Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

274 results about "Liquid manure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A development of the 20th-century Agribusiness age, liquid manure is used as an alternative to fermented manure. Manure in both forms is used as a nutrient-enriched fertilizer for plants, because farm animals excrete most of the nitrogen, phosphorus, and potassium that is present in the food they consume.

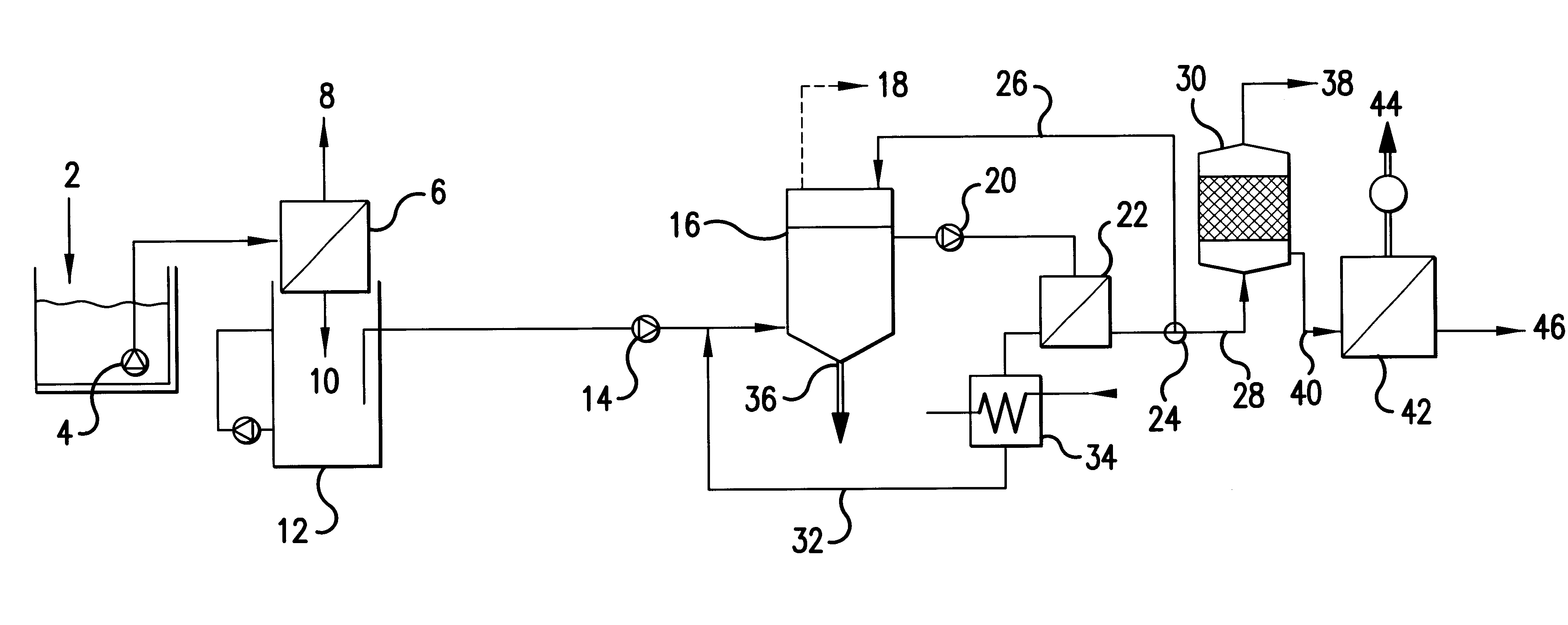

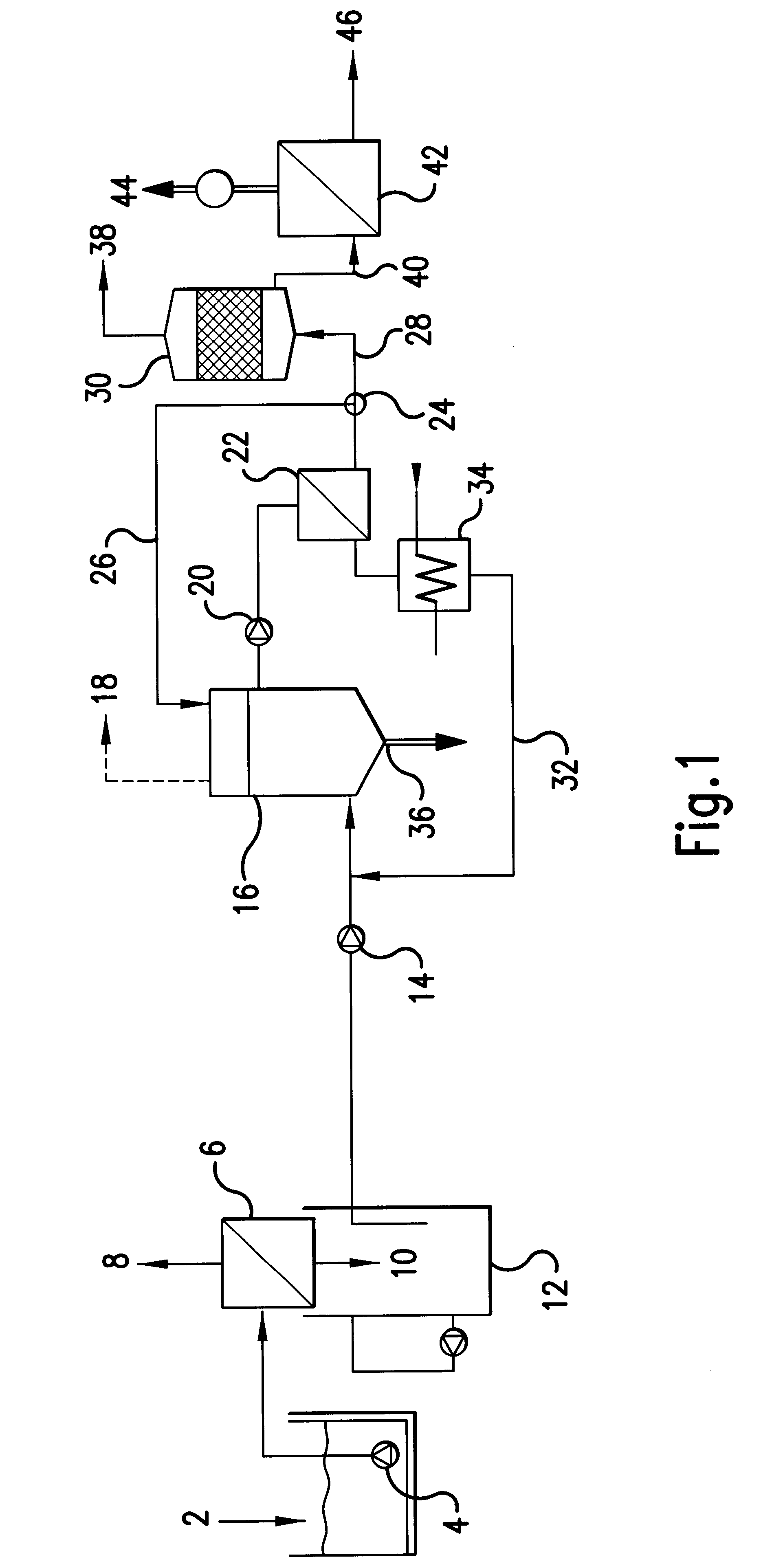

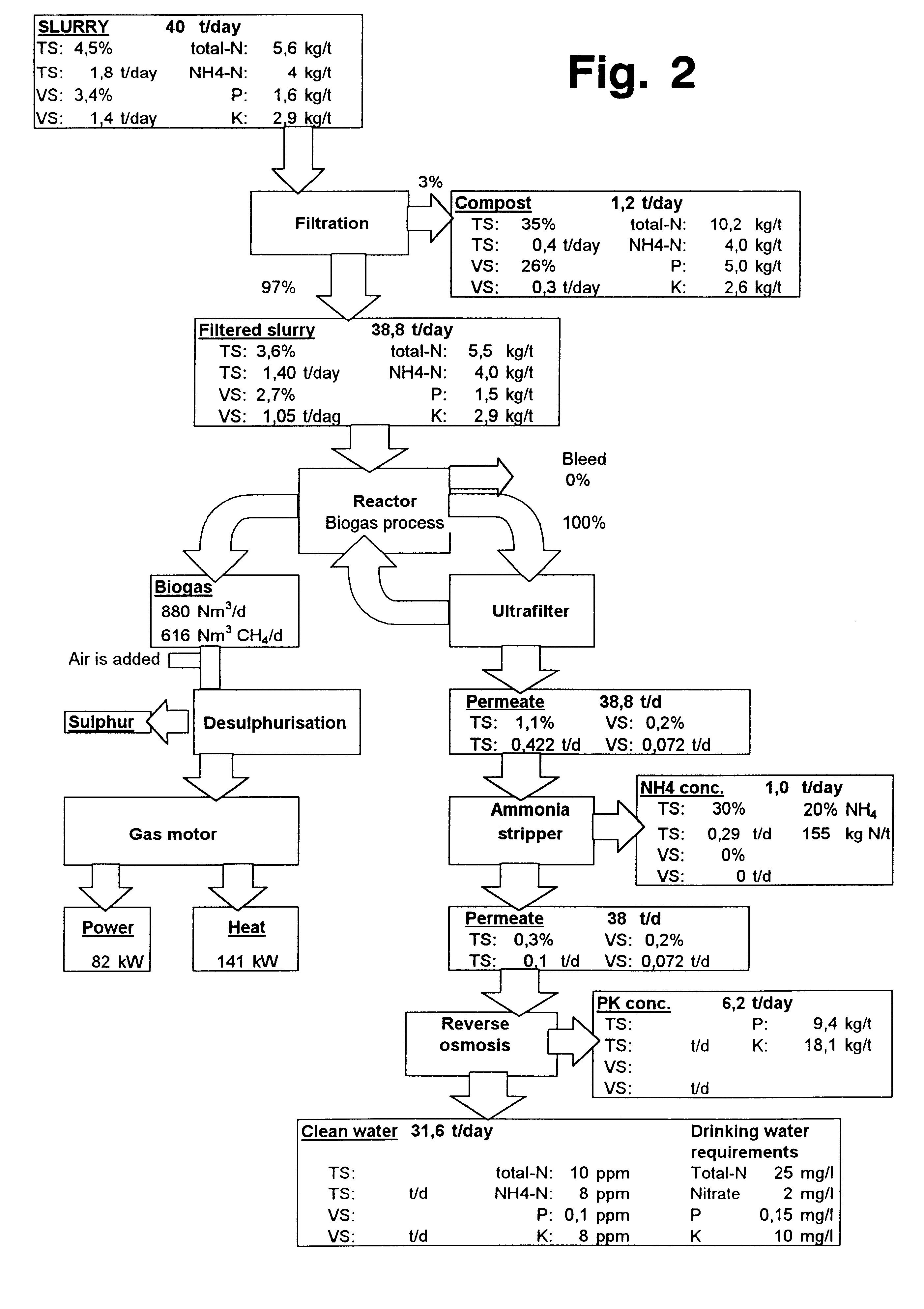

Method and plant for the treatment of liquid organic waste

InactiveUS6368849B1Increase profitReduce environmental impactBioreactor/fermenter combinationsBio-organic fraction processingFiberUltrafiltration

A method and plant for the treatment of an organic waste material in liquid form, e.g. liquid manure from livestock, the method comprising filtering fibres and particles from the liquid, subjecting the liquid to anaerobic fermentation in a biogas reactor, separating a substantially sterile and particle-free permeate stream from the biogas reactor, e.g. using ultrafiltration, subjecting the permeate stream to treatment with an ammonia stripper at an elevated temperature and preferably at reduced pressure to remove substantially all ammonia and carbon dioxide and to result in an ammonia fraction and a nutrient salt fraction, and separating the nutrient salt fraction into a fertiliser concentrate fraction and a water fraction, e.g. using reverse osmosis. The end products of the method are clean water, ammonia concentrate, fertiliser concentrate containing salts of P and K, compost and high-quality biogas with a high methane content.

Owner:GR BIOTECH

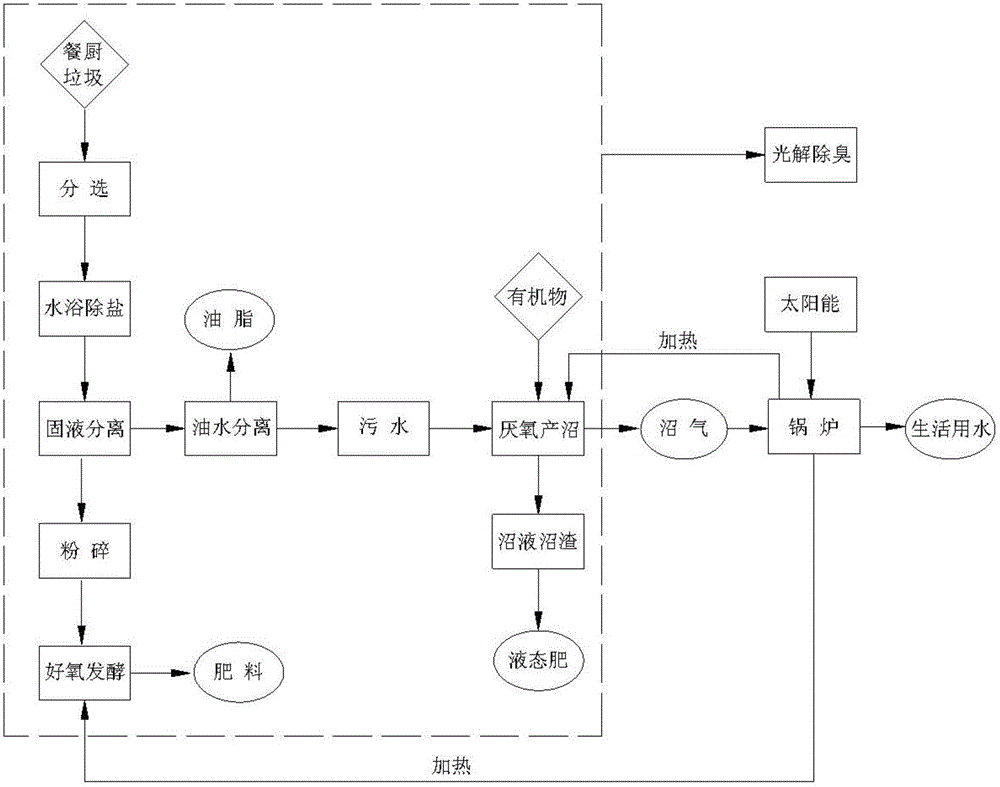

Resource-based and harmless treatment method for kitchen waste

InactiveCN104030738AEfficient removalGrowth inhibitionBio-organic fraction processingClimate change adaptationWater bathsLiquid waste

Relating to the technical field of resource recovery and recycling, the invention discloses a resource-based and harmless treatment method for kitchen waste. The method is directed at the problems of high salt content in fertilizer products, easy cause of soil salinization, and large equipment investment for anaerobic fermentation of total waste in existing kitchen waste treatment methods. The method comprises the steps of: (a) kitchen waste sorting; (b) water bath desalting: adding water, and conducting heating and stirring to dilute salt; (c) solid-liquid separation: dehydrating the waste; (d) solid material aerobic fermentation: crushing the dehydrated solid material into small particles, and conducting aerobic fermentation and drying treatment to obtain an organic fertilizer; and (e) waste liquid anaerobic fermentation: conducting oil-water separation on the waste liquid, recovering grease, subjecting sewage to anaerobic fermentation, making the produced biogas residue and biogas slurry into a liquid fertilizer, and taking the produced biogas as the fuel of a biogas boiler. The method provided by the invention is particularly suitable for resource-based and harmless treatment of kitchen waste.

Owner:习建华 +1

Moisture-retention sustained and controlled release fertilizer and method of preparing the same

InactiveCN101508616AThe synthesis process is simpleUniform thicknessFertilizer mixturesHigh absorptionDouble coating

The invention discloses a water holding slow-controlled releasing fertilizer and a preparation method thereof, belonging to the technical field of agricultural fertilizers and preparation thereof. Macromolecule coating fertilizer is taken as an inner core and a water holding layer is taken as an outside layer to form a double-coating water holding slow-controlled releasing fertilizer; an inner coating is macromolecule protective layer coating material with nutrition controlling and releasing property; an outside coating is the water holding layer with excellent water holding property. Water retention agent suspension liquid is sprayed to the surface of macromolecule coating fertilizer grains for outside coating; wherein the water retention agent is prepared by taking cyclohexane, emulsifier, acrylic acid, acrylamide, sodium hydroxide, cross linker and evocating agent and adopting the method of opposite phase suspension polymerization. The fertilizer has the function of controlled releasing, drought resistance, water saving, water holding and soil improving and the advantages of high absorption percentage, wear resistance, difficult falling and the like; utilization ratio of liquid manure is improved and the fertilizer can be widely used to desert control, lawn plant, soil improvement, gardening, agriculture and forestry and the like.

Owner:CHINA AGRI UNIV

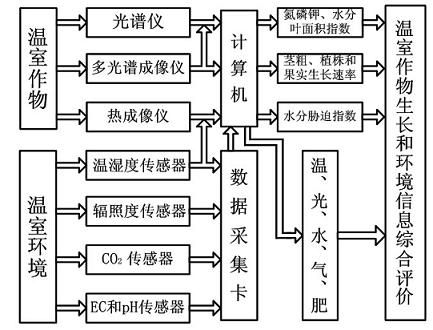

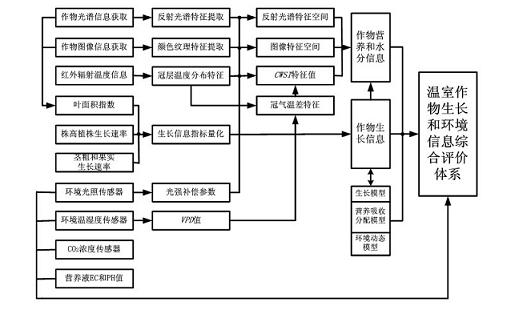

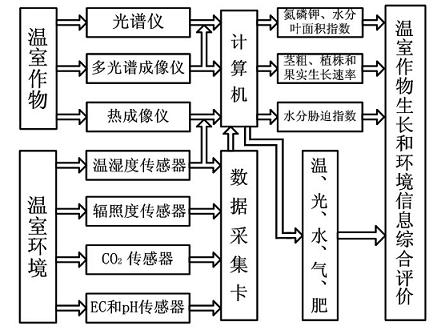

Detecting method for greenhouse crop growth information and environment information based on multi-sensor information

ActiveCN102506938AImprove acquisitionGrasp the state of growthMeasurement devicesGreenhouse cropsCharacteristic space

The invention belongs to the technical field of greenhouse crop growth information and environment information detection, and particularly discloses a detecting method for greenhouse crop growth information and environment information based on multi-sensor information. The detecting method includes the following steps: utilizing a spectrometer, a multispectral imager and a thermal imager to obtain the spectrums, the multispectral image and the canopy temperature information of the greenhouse crop; utilizing temperature, humidity, irradiance, CO2 density, EC and pH value sensors to obtain the temperature-light-moisture fertilizer environment information of the greenhouse; optimizing the spectrum, the image and the canopy temperature characteristics of the nutrition and moisture of the crop, so as to obtain the characteristic space of NPK nutrition and moisture; extracting the morphological characters of the spectrum and the image of the crop, so as to obtain the leaf area index, the stem diameter, the plant body and the fruit growth rate of the crop; and continuously monitoring and recording and formatting the obtained greenhouse environment information of the nutrition, the water, the growth vigor and the temperature-light-moisture fertilizer of the crop, so as to serve as the comprehensive detecting information of the growth and the environment of the greenhouse crop. The information obtained by means of the method can be used for the liquid manure management and environmental control and regulation according to the actual requirement of the greenhouse crop growth.

