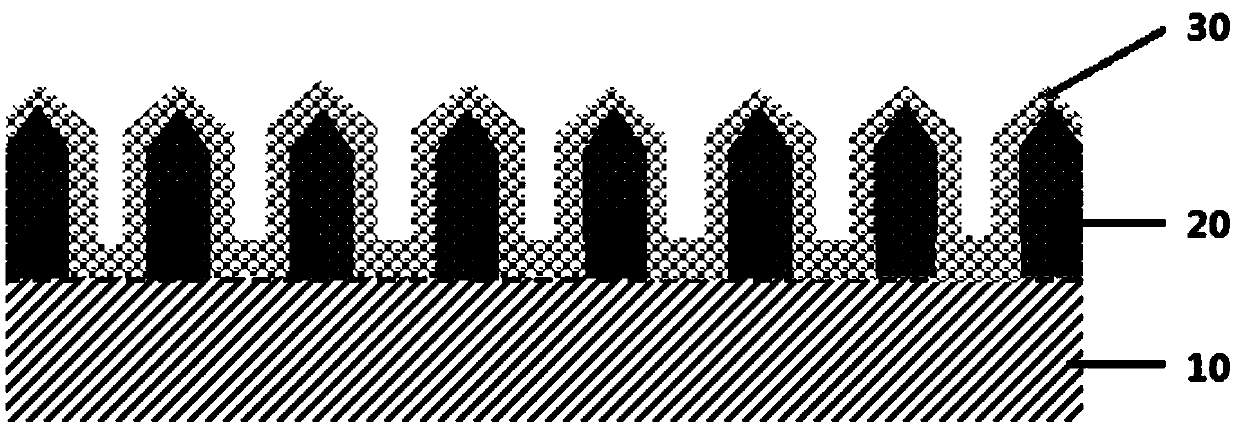

Super-hydrophobic diamond-like carbon composite layer structure and preparation method thereof

A diamond layer and diamond technology, which is applied in the field of super-hydrophobic diamond-like carbon composite layer structure and its preparation, can solve the problem that the diamond-like carbon coating does not have hydrophobicity, etc., and achieve the effects of preventing peeling, improving adhesion and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] Another aspect of the embodiments of the present invention provides a method for preparing a diamond-like composite layer structure, comprising the following steps:

[0064] S01. Provide a substrate, and sequentially perform pretreatment, glow cleaning and ion etching cleaning on the substrate;

[0065] S02. Place the cleaned substrate in the deposition chamber, inject argon gas, adjust the pressure of the vacuum chamber to 0.2-1.3Pa, turn on the first target and the second target, and control the target of the first target The power is 30-70W, the target power of the second target is controlled to be 30-70W, and the prefabricated transition layer is deposited under the condition that the substrate bias voltage is 100-300V;

[0066] S03. The sample deposited with the prefabricated transition layer is taken out, placed in a container filled with etching solution, subjected to ultrasonic treatment, and the prefabricated transition layer is etched to form a transition laye...

Embodiment 1

[0105] A preparation method of a diamond-like composite layer structure, comprising the following steps:

[0106] S11. Provide a substrate, and sequentially perform pretreatment, glow cleaning and ion etching cleaning on the substrate; specifically:

