High-selectivity composite nanofiltration membrane and preparation method thereof

A composite nanofiltration membrane and high-selectivity technology, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problem of increasing the cleaning cycle of membrane elements, easily polluting nanofiltration membranes, and reducing the life of membrane elements, etc. problem, to achieve the effect of improving pollution resistance, increasing thickness and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

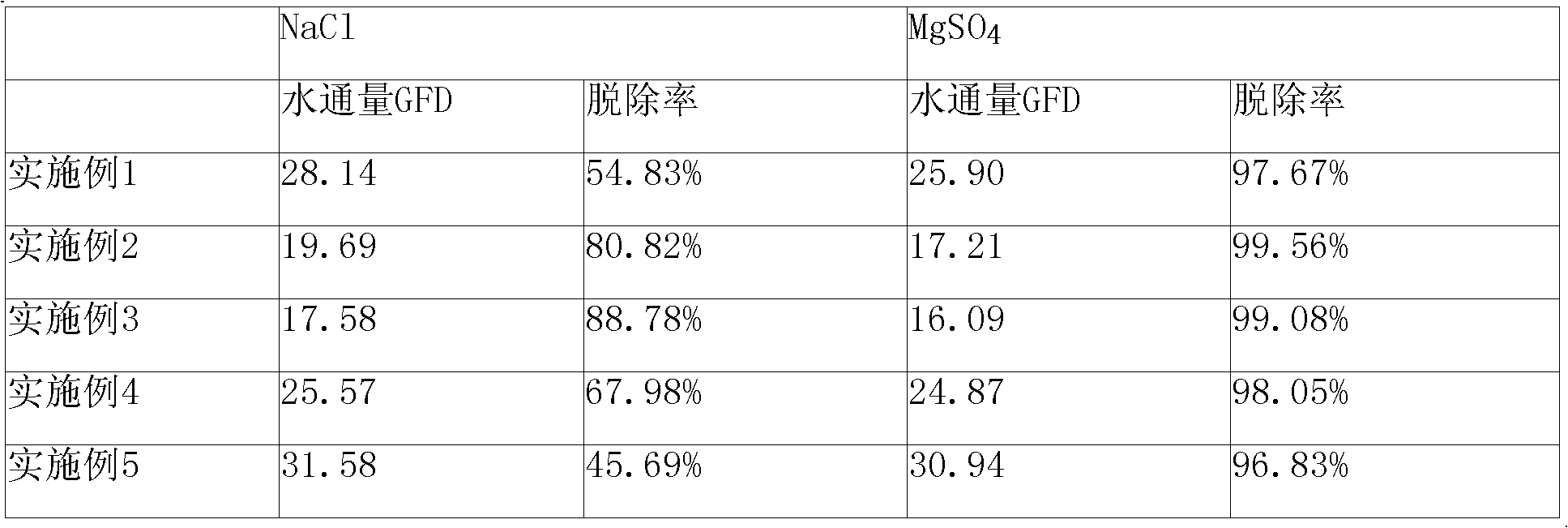

[0033] Embodiment 1: prepare composite nanofiltration membrane according to the following steps:

[0034] (1) Preparation of A solution: get 9g anhydrous piperazine and be dissolved in 985g water and be made into the solution that weight concentration is 0.9%, after dissolving completely, then add anhydrous sodium phosphate 3g (weight concentration 0.3%) in this solution 1. Sodium dodecylbenzenesulfonate 3g (weight concentration 0.3%), obtain A solution after stirring and dissolving completely.

[0035] (2) Preparation of solution B: 26.7 g of trimesoyl chloride was dissolved in 973.3 g of ethylcyclohexane to form a solution with a weight concentration of 2.6%, and solution B was obtained after the dissolution was complete.

[0036] (3) Soak the porous support layer in solution A for 20s, drain until there are no obvious drops of water on the surface and back of the membrane; Soak in citric acid solution for 10 minutes, then soak in pure water for 5 minutes, wash off excess aci...

Embodiment 2

[0038] Embodiment 2: prepare composite nanofiltration membrane according to the following steps:

[0039] (1) The preparation of A solution and B solution is the same as in Example 1.

[0040] (2) Preparation of solution C: same as that of solution A.

[0041] (3) Soak the porous support layer in solution A for 20s, drain until there are no obvious drops of water on the surface and back of the membrane; then contact with solution B for 15s, and soak in solution C for 20s after the solvent evaporates to form the second layer of polyamide layer, then soaked in a citric acid solution with a weight concentration of 6% and a temperature of 80°C for 10 minutes, then soaked in pure water for 5 minutes, cleaned the excess acid, and then used 2% triethylamine and 4% camphor sulphur The acid mixed solution was soaked for 5 minutes, and finally kept in an oven at 80° C. for 5 minutes to obtain a composite nanofiltration membrane.

[0042] Take the diaphragm and test it on the diaphragm...

Embodiment 3

[0043] Embodiment 3: prepare composite nanofiltration membrane according to the following steps:

[0044] (1) The preparation of A solution and B solution is the same as in Example 1.

[0045] (2) Preparation of C solution: get 5g m-phenylenediamine and dissolve it in 989g water to form a solution with a weight concentration of 0.5%. After the solution is completely dissolved, add anhydrous sodium phosphate 3g (weight concentration 0.3%) , N-methylpyrrolidone 3g (weight concentration 0.3%), obtain C solution after stirring and dissolving completely.

[0046] (3) Soak the porous support layer in solution A for 20s, drain until there are no obvious drops of water on the surface and back of the membrane; then contact with solution B for 15s, and soak in solution C for 15s after the solvent evaporates to form the second layer of polyamide layer, then soak in citric acid solution with a weight concentration of 6% and a temperature of 80°C for 10 minutes, then soak in pure water fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com