Owner:JIANGSU UNIV

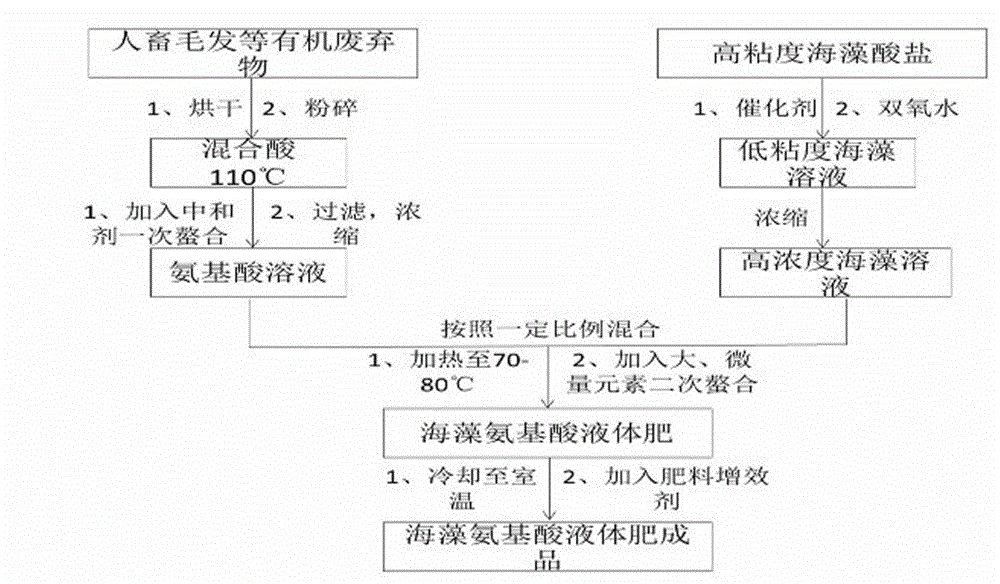

Seaweed amino acid composite liquid manure and preparation method and application thereof

The invention discloses seaweed amino acid composite liquid manure and a preparation method and application thereof, and belongs to the field of manure industry. Preparation of the seaweed amino acid composite liquid manure comprises the following steps: (1) alginate is degraded: under the condition that catalysts and hydrogen peroxide exist, the alginate is degraded to alginic acid solutions; (2) amino acid is chelated for the first time: animal fur is added to mixed acid composed of hydrochloric acid, sulfuric acid and phosphoric acid for acidolysis, and chelation of the animal fur and neutralizer under the condition that a chelating agent exists is carried out to obtain amino acid solutions; and (3) secondary chelating is carried out: the alginic acid solutions and the amino acid solutions are mixed to react, and then humic acid salt, major elements and microelements are added for the secondary chelating, and finally manure synergist is added to obtain the seaweed amino acid composite liquid manure. The prepared seaweed amino acid composite liquid manure is easily absorbed by crops and strong in physiological activity, yield of the crops is increased, quality of the crops is improved, and damage of heavy metals to human is reduced.

Owner:湖南杜高生物科技有限公司

Process for the conversion of liquid waste biomass into a fertilizer product

InactiveUS20090282882A1Minimizing energyIncrease percentageBioreactor/fermenter combinationsBio-organic fraction processingLiquid wasteAmmonium nitrate

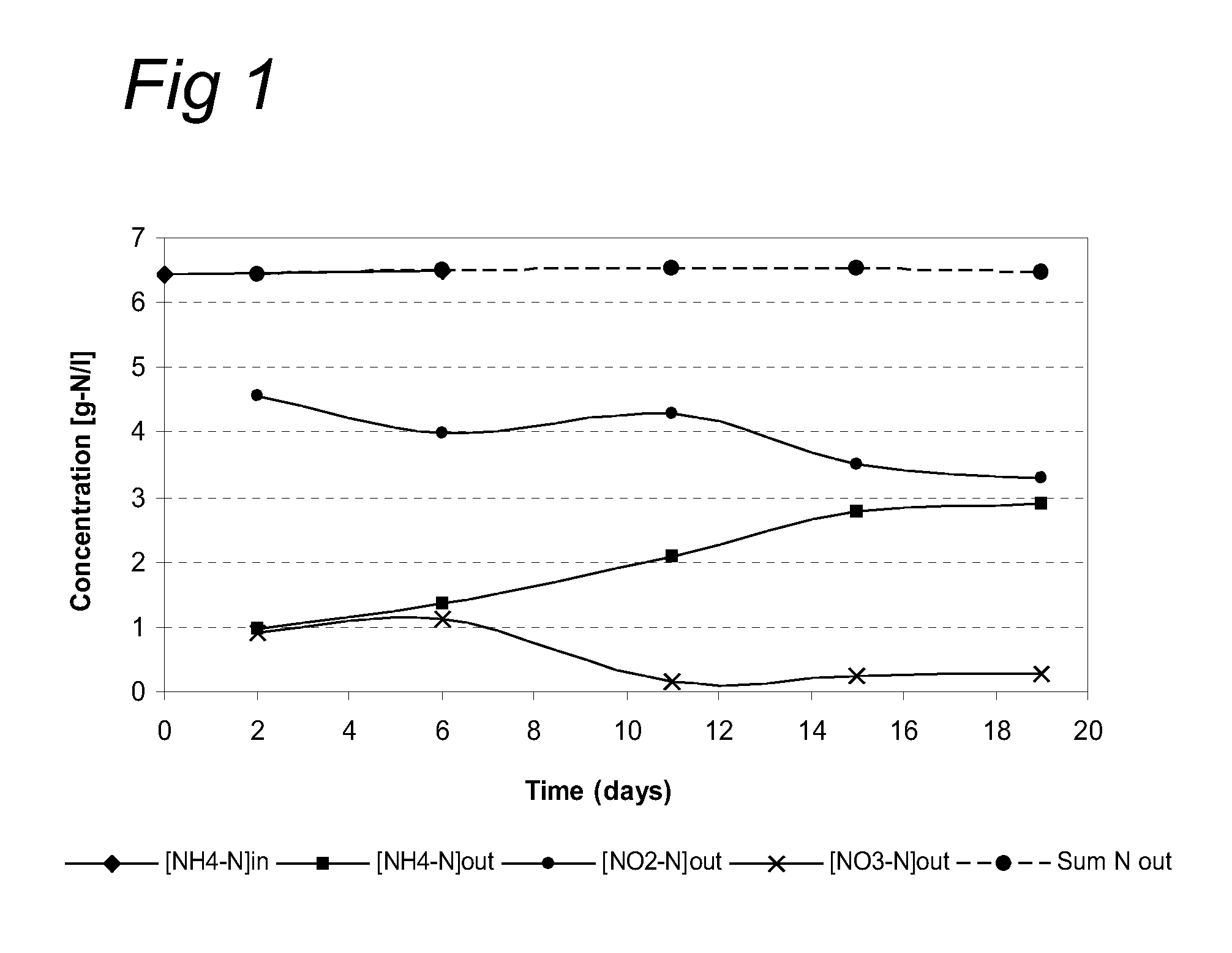

A process for the treatment of liquid waste biomass, especially liquid manure compositions, wherein the biomass is converted to a fertilizer product. The process at least includes a nitrification step including a first biological conversion stage wherein ammonium is converted to nitrite using nitritifying bacteria in an aerated reactor, and a subsequent chemical oxidation stage wherein nitrite is converted to nitrate by heating the liquid waste biomass in an aerated reactor under acidic conditions. The process is particularly suitable for treating liquid manure, because of the high ammonium nitrogen contents thereof, which render the process essentially self-regulatory. In addition a process for the treatment of liquid waste biomass wherein organic matters are converted to energy sources, referred to as biogas and green cokes, and wherein nitrogen is fixed in a fertilizer product in the form of ammonium nitrate, is provided, the process including the present nitrification process.

Owner:BEESTERZWAAG BEHEER

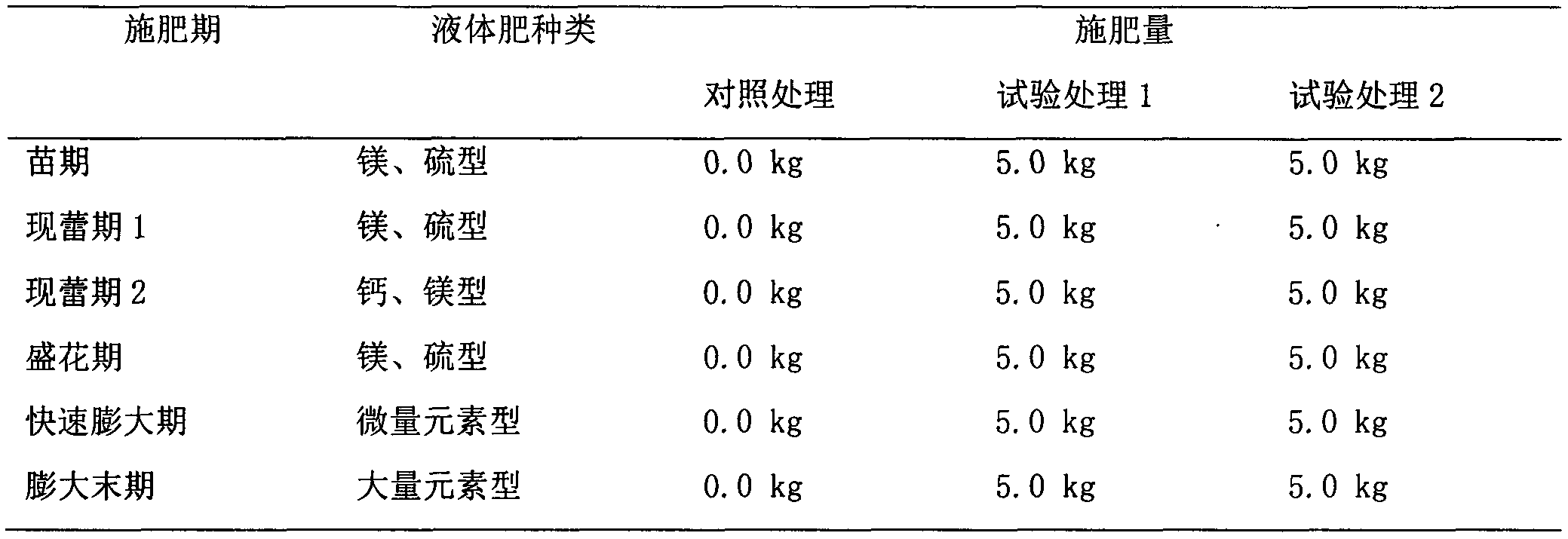

Cultivation techniques of cost-saving and yield-increasing winter-planted potatoes in southern China

InactiveCN102257917AReduce labor costsSave manpower andSeed and root treatmentFertilising methodsLiquid manureAgricultural engineering

The invention belongs to the technical field of culture of potato, and particularly discloses a cost-saving and yield-increasing culture technique for southern winter planting potato. The technique comprises the following steps of: selecting a land, preparing the land and furrowing; applying a base fertilizer; treating potato seeds; seeding; covering with soil; covering with a film; earthing up the film; managing liquid manure, weeds and insect pests; and harvesting, wherein a method of earthing up the film is that: a layer of smashed soil of 5-8 centimeters is covered on the film by using a machine or a hoe, so that the film on a ridge surface is covered fully. In the technique, an integral water manure furrow application method is used innovatively, so that the labor per acre is saved by 7 persons, and the acre yield is up to 9,136 jin. Due to the adoption of the technique, the increase in of the yield of potato is facilitated, the production cost is lowered, and the economic benefit of potato production is increased. On the aspect of technique, the process flow of potato production is completed, the production time of potato is shortened, and a solid technical foundation is laid for the popularizing scale, standardization and commercial production of the potato industry.

Owner:HUIDONG COUNTY JIUHUA FARMING & TRADING

Development method of special efficient fulvic acid liquid compound fertilizer for potatoes

InactiveCN103539575AHigh extraction rateEasy to operateOrganic chemistryFertilizer mixturesAntioxidantSurface-active agents

The invention provides a development method of a special efficient fulvic acid liquid compound fertilizer for potatoes. The special efficient fulvic acid liquid compound fertilizer comprises the following components in parts by weight: 1-10 parts of fulvic acid, 30-40 parts of major elements, 1-10 parts of secondary elements, 0.2-3 parts of trace elements, 2-12 parts of composite chelating agent, 1-2 parts of antioxidant, 0-1 part of surface active agent and 0-1 part of solution stabilizer. The development method mainly comprises the following production processes: extracting the fulvic acid by a hydrogen peroxide oxidation method, preparing fulvic acid-metal-chelating ions and preparing special liquid manure for the potatoes. According to the development method, the shortcomings of a few nutrient, unstable system and poor fertilizer effect of conventional liquid manure are overcome, and the special efficient liquid compound fertilizer for the potatoes, which is rich in fulvic acid, is provided for meeting the different nutrient requirements of the potatoes in different growth stages according to the unique botanic characteristics of the potatoes. The special efficient liquid compound fertilizer is simple in operation technology, scientific in formula, cost-saving and capable of effectively avoiding the waste of effective nutrients and substantially improving the yield and the quality of potatoes.

Owner:NANKAI UNIV

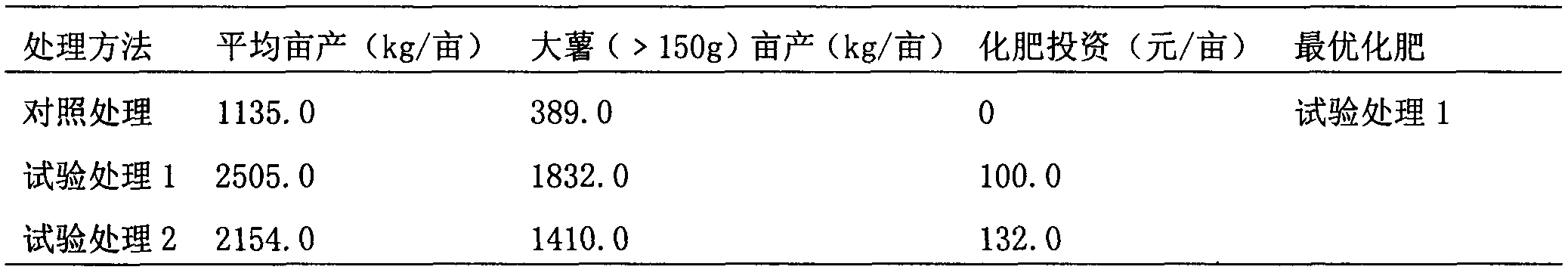

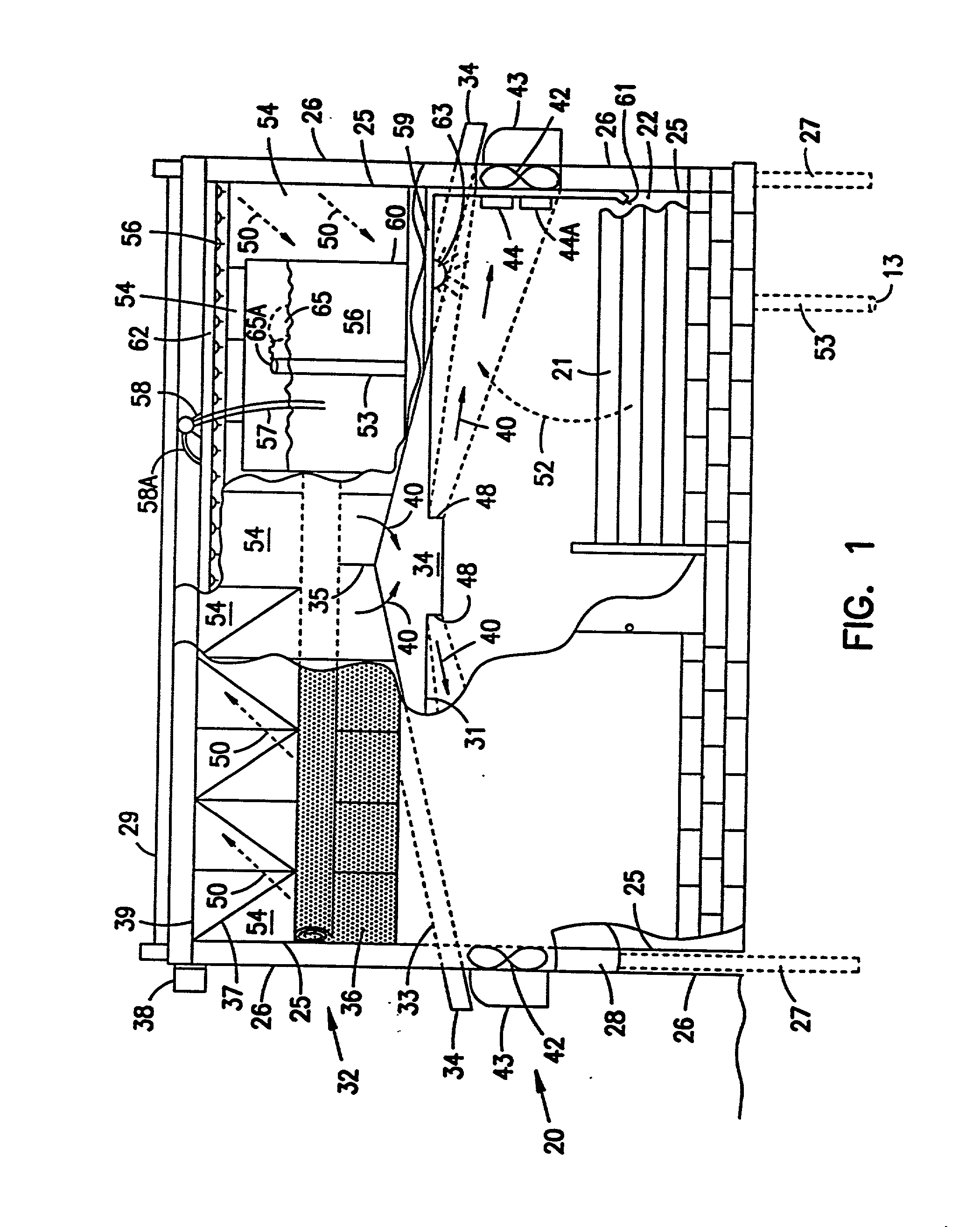

Method and apparatus for animal waste composting

InactiveUS20020046712A1Healthy and highly profitable pigsClimate change adaptationAnimal housingLiquid manureEngineering

A method and apparatus for composting animal waste. A system of gutters and conveyors collect liquid manure and urine and mix it with fibrous material such as ground corn stalks, ground cotton waste, ground peanut hulls, ground hay, or sawdust. The waste and fibrous material mixture combine to form a ground fibrous waste material or mash which is preferably transported up and down the length of the building by a pair of gutter blending conveyors located in central gutters below the service alley between two rows of pens. The mash is moved along by the gutter blending conveyors at a speed sufficiently slow so that composting can occur on a continuous basis. Animal carcases may be ground up and added to the mixture as it is composting, to dispose of the bodies.

