Porous high oil absorption resin and preparation method thereof

A high oil-absorbing resin, porous technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of high energy consumption, poor oil retention, low oil absorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0045] Add 3 g of the dispersant methylcellulose into 450 g of hot water at about 80°C, stir until completely dissolved, and cool to room temperature. Then it was added into a four-neck flask equipped with a stirrer, a reflux condenser and a thermometer. Then polymerize monomer styrene and lauryl acrylate (molar ratio is 1: 4) altogether 100g, total 1g of initiator sodium persulfate, total 3g of crosslinking agent divinylbenzene and porogen butyl acetate 157 g was added therein and stirred evenly, and nitrogen gas was passed for about 15 minutes at the same time, and the air in the reactor was removed to ensure that the suspension polymerization reaction was carried out under a nitrogen atmosphere. Under stirring, the reaction system was heated to 77.5° C. for suspension polymerization for 6.5 hours, and then the reaction system was heated to 95° C. for 1 hour of aging reaction. With stirring, the product was cooled to room temperature and filtered. The obtained product was ...

preparation Embodiment 2 to 8

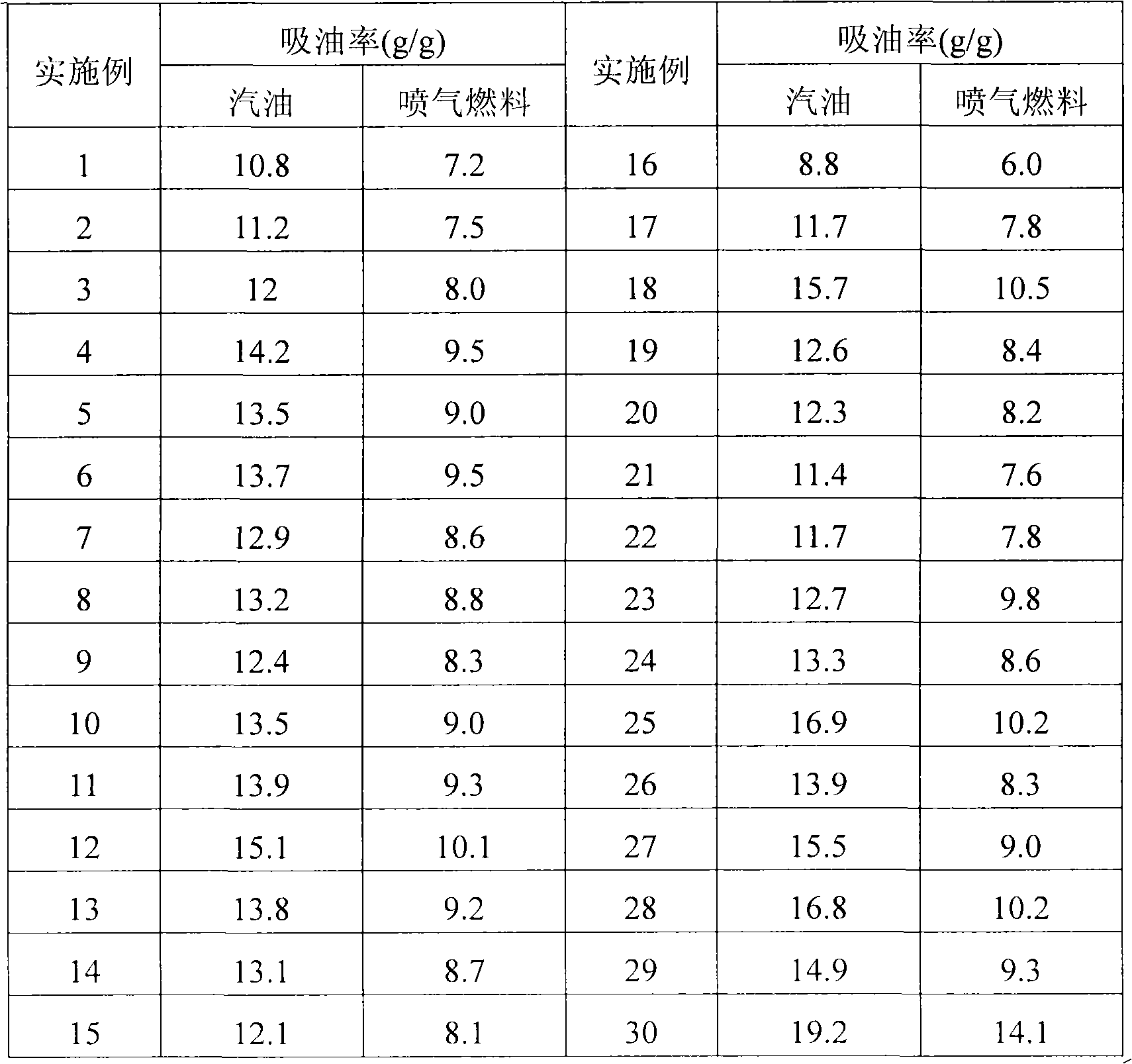

[0047] The oil-absorbing resin was prepared in the same manner as in Example 1, except that the test conditions listed in Table 1 below were adjusted accordingly.

[0048] [Table 1]

[0049]

preparation Embodiment 9 to 15

[0051] The oil-absorbing resin was prepared in the same manner as in Example 1, except that the test conditions listed in Table 2 below were adjusted accordingly.

[0052] [Table 2]

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com