Farm liquid manure treatment system and method

A technology of liquid manure and treatment system, applied in biological organic part treatment, organic fertilizer, preparation of organic fertilizer, etc., can solve the problems of insufficient treatment capacity, difficult treatment, high treatment cost, and increase the surface area of water evaporation and investment. And the effect of low operating cost and increased water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

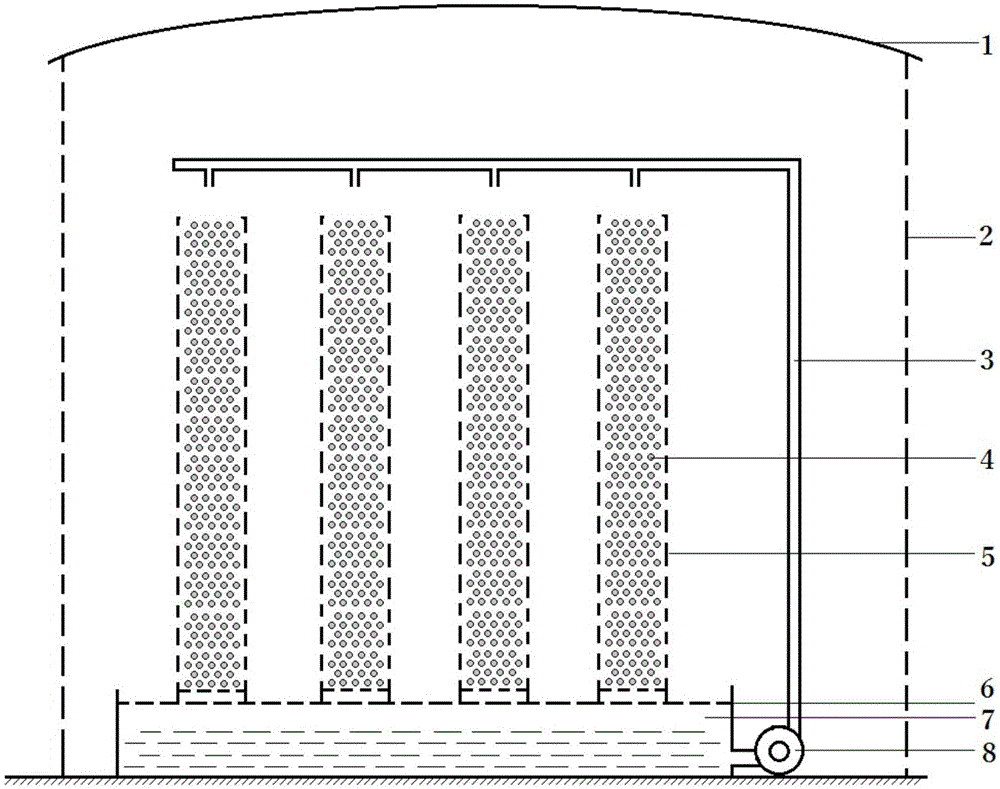

[0025] see figure 1 , There is a distance between the combined fermentation bodies of the present invention, and the distance is controlled at about 0.1 to 1 meter, so as to facilitate air to flow through the fermentation bodies. The fermentation body is installed above the liquid storage tank through a bracket, so that excess water can easily flow into the liquid storage tank from the slatted plate, so that water does not accumulate at the bottom of the fermentation body.

[0026] In order to achieve circulation treatment, the present invention is provided with a water pump and a liquid distribution pipe. A water pump is installed at the bottom of the liquid storage tank, and the water outlet end of the water pump is connected to the liquid distribution pipe. The liquid distribution pipe is arranged above the fermentation tank in the ceiling and has multiple spraying The head sprays the sewage evenly into the fermentation body.

[0027] After the liquid manure flows through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com