Owner:ONE STEP THE

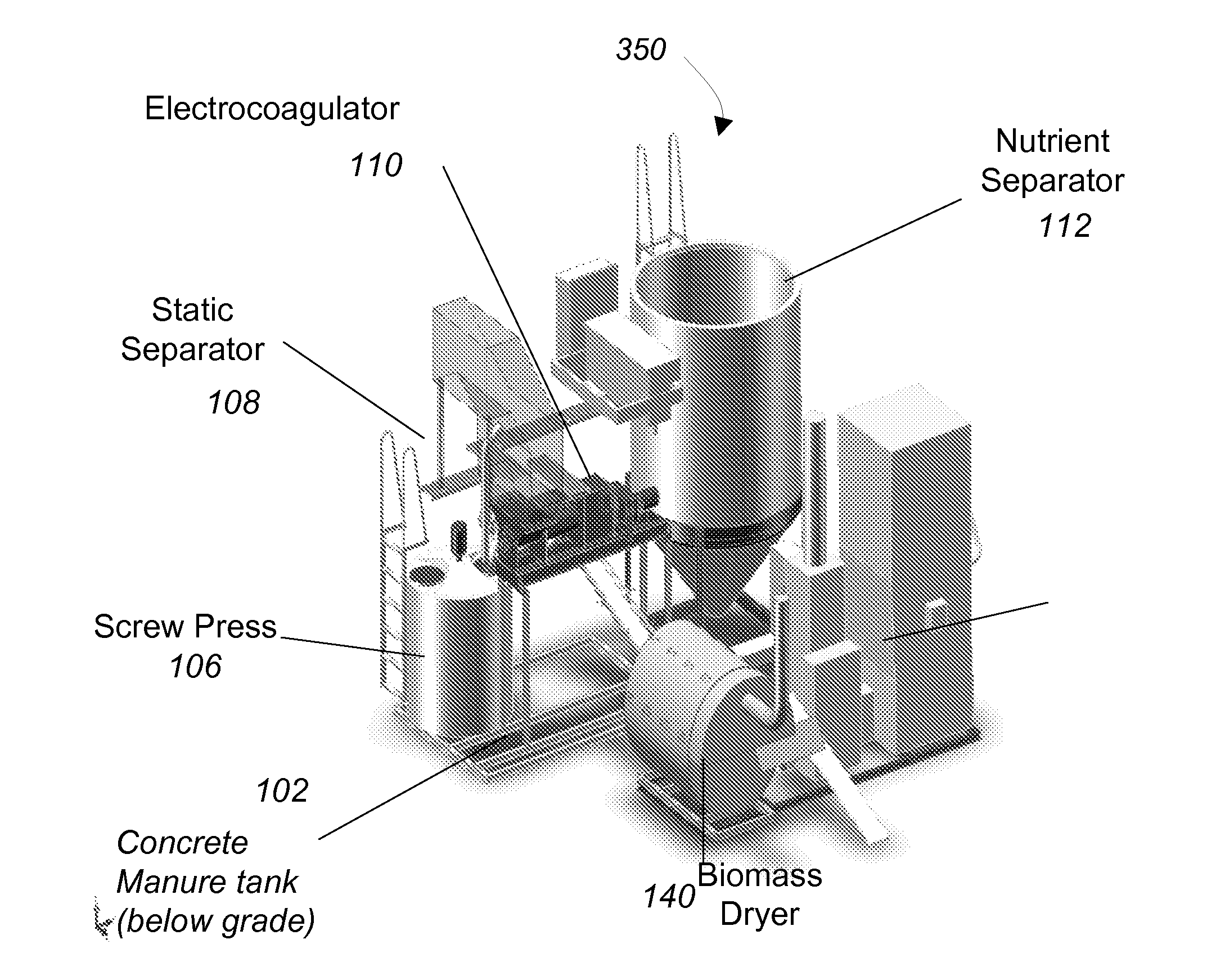

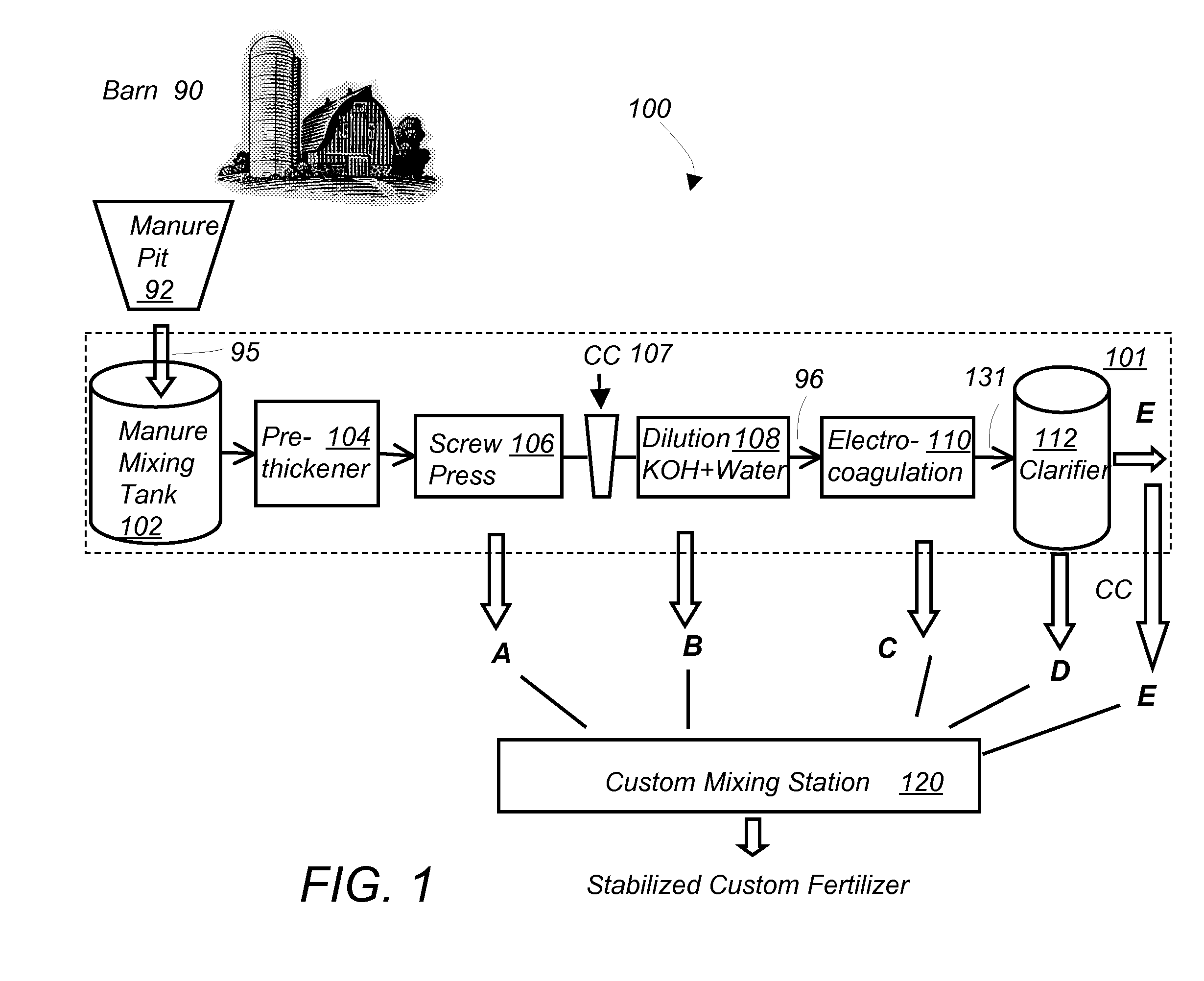

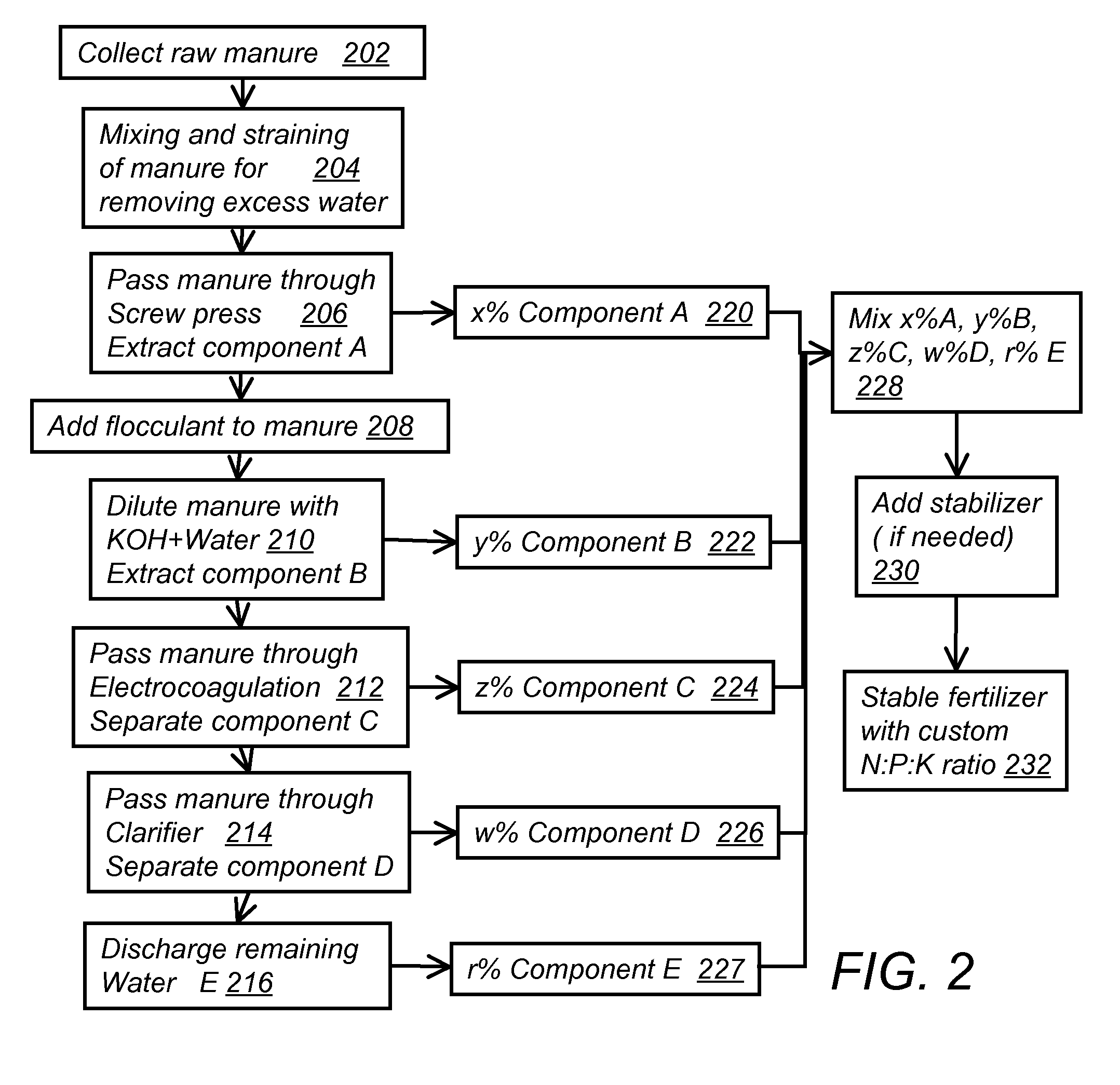

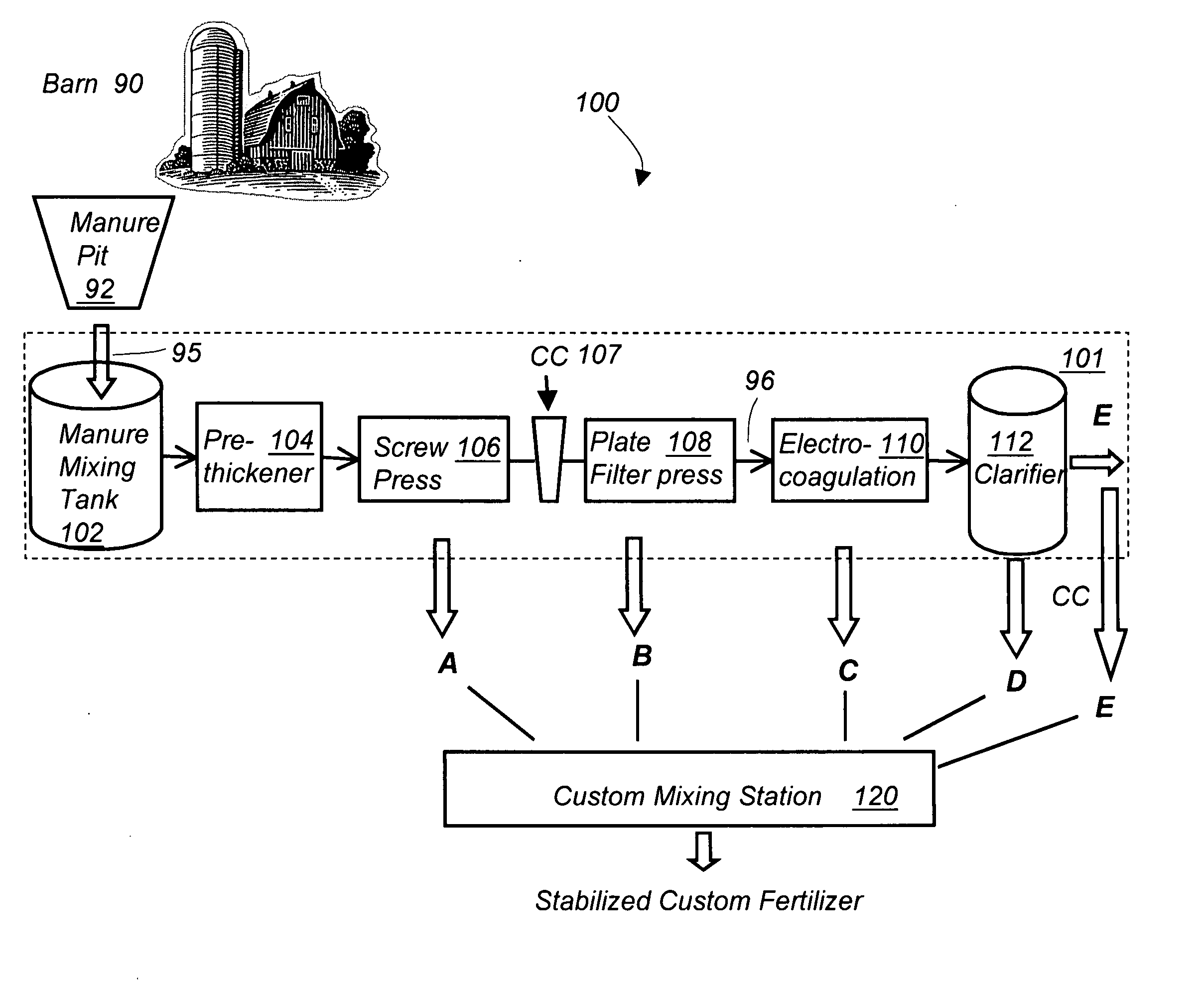

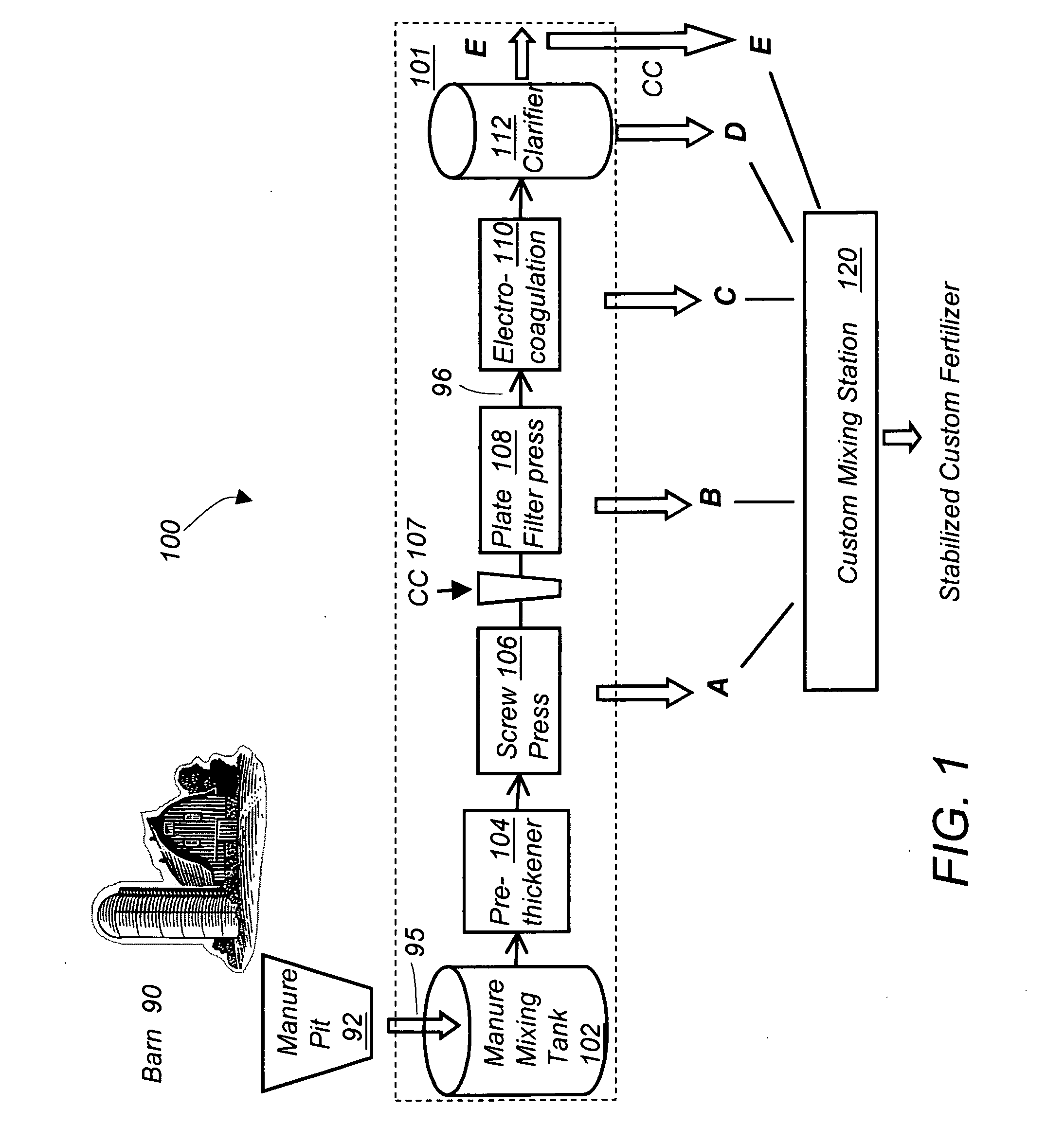

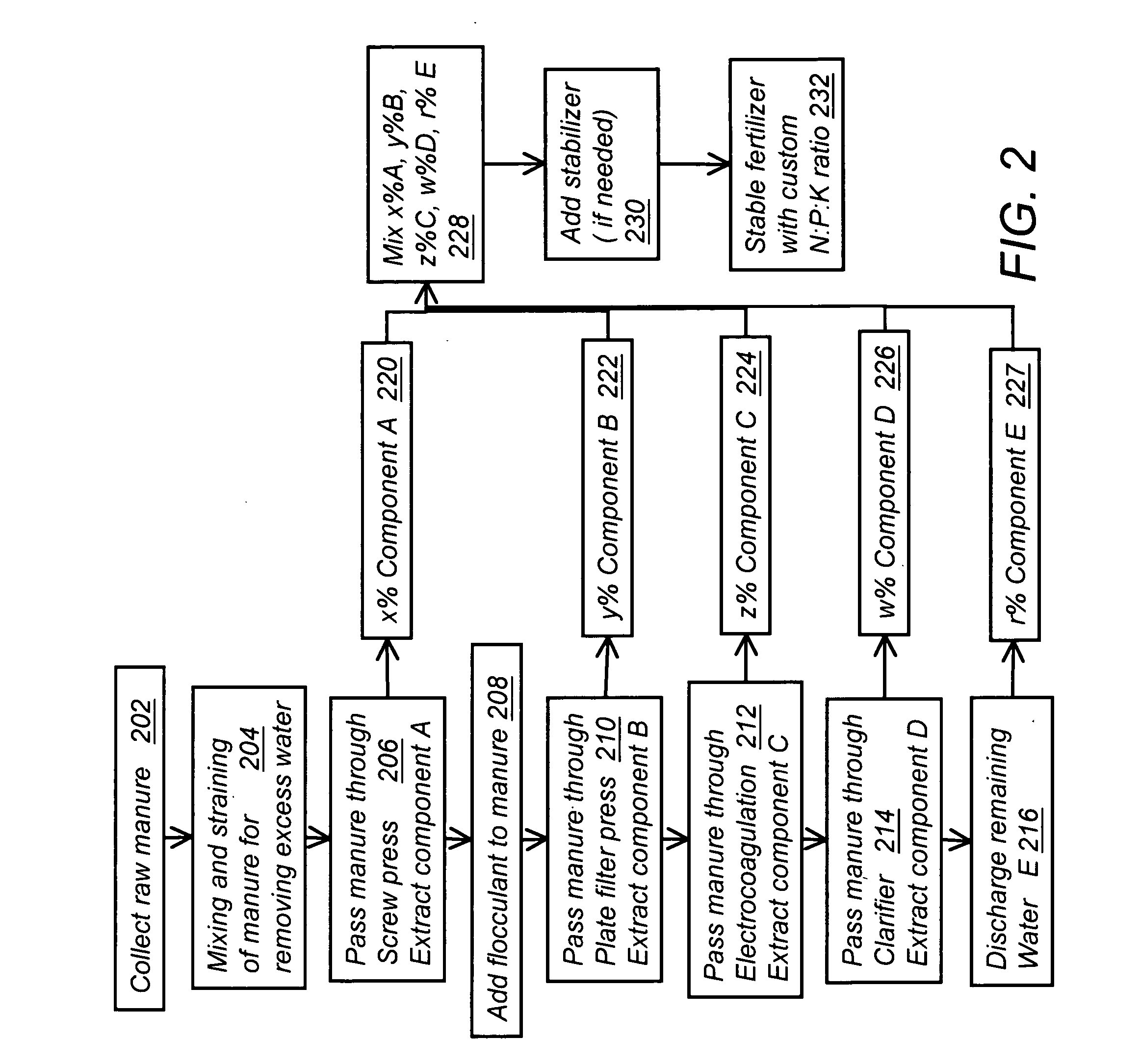

Optimized apparatus and method for manure management

InactiveUS20100199514A1Shorten the processing cycleLow costDrying solid materials with heatDrying solid materials without heatAgricultural scienceLiquid manure

An improved system for processing a liquid manure and producing organic fertilizer includes equipment for separating various solid components of the liquid manure having different nitrogen to phosphorous ratios and then mixing these components so as to produce an organic fertilizer with a predetermined nitrogen to phosphorus ratio. The system includes equipment for separating solid manure components and clarified water. Solid manure components include fertilizer, fodder / bedding material, and biomass. Fertilizer and clarified water are used to fertilize and irrigate the farming soil. Fodder is used as a bedding material for the animals or as a feed source. Biomass is used as a fuel source for running farming equipment and processes that require energy.

Owner:VERMONT ORGANICS RECLAMATION

Conditioner for quick desalination of coastal saline soil

InactiveCN101892056AImprove microenvironmentIncrease productionOrganic fertilisersSoil conditioning compositionsLiquid manureDesalination

The invention relates to a conditioner for the quick desalination of coastal saline soil, which comprises organic fertilizer, gypsum powder and polyacrylamide, wherein the application amount of the organic fertilizer is 5 to 10 cubic meters / mu, the application amount of the gypsum powder is 5 to 10 cubic meters / mu, and the application amount of the polyacrylamide is 1 to 1.3 kilograms / mu. Aiming at the special demands of sowing and seedling keeping in a coastal saline and alkaline area, the conditioner for the quick desalination of the coastal saline soil is developed, has the advantages of simple operation during use, local production of raw materials, low cost and quick desalination, can also be used for regulating the moisture and nutrients of the soil, maintaining water and soil nutrients, improving the soil and microenvironment of seeds and improving crop yield, and is a novel nontoxic conditioner for soil liquid manure.

Owner:INST OF AGRI RESOURCES & REGIONAL PLANNING CHINESE ACADEMY OF AGRI SCI

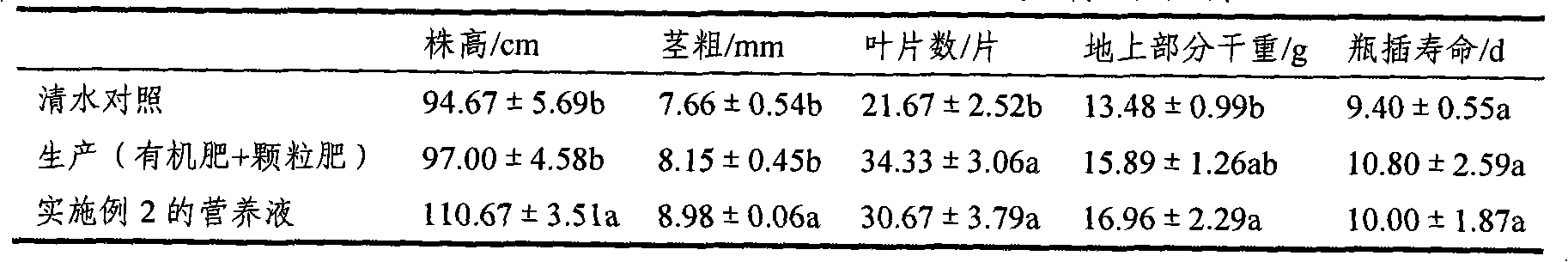

Lilium Sorbonne soilless culture nutrient solution, preparation method and application thereof

ActiveCN101941858AReduce the amount of applicationImprove utilization efficiencyAgriculture gas emission reductionCultivating equipmentsPotassiumPeat

