Composite intermediate layer sliding plate with filled polytetrafluoroethylene and method for preparing the same

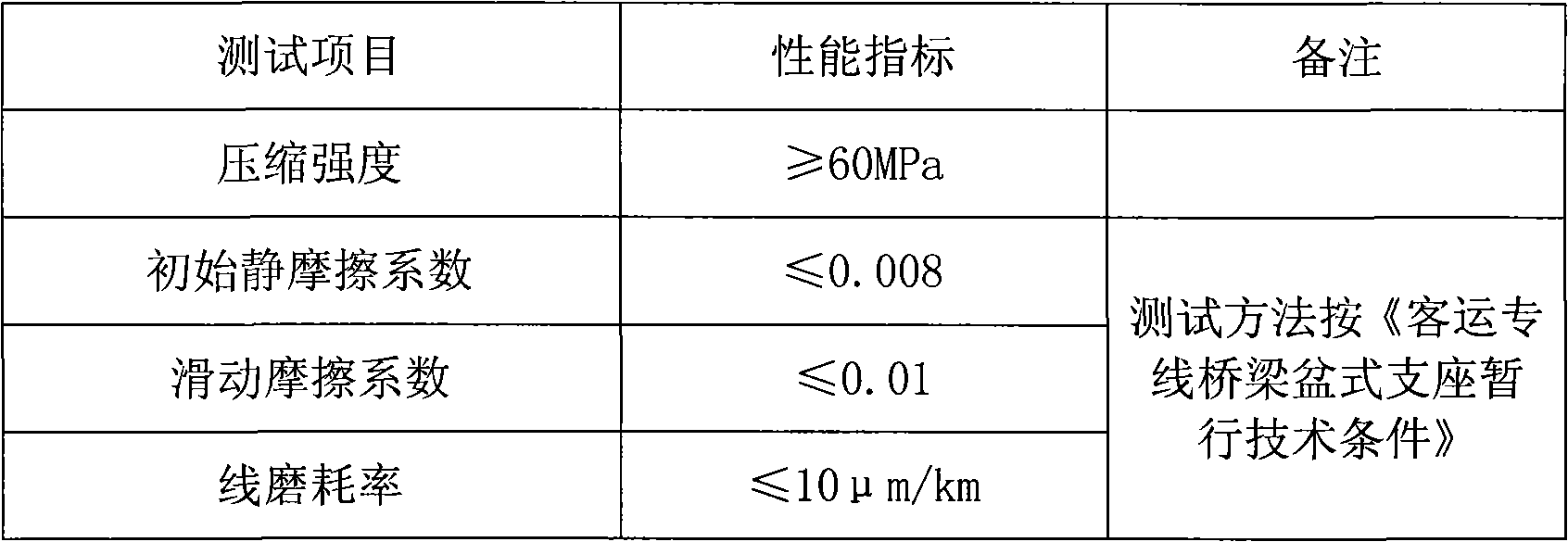

A polytetrafluoroethylene layer and polytetrafluoroethylene technology, which is used in bridge parts, bridges, buildings, etc., can solve the problem of low compressive strength of pure polytetrafluoroethylene plates, large vertical deformation of bearings, and unfavorable sliding of bearings. It can achieve the effect of low friction coefficient, conducive to bearing sliding, and small compression deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The raw material composition and mass percentage of the modified polytetrafluoroethylene layer filled in the middle layer 2 are: polytetrafluoroethylene 72%, carbon fiber 20%, MoS 2 5%, cadmium oxide 3%.

[0030] Weigh each component, put it into a high-speed mixer and mix evenly; use compression molding, fill the mold with material, the upper and lower surface layers are made of pure polytetrafluoroethylene material, the middle layer is filled with modified polytetrafluoroethylene material, and the thickness of the middle layer is 60% of the total thickness, the thickness of the upper and lower surface layers is the same, pressurize on the press, the pressure is 45MPa, hold the pressure for 5min, and release the mold to obtain the blank; put the blank into a polytetrafluoroethylene sintering furnace for sintering, slowly heat up, and the sintering temperature is 370 ℃, the sintering time is 2h, the temperature is lowered to 320°C and kept for 1h, and then slowly coole...

Embodiment 2

[0032] The raw material composition and mass percentage of the modified polytetrafluoroethylene layer filled in the middle layer 2 are 65% polytetrafluoroethylene, 30% glass fiber, 4% polyphenylene, and 1% graphite.

[0033] Weigh each component, put it into a high-speed mixer and mix evenly; use compression molding, fill the mold with material, the upper and lower surface layers are made of pure polytetrafluoroethylene material, the middle layer is filled with modified polytetrafluoroethylene material, and the thickness of the middle layer is 70% of the total thickness, the thickness of the upper and lower surface layers is the same, pressurize on the press, the pressure is 60MPa, hold the pressure for 6min, and release the mold to obtain the blank; put the blank into a polytetrafluoroethylene sintering furnace for sintering, slowly heat up, and the sintering temperature is 360 ℃, the sintering time is 2h, the temperature is lowered to 320°C and kept for 1h, and then slowly co...

Embodiment 3

[0035] The raw material composition and mass percentage of the modified polytetrafluoroethylene layer filled in the middle layer 2 are: polytetrafluoroethylene 95%, carbon fiber 4%, MoS 2 1%.

[0036] Weigh each component, put it into a high-speed mixer and mix evenly; use compression molding, fill the mold with material, the upper and lower surface layers are made of pure polytetrafluoroethylene material, the middle layer is filled with modified polytetrafluoroethylene material, and the thickness of the middle layer is 65% of the total thickness, the thickness of the upper and lower surface layers is the same, pressurize on the press, the pressure is 30MPa, hold the pressure for 2min, and release the mold to obtain the blank; put the blank into a polytetrafluoroethylene sintering furnace for sintering, slowly heat up, and the sintering temperature is 380 ℃, the sintering time is 1.5h, the temperature is lowered to 320°C and kept for 1h, and then slowly cooled to room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com