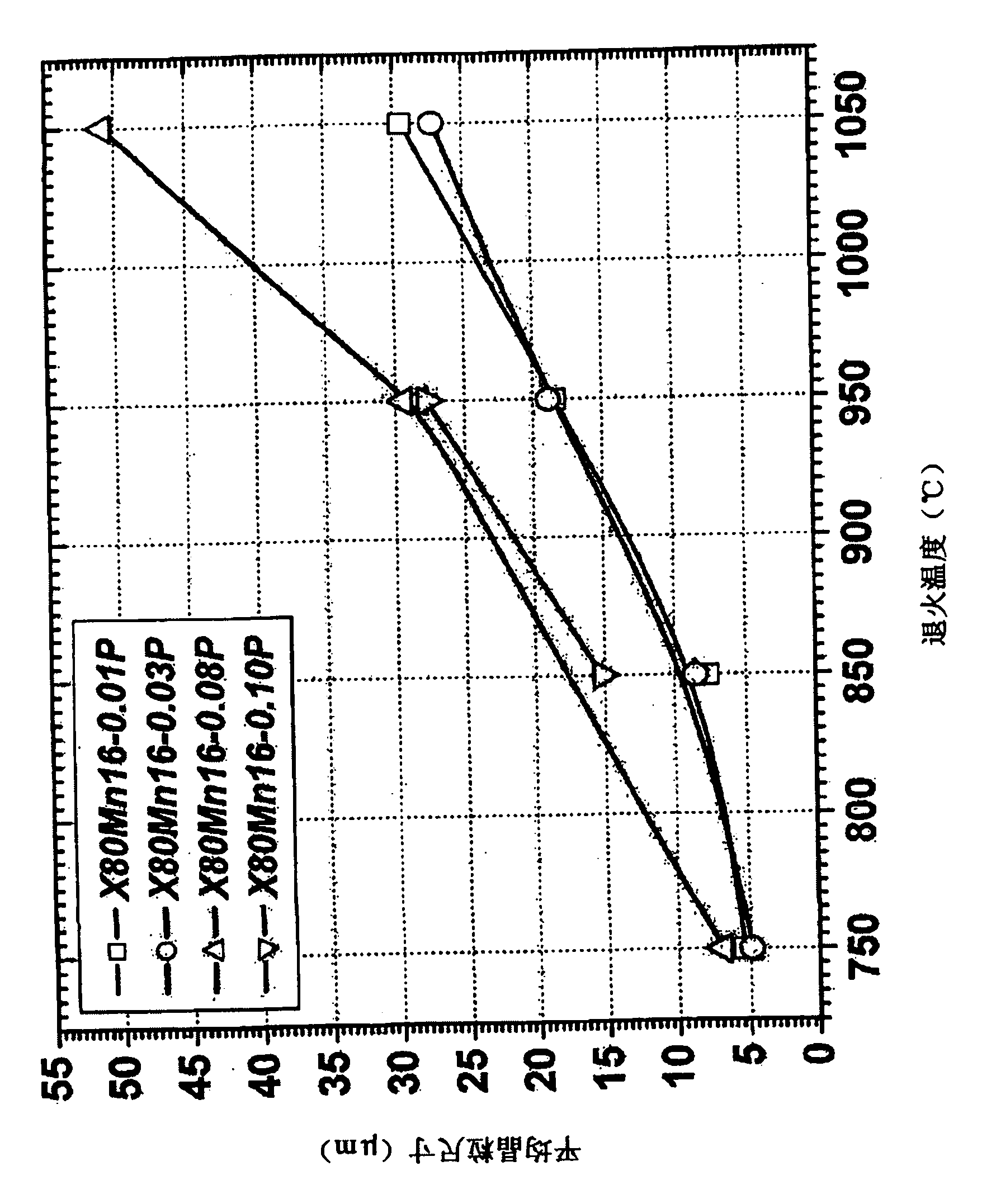

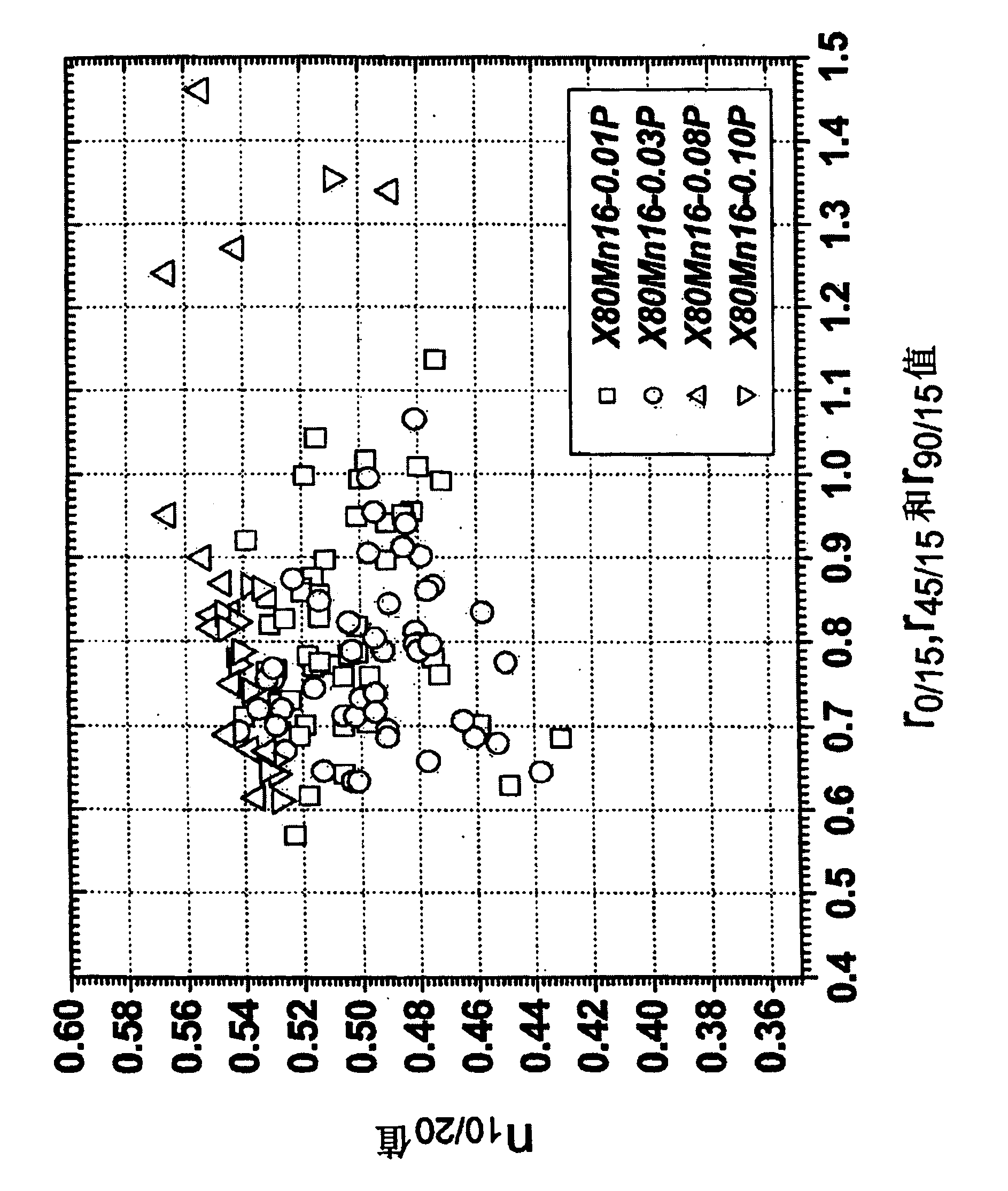

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com