The invention provides lilium Sorbonne soilless culture nutrient solution which is prepared by nitrogen, phosphorus, potassium, calcium, magnesium, iron, manganese, copper, zinc, boron, molybdenum and other nutrient elements according to the appropriate proportion. The nutrient solution is applicable to a specific soilless culture substrate (the volume ratio of coconut peat: sand: perlite: vermiculite is 3: 3: 2: 2). The lilium Sorbonne soilless culture nutrient solution is designed against the specific lily variety of Sorbonne and can meet the demands on nutrition, simultaneously reduce the application amount of the nutrient elements, and fundamentally solve the phenomena that the nutrient solution used in the lily culture adopts the formula of the nutrient solution obtained by experiences or drawing lessens from other crops ever since a long time ago, thereby causing the excess nutrient and causing the great waste during the production. The lilium Sorbonne soilless culture nutrient solution can effectively improve the utilization efficiency of a liquid manure and simultaneously reduce the environmental pollution caused during the culture process of flowers and plants. The lilium Sorbonne soilless culture nutrient solution can further reduce the production cost under the premise of ensuring the quality of cut lily flowers and have obvious social benefits, economic benefits and environmental and ecological benefits.

Owner:BEIJING FORESTRY UNIVERSITY

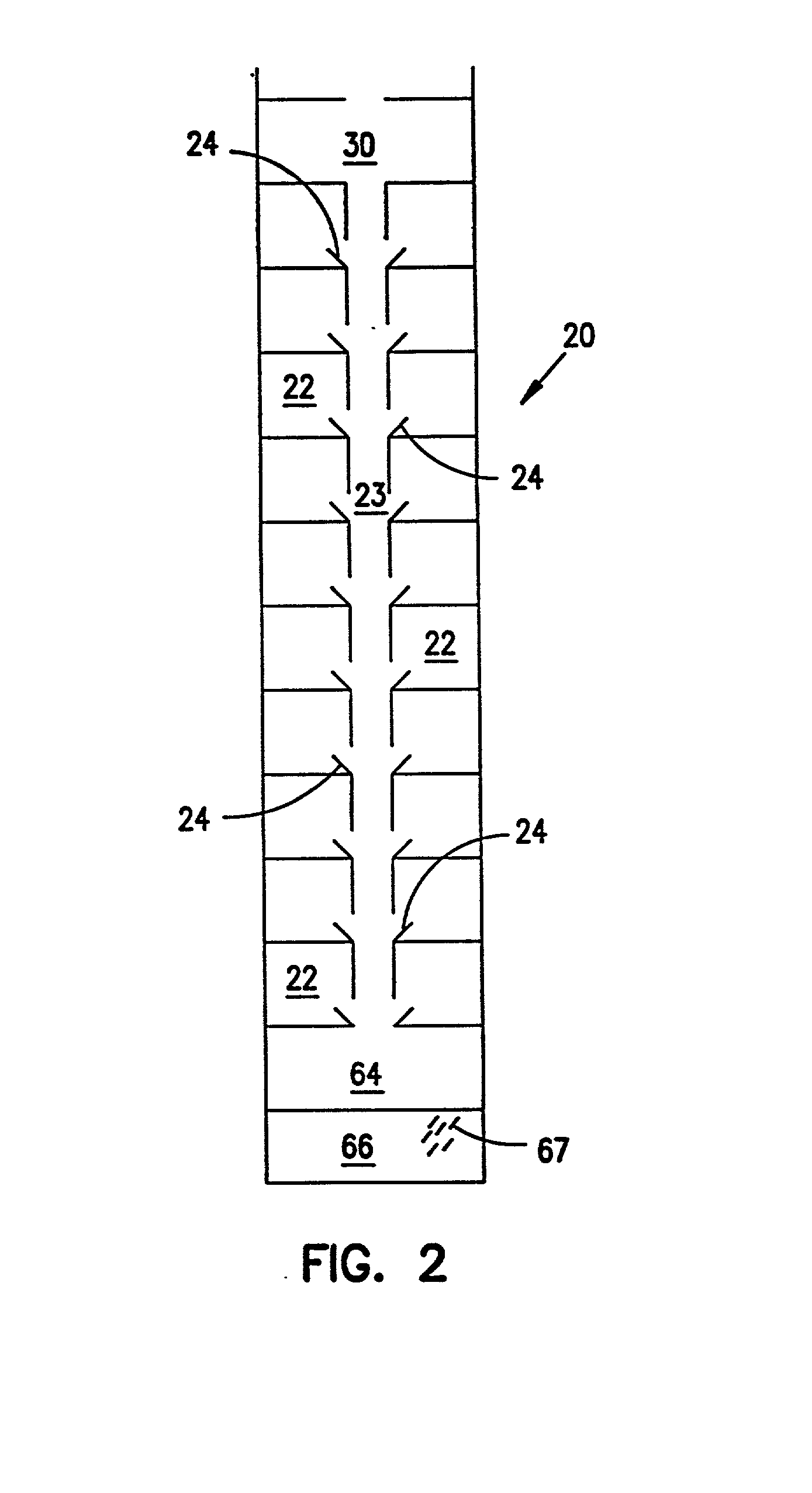

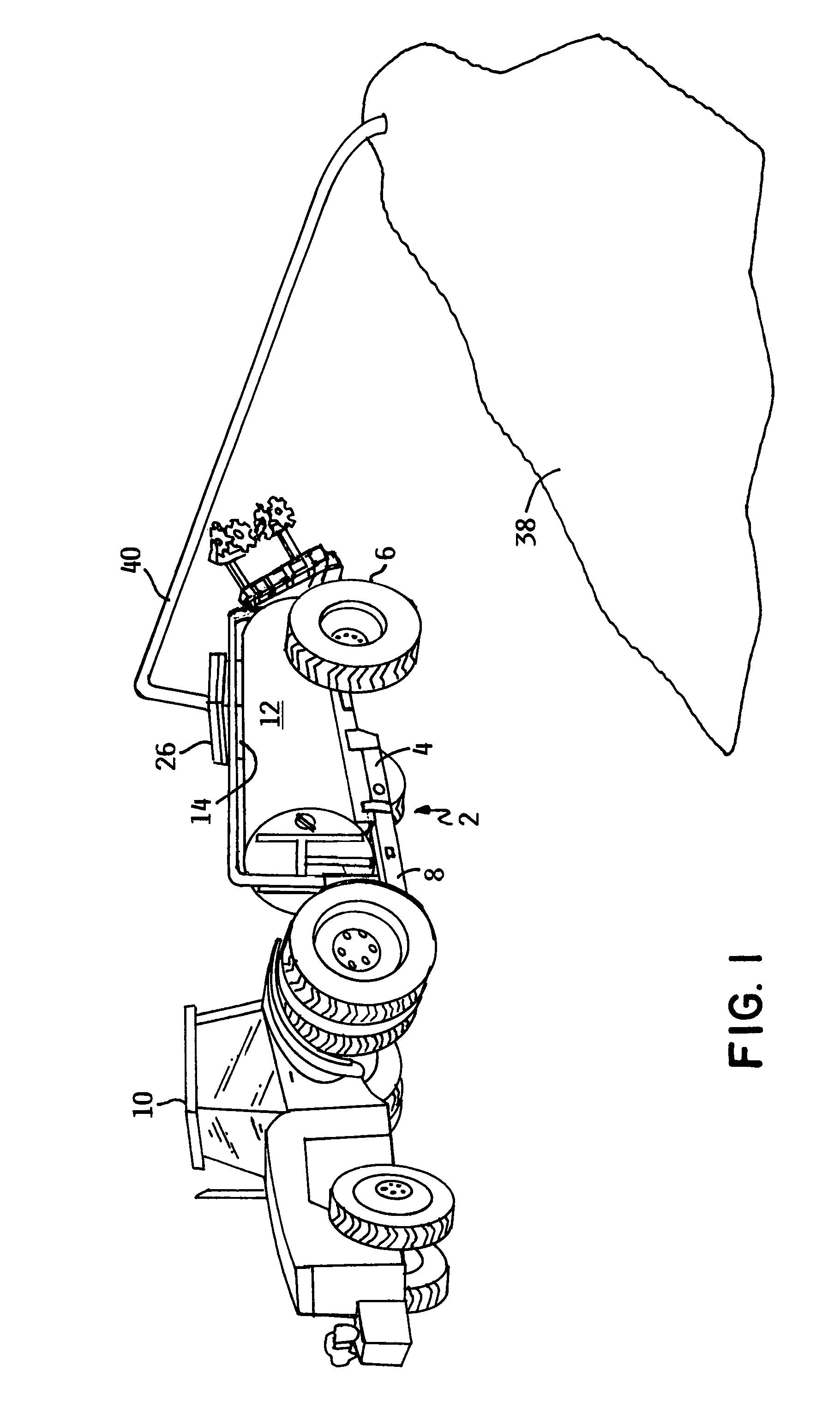

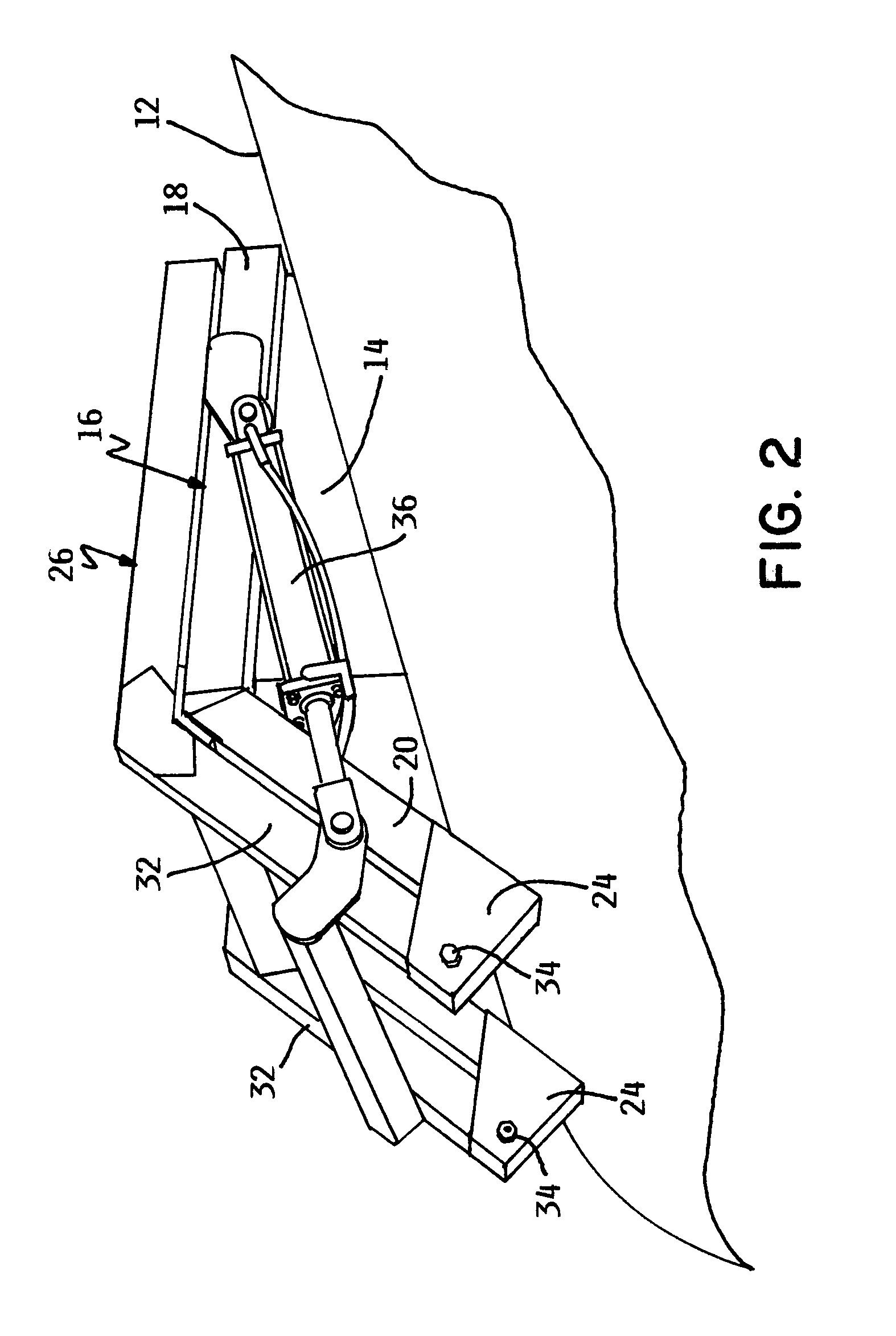

Liquid manure applicator, method, and tool with bellows type downforce system

ActiveUS7823807B1Downforce on armIncrease or decrease pressureBurnersManure treatmentLiquid manureDistributor

A liquid manure applicator comprises a tank for holding a supply of liquid manure that is distributed onto a farm field through a distributor having a plurality of distribution ports and hoses. The hoses lead to individual distribution tools that include a pair or rotary coulters and a bellows for applying downforce to the coulters. The distributor includes a ring that restricts the size of the solids entering the distribution ports and hoses to something substantially equal to or less than 50% of the cross-sectional area of the hoses. This prevents the hoses from plugging even when small diameter hoses are used to lower the application rates to values more consistent with the needs of a zone tilled field. A rotary chopper in the distributor reduces the size of larger solids until they have been broken up into pieces small enough to pass the restriction provided by the ring.

