Cloth printing assembly line

An assembly line and cloth technology, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of reducing the printing quality of cloth, ink pollution on conveyor belts, and cloth pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

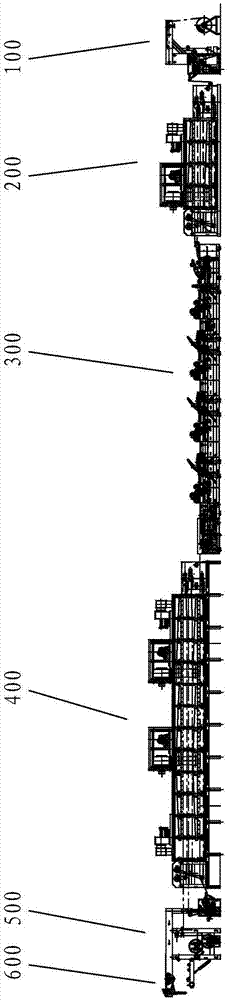

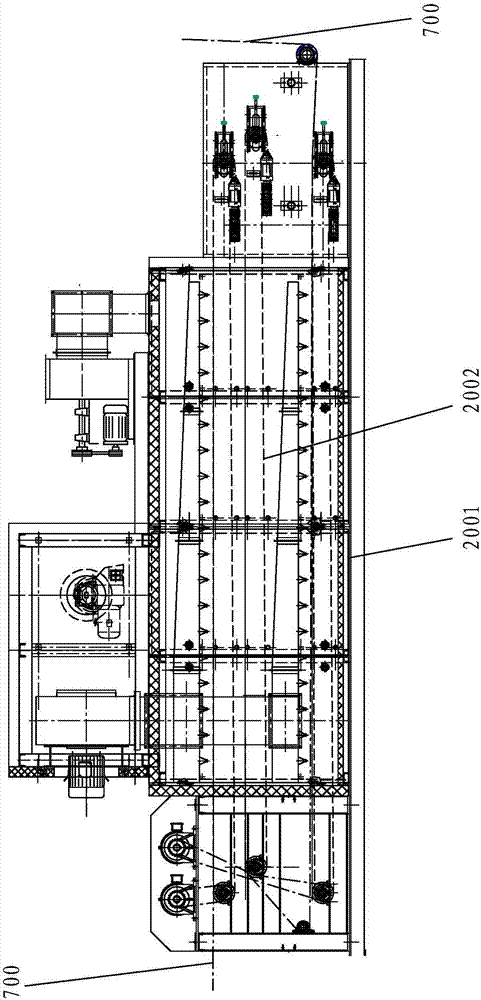

[0025] A kind of cloth printing assembly line of the present invention, as Figure 1-23 As shown, the cloth feeding section 100 , the first drying section 200 , the printing section 300 , the second drying section 400 , the cooling section 500 and the cloth receiving section 600 are sequentially included in the flow direction of the cloth 700 .

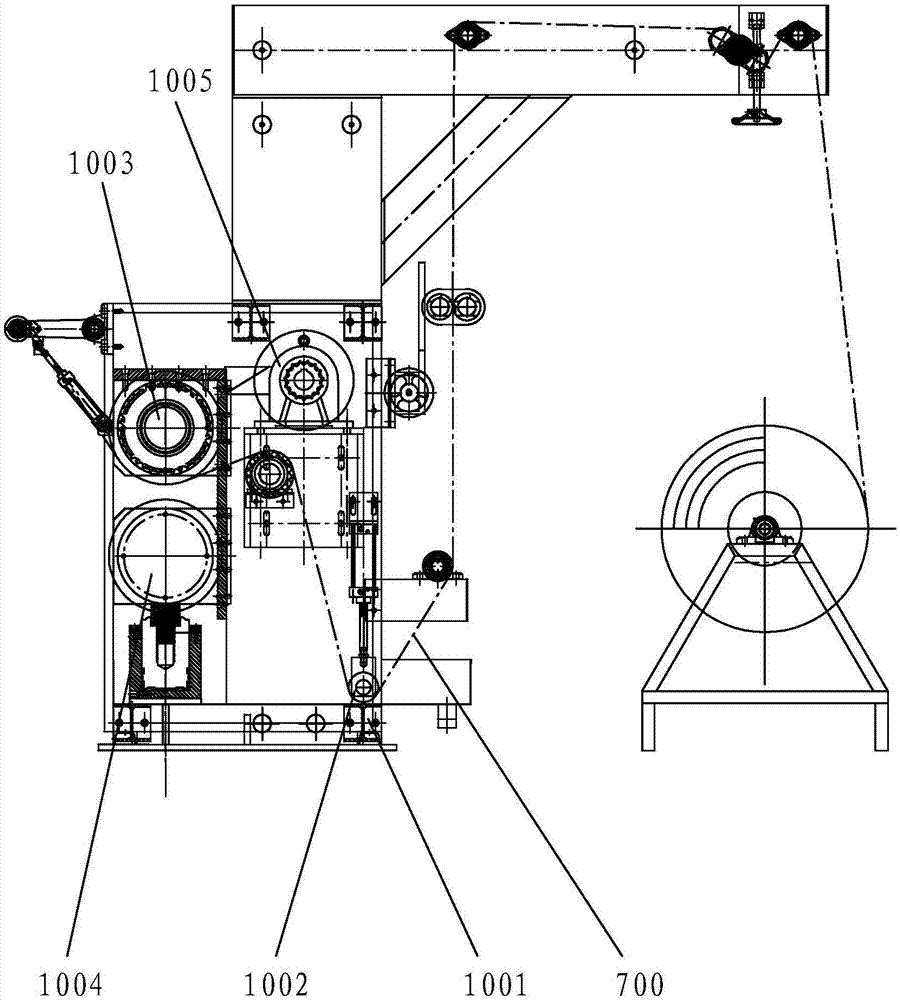

[0026]The cloth feeding section 100 includes a soaking tank 1001 filled with a soaking solution, a soaking driving roller 1002 above the soaking tank 1001 to drive the cloth 700 into the soaking tank 1001, and an active squeezing roller 1003 downstream of the soaking tank 1001 , below the active squeezing roller 1003 to push the cloth 700 against the driven squeezing roller 1004 on the active squeezing roller 1003, and a squeezing motor 1005 that rotates and drives the active squeezing rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com