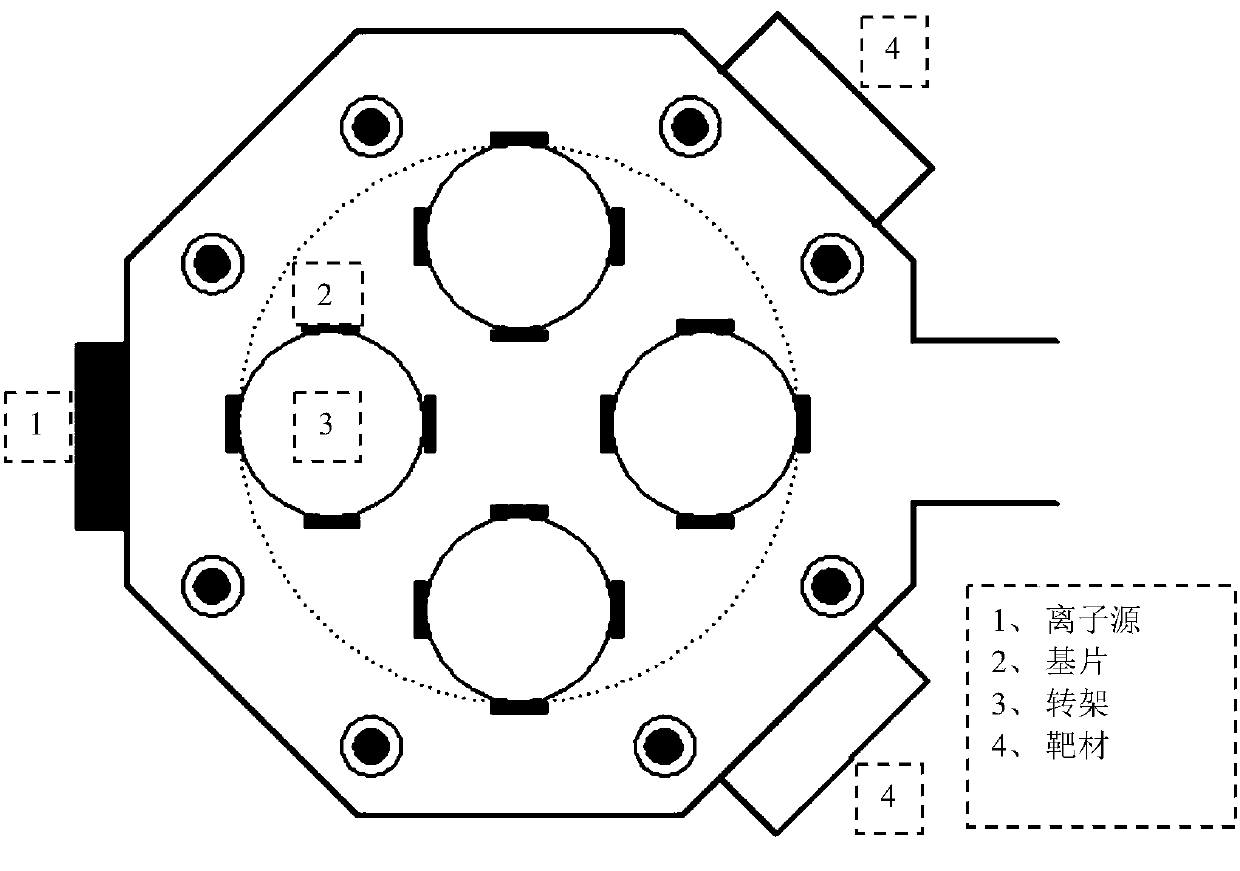

[0107] Put the substrate into distilled water and ultrasonically clean it for 5 to 30 minutes, then put the substrate into an acetone solution and ultrasonically clean it for 5 to 30 minutes, and then put the substrate into an anhydrous ethanol solution and ultrasonically clean it for 5 to 30 minutes; After finishing, dry the surface of the substrate with dry nitrogen, and finally put the sample into a blast drying oven for drying at 80-150°C. Before glow cleaning, adjust the equipment parameters, specifically, fix the dried substrate on the turntable in the ion source coating equipment; close the vacuum chamber door, turn on the water cooler to set the ion source, multi-arc target, Connect the water circuit of the molecular pum...

Embodiment 2

[0114] A method for preparing a diamond-like composite layer structure differs from Example 1 in that: the first target material is a metal copper target, the second target material is a metal aluminum target, and the etching solution is potassium hydroxide solution.

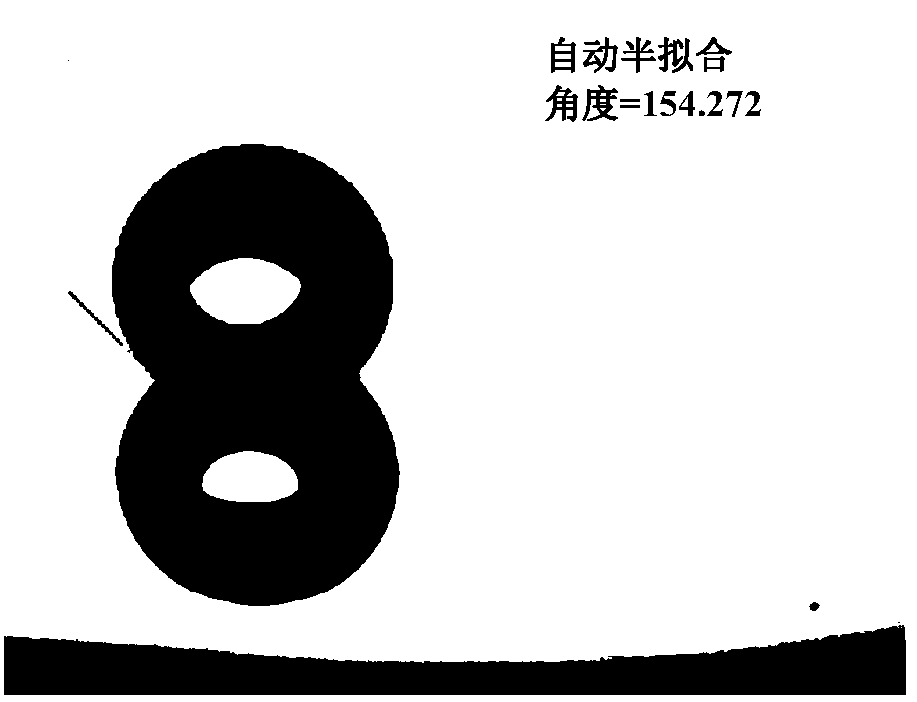

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com