Owner:ENVIRONMENTAL TILLAGE SYST

Humic acid degradable liquid manure plastic film and production method thereof

InactiveCN101560123AReduce evaporationReduce churnOrganic fertilisersPlant protective coveringsGround temperatureEvaporation

A humic acid degradable liquid manure plastic film is characterized in that the components and content proportions by weight are as follows: 55% to 65% of humic acid, 4% to 6% of accelerant, 13% to 17% of stabilizing agent, 13% to 17% of film former, and 4% to 6% of water. The humic acid degradable liquid manure plastic film can reduce more than 30% of groundwater evaporation, the soil moisture content is increased by more than 20%, and the water preserving effect is good; the ground temperature of the soil 30 to 50 mm under ground is increased by 1 to 4 DEG C, the crop growth and development period is 3 to 10 days ahead, and the heat insulation effect is good; the fertility is added, and the content of humic acid in liquid plastic film is greater than 90%; the permeability is added, the soil volume weight is decreased by 6 to 10, the soil granulation amount is greater than 0.25, which is increased by more than 10.

Owner:李保华

Apparatus and method for manure reclamation

InactiveUS20060283221A1Low costEliminate needBiocideExcrement fertilisersLiquid manureElectrocoagulation

An improved system for processing a liquid manure and producing organic fertilizer includes equipment for separating various components of the liquid manure having different nitrogen to phosphorous ratios and then mixing these components so as to produce an organic fertilizer with a predetermined nitrogen to phosphorus ratio. The system includes equipment for separating a first manure component that contains about 15 percent soluble phosphorus and about 20 percent soluble nitrogen, equipment for adding a flocculant material to the liquid manure aqueous solution, equipment for separating a second manure component that contains about 40 percent partially soluble phosphorus and about 30 percent partially soluble nitrogen, equipment for performing direct current electrocoagulation cleaning of the liquid manure aqueous solution and separating a third manure component that contains about 45 non-soluble phosphorus and about 10 percent non-soluble nitrogen and equipment for performing clarifying cleaning of the liquid manure aqueous solution and separating a fourth manure component that contains about 40 percent non-soluble nitrogen and no phosphorous.

Owner:VERMONT ORGANICS RECLAMATION

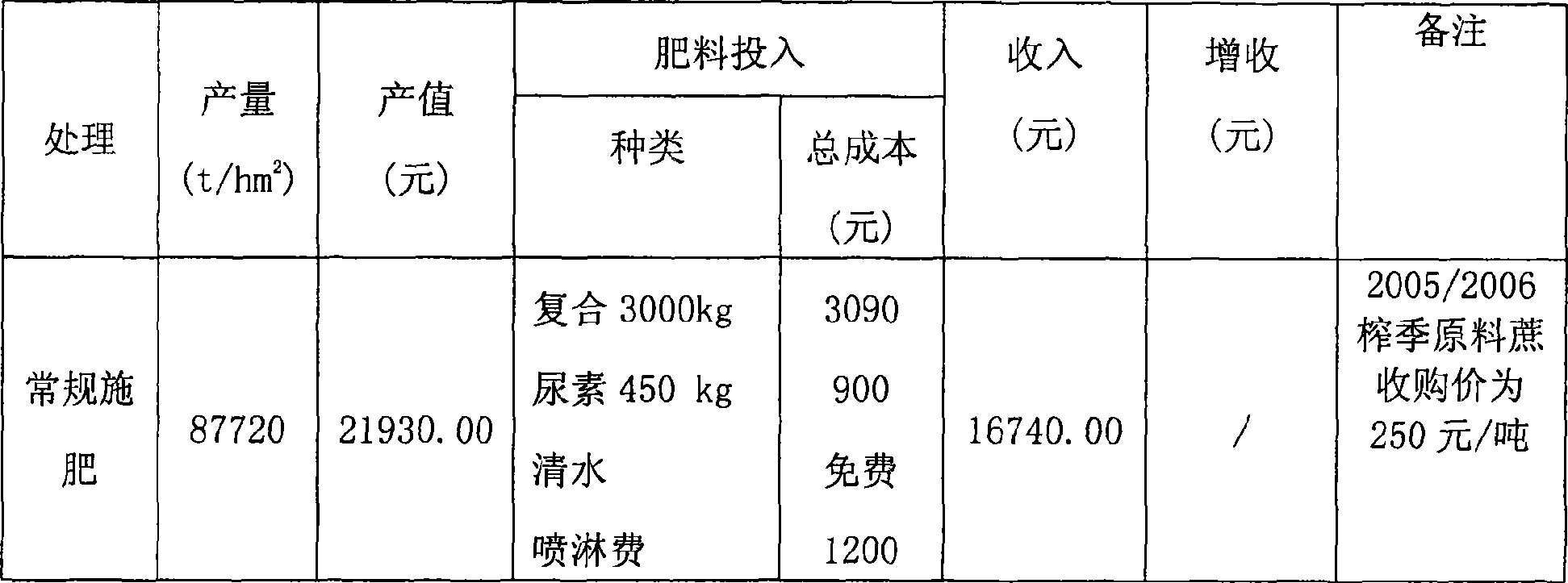

Method for using molasses alcohol fermentation liquid as sugarcane liquid fertilizer

InactiveCN101439994ASolve the problem of water and fertilizerSolve pollutionClimate change adaptationBioloigcal waste fertilisersHectarePlastic mulch

The invention discloses a method for using sugar-syrup alcohol fermentation liquid as a sugarcane liquid fertilizer. To apply the sugarcane liquid fertilizer to newly planted cane plants, the method comprises the following steps: diluting the fermentation liquid till the Baume degree reaches 6 to 8 and spraying the sugarcane liquid fertilizer in furrows for planting cane at a rate of 90 to 110 tons per hectare after the cane seeds are planted; covering a film on the next day after spraying operation and spraying pre-emergence herbicide; and removing the film after the stem pushing of cane seedlings and carrying out cultivating and hilling without applying any chemical fertilizer. To apply the sugarcane liquid fertilizer to stubble cane, the method comprises a step of diluting the fermentation liquid till the Baume degree reaches 8 to 10 and other steps which are the same as those used for newly planted cane plants. Using sugar-syrup alcohol fermentation liquid as a sugarcane fertilizer, the method solves the problem of pollution caused by sugar-syrup alcohol fermentation liquid of a sugar refinery and the problem of sugar liquid manure, recycles waste materials, increases soil fertility and improves production and yield of sugar. When applied at a rate of 45 to 105 t / hm<2>, a stock solution of the fermentation liquid can increase yield of sugar by 10 to 30 percent compared with the prior chemical fertilizer applied.

Owner:李杨瑞

Circulating system with integrated ecological cultivation, planting and liquid manure treatment

ActiveCN106688900AImprove pollutionImprove the quality of lifeBio-organic fraction processingExcrement fertilisersFecesCrusher

The invention discloses a circulating system with integrated ecological cultivation, planting and liquid manure treatment; fecal wastewater from a cultivation house in the system is discharged into a fecal wastewater collection tank and is then pumped into a solid-liquid separation station by a sewage pump, solid-liquid separation is carried out through a stainless steel mesh and gravels, solid extracted out via a solid-liquid separator is mixed with domestic waste to obtain organic fertilizer, the domestic waste is crushed with a crusher before the mixing, the separated liquid is charged into an underground permeation pipeline in a crop planting area and / or an economic forest planting area, the liquid is absorbed and purified by crops, the purified liquid is charged into an earthworm cultivation pond and permeates into a cultivation water tank, the water in the cultivation water tank is used for washing the house so that water resources are recycled, and biogas in the solid-liquid separation station is collected and stored for use. The circulating system of the invention has no emission of stinking gas, and allows resources to be recycled to achieve both pollution solving and economic income so that efficient cycle of economic development is finally achieved.

Owner:绵阳市自创科技有限公司

Manure treatment method in pig farm

InactiveCN103191904ASolve pollutionLow costBio-organic fraction processingSolid waste disposalPig farmsHuman waste

The invention discloses a manure treatment method in a pig farm. The manure treatment method comprises the following step of: separating the excrement of pigs into dry manure and liquid manure, wherein the dry manure is taken as a raw material for producing organic compound fertilizer and a fish feed respectively after being fermented; and the liquid manure is treated in two parts, one part is discharged into a biogas digester for producing biogas, the other part is sent into a settling pond for settling and disinfecting, and the liquid manure is used for cleaning pigpens after being subjected to settling and disinfecting treatment. The pollution problem caused by waste water of pig manure and urine is effectively solved, the treated pig manure and urine waste water can be applied to various related industries, and greater benefits are brought for farmers.

Owner:DEYANG CITY HONGGUO PLANTING & BREEDING DEV

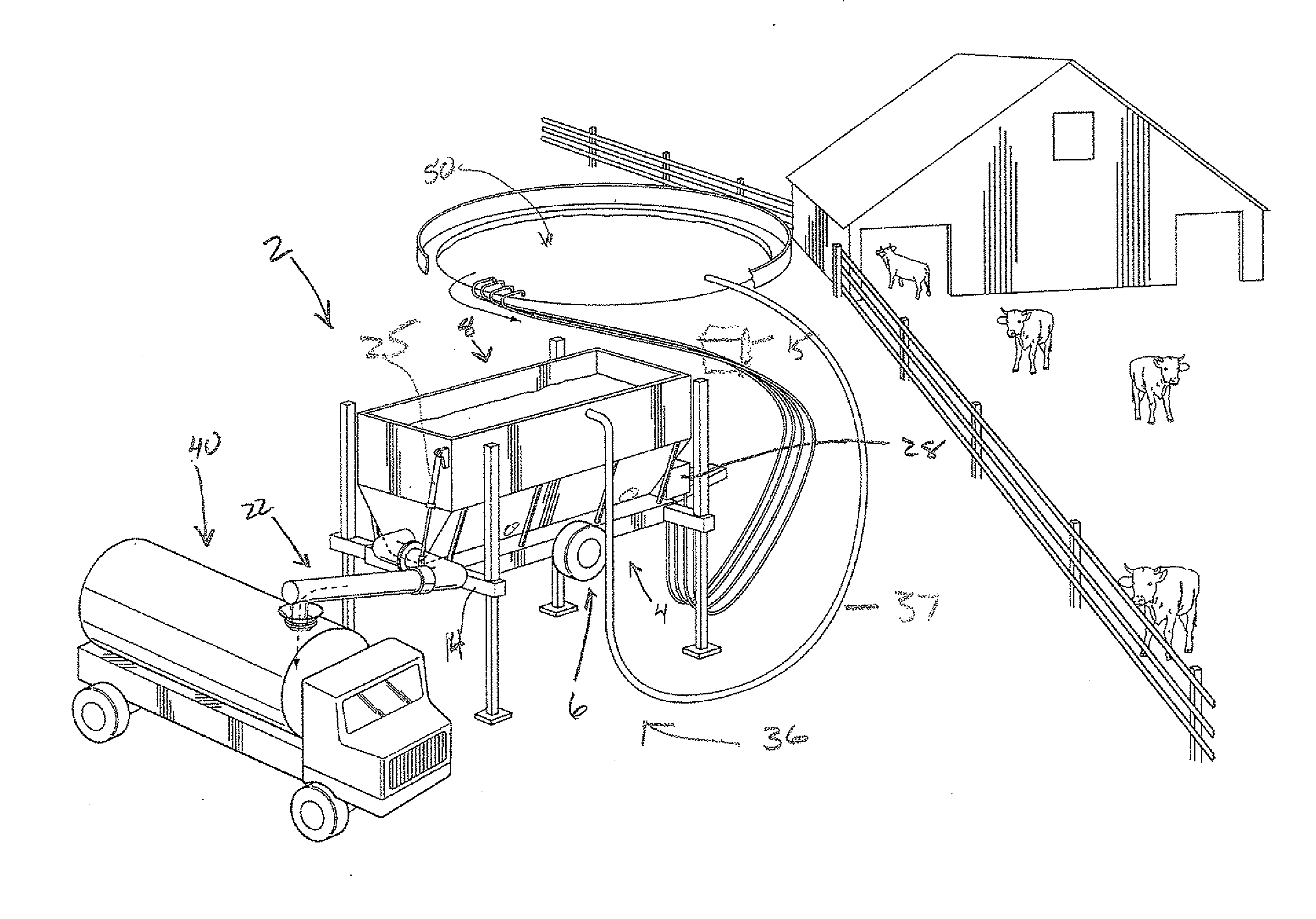

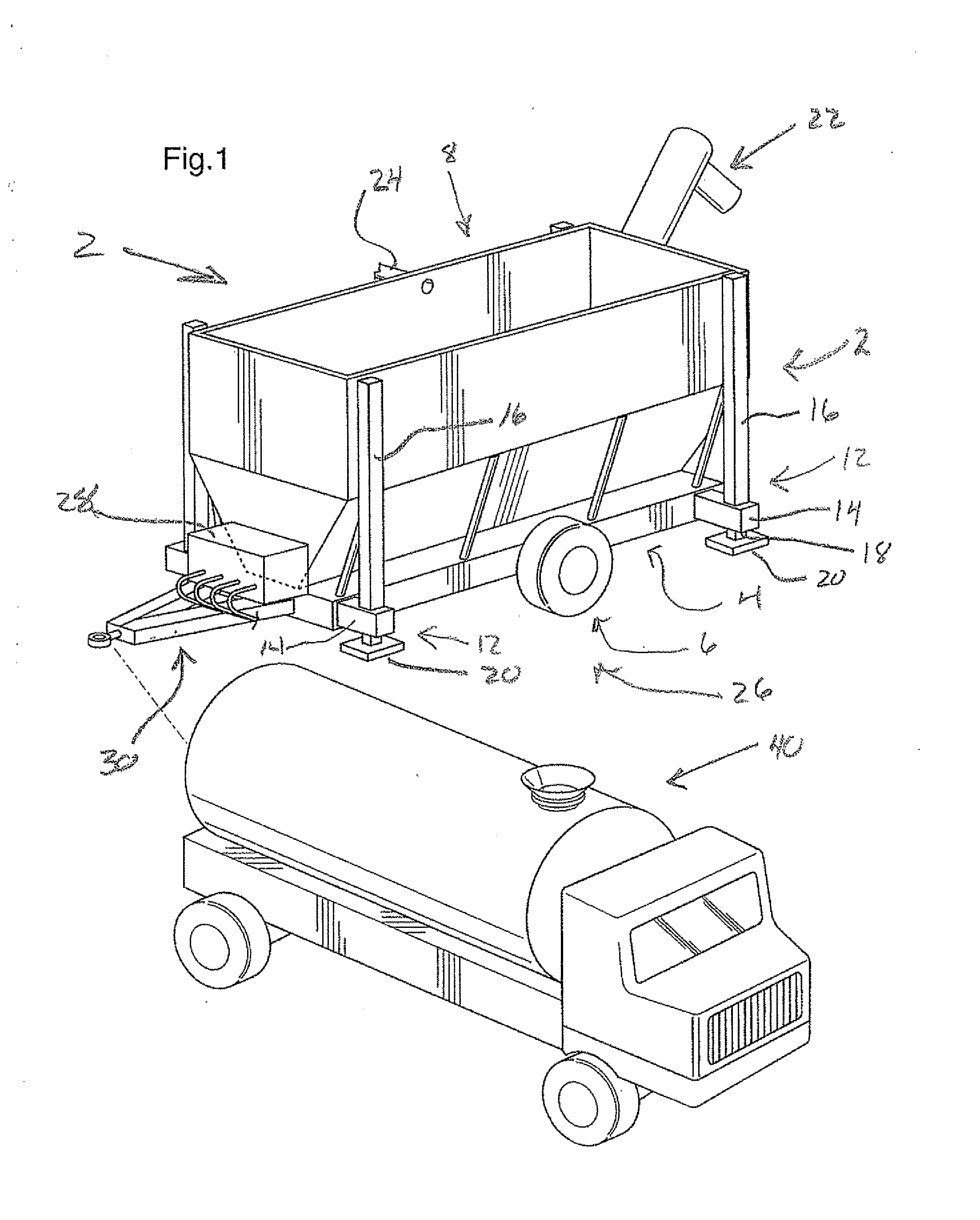

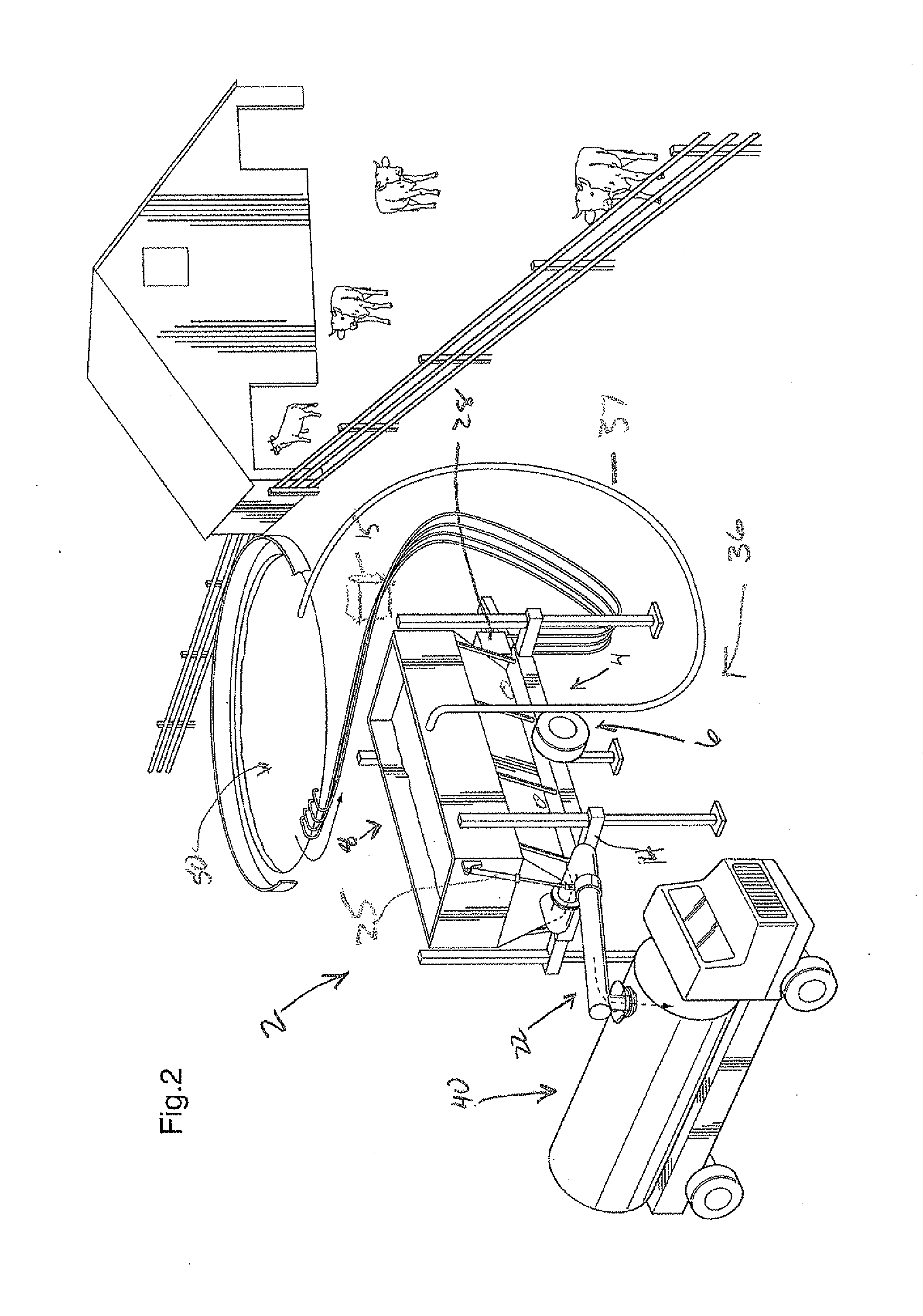

Mobile liquid waste loading system

InactiveUS20110220243A1Grow fastBarrels/casks fillingLiquid fertiliser distributionLiquid wasteLiquid manure

A mobile system for use in transfer of liquid waste reduces loading and / or unloading times required during transfer to a tank truck or transfer from a tank truck to other equipment such as spreading equipment. The system includes a transfer tank that is raised and lowered to provide improved transfer due to gravity assist. The tank is provided on a structural frame that includes a lifting arrangement for supporting the tank at least six feet above a ground position. Preferably the structural frame is part of a trailer to allow convenient transport. The system has particular application for liquid manure transfer systems.

Owner:FERTHAUL CANADA

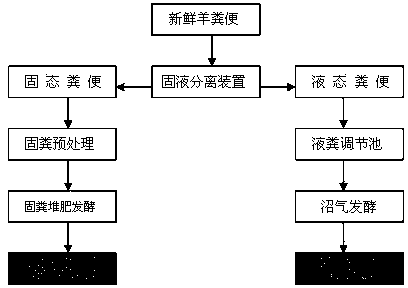

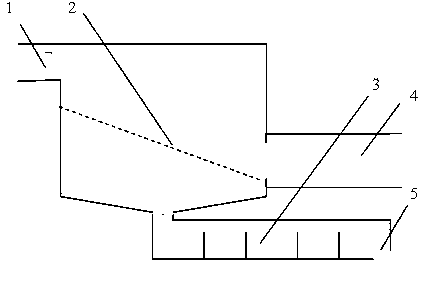

System and method for treating manure in sheep culturing farm

The invention discloses a system and a method for treating manure in a sheep culturing farm. The system comprises a manure solid-liquid separator, an adjustment tank, a manure pre-treatment shed, a manure fermentation shed, a liquid manure conveying pipe and a methane tank. The method comprises the following steps of carrying out a solid-liquid separation process on fresh manure, transferring the solid manure to a composting fermentation field by manual or mechanical conveying, carrying out composting fermentation, transferring the fermentation products into an organic fertilizer processing factory, adding some components into the fermentation products to obtain a commercial organic fertilizer, transferring the liquid manure to the methane tank by a special pipe system, and carrying out fermentation, wherein the produced biogas slurry is used for fertilization in the neighbourhood by peasants and the produced biogas is used for the living of workers and the production in the sheep culturing farm.

Owner:SOUTHWEST UNIVERSITY FOR NATIONALITIES

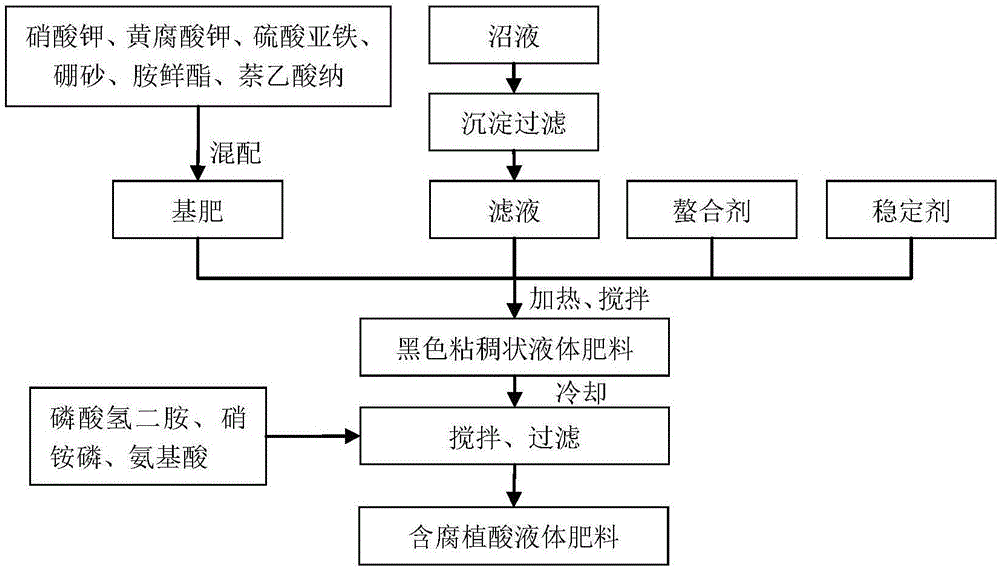

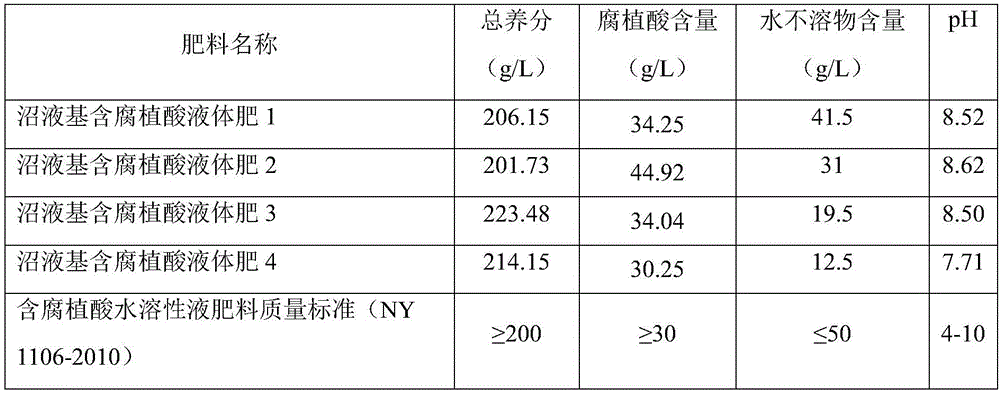

Method for using biogas slurry to prepare liquid manure containing humic acid

InactiveCN106518314AFull Quantitative UtilizationIncrease added valueAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersViscous liquidPhosphate

The invention discloses a method for using biogas slurry to prepare a liquid manure containing humic acid. The preparing method of the liquid manure containing the humic acid comprises the steps of uniformly mixing potassium nitrate, potassium fulvic acid, ferrous sulfate, borax, diethyl aminoethyl hexanoate and naphthaleneacetic acid sodium salt in proportion to obtain a base fertilizer containing the humic acid and major elements, uniformly mixing the base fertilizer, the biogas slurry, a chelating agent and a stabilizer in proportion, continuously heating and stirring the mixture to obtain a black viscous liquid manure, cooling the liquid manure and uniformly mixing the liquid manure with diammonium hydrogen phosphate, ammonium nitrate phosphate, and amino acid to obtain the liquid manure containing the humic acid. The liquid manure containing humic acid developed from the method can not only achieve full amount of use of the biogas slurry, and can also promote an additional value of the biogas slurry; meanwhile, the prepared liquid manure product is good in quality, and is high in content of the humic acid, content of nitrogen phosphorous and content of potassium; in addition, the liquid manure containing humic acid developed from the method has the advantages that the processing technology is simple in procedures and efficient.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

Liquid manure spreading apparatus

ActiveUS7744012B2Relieve pressureAvoid damageLiquid fertiliser distributionWatering devicesLiquid manureEngineering

This invention is directed to a device for applying slurry manure beneath the soil or on top of the soil with reduced crop displacement by a trailing feeder hose. More specifically, the invention is directed to an improvement of the prior art slurry reel system. The slurry reel system of the present invention places the axis of the reel spool parallel with the direction of travel instead of the conventional perpendicular orientation. This invention also utilizes a unique hose placement and retrieval apparatus or boom.

Owner:MANDERS WALTER J A +1

Peach tree fertilizer and preparation method thereof

InactiveCN103804099ANutritional diversityIncrease the granular structureFertilizer mixturesDiseaseLiquid manure

The invention discloses a peach tree fertilizer and a preparation method thereof. The formula of the peach tree fertilizer consists of the following raw materials in parts by weight: 18-22 parts of dry chicken manure, 10-14 parts of dry duck manure, 11-15 parts of dry pig manure, 28-32 parts of dry rabbit dung, 28-32 parts of plant ash, 8-12 parts of bone meal, 4-8 parts of bean pulp, 8-12 parts of monopotassium phosphate, 8-12 parts of urea, 1-5 parts of auxin, 8-12 parts of trichlorfon, 18-22 parts of phenolic resin and 4-8 parts of fennel powder. The preparation method comprises the following steps: uniformly mixing the raw materials, and smashing to 50-60 meshes; adding liquid manure, mixing uniformly by stirring, and piling; and covering with plastic cloth for fermenting twice to obtain the peach tree fertilizer. The peach tree fertilizer is wide in the raw material source and low in cost. The formula and the preparation method of the peach tree fertilizer are simple. The prepared peach tree fertilizer is comprehensive in nutrition, and the defects of small peach tree leaf area, low growing speed, poor development, withering and falling of leaves, poor fruiting, small fruits and easiness in casing various pest and disease damages due to unreasonable match of a conventional fertilizer are overcome.

Owner:张儒丽

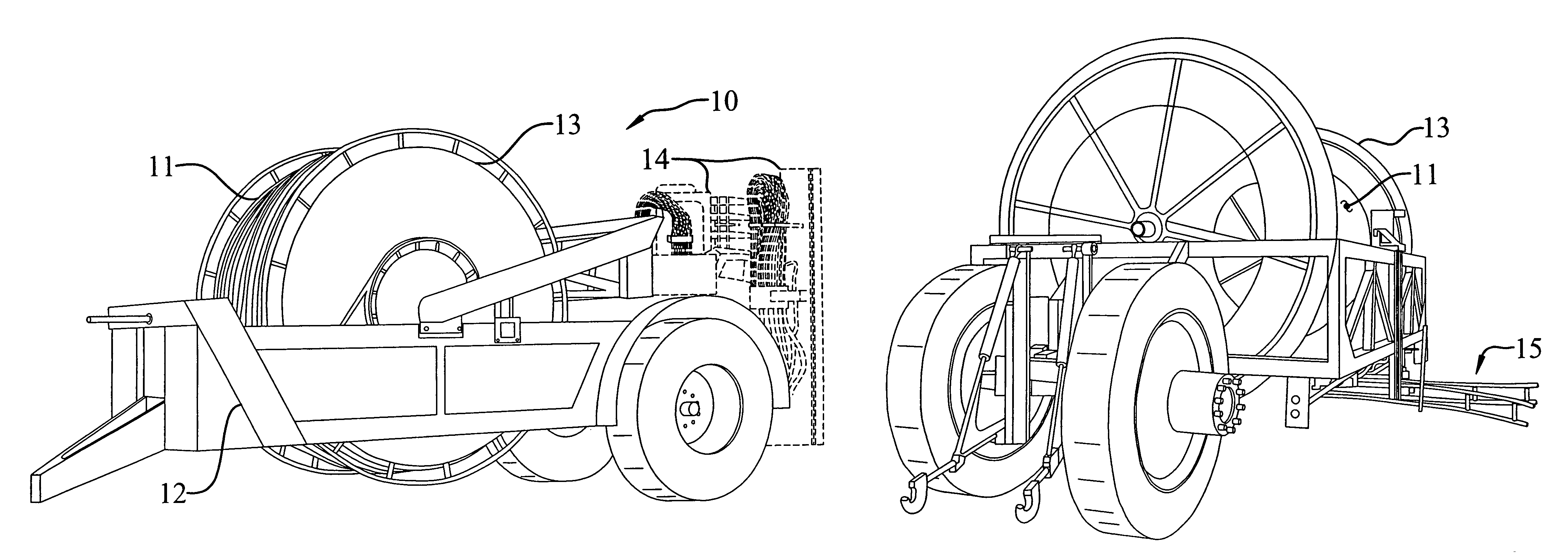

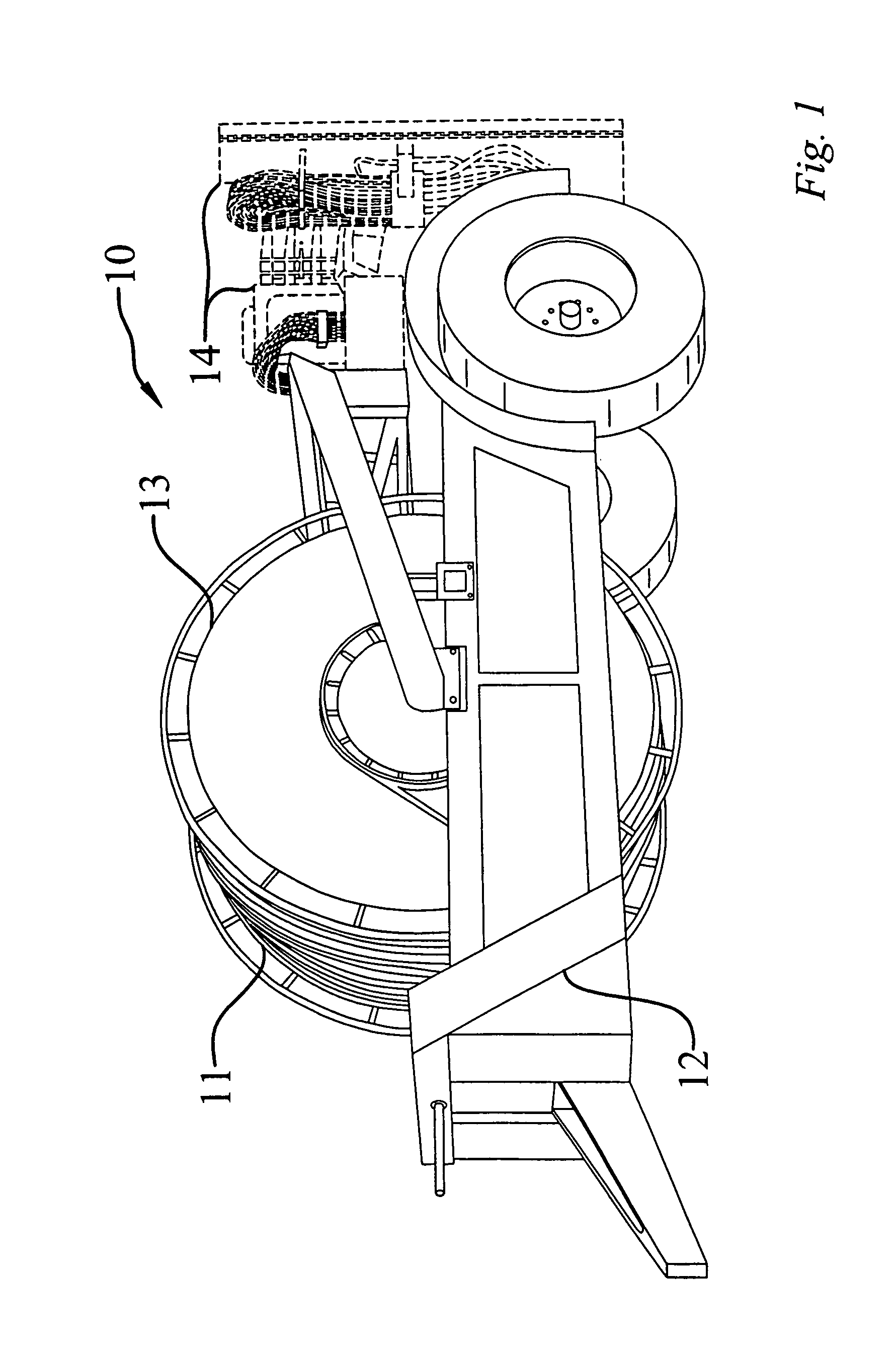

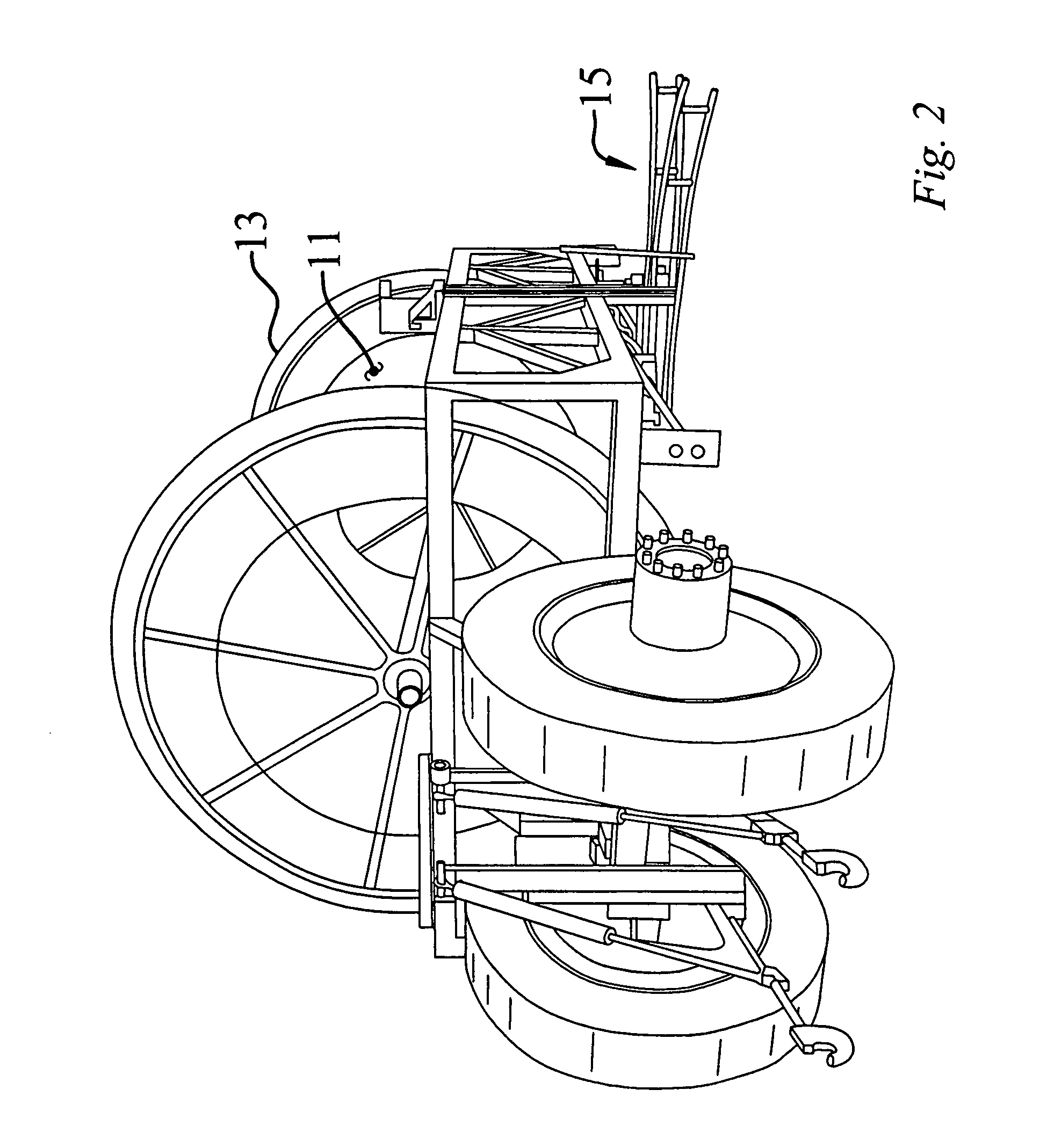

Hose reel system

ActiveUS7530521B2Efficient windingLow costLiquid fertiliser distributionTowing devicesLiquid manureEngineering

A hose reel system for winding a liquid manure hose. The hose reel includes a spool pivoted in alignment with the wheels and axles of the system to allow for even winding of the hose on a spool. The spool is provided with curved domes on either, end and a protective bar to prevent the hose from winding beyond the ends of the spool. Pivoting the spool in alignment with the axle allows for a more even winding and unwinding of the hose, thereby reducing torsion, kinks and other damage to the hose during the rolling and unrolling processes.

Owner:PUCK CUSTOM ENTERPRISES

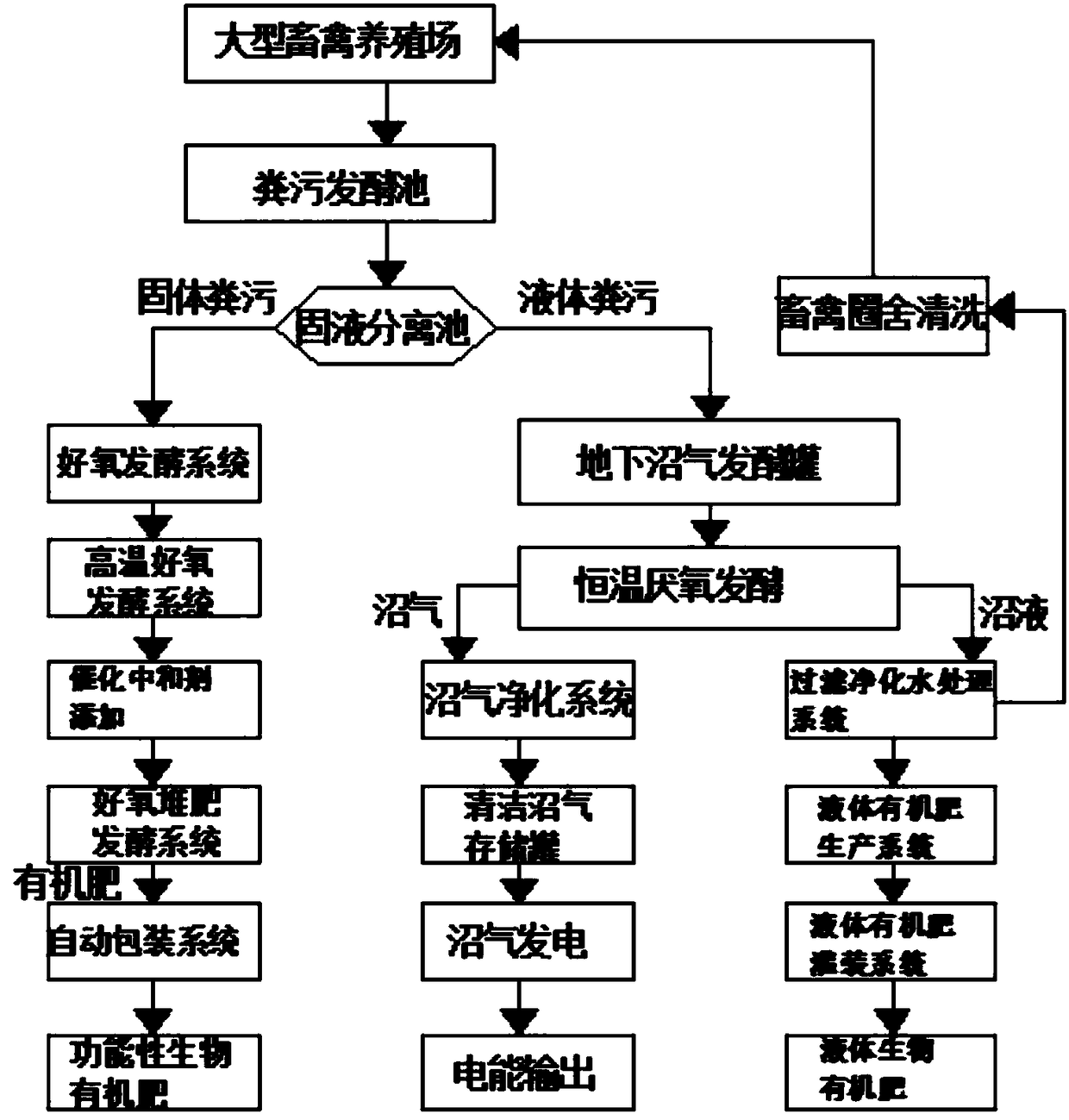

Method for harmless treatment and resource utilization of manure of large livestock and poultry

PendingCN108285363ACreate economic efficiencyProduction chain harmony and balanceCalcareous fertilisersBio-organic fraction processingElectricityLiquid manure

The invention discloses a method for harmless treatment and resource utilization of manure of large livestock and poultry. The method comprises the following whole technological process and method: separating solid manure and liquid manure of manure in a production field of a breeding farm of large livestock and poultry, then separately carrying out post-treatment to finally produce a functional biological organic fertilizer and a liquid biological organic fertilizer, and finishing energy source conversion by using biogas generated in the treatment process to generate electricity. According tothe method provided by the invention, separation and harmless treatment are carried out on the manure of the livestock and poultry, then the functional biological organic fertilizer and the liquid biological organic fertilizer are formed, and energy source conversion is finished by using biogas formed in the treatment process to generate electricity, so that harmless treatment and resource utilization of manure of large livestock and poultry are achieved, economic efficiency is created, the environment is protected, and the production chain of the nature is kept to be harmonious and balanced.

Owner:浙江泽华环保科技有限公司

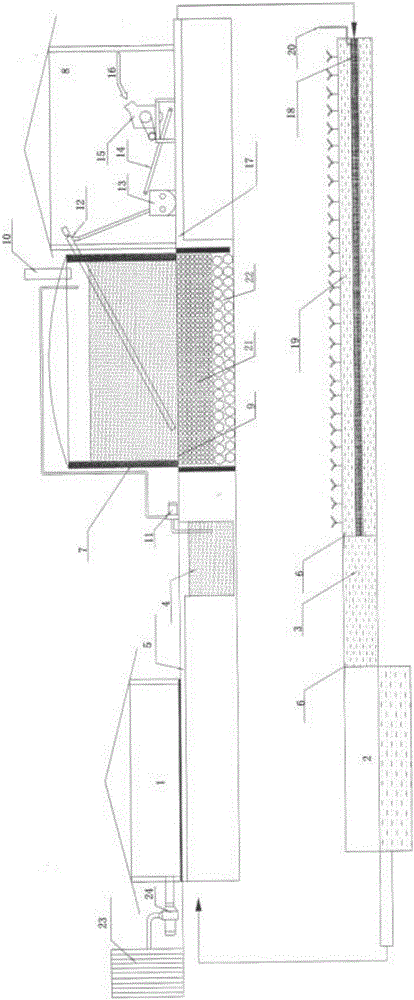

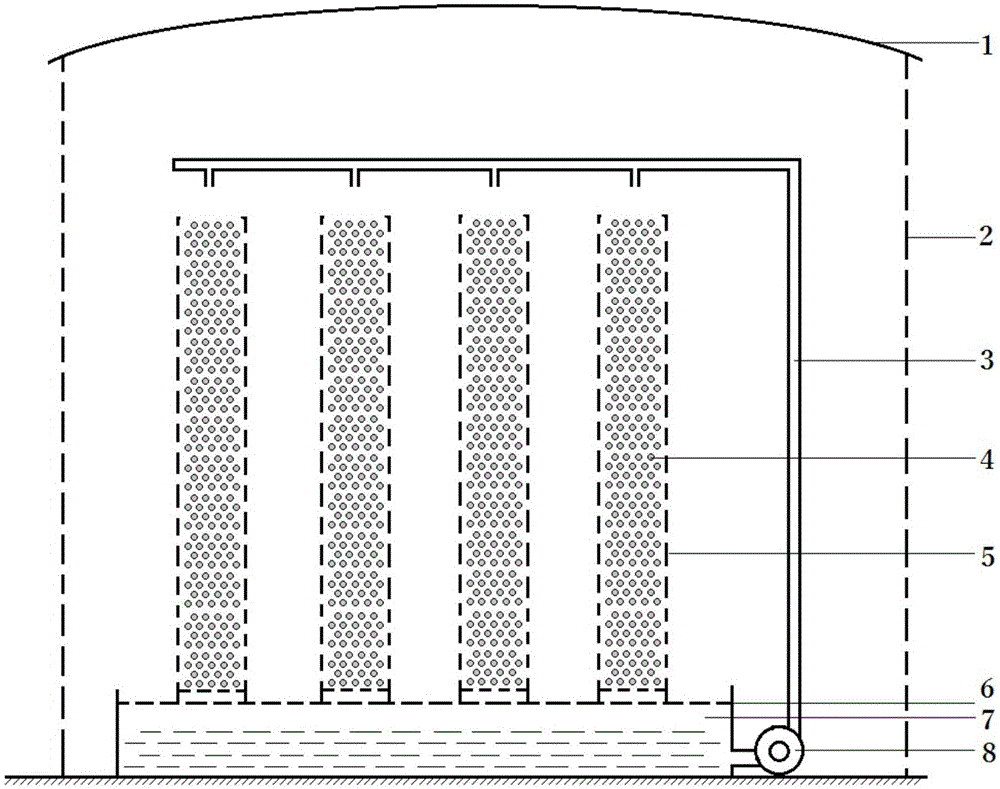

Farm liquid manure treatment system and method

InactiveCN105036836AIncrease the surface area for water evaporationIncrease the evaporation surface areaBio-organic fraction processingOrganic fertiliser preparationWater vaporTreatment field

The invention discloses a farm liquid manure treatment system and method. The system comprises a treatment field shed body, a plurality of fermentation bodies, a liquid storage tank for storing liquid manure, a liquid distribution pipe and a sewage pump. The invention has the technical effects that liquid manure enters each fermentation body through the sewage pump and a water distribution pipe and is quickly decomposed and digested by microorganisms in padding in each fermentation body, water is evaporated through the side wall of each fermentation body, redundant sewage falls into the liquid storage tank through a leak board at the bottom of each fermentation body and is regularly sprayed into each fermentation body through a sewage pump and the liquid distribution pipe, and the processes are circulated. Fresh air can enter each fermentation body from the periphery of each fermentation body, thereby providing sufficient oxygen for microorganism growth, carrying away vapor and promoting sewage evaporation. The number of the fermentation bodies of the system can be correspondingly increased or reduced according to the liquid manure treatment capacity, the padding does not need to be raked, the investment and operation costs are low, the operation is simple, and regularly replaced padding can be prepared into high-quality organic fertilizer.

Owner:许道军

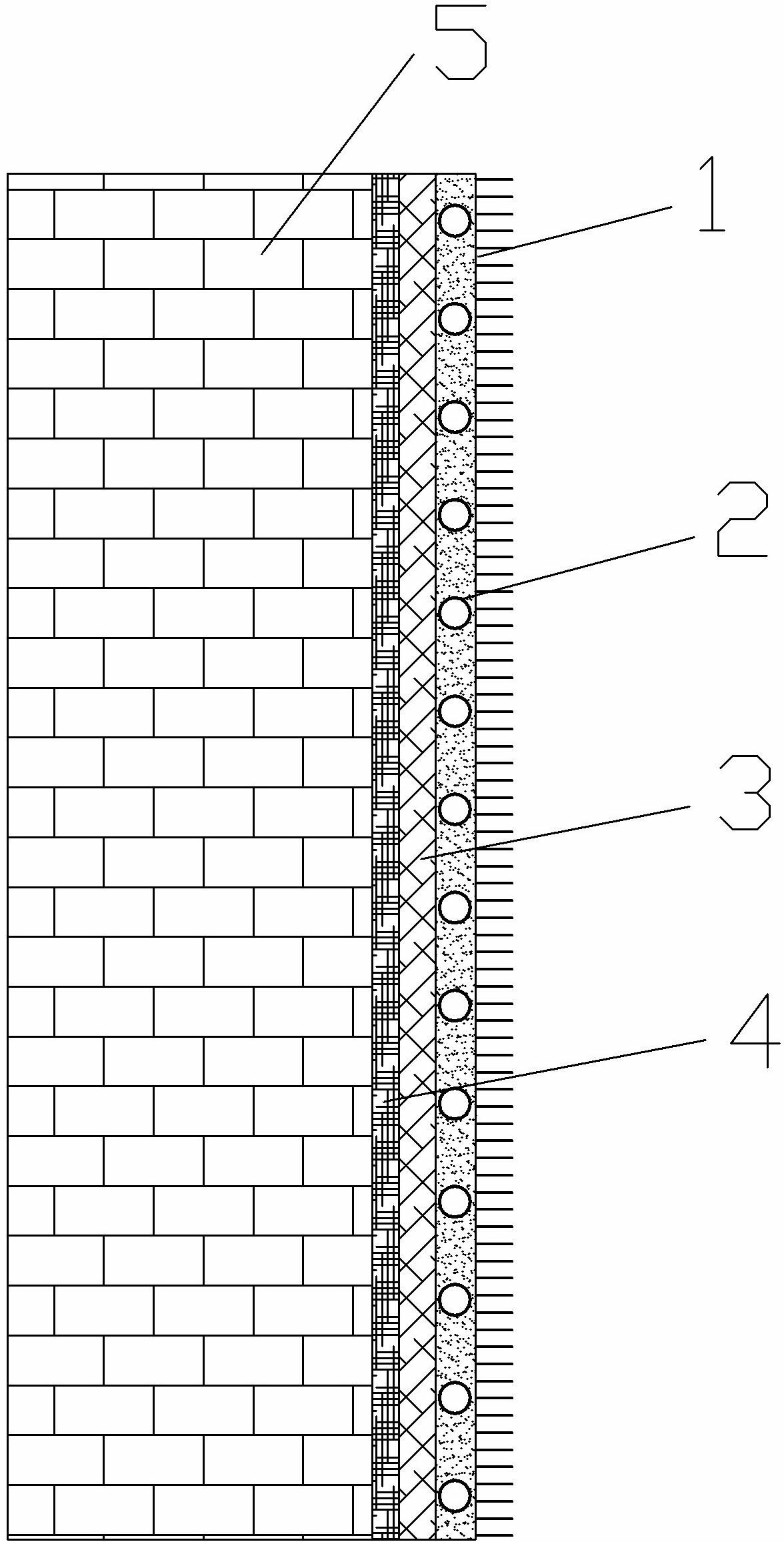

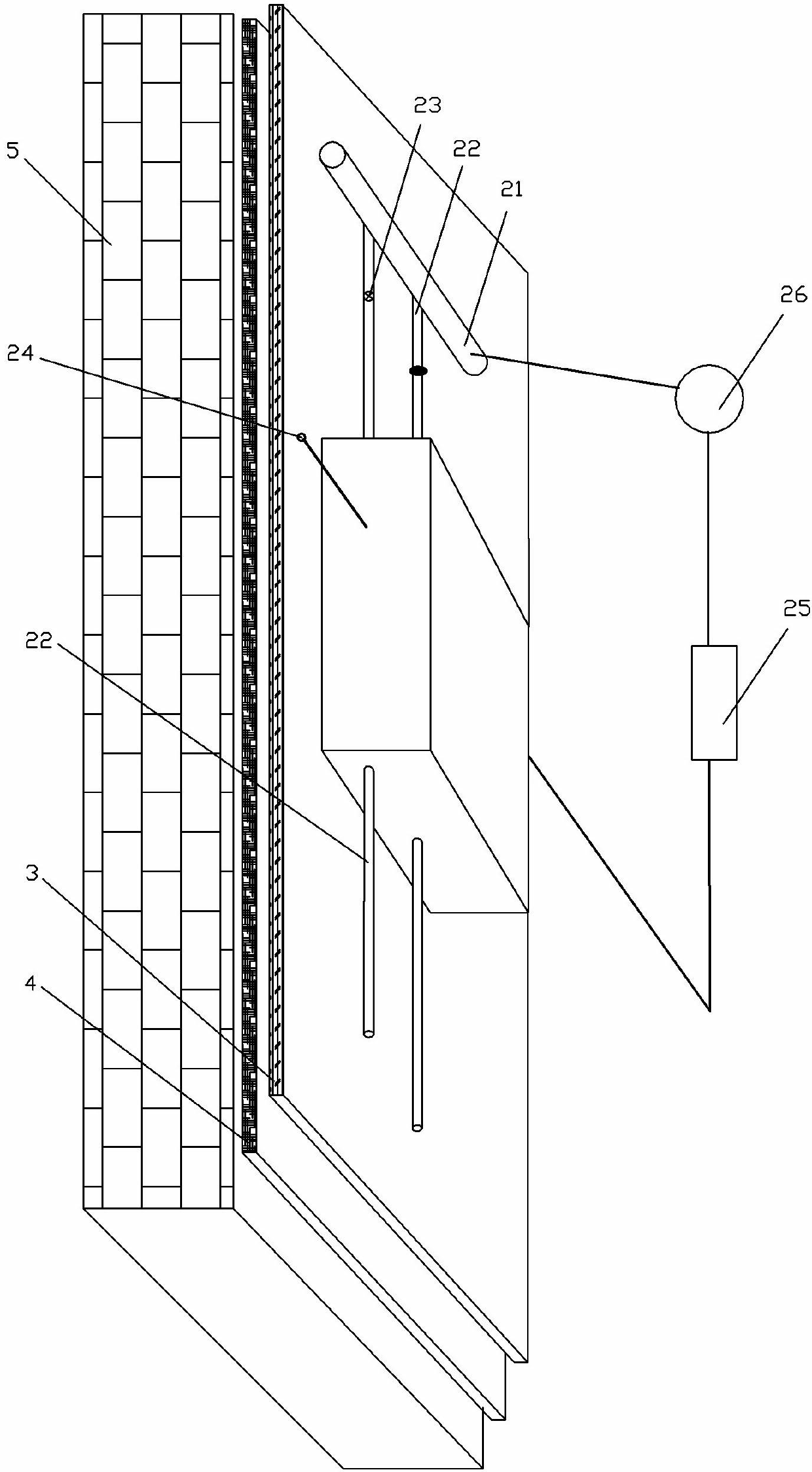

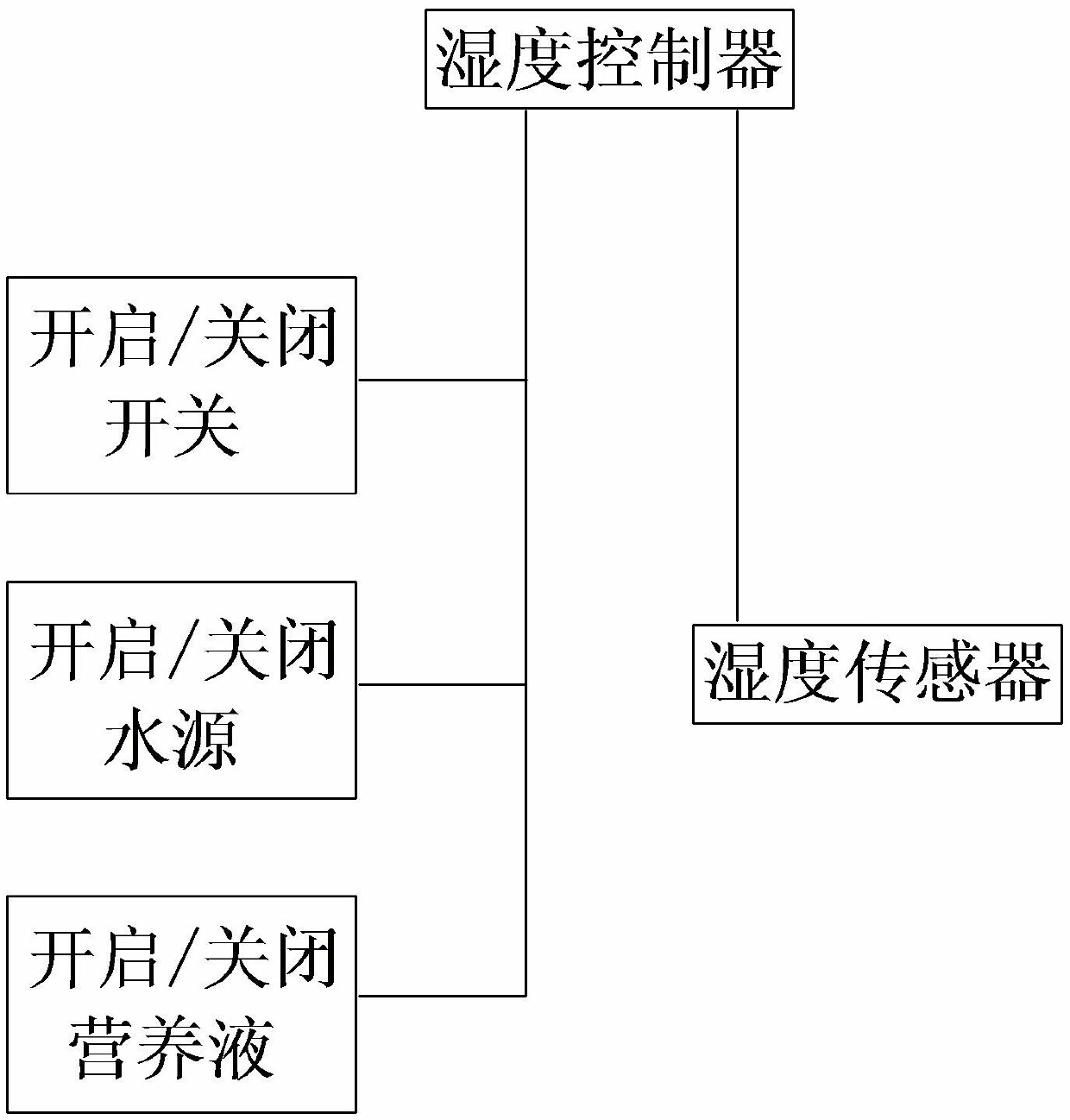

Three-dimensional greening structure for soilless lawn and construction method thereof

InactiveCN102165890ASimple structureSimple Quantitative ControlWallsClimate change adaptationWater savingLiquid manure

The invention relates to a three-dimensional greening structure for a soilless lawn and a construction method thereof. The three-dimensional greening structure for the soilless lawn comprises a waterproof layer laid outside a wall body, a fixed framework layer, a liquid distribution pipe network for spraying liquid manure to a soilless lawn layer and the soilless lawn layer from inside to outsidein turn, wherein the fixed framework layer is fixedly arranged on the wall body; and the soilless lawn layer is lapped and fixed to the outer side of the fixed framework layer. The construction method comprises the following steps that: the waterproof layer is laid on the surface of the wall body; the fixed framework layer is fixed with the wall surface of the wall body by a bolt, welding, a hook, a truss and the like; the outer surface of the fixed framework layer is connected with the soilless lawn layer; and the liquid distribution pipe network is arranged between the fixed framework layerand the soilless lawn layer. The three-dimensional greening structure has the characteristics of long service life (more than 10 years), low maintenance cost and the like, is simple, and convenient to install, increases a green looking ratio, has dust absorption and noise reduction effects and obvious water saving and energy conservation effects and is easy to popularize, and the liquid manure can be controlled simply, easily and quantitatively.

Owner:HENAN XIFANGE GREENING PROJECT

Spinach planting method

The invention belongs to the technical field of vegetable cultivation, and particularly relates to a spinach planting method. The spinach planting method comprises steps as follows: 1, determination of sowing time and varieties of autumn spinach: seeds are sown during August and September and can be harvested in batches after being sown for 30-40 days; 2, soil preparation and bedding: loose, fertile and subacid soil with water and nutrient retention functions and good irrigation and drainage conditions is preferably selected, and the pH (potential of hydrogen) value is 5.5-7; 3, sowing and seedling raising: broadcast sowing is generally adopted, the seeds are soaked for 12 hours one week before sowing in summer and autumn, then subjected to germination acceleration at the temperature of 20-25 DEG C and sown after germination in 3-5 days; 4, field management: diluted liquid manure is applied once after autumn spinach grow true leaves, additional fertilizers are applied in the principle that the concentration of the fertilizers is gradually increased in combination of thinning and weeding after two true leaves grow out, and more composted manure fertilizers are applied at the earlier stage; 5, control of diseases and pests: dimethoate which has the concentration of 40% and is diluted for 1000 times or pirimicarb which has the concentration of 50% and is diluted for 2000-3000 times is applied for controlling aphid; 6, timely harvesting: generally, when seedlings are 10 cm high or higher, the spinach can be harvested in batch.

Owner:李志刚

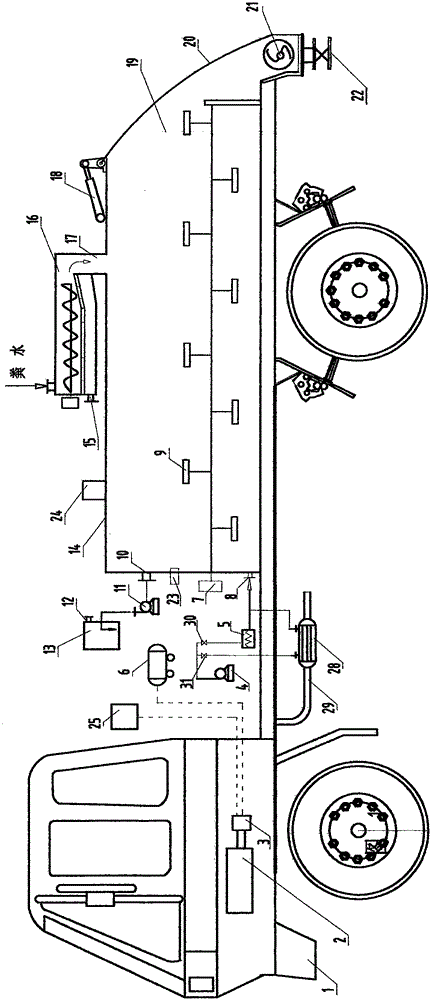

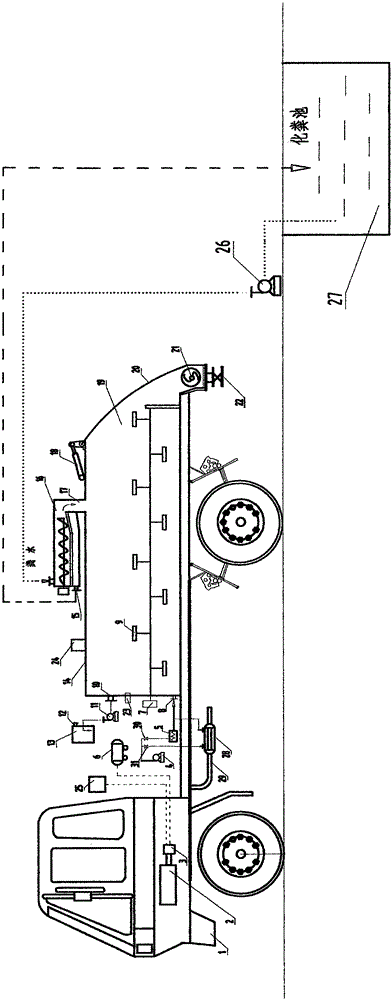

Method for solid-liquid separation of liquid manure and fertilizer making with manures and special vehicle

InactiveCN106364390AImprove efficiencyImprove resource utilizationBio-organic fraction processingClimate change adaptationLiquid manureResource utilization

The invention discloses a method for solid-liquid separation of liquid manure and fertilizer making with manures and a special vehicle. Particularly, at a position close to a toilet septic tank, solid-liquid separation of the liquid manure in the toilet septic tank is performed, the septic tank is dredged, solid manure is collected, and the collected solid manure is fermented to produce organic fertilizers, so that innocent treatment and resource utilization of the liquid manure are achieved. The invention further discloses the special vehicle for implementing the method.

Owner:周鼎力

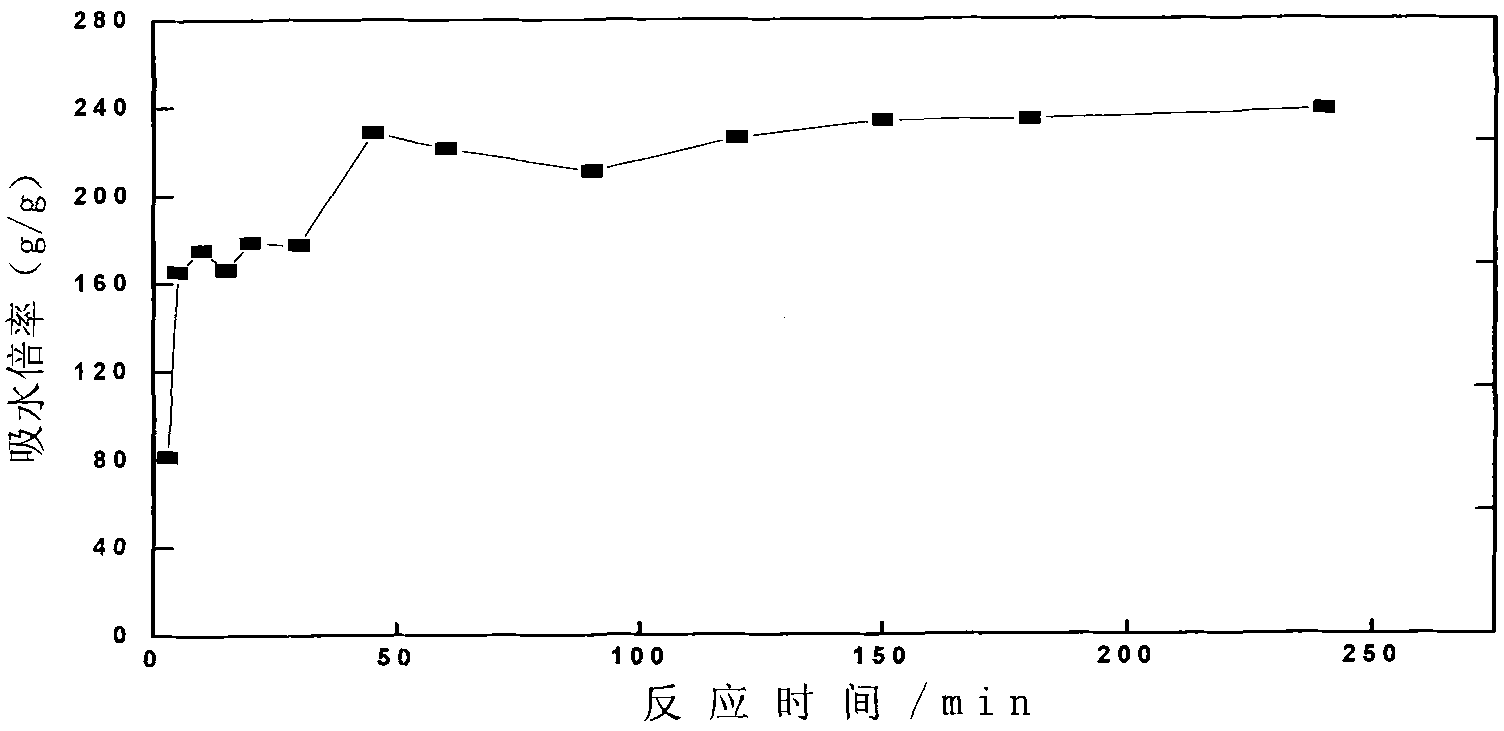

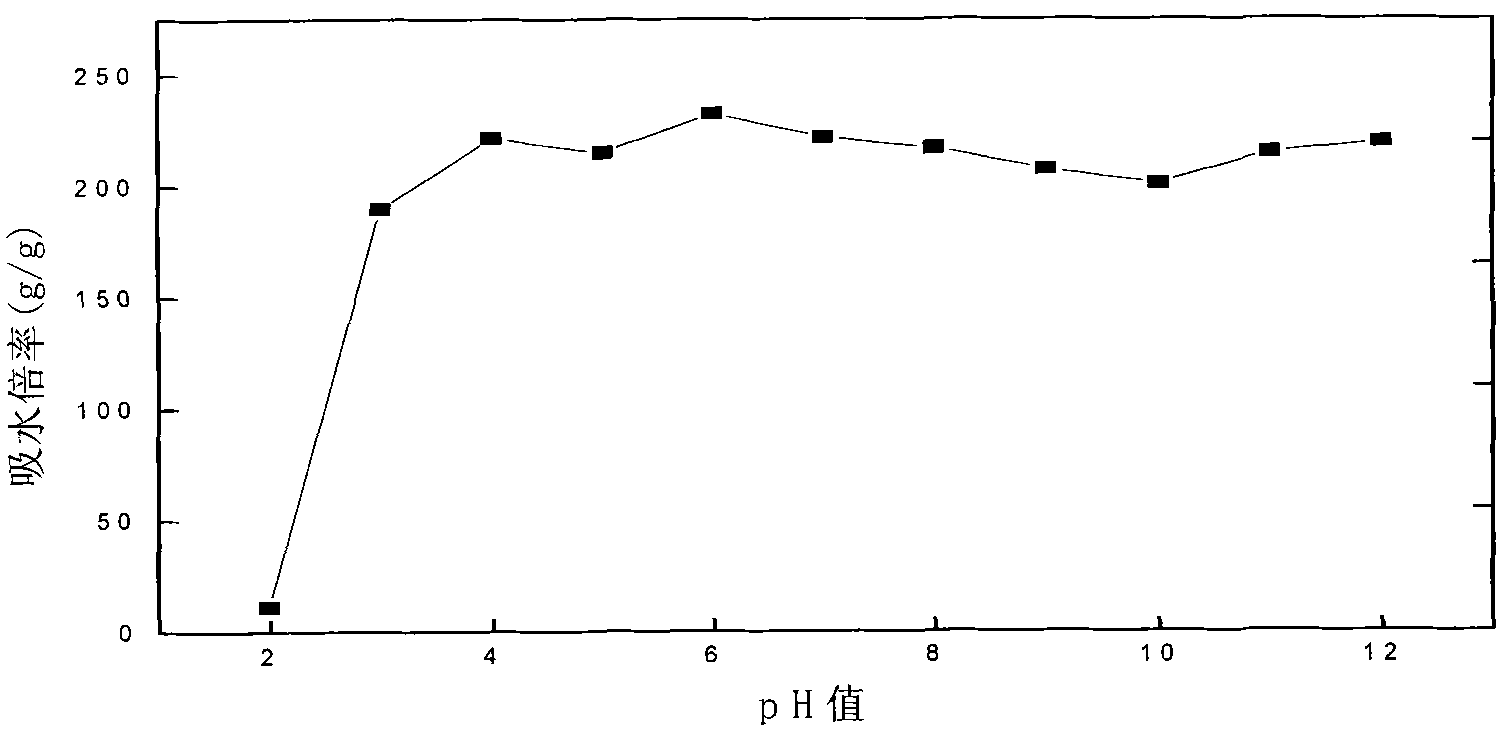

Straw-based amphoteric liquid manure controlled-release agent and application thereof

InactiveCN101838171AImprove water absorptionApplicable to a wide range of pHFertilizer mixturesCerium nitrateSulfite salt

The invention discloses a straw-based amphoteric liquid manure controlled-release agent, which is prepared under a condition that wheat straws, acrylic acid, acrylamide and dimethyl diallyl ammonium chloride are used as raw materials and persulfate, cerium nitrate amine and sodium sulfite as composite initiators. The straw-based amphoteric liquid manure controlled-release agent has the characteristics of high water absorbency, wide pH value application range, strong salty ion concentration adjustment, long useful substance storage time, biodegradability and low cost, is very favorable for liquid manure control, and can be widely applied to agricultural moisture maintenance and / or fertilizer maintenance. Simultaneously, a preparation method of the straw-based amphoteric liquid manure controlled-release agent has the advantages of simple and direct process, low cost, economical efficiency, practicability and the like.

Owner:SHANDONG UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com